Information

-

Site Name & Tool Box Talk Subject:

-

Client:

-

Conducted on

-

Location

-

Lead Personnel:

-

CITB Registration Number: 3215901

Superior Roofing and Building Services Ltd.

Superior House

Sarbir Industrial Park

Harlow

Essex

CM20 2EU

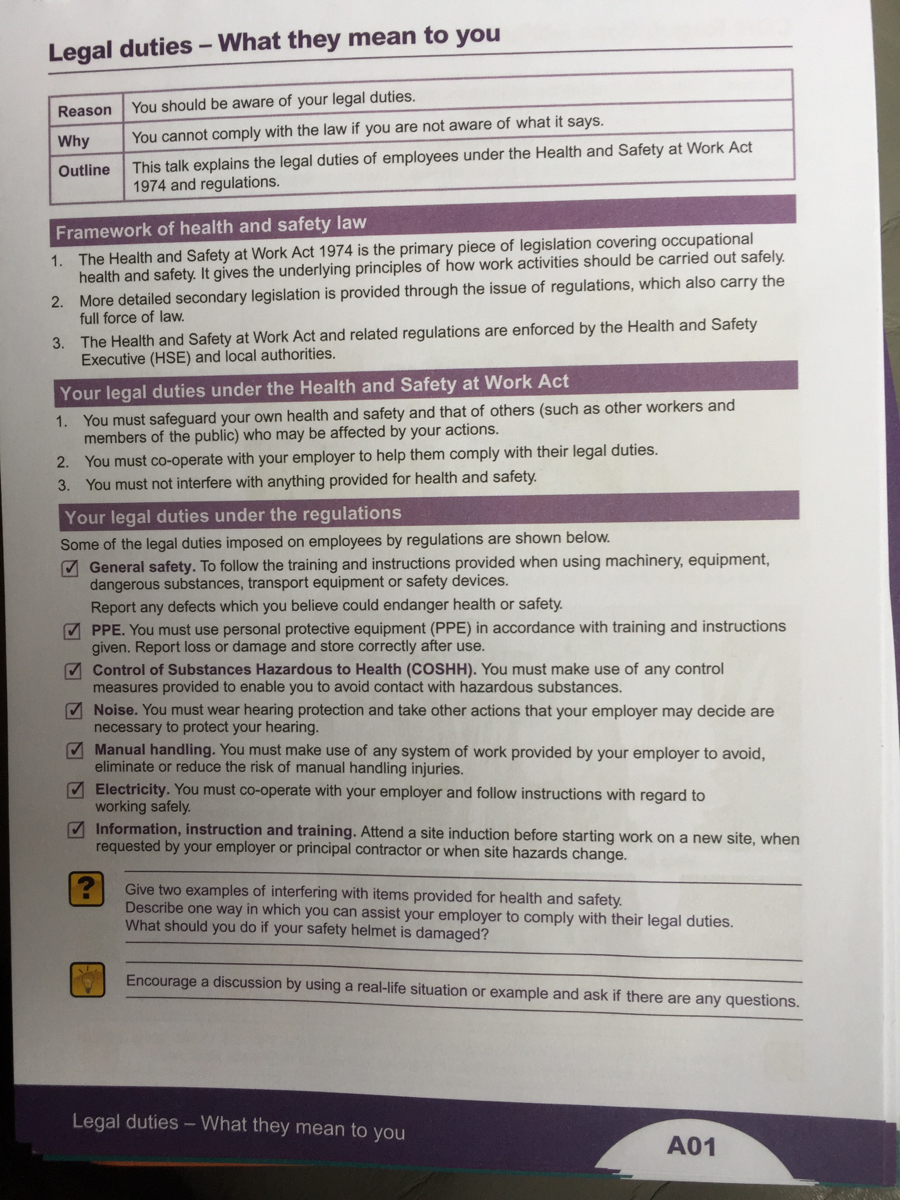

- A01. Legal Duties-what they mean to you

A01. Legal Duties-what they mean to you

-

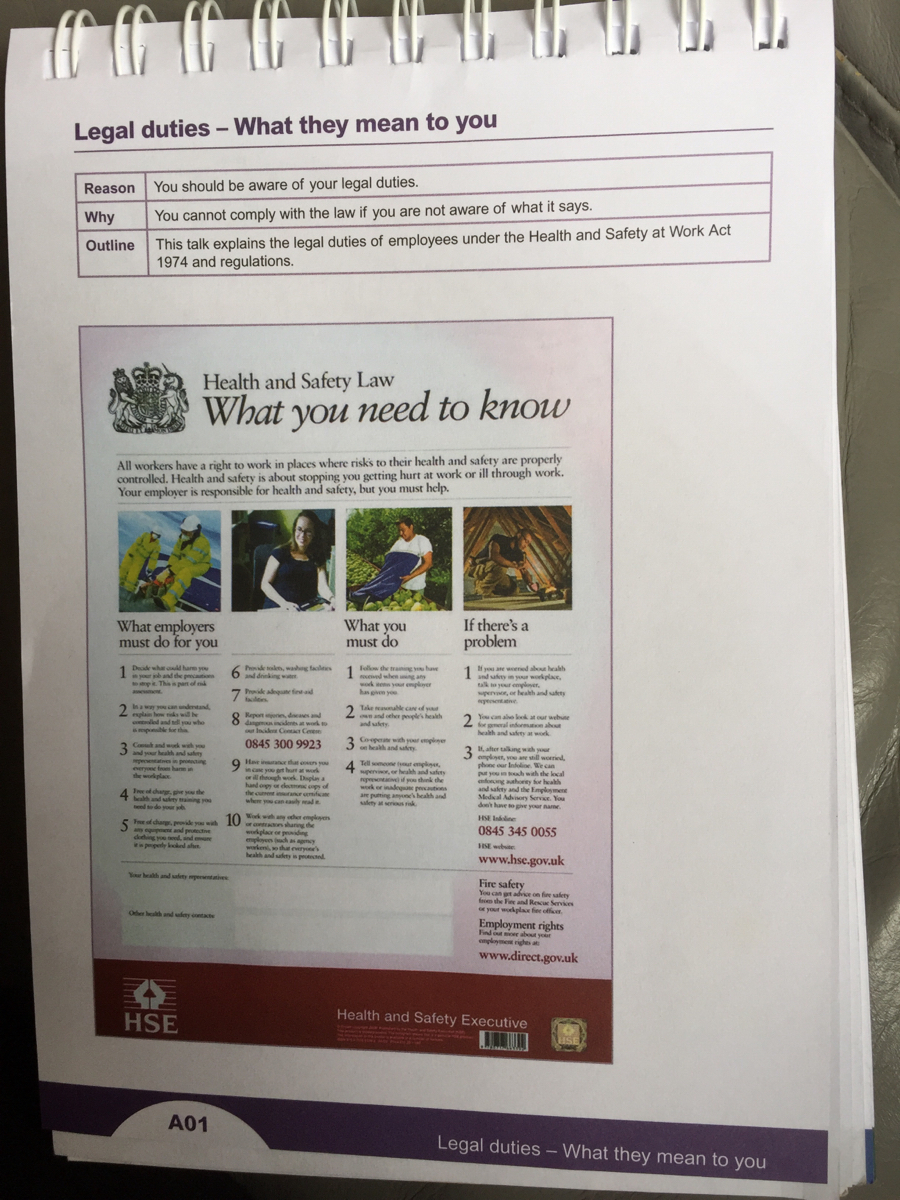

What you need to know page 1

-

Page 2

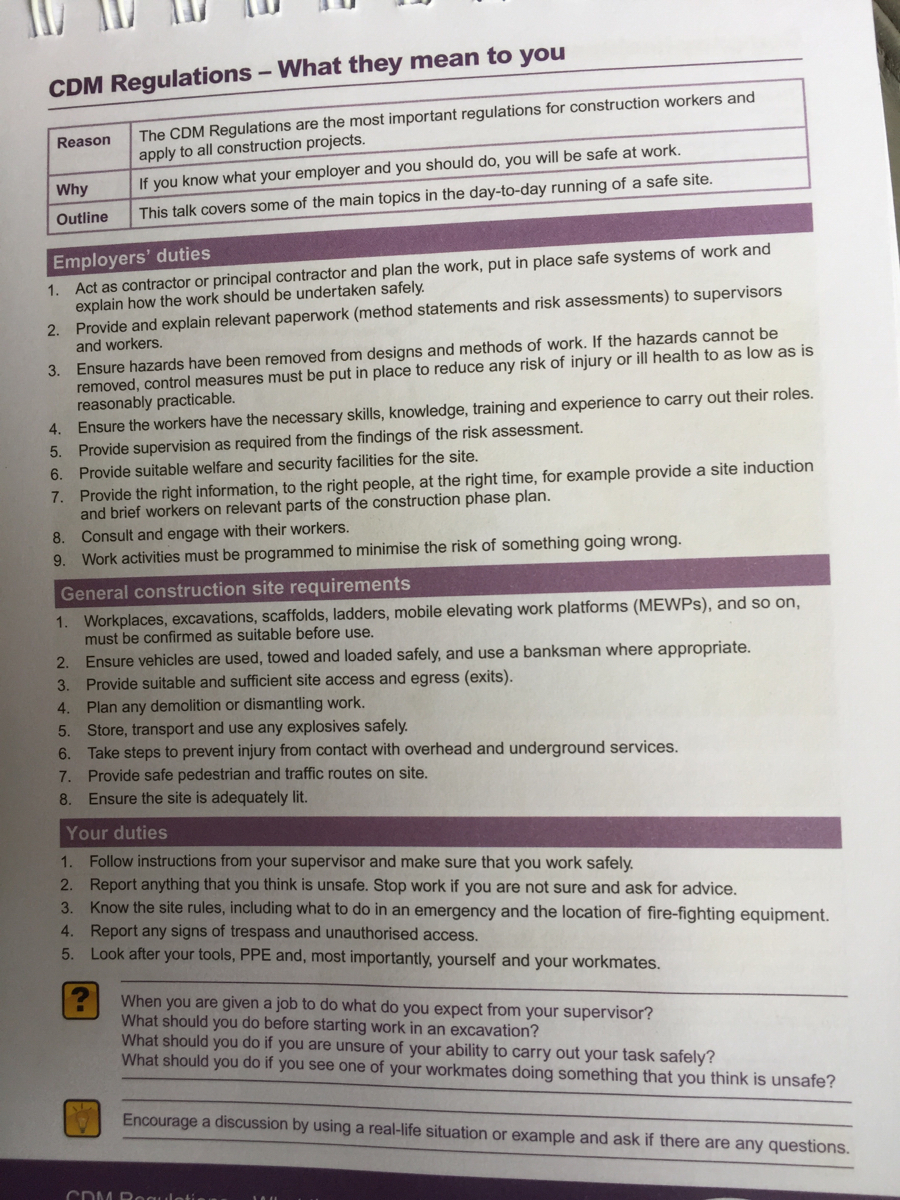

A02. CDM Regulations

A02. CDM Regulations

-

What you need to know:

-

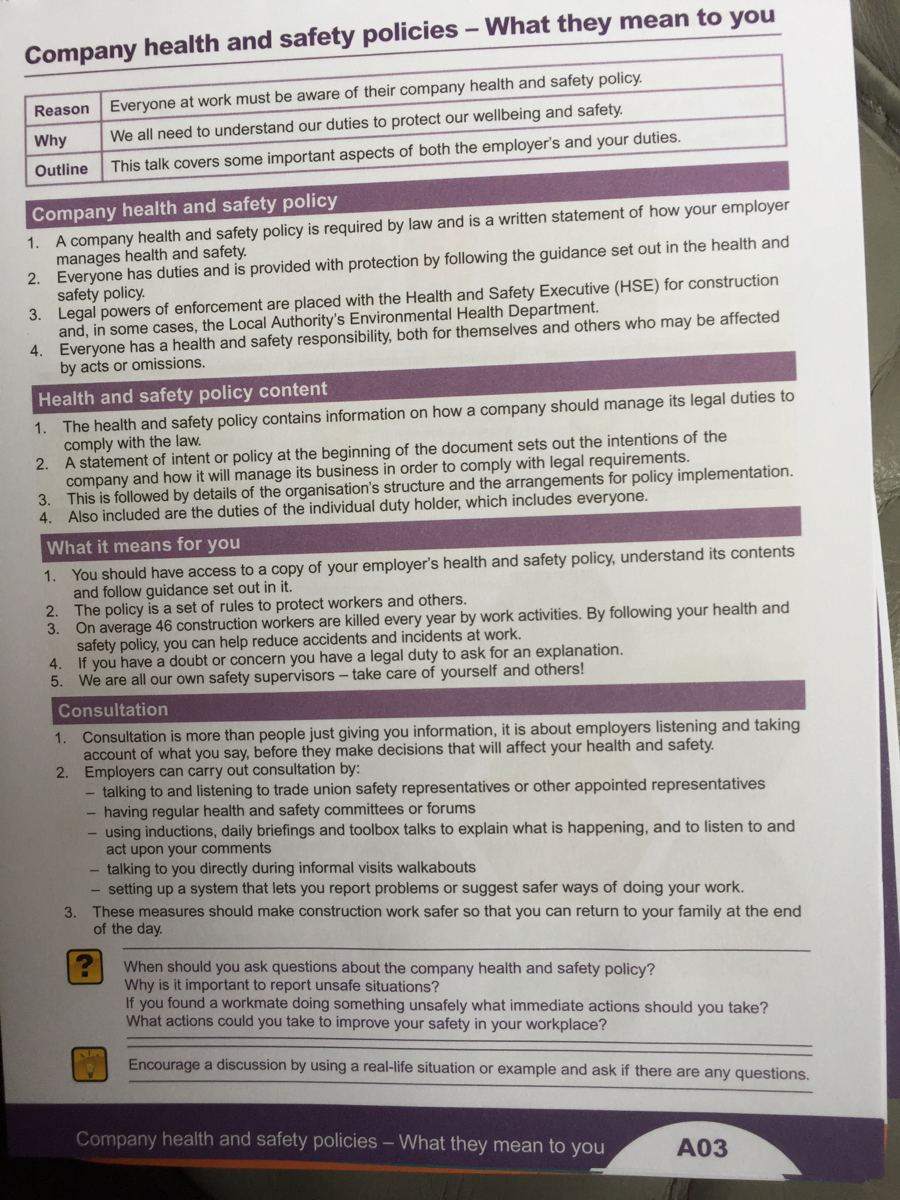

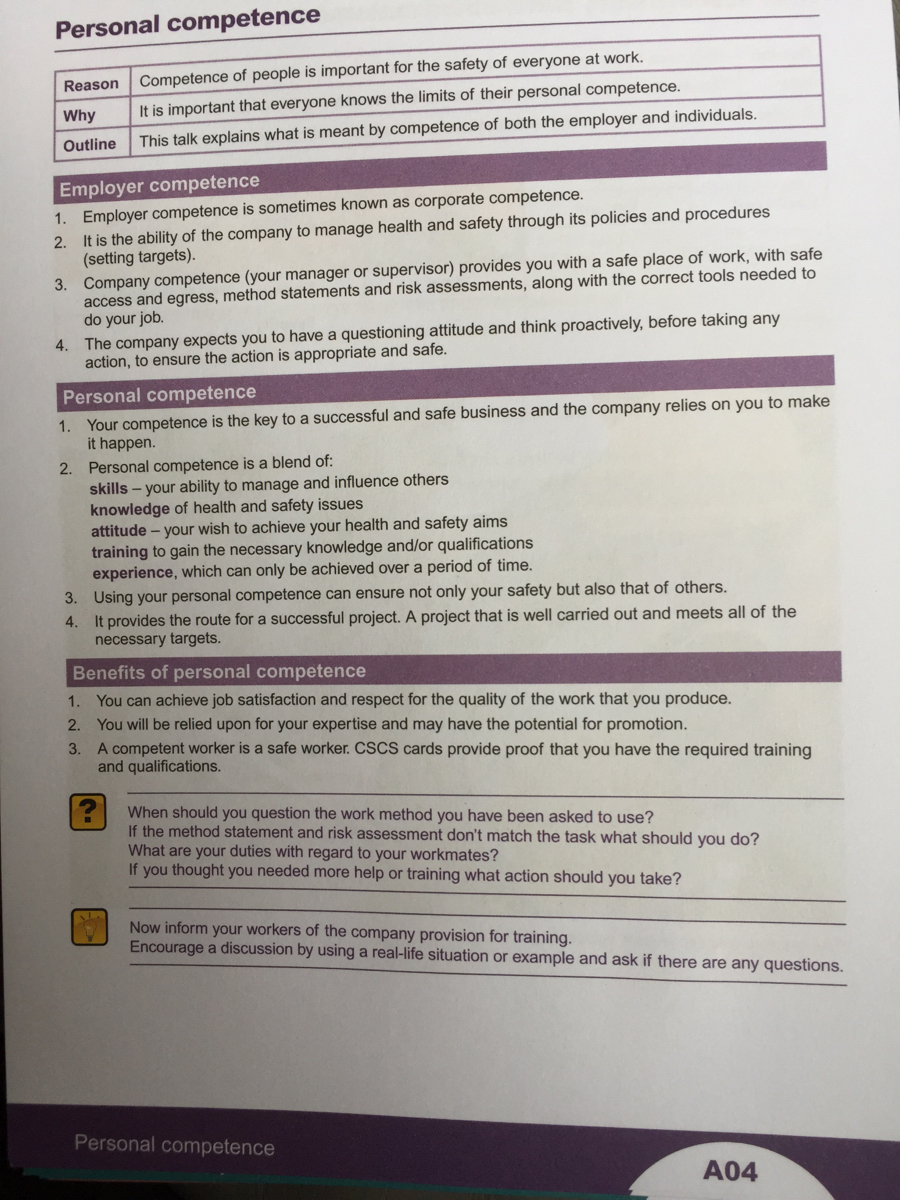

A03. Company H+S policies

-

What do you need know:

-

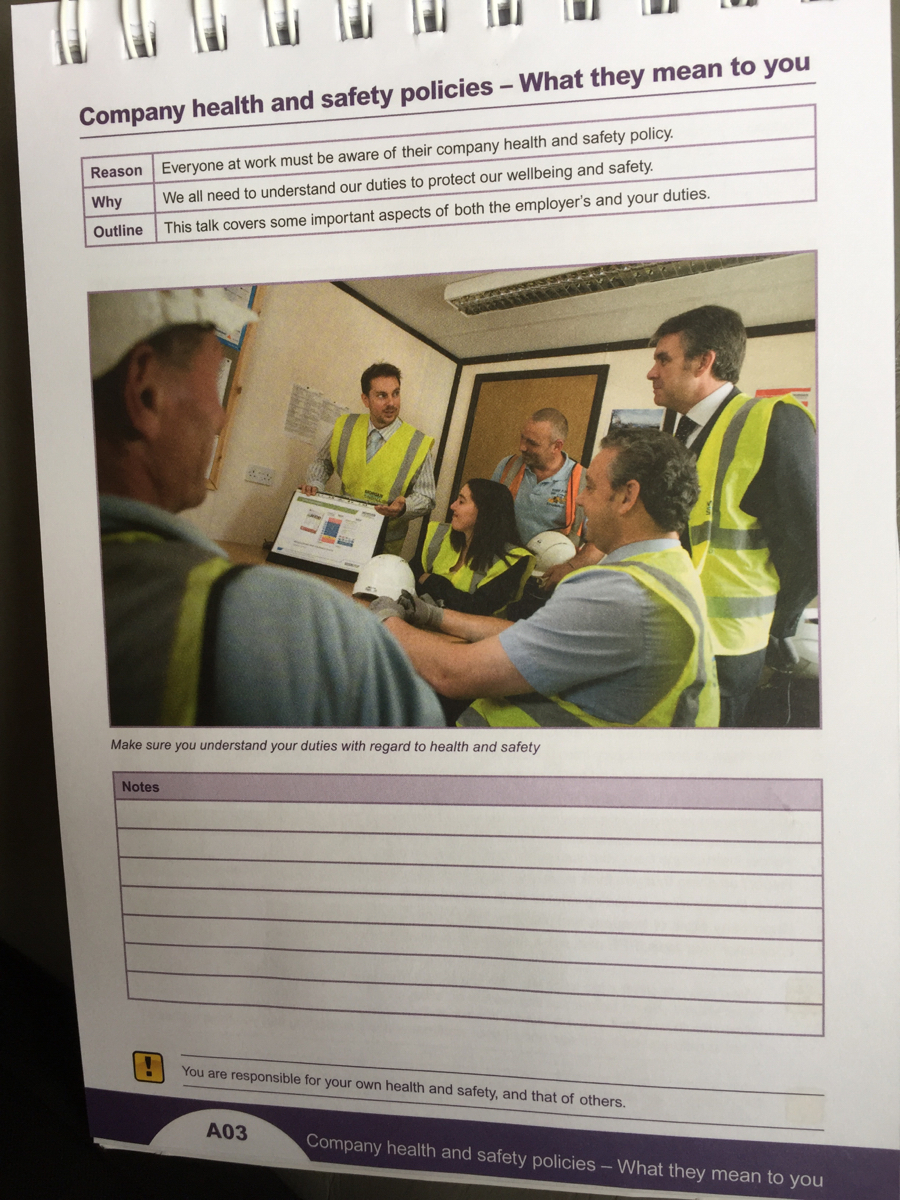

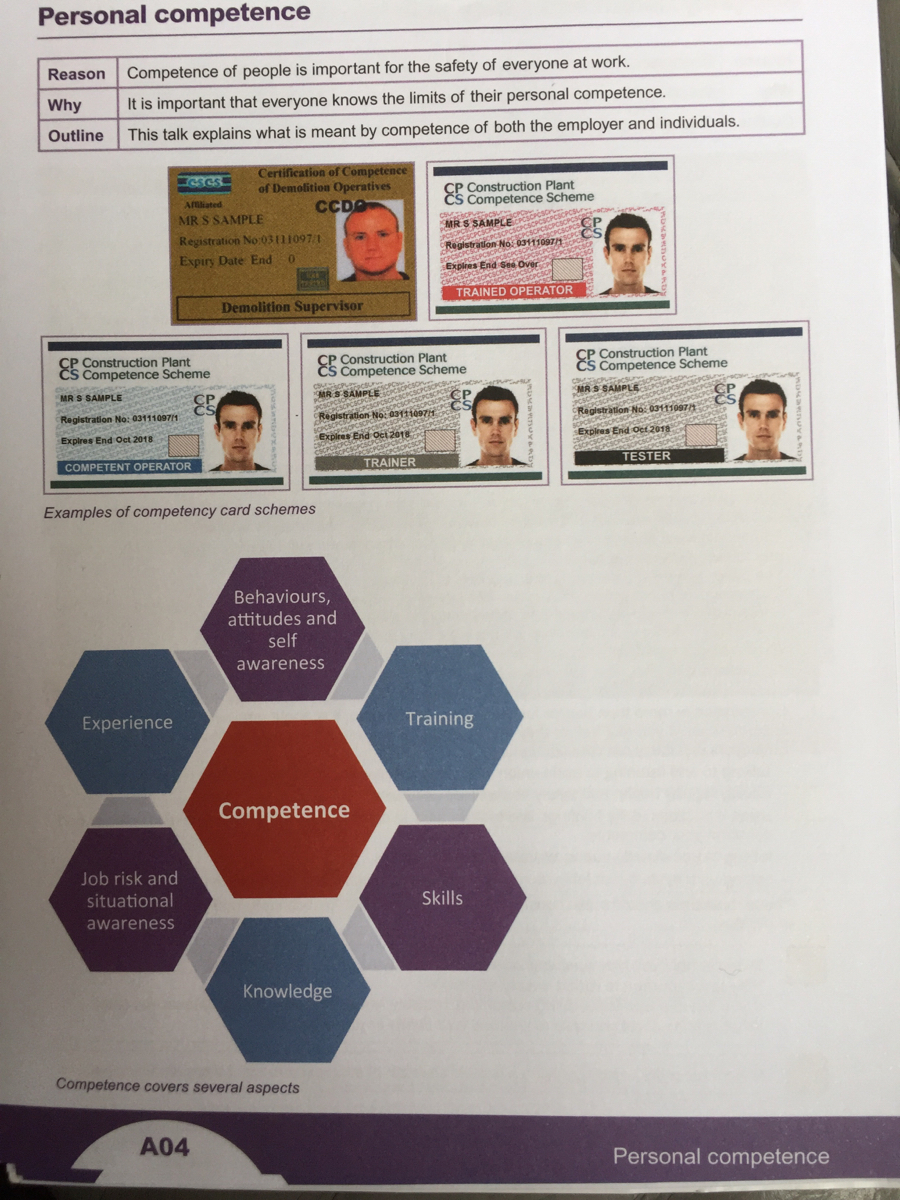

A04. Personal Competence

-

What you need to know:

-

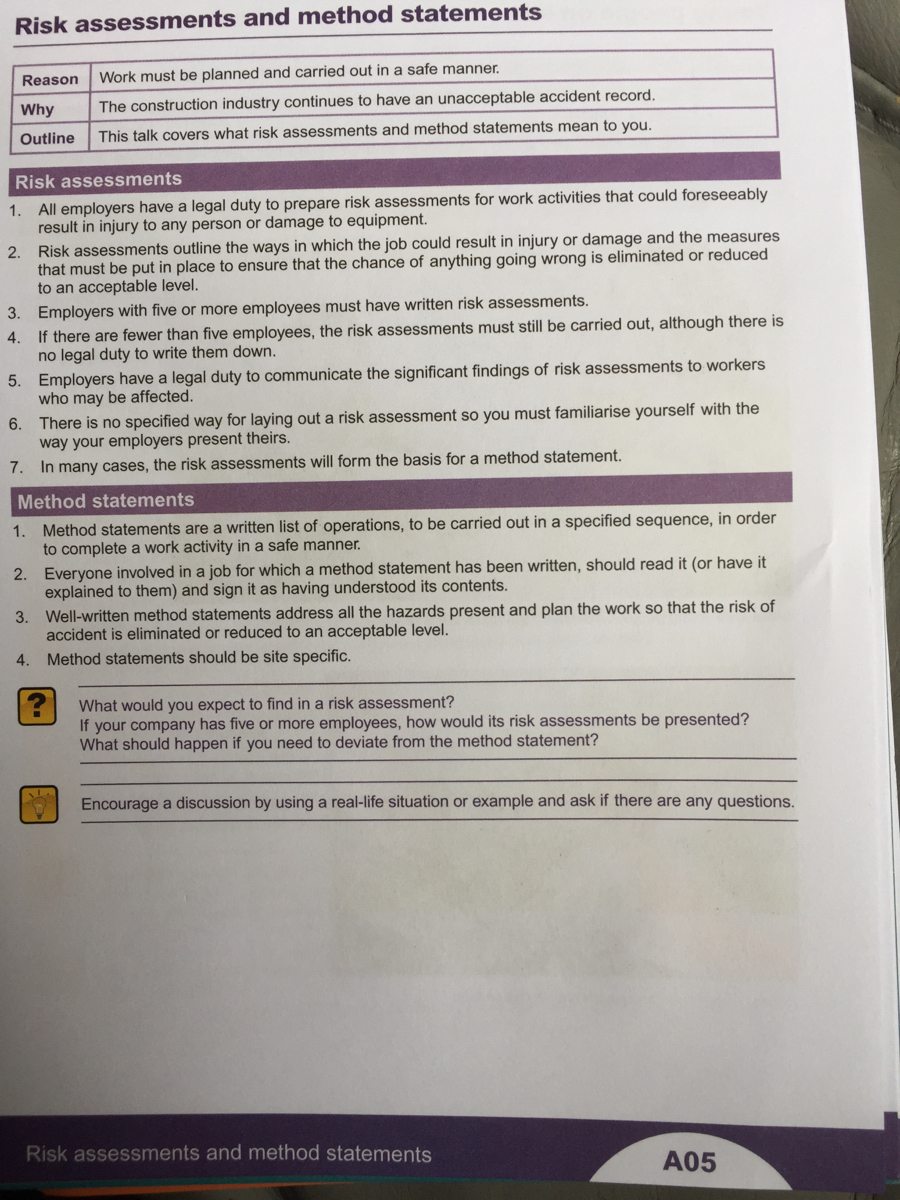

A05. Risk Assessments and Method Statements

-

What you need know:

-

A06. Young people on site

-

What do you need to know:

-

A07. Worker Engagement

-

What you need to know:

-

A08. Fairness and inclusion

-

What do you need know

A09. Respect health and well being

A09. Respect health and well being

A10. Fairness, inclusion and respect -respect

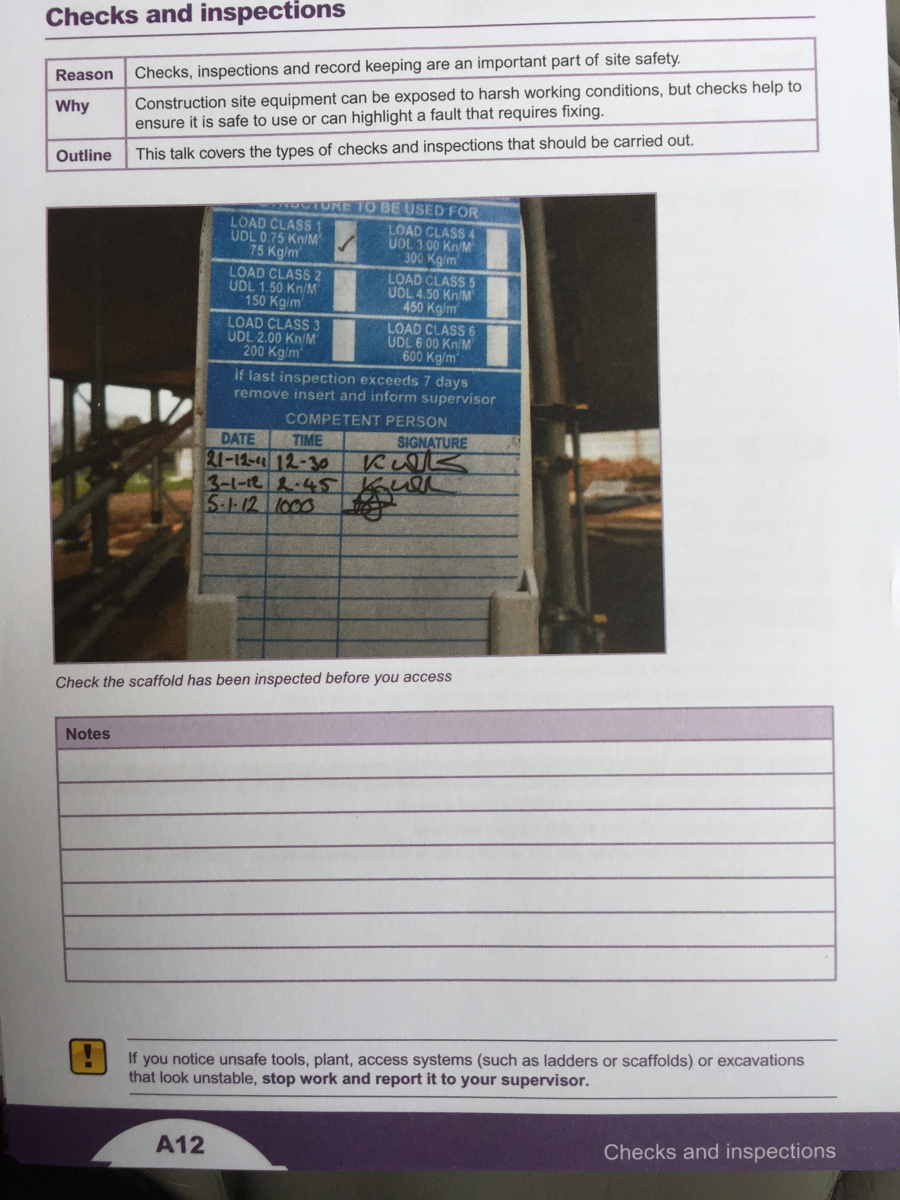

A12. Checks and inspections

-

What you need to know

-

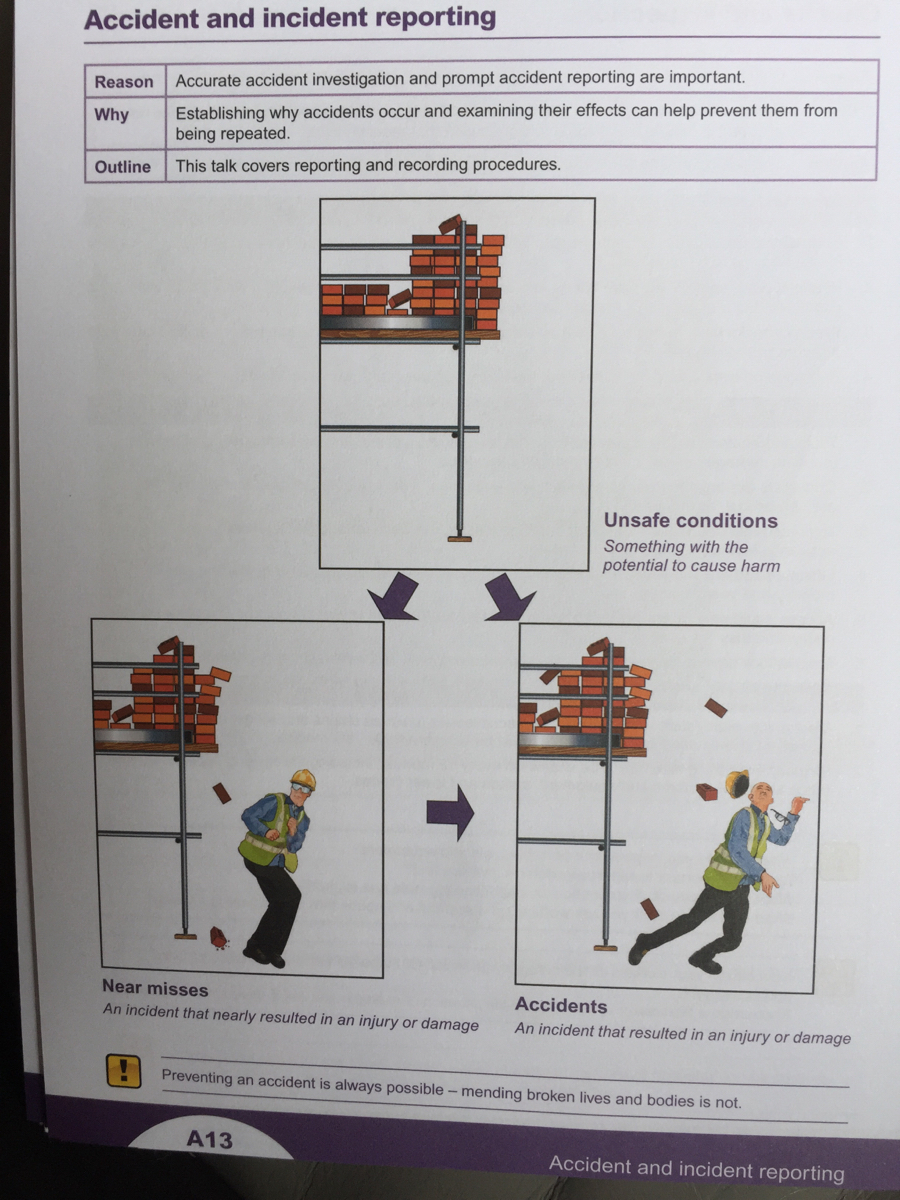

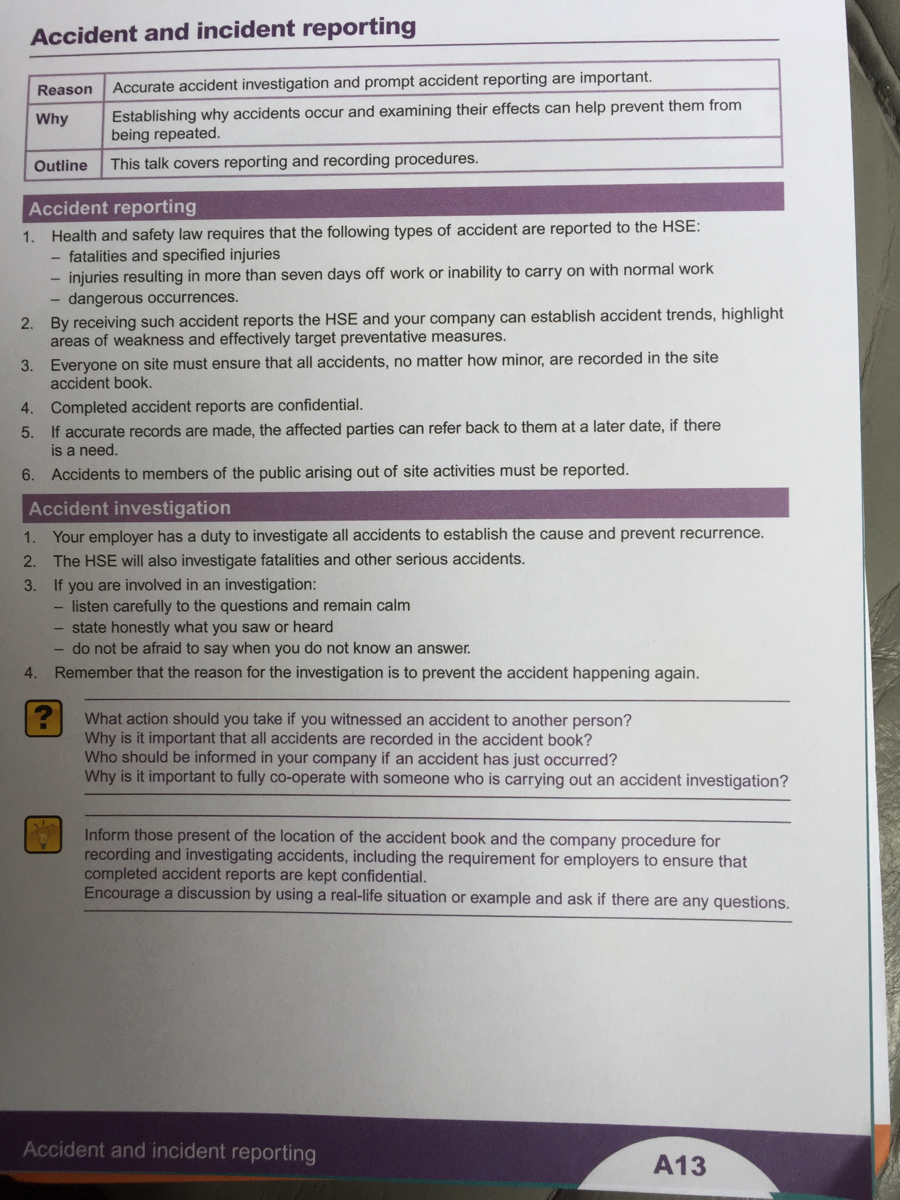

A13. Accident and incidents

-

What you need know:

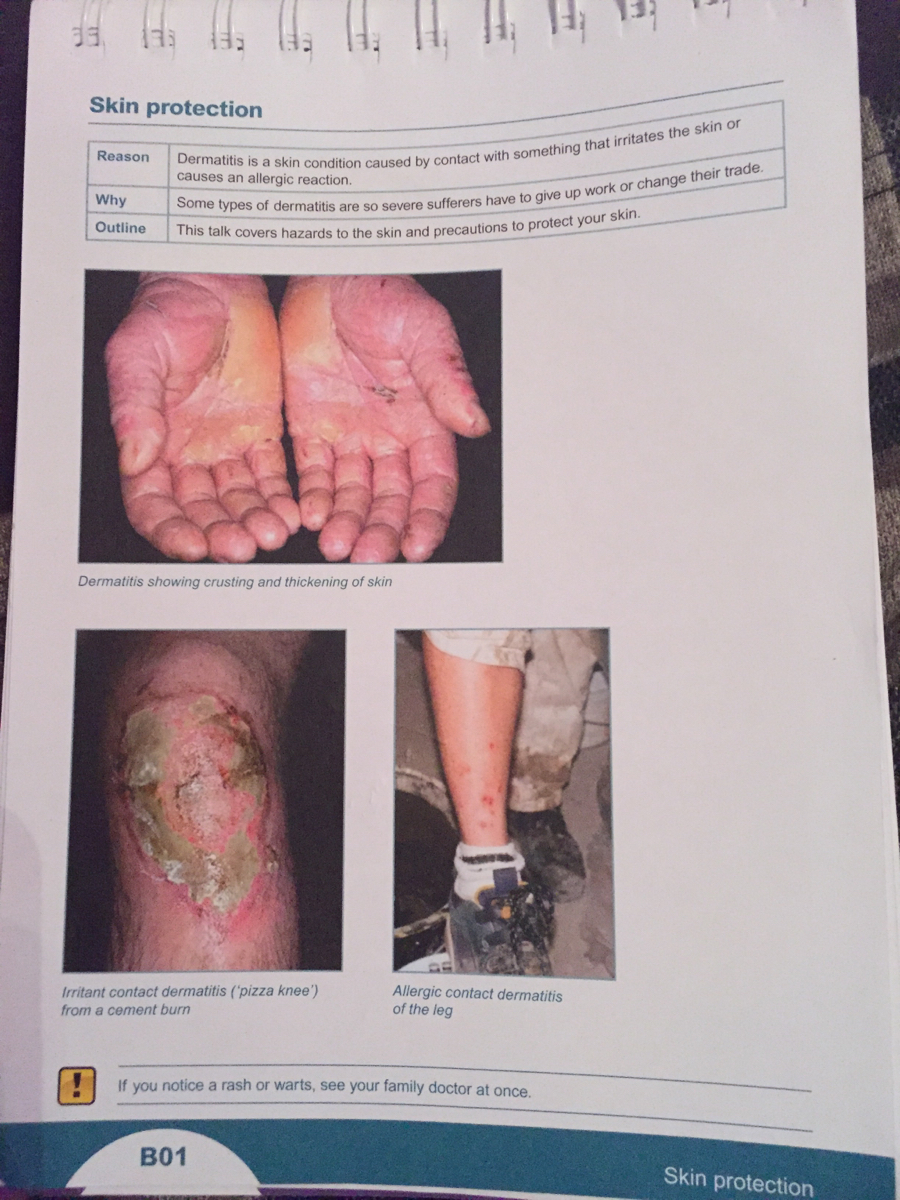

B01. Skin protection

B01. Skin protection

-

What you need know:

-

B01. Sun protection

-

What you need know:

-

B08. First aid

-

What you need know:

- B10. Eye protection

B10. Eye protection

-

What you need know:

B11. Respiratory protection

B11. Respiratory protection

-

What you need know:

-

B13. Asbestos

-

What you need know:

B14. Silica dust

B14. Silica dust

-

What you need know:

B15. Noise

B15. Noise

-

What you need know:

B16. Hand-arm vibration

B16. Hand-arm vibration

-

What you need know:

B17. COSHH

B17. COSHH

-

What you need to know

B18. Lead

B18. Lead

-

What you need to know

C03. Material storage

C03. Material storage

-

What you need to know

C04. Slip, trips and falls

C04. Slip, trips and falls

-

What you need to know

C05. fire

C05. fire

-

What you need to know

C06. LPG

C06. LPG

-

What you need to know

C07. Petrol and diesel

C07. Petrol and diesel

-

What you need to know

C10. Plant & Equipment

C10. Plant & Equipment

-

What you need to know

C11. Abrasive wheels

C11. Abrasive wheels

-

What you need to know

C13. Cartridge operated tools

C13. Cartridge operated tools

-

What you need to know

C16. Portable hand held tools

C16. Portable hand held tools

-

What you need to know

D03. Working on scaffolds

D03. Working on scaffolds

-

What you need to know

D06. Ladders and step ladders

D06. Ladders and step ladders

-

What you need to know

-

Tool Box Talk: Housekeeping

Select Tool Box Talk: Housekeeping

Tool Box Talk: Housekeeping

-

Tool Box Talk: Manual Handling

Select Tool Box Talk: Manual Handling

Tool Box Talk: Manual Handling.

-

Lifting and moving loads manually is one of the most common causes of injury at work.

56,000 Work Related MSD cases in construction per year

There is no truly ‘safe’ weight limit for manual handling operations so try to find alternatives. -

Task - how often, how much twisting or bending is needed?

Individual capability - male or female, old or young, experienced or inexperienced?

Load - how heavy? Good grip? Bulky? Heavier at one end?

Environment - hot, cold, uneven floor, windy, stairs?

REMEMBER: TILE!!

Roofing Materials & Masonry blocks:

-

- Specify/order blocks that weigh less than 20kg

- Store blocks where they will not get wet (and increase their weight)

- Arrange work so that lifting over shoulder height is not carried out

- Deliver blocks as close to the point of laying as possible

- Do not carry them up ladders

- Raise spot boards to a comfortable working height

- Adjust scaffold platform to be at a height to allow the bricklayer to work between their knees and chest (if hop up used make sure that edge protection is provided on the main scaffold that takes account of this -

-

Panel Products and Plaster Boards:

-

- Much more difficult to manoeuvre (and risky) in windy conditions

- 8’x4’ boards of 15mm thickness are all over 25kg and some ‘special’ boards can be up to 50kg

- It is possible to select smaller boards which are lighter and more manoeuvrable

- Don’t remove handrails/banisters to move boards up stairs as this creates a fall risk

- Use aids to hold and position boards

Heavy Lintels:

-

- In this case there were 150 lintels each weighing 115 kg. The firm calculated each lift needed a team of 5 which was not physically possible! They identified that a lift truck could be used.

- An alternative is to specify lightweight steel lintels where possible.

Bagged Aggragate:

-

- Order materials in smaller unit weights (max. 25kg) so that they can be more easily handled….OR

- Order the materials in such large unit weights that they can only be handled mechanically.

Hazardous manual handling:

-

- Do not try to manually handle items that weigh over 100kg

- Do not try to use manual handling teams of more than 4 people.

Top Tips:

-

- Plan and prepare for deliveries

- Find out how much commonly used items weigh

- Use simple aids

- Do not try to handle items heavier than 100kg or use teams of more than 4 people -

1. We should regard housekeeping at work with the same importance as ‘at home’. Do not rely on others to clear things up, its just as easy to put tools away tidily as it is to leave them laying around benches, on the floor, on scaffolding, resting on pipes or other positions where they can create a tripping hazard, fall onto a person or be damaged in a fall. A place for everything and everything in its place.

2. Stack parts away neatly and tidily. Do not leave materials in gangways, they could cut off someone’s escape route or cause a tripping hazard. If dismantling anything constructed of wood, make sure all nails are removed. If this is not possible hammer nails flat, making sure that no parts are left protruding that could cause injury to fellow employees.

3. All rubbish should be placed in skips to be removed. In this way, should a fire occur, it can be confined to a small area and dealt with quickly and efficiently thus preventing the fire spreading, especially in high winds.

4. If tools get damaged, get them repaired or replaced. Do not leave them lying around to cause hazards.

5. When finishing work put personal overalls and other gear in drying room provided, don’t just leave things lying about hoping they’ll be there when you return.

6. If you notice rubbish piling up which you cannot remove, bring this to the attention of your supervisor who will make arrangements to have it removed.

7. Should you be working at height and notice loose objects on boards or walkways, put them somewhere where they cannot be dislodged so that they cannot fall and hurt someone. -

Tool Box Talk: Inclement Weather

Select Tool Box Talk: Inclement Weather

Tool Box Talk: Inclement Weather

-

Working in the winter can be quite unpleasant at times; you start work in the dark and go home in the dark, often very wet, cold, and windy. What starts off as a simple task can sometimes turn out to be very hazardous. Activities can take longer to complete during the winter due to the working conditions, and allowances should be made when planning work activities during the winter period.

Adverse weather

Layers of thin clothing are warmer than a thick jumper or coat. Thermal underwear will give good protection against the cold

Ensure sufficient waterproofs are readily available and in good condition

Maintain sufficient welfare arrangements

Fuel your body with hot drinks and a hot meal

Icy conditions can be extremely hazardous for pedestrians and very challenging for drivers of moving vehicles. Pedestrian walkways, site entrances and roads must be gritted to avoid people slipping and vehicles loosing control.

Working with water in freezing temperatures requires extra care to ensure that ice patches are not created by work activities.

When driving in the dark or adverse weather, leave more space between you and the vehicle in front as this will give you more reaction time for braking. Make sure all vehicles are maintained, checking all lights are working. Check tires are in good condition, windows clean and ensure the washer bottle is topped up

Lighting

Ensure provisions are made to light all working areas outside daylight hours

Keep all traffic cones, signs, and boards clean so they remain visible to road users

Maintain sufficient lighting for pedestrian walkways to prevent people tripping over

in the dark

General

Manual handling

Ensure weather conditions and the working environment are risk assessed

Take extra care whilst undertaking manual handling activities in the cold, Warm up

before undertaking any manual handling

Using vibration tools

Ensure gloves are worn

Take regular breaks to warm hands

Exercise fingers to maintain good circulation -

Tool Box Talk: LPG Gas

Select Tool Box Talk: LPG Gas

Tool Box Talk: LPG Gas

-

Reason: Liquefied petroleum gas (LPG), if used safely, are a convenient and valuable source of energy.

Why? IF you know how to use it safely you can prevent serious accidents and injury.

Outline: The talk covers hazards, use, storage and transportation.

Hazards:

1. Treat every cylinder as being full and handle carefully.

2. Keep cylinders away from sun, artificial heat, flammable materials, corrosive chemicals and fumes.

3. Avoid damage to valves and fittings, don't use these for lifting or carrying.

4. When using mixed gasses, such as welding, flashback arrestors must be fitted.

5. Don't smoke when using compressed gasses.

6. Don't use cylinders as rollers for moving equipment.

7. If gas cylinders are being heated in a fire, call the fire brigade and evacuate the area. -

Safe Use:

1. Regular inspection of hoses, cylinders and valves should be undertaken before use.

2. Open cylinder valves slowly and close sufficiently to shut off gas - never use force.

3. Ensure that gloves (if worn) are free from oil and grease.

4. Keep valves and fittings of oxygen cylinders free from oil and similar items.

5. Keep gas hoses clear of traffic to prevent them from being damaged.

6. Know what to do in an emergency.

7. Ensure a fire extinguisher is always available for hot work but only try to fight secondary fires.

8. If there's a hot work permit or procedure, follow it. -

Storage and Transportation:

1. Always secure acetylene cylinders in an upright position.

2. Store cylinders so that they cannot fall or roll.

3. Always lift cylinders from trucks, don't drop or slide them.

4. Move full size cylinders using a trolley. If one is not available, get assistance.

5. Transport cylinders in vehicles with good ventilation. -

Toolbox Talks: Hoists and Hoist Towers

Select: Toolbox Talks: Hoists and Hoist Towers:

Tool Box Talks: Hoists and Hoist Towers

-

Reason: All persons must be aware of the safe methods of using hoists

Why? A hoist can be a dangerous piece of equipment if used unsafely.

Outline: This talk covers the safe working practices when using hoists. -

Construction and Maintenance:

1. The erection, alteration or dismantling of a hoist is a specialist operation and should only be carried out by a competent person.

2. Any fixed hoist tower must be adequately tied to the hoist structure.

3. Hoists should be constructed in such a way to prevent the fall of materials from the platform or cage. -

Safety Features:

1. All hoist cages and platforms must be market with the SWL.

2. All hoists must be marked whether they are for goods or for passenger use.

3. Passenger hoists must be fitted with interlocked gates at every landing place.

4. All hoists should be fitted with an efficient braking device capable of supporting the platform and load in the event of a failure of the lifting gear. -

Operation:

1. Hoists should only be operated by authorised persons.

2. All ground level and landing gates should be kept closed whilst the hoist platform or cage is in motion.

3. Passengers must never attempt to travel in hoists designed for goods only.

4. Hoists should never be operated in excess of SWL. -

Inspection:

1. All hoists must be subject to a periodic examination be a competent person.

2. Passenger lifts must be examined to test safety devices every time the height of the hoist way is altered. -

Toolbox Talks: Fragile Roof

Select Toolbox Talks: Fragile Roof.

Toolbox talks: Fragile Roof.

-

Reason: On average 7 people are killed each year after falling through a fragile roof or a fragile roof lights. Many others suffer permanent disability.

Why? Fragile roof incidents are not inevitable. They can be prevented by careful planning, using trained a experienced workers with suitable equipment and employing a high level of supervision.

Outline: This toolbox talk will cover some of the types of fragile roofs, what you need to do before and during the work and the requirements for working on a fragile roof. -

Types of Fragile (non-load bearing) roofs:

1. Cement sheeting - non reinforced sheets, irrespective of profile type, for example asbestos.

2. Roof lights - these are difficult to see in certain light conditions and can be hidden when painted or covered by moss.

3. Liner panels on built up sheet roofing.

4. Corroded metal sheets.

5. Glass including wired glass.

6. Rotten chipboard.

7. Other materials, including wood wool slabs, slates and tiles. -

Before and During work:

1. Planning and supervision are key to reducing risk of a fall. Work should not start until the findings of a risk assessment have been taken into account and control measure have been put in place.

2. First ask yourself if the work can be done in a safer way, for example from under a work platform.

3. If not, put a planned system of work in place before the work starts.

4. Endure the planned safe system of work is used by everyone on site.

5. As work progresses, check that safe systems are still suitable. If not, stop work until they are adapted.

6. if nets, air bags, or other safe landing systems are used, they should be properly installed and inspected regularly. -

Requirements for working in fragile roofs:

1. Ideally a safe system of work should be identified to enable the job to be carried out without anyone having to go on the roof.

2. Where this is not possible, install perimeter edge protection and spread the load with a stable, temporary working platform and guard rails.

3. Ensure all the work and access platforms are fitted with guard rails. If this is not possible, install safety nets, air bags or the like underneath the roof or use a harness system.

4. Where harness are used, make sure they have adequate anchorage points and they are properly used.

5. Load bearing surfaces that cannot be dislodged should be bitter over skylights, particularly where fragile skylights are fitted to an otherwise load bearing roof. -

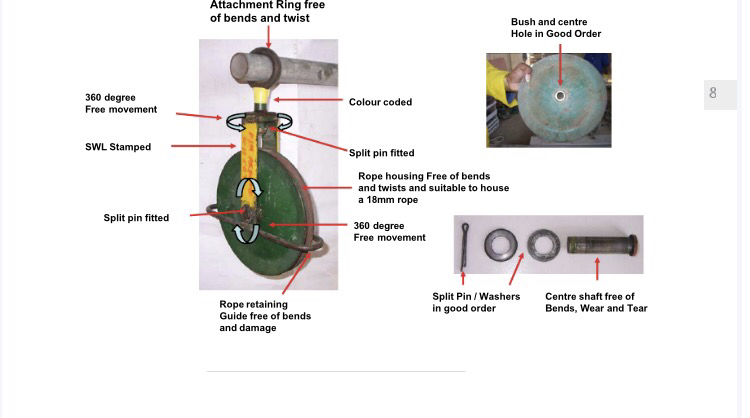

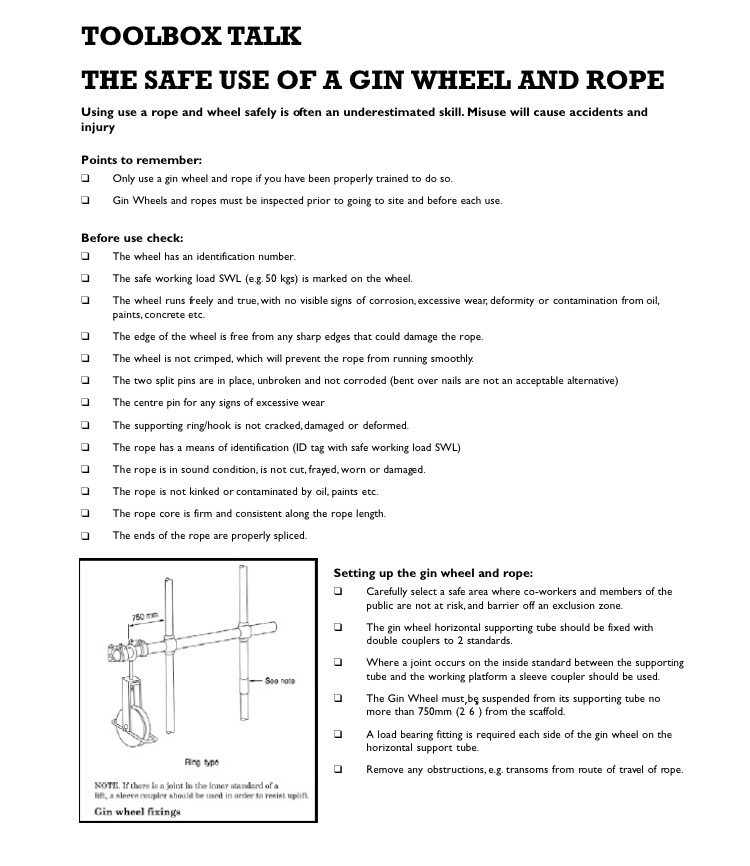

Tool box talks: gin wheel

Add tool box talk: gin wheel

Tool box talk: Safe use of a gin wheel

-

Inspecting a gin wheel before use:

-

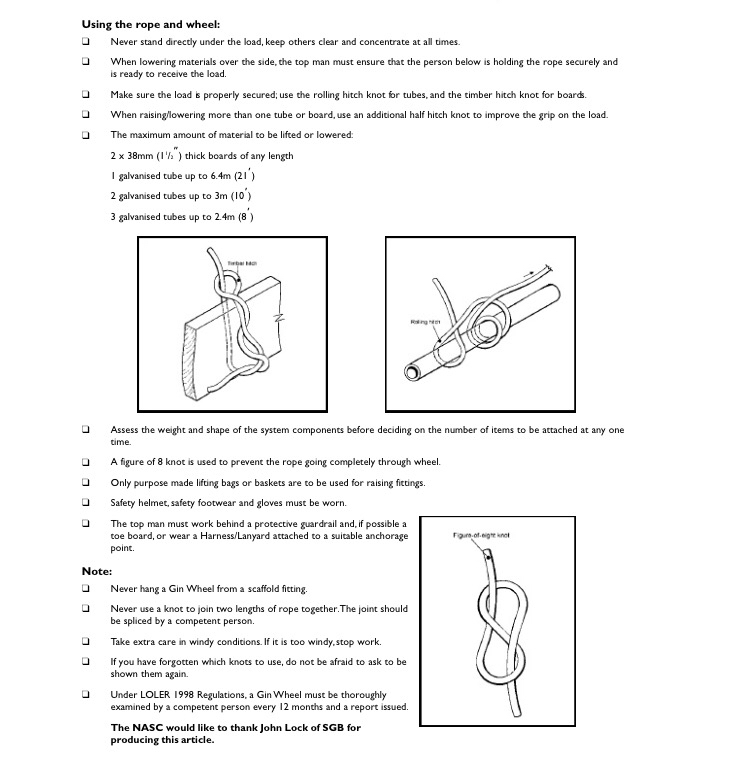

The do's and don'ts when operating a gin wheel:

-

Types of knots:

Personel:

-

Tool box talk provided:

- B19. Manual Handling

- Housekeeping

- Inclement Weather

- C06. LPG Gas

- C20. Hoist & Hoist Towers

- D02. Fragile Roofs

- A01: Legal Duties- what they mean to you

- A02. CDM Regulations-what they mean to you

- A03. Company H+S policies-what they mean to you

- A04. Personal competence

- A05. Risk Assessment and Method Statement

- A06. Young Persons

- A07. Worker Engagement

- A08. Fairness, Inclusion and Respect

- A10. Fairness and respect Acceptable

- A12. Checks and inspections

- A13. Accidents and Reporting

- B01. Skin Protection

- B02. Sun protection

- B03. Weil's Disease

- B04. Drugs and Alcohol

- B05. Needle Stick Injuries

- B06. Health and Well being

- B07. Welfare arrangements and hygiene

- B08. First aid

- B09. PPE

- B10. Eye Protection

- B11. Respiratory protection

- B12. Dust and Fumes

- B13. Asbestos

- B14. Silica Dust

- B16. Noise

- B16. Hand-arm vibration

- B17. COSHH

- B18. Lead

- Safe use of Gin Wheel

-

Add Operative:

Operative

-

Name and Signature

-

Tool Box Talk Provider: