Information

-

Installation:

-

Conducted on

-

Conducted by:

-

Conducted by:

12.1 Helideck

-

12.1.1 The Heli deck meets Annex 14 of the ICAA , ADMA Inspection carried out & approval issued.<br>

-

12.1.2 The wind direction indicator is in good condition and highly visible<br>

-

12.1.3 Non-skid surfacing on deck and approaches<br>

-

12.1.4 Recessed tie-down points<br>

-

12.1.5 Free of projections<br>

-

12.1.6 Helideck is clear of loose objects<br>

-

12.1.7 Two access routes<br>

-

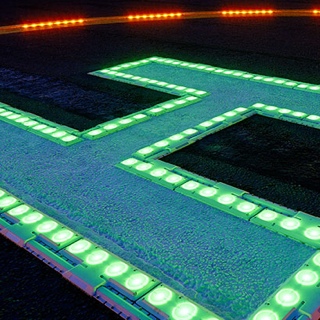

12.1.8 Perimeter lights Green (not more than 10' apart)<br>

-

12.1.9 Continuous line (16" wide) around perimeter<br>

-

12.1.10 Aiming circle<br>

-

12.1.11 Rig identification plus large (H)<br>

-

12.1.12 Mark size of helicopter and max allowable gross weight (xx ton)<br>

-

12.1.13 Foam system as primary fire protection<br>

-

12.1.14 Operating controls at each hose location<br>

-

12.1.15 Instructions posted for foam system operation<br>

-

12.1.16 Hose reel mounted<br>

-

12.1.17 Enough hose to cover entire deck<br>

-

12.1.18 Nozzle functional in stream, spray and off positions<br>

-

12.1.19 Class B IV portable fire extinguishers, foam 20 gas. or CO2 50 lbs or DC-30 lbs(not required where fixed foam system is installed)<br>

-

12.1.20 Rescue Ladders available for emergency.<br>

-

12.1.21 Warning signs at each access "Beware of Tail Rotor"<br>

-

12.1.22 Heli loader available S.W.L.<br>

-

12.1.23 Helicopter Prohibitiontion to Land Flag<br>

-

12.1.24 Communication between radio operator, helicopter pilot and HLO is adequate<br>

-

12.1.25 Radio room CCTV required if not in direct sight of helideck<br>

-

12.1.26 Are Helicopter Manifests showing the number of bags along with the weight<br>

-

12.1.27 Braked baggage trolley available<br>

12.2 Firemans Outfit & Helideck Crash Box

-

12.2.1 Fireman suit with flame retardant outer surface

-

12.2.2 Non-conductive boots<br>

-

12.2.3 2 x Helmet with visor<br>

-

12.2.4 2 x Self contained breathing apparatus with 50' lifeline attached<br>

-

12.2.5 Extra air tank in hydro date<br>

-

12.2.6 Explosion proof flashlights/extra batteries<br>

-

12.2.7 At least 2 fire axes<br>

-

2.2.8 Life lines (at least 50', wire cable with hook and snap)<br>

-

12.2.9 Hacksaw

-

12.2.10 Knife<br>

-

12.2.11 Bolt Cutter<br>

-

12.2.12 Checklist for crash kit<br>

12.3 Radio Room / Jacking Control Room

-

12.3.1 All control board lights are operable.<br>

-

12.3.2 All porthole windows are in good condition.

-

12.3.3 Emergency lights operate properly.<br>

-

12.3.4 Communications system (PA) is operational and audible.<br>

-

12.3.5 Fire & Gas detection system tested and logged on weekly basis.<br>

-

12.3.6 Portable Gas Detectors are functional.<br>

-

12.3.7 All Radio Equipment ( VHF, HF, Telex, SATCOM, etc.) in working order & tested weekly.

-

12.3.8 Is the OPQL installation in good order, no exposed wiring?<br>

-

12.3.9 Exits identified<br>

-

12.3.10 Emergency portable spot light<br>

-

12.3.11 VHF Radio Log Book used<br>

-

12.3.12 Frequencies posted<br>

-

12.3.13 Emergency numbers posted<br>

-

12.3.14 Firefighting equipment available<br>

-

12.3.15 General bell and alarm are marked<br>

-

12.3.16 Navigation lights<br>

-

12.3.17 Inclinometer available <br>

-

12.3.18 Water tight integrity pre-checks list provided<br>

-

12.3.19 Distress signals in cert. (12 off)<br>

-

12.3.20 Regulations posted outside door<br>

-

12.3.21 Station bill posted outside door<br>

12.4 Emergency Generator Room

-

12.4.1 Ventilation is adequate<br>

-

12.4.2 Proper non-conductive floor mats are provided in front of the switch panel<br>

-

12.4.3 Auto switch when power failure timing<br>

-

12.4.4 Switch box and connector box covers are in place and labeled.<br>

-

12.4.5 Fire fighting equipment is adequate and properly maintained<br>

-

12.4.6 Housekeeping is adequate<br>

-

12.4.7 Emergency lights are operable<br>

-

12.4.8 Batteries are properly protected. Eyewash station available in area.<br>

-

12.4.9 Adequate lighting<br>

-

12.4.10 Adequate emergency lighting, tested and marked "e"<br>

-

12.4.11 Remote fuel shut-off operational<br>

-

12.4.12 Non-conductive mat provided in front of panel<br>

-

12.4.13 Machinery guarded<br>

-

12.4.14 Unobstructed access and egress<br>

-

12.4.15 Electrical hand gloves available and in date.<br>

-

12.4.16 Electrical rescue pole (hot stick) available and in certification.<br>

-

12.4.17 Diesel day tank free of leaks, fuel level tubing fitted and clear<br>

-

12.4.18 Electric shock first aid instructions posted.<br>

-

12.4.19 Information available indicating what equipment will operate on E power<br>

-

12.4.19 Information available indicating what equipment will operate on E power<br>