Information

-

Organization Inspected:

- ARW Headquarters

- Medical Group

- Mission Support Group

- Maintenance Group

- Operations Group

- Other

- 220th EIS

- 164 WF

-

Area:

-

Unit:

-

Unit:

-

Date of Assessment:

-

Assessment Conducted by:

-

Mishap Prevention Program Conformance Grade:

- Met and Effective

- Met But Needs Minor Improvements

- Met but Needs Significant Improvements

- Not Effective

MISHAP PREVENTION PROGRAM EFFECTIVENESS

12 Month Mishap Summary

-

Where there any reported mishaps within the last 12 months within this unit?

-

Total Mishaps:

-

Lost Workdays:

-

Days on Restricted Duty:

-

On-Duty Mishaps:

-

Off-Duty Mishaps:

-

Management and Supervisory Support

-

What was found unsatisfactory for the unit's mishap prevention program?

-

Experience and Trends:

-

Remarks:

Outstanding Performers

-

Were there any outstanding performers within the unit?

-

Comments:

UNIT SAFETY REPRESENTATIVE

Unit Safety Representative (USR) Program IAW AFI 91-202_ANGSUP, Chapters 2 & 8

-

2.2. Primary & Alternate. Does the unit have a primary and alternate USR. (T-1) (Primary and alternate Additional Duty Weapons Safety Representative and Squadron Assigned Flight Safety Officer, as applicable)

-

2.2. Training. Have the USR's assigned at the unit level received training from the base safety office or through an approved MAJCOM course?

-

2.2. Training. (Table 14.4) Have the appointed USR's completed an Air Force Risk Management (RM) fundamentals course and is their training completion certificate maintained and accessed by the individual or Unit Training Manager? (ADLS or Media Equivalent)

-

2.2.2.2. Spot Inspections. Does the USR conduct and verify monthly spot inspections are being performed and documented? (USR/Supervisors)

-

2.2.2.3. Mishaps. Does the USR ensure mishap notification procedures are established in the unit and assist installation safety, unit commander, and supervisors with mishap investigations?

-

2.2.2.4. JSTO & JHA. Does the USR assist supervisors who develop Job Safety Training Outlines and Job Hazard Analysis?

-

When was the last review of the Shop's JSTO's and JHA's (if applicable)

-

2.2.2.5. Education. Does the USR conduct and document safety briefings and provide unit personnel with educational safety materials?

-

2.2.2.6. Hazard Abatement. Does the USR assist the unit commander and supervisors with hazard abatement processes?

-

8.5.1. Quarterly Meetings. Does the USR advise the commander on safety related matters at least on a quarterly basis or more frequently as necessary and document key elements briefed?

-

8.5.2 Hazard Abatement. Does USR assist supervisors and unit personnel with hazard abatement process

-

8.5.6. USR Meetings. Does the USR comply with the safety program requirements to include attending USR meetings?

-

8.5.7. Visual Aid. Does the USR post AFVA 91-209, Air Force Occupational Safety and Health Program in a conspicuous location readily accessible to all employees and applicants for employment?

-

8.5.8 Does USR provide safety office with current listing of all facilities owned/used by their unit.

Findings

- Finding

-

Discrepancy or Observation:

-

-

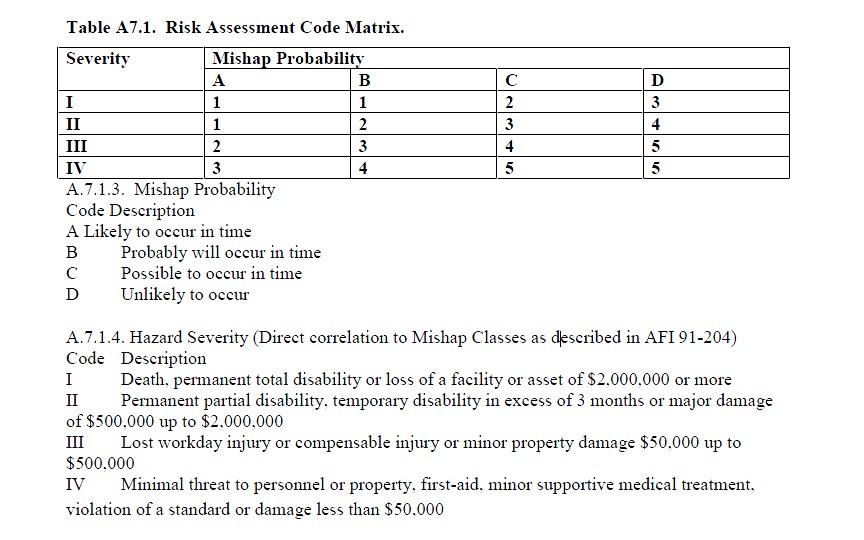

Probability:

-

Severity:

-

Risk Assessment Code:

-

Reference:

-

Cause:

- Training

- Equipment

- Technical Data

- Human Error

- Misconduct

- Process Inadequate or Faulty

- Leadership/Supervision

- Other

-

Describe:

-

Recommended Action:

-

Functional Area or Shop Inspected:

-

Supervisor or POC:

-

Phone Number:

-

Date and Time:

-

Bld:

- 2006 (Main Gate)

- 2000

- 917

- 911

- 909

- 903

- 888

- 887

- 885

- 883

- 876

- 875

- 872

- 849

- 846

- 820

- 220

- Unlisted

-

Describe:

-

Room(s):

-

Follow-Up Date:

Out Brief

Formal Outbrief

-

Was the commander available for a formal out brief within 3 days?

-

CC Rank, Name, Title:

-

Out brief conducted on:

-

Signature:

-

Supervisor or POC Rank, Name, Title:

-

Out brief conducted on:

-

Signature:

-

Why was the CC not briefed?

Formal Report

-

Formal report sent to the commander on:

-

Safety office representative rank and name:

-

Signature:

Explanation of Causes and RACs

-

TR- TRAINING: Inadequate training in: guidance/policy/procedure, training oversight, initial qualification training, hands-on training , controls/metrics of training process/progress, training evaluation, training documentation, individual(s) not qualified, not experienced enough to perform task.

EQ- EQUIPMENT: Correct tools/equipment not available, unserviceable or not used, incorrect tool selection. Equipment defect or design flaw, inadequate equipment maintenance.

TD- TECHNICAL DATA: Tech data, operating instruction, or checklist incorrect, conflicting, misleading, unavailable, overly complex , outdated. (If tech data is incorrect/conflicting, misleading or too complex, individual must generate AFTO 22 and submit copy to MXS supervision)

HE- HUMAN ERROR: Used as last resort. When all equipment, technical data, training, and other factors are adequate. When another qualified technician would not have made the same error.

MC- MISCONDUCT: When all equipment, technical data, training, and other factors are adequate. The technician is fully aware of all requirements, demonstrates task competency, and the process is correct as written. Another qualified technician would not have made the same error and there is clear evidence the technician consciously disregarded technical data and/or regulations.

PI- PROCESS INADEQUATE OR FAULTY: Used when root cause analysis indicates all other root cause codes are not applicable. Established shop process for accomplishing the task is faulty and will be changed as a result of the root cause analysis.

LS- LEADERSHIP/SUPERVISION: Ineffective communication, decision making process ineffective, involvement insufficient, physical work environment issue, failure to adequately program resources.

OT- OTHER: Enter specific issues that cannot be linked to ROOT CAUSES above. -