Information

-

Branch

-

Date/Time of Assessment

-

Prepared by

- Safety Committee

- Neal Seyfert

- Clint Brocato

- Sidney Nigro

- Tyler Mantler

- Brady Baldwin

- Jeremy Gremminger

- Harrison Miller

- Chris Parks

- Chris Davis

General Facilities

General

-

Is there "No Smoking" signage posted at all building entrances?

-

Is there "No Firearms" signage posted at all building entrances?

-

Do all break rooms, locker rooms, restrooms, and drivers' lounges meet MHC housekeeping standards?

-

Do all other general areas of the facility meet MHC housekeeping standards?

-

-

Is the correct "Right to Work/Know Your Rights" OSHA paperwork posted?

-

Are storm shelters clearly marked with proper signage?

-

Are you conducting the self-audit in GA, CO, or TX?

-

This state requires a Medical Provider Panel/Approved Provider List, is it posted?

Egress & Exits

-

Do all lighted exit signs and emergency lighting work when tested?

-

MHC Egress and Exit Standards - Walkways to exits must be clean.

- Exits must not be obstructed from inside or outside.

- Exit doors must unlocked from the inside during business hours. -

Do all exits and egress paths meet standard?

-

Which part does not meet standard?

- Walkways Not Clean

- Exits Obstructed

- Exit Doors Locked

- Other

Electrical

-

Are all electrical outlets in common areas equipped with the proper covers and faceplates?

-

Are outlets near sinks and water sources protected by GFCIs?

-

Do all outdoor outlets have the proper weather cover?<br>

Groundskeeping

-

Is the exterior of the building free of damage?

-

Is the trash bin area free of trash laying around the bins?

-

Is the fencing, landscaping, and shrubbery maintained and meeting MHC standards?

-

Is the curbing in good condition and free from damage?

-

Are the bollards painted yellow or red, free from damage, and is the paint in good condition?

-

Are sidewalks and parking lots maintained relative to the weather conditions?

-

Are all walkways free of slip, trip and fall hazards?

-

Are grounds free from trash and debris?

Lighting

-

Does the branch have adequate lighting inside?

-

Does the branch have adequate lighting outside?

-

Are lights in good working condition and not burnt out?

Decking Hosit

-

Does the branch have a decking hoist?

-

MHC Decking Hoist Standard

- Must have a weight rating on the structure, hoist, and hook.

- Must have an inspection within the last year and a tag on the structure with the inspection date.

- The apparatus must be free from damage or defects. - The area must meet MHC housekeeping standards.

- The hook should have a safety latch. -

Does the decking hoist meet all applicable standards? <br>

-

Which part of the decking hoist does not meet standard?

- Missing Weight Rating

- Missing Inspection/Inspection Not Current

- Damaged

- Housekeeping

- Safety Latch

Sprinkler/Backflow System

-

Does the branch have a sprinkler system?

-

Does the branch have an annual inspection readily available?

-

MHC Sprinkler System Standards

- The sprinkler system must be inspected annually.

- The butterfly valve must be in the open position.

- The backflow system must be tested annually.

- The sprinkler system should be kept clear of debris and storage by 3 feet for ease of access. -

Does the sprinkler system meet all applicable standards?

-

Which part of the sprinkler system does not meet standard?

- No inspection/Inspection Out of Date

- Butterfly Valve Not Open

- Backflow Not Tested

- Access to Sprinkler Blocked

IT Room

-

Can the IT room be properly secured?

-

Is it secured?

-

Are there any issues with the IT servers?

Service

Service

-

Does the branch have a Service Department?

Service

General Housekeeping

-

Does the department meet all MHC housekeeping standards?

-

Is there perimeter/floor striping?

-

Is it good condition?

-

Take a picture of the perimeter/floor striping.

-

Is the department free from slips, trips, and fall hazards?

-

Take pictures of each slip, trip, or fall hazard.

-

Is there “Employees/Authorized Personnel Only" signage?

-

-

Are all oil lines free from leaking, so they do not cause a trip or fall?

-

Take a picture of the leaking oil line(s).

-

When asked can an employee name the FOS 4 States of Mind?

-

Educate the employee on FOS and the importance behind it.

-

Did this department have a new hire?

-

Was the employee onboarded correctly and was it completed through Safety Culture?

-

Provide employees Name and Number.

Air Compressor

-

Does the department have an air compressor?

-

What state is the audit being conducted?

- Alabama

- Arkansas

- Colorado

- Georgia

- Illinois

- Iowa

- Kansas

- Louisiana

- Mississippi

- Missouri

- Nebraska

- New Mexico

- North Carolina

- Ohio

- Oklahoma

- Tennessee

- Texas

- Wyoming

-

You state does not require air compressor inspections. Continue to the next question.

-

Has the air compressor been inspected by the state within the last year?

-

Has the air compressor been inspected by the state within the past 24 months?

-

Has the air compressor been inspected by the state within the past 36 months?

-

Air Compressor Standards

-Must have a "Machine Starts Automatically" sign

-All drive belts must be guarded

-Must be equipped with pressure relief valves & accurate pressure gauges -

Does the air compressor meet all standards?

-

Which part of the air compressor does not meet standard?

- Missing "Machine Starts Automatically" Sign

- Unguarded Belts

- Pressure Relief Valve Missing/Broken

- Pressure Gauge Missing/Broken

Air Hoses

-

Air Hose Standards

- Hoses must never be left on the floor when not in use

- Hoses must be free from physical damage and non-approved repairs (hose clamp and tape)

- Air guns must be OSHA approved with the safety relief tip when used for cleaning purposes -

Does the department meet all air hose standards?

-

What part of the air hoses do not meet standard?

- Hoses on Floor

- Damaged/Non-Approved Repairs

- Blow Guns Not OSHA Approved

- Other

Alignment Pit

-

Does the department have an alignment pit?

-

Alignment Pit Standards

- Housekeeping meets MHC standard

- Must have barriers around pit

- All ramps and columns must be free from damage -

Does the alignment pit meet all applicable standards?

-

Which part of the alignment pit does not meet standard?

- Housekeeping

- No Barrier

- Damage to Ramps or Columns

- Other

Behavioral Observations

-

Discuss with the Service Manager and Technicians on how often the Foreman is seen walking the shop.

-

*Foreman Tower: How often does the foreman walk the shop?

-

Observe a technician and ask the following questions:

-

Which job is the technician working on?

- DriveLines

- Transmissions

- Overhauls - Out of Frame Engine Work

- Preventative Maintenance

- Other

-

Can the technician effectively discuss what they are working on?

-

Can the technician determine hazards and risk present in each task?

-

Can the technician explain what preventative controls they have taken in order to conduct the work safely?

-

Can the technician effectively discuss what they are working on?

-

Can the technician determine hazards and risk present in each task?

-

Can the technician explain what preventative controls they have taken in order to conduct the work safely?

-

Can the technician effectively discuss what they are working on?

-

Can the technician determine hazards and risk present in each task?

-

Can the technician explain what preventative controls they have taken in order to conduct the work safely?

-

Can the technician effectively discuss what they are working on?

-

Can the technician determine hazards and risk present in each task?

-

Can the technician explain what preventative controls they have taken in order to conduct the work safely?

-

Can the technician effectively discuss what they are working on?

-

Can the technician determine hazards and risk present in each task?

-

Can the technician explain what preventative controls they have taken in order to conduct the work safely?

-

Are creepers up when not in use, so they do not cause a trip hazard?

-

If the steer axle is lifted, has the air system been bled and the parking brake been set?

-

Are employees maintaining 3 points of contact at all times?

-

Are proper lifting techniques being observed?

-

Are employees using proper lifting equipment when lifting heavy items?

-

Are employees using assisted lifting devices/team lifting for items over 50 lbs?

-

Are employees using goggles when under a truck?

-

Are employees using retractable knives when cutting and demonstrating proper cutting techniques?

-

How often is the department holding Safety Huddles?

-

How often is the department holding Crew Meetings?

Batteries

-

Is the department storing batteries?

-

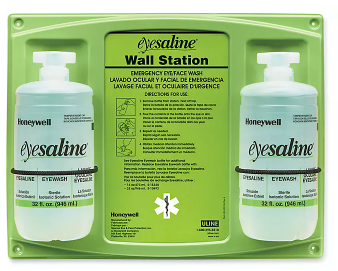

Battery Storage Standards

- Battery cores must be stored on a containment pallet

- Batteries that do not have a handle must be transported by battery carrier - Eye wash station must be within 75 feet of batteries

- Batteries must be stacked in an orderly fashion and ready for collection (not in a pile or out of order) -

Does the department meeting all battery storage standards?

-

Which part of storing batteries does not meet standard?

- Batteries not stored on containment pallet

- Batteries not being moved by a handle or carrying device

- Eye wash station not within 75 feet

- Not being stacked correctly

- Other

-

Take a picture of the battery storage area.

Bay Doors

-

Bay Door Standard

- Must be all the way open or closed, not partially open

- Must be free of damage -

Is the branch meeting all bay door standards?

-

Which part of the bay doors do not meet standard?

- Doors Not Fully Open/Closed

- Damaged Doors

- Other

Bench Grinder

-

Does the department have a bench grinder?

-

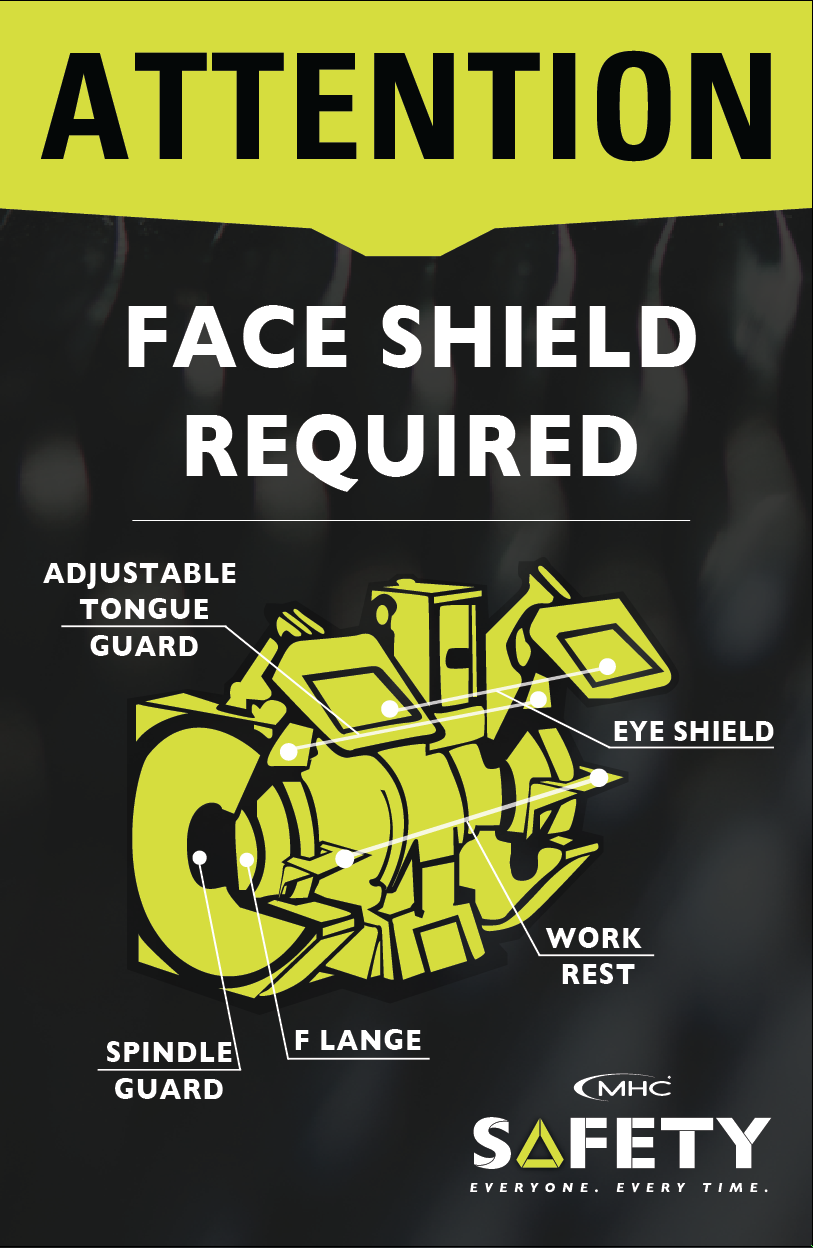

Bench Grinder Standards

- Sideguards must cover nut and flange

- Work rest must be within1/8-inch of the wheel

- Tongue guard must be within 1/4-inch of the wheel

- Grinding edge of wheel must flat and free of metal impingements or chips

- Face shield must be available at station and worn when in use -

Does the bench grinder meet all standards?

-

Which part of the bench grinder does not meet standard?

- Side Guards

- Tongue Guard

- Grinder Wheel

- Face Shield

- PPE Not Available or Being Used

- Work Rest

Chock Blocks

-

Are chock blocks located in a designated area, so they do not cause a trip hazard when not in use?

-

Are chock blocks used for all vehicles that are being serviced inside and outside the bays?

-

Are chock blocks in good condition?

Chop Saw

-

Does the department have a chop saw?

-

Chop Saw Standards

- Must be in good working condition

- Work area must be clean and orderly with no used parts or waste

- Face shield & leather gloves must be at the station and worn when in use

- Power cord must be free from defects and have a ground prong

- Must be secured/anchored to work area -

Does the chop saw meet all standards?

-

Which part of the chop saw does not meet standard?

- Condition

- Work Station Housekeeping

- PPE Missing

- PPE Not Being Used

- Power Cord

- Unit Not Anchored/Secured

- Other

CNG/LNG

-

Is the department performing work on CNG/LNG vehicles?

-

Is the facility equipped with a gas detection sensors?

-

Is the CNG service being performed inside or outside the building?

-

If the facility doesn't contain a detection system, CNG powered vehicles are only allowed in a facility if the vehicle is completely purged with a wash out ticket. If the vehicle is not completely purged with a wash out ticket, it must be removed from inside the facility immediately.

-

Working on CNG vehicles outside is permitted. Please continue the audit.

-

Facilities with gas detection systems are permitted to work on CNG/LNG vehicles inside. Please continue the audit.

Diesel Particulate Filter

-

Does the department have a DPF cleaner?

-

DPF Cleaner Standards

- Must have and use a DPF handler (cart) to transport DPFs

- N95 dust mask and splash proof safety googles must worn when handling the soot collection bucket -

Is the department meeting all DPF cleaner standards?

-

Which part of the DPF cleaning practices does not meet standard?

- DPF Handler

- PPE

Drill Press

-

Does the department have a drill press?

-

Drill Press Standard

- Drill bit must have a guard

- Power cord must be free from defect and include a ground prong

- Face shield must be present and used during operation

- Drive belts must be guarded

- Drill press must be secured/anchored -

Does the drill press meet all standards?<br>

-

What part of the drill press does not meet standard?

- Drill Bit Guard

- Power Cord/Ground Prong

- Face Shield

- Belts Not Guarded

- Unit Not Secured/Anchored

Egress & Exits

-

Do all lighted exit signs and emergency lighting work when tested?

-

MHC Egress and Exit Standards

- Walkways must be clean

- Exits must not be obstructed from inside or outside

- Doors must unlocked from the inside during business hours -

Do all exits and egress paths meet MHC standard?

-

Which part of the exit or egress does not meet standard?

- Walkways Not Clean

- Exits Obstructed

- Exit Doors Locked

- Other

Electrical

-

Electrical Outlet Standards

- Outlets must be covered and free from holes or openings

- Outlets exposed to weather (outside or moisture) must have weather covers

- Junction boxes must be covered and free from holes or openings -

Is the department meeting all electrical outlet standards?

-

Which part of the electrical outlets do not meet standard?

- Uncovered/Holes

- Weather Covers

- Junction Boxes

- Other

-

Extension Cord Standards

- Must be free from damage, including missing ground prong & repair with electrical tape

- Must be hung up out of the way when not in use

- Must not be used as permanent wiring (zip tied to conduit or run through walls or doors) -

Is the department meeting all extension cord standards?<br>

-

Which part of the extension cords do not meet standard?

- Damaged Cord

- Missing Prong

- Cord zip tied to conduit

- Runs Through Wall or Door

- Other

-

Electrical Panel Standards

- Panels must be labeled with Danger, High Voltage and Keep Out signage

- All breakers must be properly labeled

- All breaker boxes must be free of open void or holes greater than 1/8th inch

- All breakers must be in proper working condition without tape

- All electrical panels must have clear access and cannot be obstructed -

Is the department meeting all electrical panel standards?

-

Which part of the electrical panel does not meet standard?

- High Voltage Warning Signs

- Breaker Labels

- Open Voids or Holes

- Other

- Panels Obstructed

-

Have any employees completed Level 0 and Level 1 electric vehicle safety training through Kenworth?

Eye Wash Station/Bottles

-

Does this department have an eye wash station or bottles?

-

What type?

- Plumbed Eye Wash Station

- Gravity Fed Eye Wash Station

- Eye Wash Bottles

-

-

Plumbed Eye Wash Station Standards

- Caps must be in place.

- Basin must be clean and not broken.

- Station must be clear from all obstructions. -

Is the plumbed eye wash station meeting all standards?

-

Which part(s) of the plumbed eye was station does not meet standard?

- Caps not in Place

- Basin not Clean/Is Broken

- Station is Obstructed

- Other

-

-

Gravity Fed Eye Wash Station Standards

- Basin must be clean.

- Station must be clear from all obstructions. -

Is the gravity fed eye wash station meeting all standards?<br>

-

Which part(s) of the gravity fed eye was station does not meet standard?

- Caps not in Place

- Basin not Clean/Is Broken

- Station is Obstructed

- Other

-

-

Eye Wash Bottles Standards

Bottles cannot be a substitute for an eye wash station. They must only used as supplemental protection.

- Cannot be expired.

- Must be free from all obstructions. -

Are the eye wash bottles meeting all standards?

-

Which part(s) of the eye wash bottles do not meet standard?

- Used as a Substitute for Eye Wash Station

- Bottles are Expired

- Access to Bottles is Obstructed

- Other

Flammable Storage

-

Are shop rags disposed of properly in an OSHA-approved container with a self-closing lid?

-

Does the branch have a flammable cabinet?

-

Does the branch have any gas or fuel cans?

-

Fuel Can Standard

All gas or fuel cans must be:

- Metal

- Have a self-closing lid

- Have a flash arrestor -

Are the fuel cans meeting standard?<br><br>

-

Which part of the fuel cans does not meet standard?

- OSHA Approved

- Not Metal

- No Self-Closing Lid

- No Flash Arrestor

First Aid

-

Does the department have a first aid kit?

-

First Aid Kit Standards

- Cannot have any oral medication.

- Must have bloodborne pathogen kit.

- Must be clean and maintain a professional image. -

Does the first aid kit meet all standards?

-

Which part of the first aid kit does not meet standard?

- Oral medictions

- Blood borne pathogen kit

- Appreance

- Other

Fire Extinguishers

-

-

Fire Extinguisher Standards

- Annual inspections must be completed by a third party.

- Monthly inspections must be completed by the branch.

- Must be clearly marked, free from obstruction, and mounted every 75'.

- Must be mounted 3-5 feet from the floor.

- Safety signage must be present. -

Is the department meeting all fire extinguisher standards?

-

Which part(s) of the fire extinguishers does not meet standard?

- Annual Inspection

- Monthly Inspections

- Not Marked

- Obstructed

- Improperly Mounted

- Seal was Tampered With

- Pin not in Place

- Gauge not in Green

- MHC Signage

Flywheel Machine

-

Does the department have a flywheel machine?

-

Flywheel Machine Standards

-Controls must function properly & be free of damage, missing knobs/buttons

-Power cord must free of damage

-Grinding wheel must be free of chips, cracks, or any other damage

-Front guard must be installed while the flywheel machine is operating -

Does the flywheel machine meet all standards?

-

Which part of the flywheel machine does not meet standard?

- Controls

- Power Cord

- Grinder Wheel

- Front Guard Missing/Not in Use

- Other

Forklift

-

Does the department have a forklift?

-

What is the instructor(s) name and employee #?

-

Have they been trained on ShareKnowledge?

-

Are new hires being trained via the Safety Culture app?

-

Have all employees who may operate a forklift in this department completed ShareKnowledge training in the last 3 years?

-

Do all employees who may operate a forklift in this department have a Hands On Evaluation on file on paper or in the SafetyCulture app?

-

Forklift Safe Operation Conditions

- All components must be free wear, damage, or modification

- Top of cab must be free of visual obstructions -

Is the forklift in a safe operating condition?

-

Which component is not within safety operating condition?

- Components Worn/Damaged

- Top of Cab Obstructed

- Other

-

Required Forklift Paperwork

- Weekly Inspections - Quarterly Preventative Maintenance -

Does the branch have proper inspections and maintenance records?

-

Which paperwork is out of compliance?

-

Forklift Safe Operation Standards

- Seatbelt must be worn by all operators

- Forks must be left down when not in use

- Propane must be turned off at end of shift

- Parking brake set when not being used

- Horn sounded when passing through doors and reversing -

Is the forklift being operated in a safe manner?

-

Which part of the forklift is not being operated in a safe manner?

- Seatbelt

- Forks Left Up

- Propane Left On

- Parking Brake Not Set

- Horn Not Sounded

- Other

Hazard Communication (HazCom)

-

Is the HazCom signage posted in the department?

-

Are all secondary containers/spray bottles properly labeled with their contents?

-

When asked, do employees know how to access Safety Data Sheets?

Hot Works

Oxygen/Acetylene

-

Is the department storing extra oxygen or acetylene?

-

Oxygen/Acetylene Storage Standards

- All oxygen cylinders must be stored 20 feet from flammables

- All compressed gas cylinders must be secured upright

- All compressed gas cylinders must be capped when not in use -

Is the department meeting all oxygen and acetylene storage standards?<br>

-

Which part of the oxygen and acetylene storage does not meet standard?

- Oxygen Stored Near Flammables

- Cylinders Not Secured

- Cylinders Not Capped

- Other

-

Does the department have a torch cart?

-

Torch Cart Standards

- Cart must have a 5ft high fire wall

- All gauges must be working with no broken or missing glass or plastic

- Flash arrestors must be present on the torch

- Appropriate gloves and goggles must be available on the cart -

Does the torch cart meet all applicable standards?<br>

-

Which part of the torch cart does not meet standard?

- Missing Firewall

- Broken Gauges

- Flash Arrestors

- Other

Welder

-

Does the department have a welder?

-

Welder Standards

- Welder must wear welding gloves

- Welder must have appropriate welding helmet

- Welder power cord must be free from all defects, including exposed or taped wiring -

Does the welder meet all applicable standards?

-

Which part of the welder does not meet standard?

- Gloves

- Mask

- Power cord

- Other

Hydraulic Press

-

Does the department have a hydraulic press?

-

Hydraulic Press Standards

- Must have guarding covering work area

- Area around press must meet MHC housekeeping standards

- Must be anchored/secured to prevent walking or tipping -

Does the hydraulic press meet all applicable standards?

-

Which part of the press does not meet standard?

- Gaurding

- Housekeeping

- Anchored/Secured

- Other

Ladders/Work Platforms

-

Is the department free from all homemade or non-approved work platforms? (A frame ladders, homemade boxes, etc)

-

Does the department have a staircase ladder?

-

Is it in good condition with required rubber feet that are free from damage?

-

Do all podium ladders, step ladders, and other work platforms meet the minimum 375lbs rate rating?

-

Are all podium ladders properly secured by hook or chain in a designated area when not in use?

Lifting/Load Bearing Equipment

-

When asked, do employees know when they are required to use assisted lifting?

Jacks/Jack Stands

-

Are jack stands being utilized under all vehicles when the load is supported by a jack?

-

Are all jacks and jack stands free of defects and damage, labeled with the capacity, and equipped with the proper pin?

-

Which part of the jacks and jack stands does not meet standard?

- Defective/Damaged

- Labeled with Capacity

- Proper Pin

Drive Line Tooling

-

All branches should have at least one DriveLine PRO.

-

Is the Drive Line Pro being utilized under all vehicles when doing any driveline work?

-

Are all Drive Line Pro's free of defects and damages?

Disc Brake Hub Handler

-

-

Does this branch have a Disc Hub Handler?

-

Is the Disc Hub Handler being utilized appropriately and in safe working conditions?

Engine Work

-

Does the facility perform out of frame engine work?

-

How many engine stands does the branch have?

-

Engine Work Standards

All out of frame engine work must be done on an MHC approved engine stand or must have 4 points of contact AND an overhead support, meaning it must be on an engine stand or 4 jacks and hoist (or another form of overhead support) -

Does the out of frame engine work meet MHC standards?

-

Which part of the engine work did not meet standard?

-

Does the facility do midsize engine work?

Hoists, Cranes, Chain, Etc.

-

Does the department have a hoist/crane?

-

Hoist/Crane Standards

- Load rating must be displayed on the structure, assembly, and hook

- Crane/hoist must be inspected on an annual basis and inspection date must be clearly labeled on the crane/hoist

- Crane controls must be clearly labeled

- Hook has safety latch if it was designed with one -

Does the crane/hoist meet all applicable standards?<br>

-

Which part of the crane/hoist does not meet standard?

- Weight Rating

- Pendant Controls

- Inspection Out of Date

- Inspection Not Visible on Crane

- Missing/Broken Safety Latch

-

Does the department have a cherry picker?

-

Cherry Picker Standards

- Must be in proper working order/manufacturer’s intended condition

- Must be labeled with weight capacity at each arm setting

- If hook is designed to have safety latch, it must have one

- Must have annual inspection and date of inspection must be labeled on cherry picker -

Does the cherry picker meet all applicable standards?

-

Which part of the cherry picker does not meet standard?

- Condition

- Weight Rating

- Hook Safety Latch

- Annual Inspection

- Annual Inspection Label

- Other

-

Chain Standards

- All lifting chains must be at least grade 8,80,800 or higher

- All chains must be tagged with correct load rating

- All chains must have annual inspection -

Does all chain meet the applicable standards?

-

Which part of the chain does not meet standard?

- Grade

- Not Tagged with Weight Rating

- Inspection Out of Date

- Other

-

Are all vehicles being serviced with lifted dump beds using a secondary locking device? Wood blocks are not approved as a secondary locking device.

Lighting

-

Does the department have adequate lighting?

-

Does the branch have fluorescent bulbs?

-

Is the branch disposing of fluorescent bulbs?

-

Do they have an approved Waste Management recycling box?

-

Is it properly labeled with an accumulation start date that is less than 1 year from today?

-

Are there records showing that a vendor is properly disposing of fluorescent bulbs?

-

Are all light bulbs working (no lights out)?

-

Is the department free of all metal, caged drop lights?

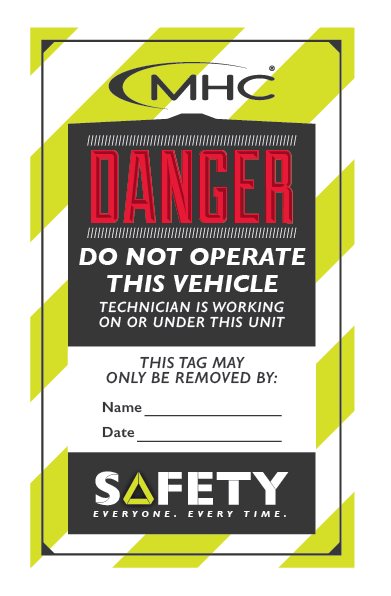

Lock Out/Tag Out

-

-

Lock Out/Tag Out Standard

All vehicles in the shop will have:

- Key on floorboard

- Tag hung from turn signal -

Is the LOTO program in effect and properly administered per the work instruction?

-

Which part(s) of the LOTO Program does not meet standard?

- Key Not on Floorboard

- Tag not Hung from Turn Signal

- Other

Parts Cleaner (Solvent-Based Basin)

-

Is the parts cleaner free of all flammable products?

-

Are parts cleaners being used for their intended purpose and not as a work station?

Parts Washer (Automatic Steamer Cabinet)

-

Does the department have an automatic parts steamer cabinet?

-

Steamer Cabinet Standards

- Must have signage stating "Caution/Hot"

- Power cord must be free from all defects -

Does the parts steamer cabinet meet all applicable standards?

-

Which part of parts steamer cabinet does not meet standard?

- Signage

- Power Cord

Personal Protective Equipment

-

Are safety glasses being worn by employees in the shop at all times?

-

Is the visitor safety glasses bin stocked and safety glasses readily available?

-

Are all visitors, vendors, and other MHC employees wearing safety glasses in the shop?

-

Are steel-toed or composite-toed boots being worn by all employees in the shop at all times?

-

Are all employees handling any tools, parts, or materials wearing cut resistant gloves?

-

Does this department have bump caps?

-

Is hearing protection (ear plugs) available for all employees?

Rotary/Die Grinders

-

MHC Grinding and Cutting Standards

- All rotary/die grinders including personal grinders must be equipped with the proper guards

- The max revolutions per minute (rpm) rating of each abrasive wheel must be compatible with the rpm rating of the grinder motor

- The power cord must free of damage including missing ground prong -

Does the department meet all the grinding and cutting standards?

-

Which part of the cutting and grinding standards are not being followed?

- Missing Guard

- Wheel not Rated for Grinder

- Power Cord

- Other

-

Are all employees using cutting wheels or grinders wearing safety glasses AND face shields?

Service Pit

-

Does the department have a service pit?

-

Service Pit Standards

- Must be clean without trash, rags, or spills

- Must have a barrier around or over the the open pit

- Must be well lit with all lights working -

Does the service pit meet all applicable standards?

-

Which part of the service pit does not meet standard?

- Housekeeping

- No Barrier

- Lighting

- Other

Spill Control

-

Does the branch have a Spill Prevention Control Countermeasure (SPCC) Plan developed and available?

-

Is spill containment (Green Stuff, oil dry) material present and readily available?

-

What is the branch using for spill containment?

-

Does the department have a spill kit for larger spills?

Tool Room

-

Is the tool room organized and free of slips, trips, and falls?

-

Does it meet the MHC housekeeping standard?

-

Is it free of homemade tools?

-

Are all tools and equipment free of broken or fractured handles and in good working condition?

-

Are the striking ends of all seal drivers in good condition?

-

Are the power cords of all tools and equipment free from damage, including missing ground prongs?

Tooling and Equipment

-

Does this facility have a tool list?

-

Check the tools that are missing from the list.

- DPF Cleaning

- Rotating Engine Stand

- Overhead Crane

- Undocking A-frame

- Heavy Duty Cherry Picker

- Dump Bed - Hinge Locks/Alternative Safety Device

- Wheel Dolly

- Drive Line Support/Removal Tool

- Brake Drum Dolly

- EGR Flush Kit

- Jump Start Box/Cart

- A/C Machine 134A Only

- Disc Hub Brake Remover

- Column Lifts

- Stationary Engine Stands

- MX Counterbore Cutting Tool Monaco/Mira

- Pico Scope

- Transmission High Lift Jack

- Transmission Jack

- Clutch Jack

- DPF Aftertreatment Jack

- Tiger Tool - Steering/Suppression Press

- Alignment Machine

- Flywheel Cutting Machine

- Press

- Welder

Wash Bay

-

Does the department have a wash bay?

-

Is the wash bay organized and does it meet MHC housekeeping standards?

-

Do all electrical outlets have the proper weather covers?

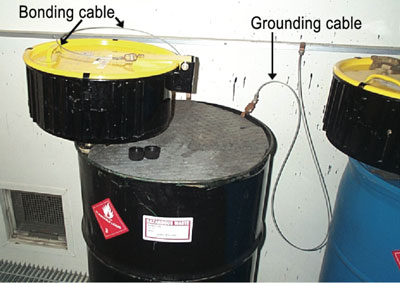

-

Is the wash bay free from storage of excess barrels?

-

Is the wash bay free from any barrels containing flammables?

Waste Lubricants

-

Are all oils and lubricants cleaned up and disposed of in the designated area?

-

Are all the spent oil materials (including mats, absorbent, socks) being disposed of properly?

-

Are all used oil, antifreeze, and fuel tanks labeled properly?

-

Per state regulations, is the department disposing of oil filters properly?

Oil Water Separator

-

Does the department have an oil water separator?

-

Is there paperwork showing the separator has been cleaned in the last year?

-

Take a picture of the paperwork.

-

Are all drain grates in place, free from damage, and serving their original purpose?

Vehicles

-

Ask multiple employees their opinion on why we have Vehicle Safety Standards and DriveCam.

-

Was the employee able to discuss the Vehicle Safety Standards?

-

Educate the employee on MHC's Vehicle Safety Standards program and the importance of it.

-

Does this department have a vehicle?

-

Vehicle Inspection

Vehicle

-

Asset Number

-

Take multiple pictures of the vehicle's exterior and interior condition.

-

Vehicle Safety Sticker

-

Does the vehicle have 3 of the stickers above?

-

No Phone Sticker

-

Does the vehicle have 1 of the stickers above on the pillar next to the driver's side door?

-

Max Speed Sticker

-

Does the vehicle have 1 of the stickers on the back bumper?

-

Is this a DOT or non-DOT vehicle?<br>- DOT vehicles have a GVWR over 10,00 lbs (anything bigger than F250)<br>- Non-DOT vehicles have a GVWR of 10,000 lbs and under (F250 and smaller)

-

Does the vehicle have proper daily DVIRs and weekly MHC inspections?

-

Take a picture of the inspections.

-

Does the vehicle have all required paperwork? Includes: <br>- Valid Registration<br>- Valid insurance card<br>- Collision Assistance Kit<br>- Annual DOT inspection (paperwork & legible sticker on vehicle)

-

Which required paperwork is missing?

- Insurance Card

- Valid Registration

- Vehicle Collision Assistance Guide

- Annual DOT Vehicle Inspection

-

Take a picture of the paperwork.

-

Does the vehicle have all required safety items?<br>- Functioning DriveCam<br>- First Aid Kit<br>- Reflective Vest and Hi-Viz Seatbelt Covers <br>- Cargo Securement<br>- Bluetooth<br>- Spill kit<br>- Safety Glasses<br>- Cut Resistant Gloves<br>- Phone Mount <br>- Lock Out Tags<br>- Extra Fuses<br>- Triangles or Flairs<br>- Secured Fire Extinguisher<br>- Wheel Chocks

-

Which safety items are missing?

- DriveCam

- First Aid Kit

- Reflective Vest

- Cargo Securment

- Hazmat Spill Kit

- Safety Glasses

- Cut Resistant Gloves

- Phone Mount

- Secured Fire Extinguisher

- Hi-Viz Seat Belt Covers

-

Does the vehicle’s condition meet MHC standards? Includes: <br>- Must be clean inside/out and present a world-class appearance<br>- Asset number must be displayed - DOT # must be displayed on both sides in 2-inch bold letters<br>- Logos must be in good condition and free from peeling or tears<br>- Mirror and dash must be clear of all obstructions and items<br>- Vehicle must backed in or parked in a pull through manner <br>- Tires must not be damaged & have 1/8th of an inch tread<br>- Vehicle must be free from all damage, including tailgate<br>- Windshield must be free from all damage, including chips/cracks

-

What part of the vehicle’s condition and image does not meet standard?

- Vehicle Cleanliness

- Asset Number

- Logos

- Parked Properly

- Mirror/Dash Not Clean

- Windshield

- Tailgate

- DOT Number

-

Does the vehicle proper weekly inspections?

-

Does the vehicle have all of the required paperwork? Includes: <br>- Valid Registration<br>- Valid Insurance Card<br>- Collision Assistance Kit

-

Which required paperwork is missing?

- Registration

- Insurance Card

- Collision Assistance Kit

-

Does the vehicle have ALL required safety items? Includes: <br>- Functioning DriveCam<br>- First Aid Kit<br>- Hi-Viz Seatbelt Covers <br>- Cargo Securement <br>- Bluetooth<br>- Spill Kit<br>- Safety Glasses<br>- Cut Resistant Gloves<br>- Phone Mount<br>- Lock Out Tag<br>- Secured Fire Extinguisher

-

Which safety items are missing?

- DriveCam

- First Aid Kit

- Reflective Vest

- Cargo Securment

- Hazmat Spill Kit

- Safety Glasses

- Cut Resistant Gloves

- Phone Mount

- Secured Fire Extinguisher

- Hi-Viz Seat Belt Covers

-

Does the vehicle’s condition meet MHC standards? Includes: <br>- Must be clean inside/out and present a world-class appearance<br>- Asset number must be displayed <br>- Logos must be in good condition and free from peeling or tears<br>- Mirror and dash must be clear of all obstructions and items<br>- Vehicle must backed in or parked in a pull through manner <br>- Tires must not be damaged & have 1/8th of an inch tread<br>- Vehicle must be free from all damage, including tailgate<br>- Windshield must be free from all damage, including chips/cracks

-

What part of the vehicle’s condition and image does not meet standard?

- Vehicle Cleanliness

- Asset Number

- Logos

- Parked Properly

- Mirror/Dash Not Clean

- Windshield

- Tailgate

- DOT Number

Medium Duty Service

-

Does the branch have a Medium Duty Service Department?

Medium Duty Service

General Housekeeping

-

Does the department meet all MHC housekeeping standards?

-

Is there perimeter/floor striping?

-

Is it good condition?

-

Take a picture of the perimeter/floor striping.

-

Is the department free from slips, trips, and fall hazards?

-

Take pictures of each slip, trip, or fall hazard.

-

Is there “Employees/Authorized Personnel Only" signage?

-

-

Are all oil lines free from leaking, so they do not cause a trip or fall?

-

Take a picture of the leaking oil line(s).

-

Did this department have a new hire?

-

Was the employee onboarded correctly and was it completed through Safety Culture?

-

Provide employees Name and Number.

Air Compressor

-

Does the department have an air compressor?

-

What state is the audit being conducted?

- Alabama

- Arkansas

- Colorado

- Georgia

- Illinois

- Iowa

- Kansas

- Louisiana

- Mississippi

- Missouri

- Nebraska

- New Mexico

- North Carolina

- Ohio

- Oklahoma

- Tennessee

- Texas

- Wyoming

-

You state does not require air compressor inspections. Continue to the next question.

-

Has the air compressor been inspected by the state within the last year?

-

Has the air compressor been inspected by the state within the past 24 months?

-

Has the air compressor been inspected by the state within the past 36 months?

-

Air Compressor Standards

-Must have a "Machine Starts Automatically" sign

-All drive belts must be guarded

-Must be equipped with pressure relief valves & accurate pressure gauges -

Does the air compressor meet all standards?

-

Which part of the air compressor does not meet standard?

- Missing "Machine Starts Automatically" Sign

- Unguarded Belts

- Pressure Relief Valve Missing/Broken

- Pressure Gauge Missing/Broken

Air Hoses

-

Air Hose Standards

- Hoses must never be left on the floor when not in use

- Hoses must be free from physical damage and non-approved repairs (hose clamp and tape)

- Air guns must be OSHA approved with the safety relief tip when used for cleaning purposes -

Does the department meet all air hose standards?

-

What part of the air hoses do not meet standard?

- Hoses on Floor

- Damaged/Non-Approved Repairs

- Blow Guns Not OSHA Approved

- Other

Alignment Pit

-

Does the department have an alignment pit?

-

Alignment Pit Standards

- Housekeeping meets MHC standard

- Must have barriers around pit

- All ramps and columns must be free from damage -

Does the alignment pit meet all applicable standards?

-

Which part of the alignment pit does not meet standard?

- Housekeeping

- No Barrier

- Damage to Ramps or Columns

- Other

Behavioral Observations

-

Are creepers up when not in use, so they do not cause a trip hazard?

-

If the steer axle is lifted, has the air system been bled and the parking brake been set?

-

Are employees maintaining 3 points of contact at all times?

-

Are proper lifting techniques being observed?

-

Are employees using proper lifting equipment when lifting heavy items?

-

Are employees using assisted lifting devices/team lifting for items over 50 lbs?

-

How often is the department holding Safety Huddles?

-

How often is the department holding Crew Meetings?

Batteries

-

Is the department storing batteries?

-

Battery Storage Standards

- Battery cores must be stored on a containment pallet

- Batteries that do not have a handle must be transported by battery carrier - Eye wash station must be within 75 feet of batteries

- Batteries must be stacked in an orderly fashion and ready for collection (not in a pile or out of order) -

Does the department meeting all battery storage standards?

-

Which part of storing batteries does not meet standard?

- Batteries not stored on containment pallet

- Batteries not being moved by a handle or carrying device

- Eye wash station not within 75 feet

- Not being stacked correctly

- Other

Bay Doors

-

Bay Door Standard

- Must be all the way open or closed, not partially open

- Must be free of damage -

Is the branch meeting all bay door standards?

-

Which part of the bay doors do not meet standard?

- Doors Not Fully Open/Closed

- Damaged Doors

- Other

Bench Grinder

-

Does the department have a bench grinder?

-

Bench Grinder Standards

- Sideguards must cover nut and flange

- Work rest must be within1/8-inch of the wheel

- Tongue guard must be within 1/4-inch of the wheel

- Grinding edge of wheel must flat and free of metal impingements or chips

- Face shield must be available at station and worn when in use -

Does the bench grinder meet all standards?

-

Which part of the bench grinder does not meet standard?

- Side Guards

- Tongue Guard

- Grinder Wheel

- Face Shield

- PPE Not Available or Being Used

- Work Rest

Chock Blocks

-

Are chock blocks located in a designated area, so they do not cause a trip hazard when not in use?

-

Take pictures of all chock blocks not in a designated area.

-

Are chock blocks used for all vehicles that are being serviced inside and outside the bays?

-

Are chock blocks in good condition?

Chop Saw

-

Does the department have a chop saw?

-

Chop Saw Standards

- Must be in good working condition

- Work area must be clean and orderly with no used parts or waste

- Face shield & leather gloves must be at the station and worn when in use

- Power cord must be free from defects and have a ground prong

- Must be secured/anchored to work area -

Does the chop saw meet all standards?

-

Which part of the chop saw does not meet standard?

- Condition

- Work Station Housekeeping

- PPE Missing

- PPE Not Being Used

- Power Cord

- Unit Not Anchored/Secured

- Other

CNG/LNG

-

Is the department performing work on CNG/LNG vehicles?

-

Is the facility equipped with a gas detection sensors?

-

Is the CNG service being performed inside or outside the building?

-

If the facility doesn't contain a detection system, CNG powered vehicles are only allowed in a facility if the vehicle is completely purged with a wash out ticket. If the vehicle is not completely purged with a wash out ticket, it must be removed from inside the facility immediately.

-

Working on CNG vehicles outside is permitted. Please continue the audit.

-

Facilities with gas detection systems are permitted to work on CNG/LNG vehicles inside. Please continue the audit.

Diesel Particulate Filter

-

Does the department have a DPF cleaner?

-

DPF Cleaner Standards

- Must have and use a DPF handler (cart) to transport DPFs

- N95 dust mask and splash proof safety googles must worn when handling the soot collection bucket -

Is the department meeting all DPF cleaner standards?

-

Which part of the DPF cleaning practices does not meet standard?

- DPF Handler

- PPE

Drill Press

-

Does the department have a drill press?

-

Drill Press Standard

- Drill bit must have a guard

- Power cord must be free from defect and include a ground prong

- Face shield must be present and used during operation

- Drive belts must be guarded

- Drill press must be secured/anchored -

Does the drill press meet all standards?<br>

-

What part of the drill press does not meet standard?

- Drill Bit Guard

- Power Cord/Ground Prong

- Face Shield

- Belts Not Guarded

- Unit Not Secured/Anchored

Egress & Exits

-

Do all lighted exit signs and emergency lighting work when tested?

-

MHC Egress and Exit Standards

- Walkways must be clean

- Exits must not be obstructed from inside or outside

- Doors must unlocked from the inside during business hours -

Do all exits and egress paths meet MHC standard?

-

Which part of the exit or egress does not meet standard?

- Walkways Not Clean

- Exits Obstructed

- Exit Doors Locked

- Other

Electrical

-

Electrical Outlet Standards

- Outlets must be covered and free from holes or openings

- Outlets exposed to weather (outside or moisture) must have weather covers

- Junction boxes must be covered and free from holes or openings -

Is the department meeting all electrical outlet standards?

-

Which part of the electrical outlets do not meet standard?

- Uncovered/Holes

- Weather Covers

- Junction Boxes

- Other

-

Extension Cord Standards

- Must be free from damage, including missing ground prong & repair with electrical tape

- Must be hung up out of the way when not in use

- Must not be used as permanent wiring (zip tied to conduit or run through walls or doors) -

Is the department meeting all extension cord standards?<br>

-

Which part of the extension cords do not meet standard?

- Damaged Cord

- Missing Prong

- Cord zip tied to conduit

- Runs Through Wall or Door

- Other

-

Electrical Panel Standards

- Panels must be labeled with Danger, High Voltage and Keep Out signage

- All breakers must be properly labeled

- All breaker boxes must be free of open void or holes greater than 1/8th inch

- All breakers must be in proper working condition without tape

- All electrical panels must have clear access and cannot be obstructed -

Is the department meeting all electrical panel standards?

-

Which part of the electrical panel does not meet standard?

- High Voltage Warning Signs

- Breaker Labels

- Open Voids or Holes

- Other

- Panels Obstructed

-

Have any employees completed Level 0 and Level 1 electric vehicle safety training through Kenworth?

Eye Wash Station/Bottles

-

Does this department have an eye wash station or bottles?

-

What type?

- Plumbed Eye Wash Station

- Gravity Fed Eye Wash Station

- Eye Wash Bottles

-

-

Plumbed Eye Wash Station Standards

- Caps must be in place.

- Basin must be clean and not broken.

- Station must be clear from all obstructions. -

Is the plumbed eye wash station meeting all standards?

-

Which part(s) of the plumbed eye was station does not meet standard?

- Caps not in Place

- Basin not Clean/Is Broken

- Station is Obstructed

- Other

-

-

Gravity Fed Eye Wash Station Standards

- Basin must be clean.

- Station must be clear from all obstructions. -

Is the gravity fed eye wash station meeting all standards?<br>

-

Which part(s) of the gravity fed eye was station does not meet standard?

- Caps not in Place

- Basin not Clean/Is Broken

- Station is Obstructed

- Other

-

-

Eye Wash Bottles Standards

Bottles cannot be a substitute for an eye wash station. They must only used as supplemental protection.

- Cannot be expired.

- Must be free from all obstructions. -

Are the eye wash bottles meeting all standards?

-

Which part(s) of the eye wash bottles do not meet standard?

- Used as a Substitute for Eye Wash Station

- Bottles are Expired

- Access to Bottles is Obstructed

- Other

Flammable Storage

-

Are shop rags disposed of properly in an OSHA-approved container with a self-closing lid?

-

Does the branch have any gas or fuel cans?

-

Fuel Can Standard

All gas or fuel cans must be:

- Metal

- Have a self-closing lid

- Have a flash arrestor -

Are the fuel cans meeting standard?<br><br>

-

Which part of the fuel cans does not meet standard?

- OSHA Approved

- Not Metal

- No Self-Closing Lid

- No Flash Arrestor

First Aid

-

Does the department have a first aid kit?

-

First Aid Kit Standards

- Cannot have any oral medication.

- Must have bloodborne pathogen kit.

- Must be clean and maintain a professional image. -

Does the first aid kit meet all standards?

-

Which part of the first aid kit does not meet standard?

- Oral medictions

- Blood borne pathogen kit

- Appreance

- Other

Fire Extinguishers

-

-

Fire Extinguisher Standards

- Annual inspections must be completed by a third party.

- Monthly inspections must be completed by the branch.

- Must be clearly marked, free from obstruction, and mounted every 75'.

- Must be mounted 3-5 feet from the floor.

- Safety signage must be present. -

Is the department meeting all fire extinguisher standards?

-

Which part(s) of the fire extinguishers does not meet standard?

- Annual Inspection

- Monthly Inspections

- Not Marked

- Obstructed

- Improperly Mounted

- Seal was Tampered With

- Pin not in Place

- Gauge not in Green

- MHC Signage

Flywheel Machine

-

Does the department have a flywheel machine?

-

Flywheel Machine Standards

-Controls must function properly & be free of damage, missing knobs/buttons

-Power cord must free of damage

-Grinding wheel must be free of chips, cracks, or any other damage

-Front guard must be installed while the flywheel machine is operating -

Does the flywheel machine meet all standards?

-

Which part of the flywheel machine does not meet standard?

- Controls

- Power Cord

- Grinder Wheel

- Front Guard Missing/Not in Use

- Other

Forklift

-

Does the department have a forklift?

-

What is the instructor(s) name and employee #?

-

Have they been trained on ShareKnowledge?

-

Are new hires being trained via the Safety Culture app?

-

Have all employees who may operate a forklift in this department completed ShareKnowledge training in the last 3 years?

-

Do all employees who may operate a forklift in this department have a Hands On Evaluation on file on paper or in the SafetyCulture app?

-

Forklift Safe Operation Conditions

- All components must be free wear, damage, or modification

- Top of cab must be free of visual obstructions -

Is the forklift in a safe operating condition?

-

Which component is not within safety operating condition?

- Components Worn/Damaged

- Top of Cab Obstructed

- Other

-

Required Forklift Paperwork

- Weekly Inspections - Quarterly Preventative Maintenance -

Does the branch have proper inspections and maintenance records?

-

Which paperwork is out of compliance?

-

Forklift Safe Operation Standards

- Seatbelt must be worn by all operators

- Forks must be left down when not in use

- Propane must be turned off at end of shift

- Parking brake set when not being used

- Horn sounded when passing through doors and reversing -

Is the forklift being operated in a safe manner?

-

Which part of the forklift is not being operated in a safe manner?

- Seatbelt

- Forks Left Up

- Propane Left On

- Parking Brake Not Set

- Horn Not Sounded

- Other

Hazard Communication (HazCom)

-

Is the HazCom signage posted in the department?

-

Are all secondary containers/spray bottles properly labeled with their contents?

-

When asked, do employees know how to access Safety Data Sheets?

Hot Works

Oxygen/Acetylene

-

Is the department storing extra oxygen or acetylene?

-

Oxygen/Acetylene Storage Standards

- All oxygen cylinders must be stored 20 feet from flammables

- All compressed gas cylinders must be secured upright

- All compressed gas cylinders must be capped when not in use -

Is the department meeting all oxygen and acetylene storage standards?<br>

-

Which part of the oxygen and acetylene storage does not meet standard?

- Oxygen Stored Near Flammables

- Cylinders Not Secured

- Cylinders Not Capped

- Other

-

Does the department have a torch cart?

-

Torch Cart Standards

- Cart must have a 5ft high fire wall

- All gauges must be working with no broken or missing glass or plastic

- Flash arrestors must be present on the torch

- Appropriate gloves and goggles must be available on the cart -

Does the torch cart meet all applicable standards?<br>

-

Which part of the torch cart does not meet standard?

- Missing Firewall

- Broken Gauges

- Flash Arrestors

- Other

Welder

-

Does the department have a welder?

-

Welder Standards

- Welder must wear welding gloves

- Welder must have appropriate welding helmet

- Welder power cord must be free from all defects, including exposed or taped wiring -

Does the welder meet all applicable standards?

-

Which part of the welder does not meet standard?

- Gloves

- Mask

- Power cord

- Other

Hydraulic Press

-

Does the department have a hydraulic press?

-

Hydraulic Press Standards

- Must have guarding covering work area

- Area around press must meet MHC housekeeping standards

- Must be anchored/secured to prevent walking or tipping -

Does the hydraulic press meet all applicable standards?

-

Which part of the press does not meet standard?

- Gaurding

- Housekeeping

- Anchored/Secured

- Other

Ladders/Work Platforms

-

Is the department free from all homemade or non-approved work platforms? (A frame ladders, homemade boxes, etc)

-

Does the department have a staircase ladder?

-

Is it in good condition with required rubber feet that are free from damage?

-

Do all podium ladders, step ladders, and other work platforms meet the minimum 375lbs rate rating?

-

Are all podium ladders properly secured by hook or chain in a designated area when not in use?

Lifting/Load Bearing Equipment

Jacks/Jack Stands

-

Are jack stands being utilized under all vehicles when the load is supported by a jack?

-

Are all jacks and jack stands free of defects and damage, labeled with the capacity, and equipped with the proper pin?

-

Which part of the jacks and jack stands does not meet standard?

- Defective/Damaged

- Labeled with Capacity

- Proper Pin

Engine Work

-

Does the facility perform out of frame engine work?

-

How many engine stands does the branch have?

-

Engine Work Standards

All out of frame engine work must be done on an MHC approved engine stand or must have 4 points of contact AND an overhead support, meaning it must be on an engine stand or 4 jacks and hoist (or another form of overhead support) -

Does the out of frame engine work meet MHC standards?

-

Does the facility do midsize engine work?

Hoists, Cranes, Chain, Etc.

-

Does the department have a hoist/crane?

-

Hoist/Crane Standards

- Load rating must be displayed on the structure, assembly, and hook

- Crane/hoist must be inspected on an annual basis and inspection date must be clearly labeled on the crane/hoist

- Crane controls must be clearly labeled

- Hook has safety latch if it was designed with one -

Does the crane/hoist meet all applicable standards?<br>

-

Which part of the crane/hoist does not meet standard?

- Weight Rating

- Pendant Controls

- Inspection Out of Date

- Inspection Not Visible on Crane

- Missing/Broken Safety Latch

-

Does the department have a cherry picker?

-

Cherry Picker Standards

- Must be in proper working order/manufacturer’s intended condition

- Must be labeled with weight capacity at each arm setting

- If hook is designed to have safety latch, it must have one

- Must have annual inspection and date of inspection must be labeled on cherry picker -

Does the cherry picker meet all applicable standards?

-

Which part of the cherry picker does not meet standard?

- Condition

- Weight Rating

- Hook Safety Latch

- Annual Inspection

- Annual Inspection Label

- Other

-

Chain Standards

- All lifting chains must be at least grade 8,80,800 or higher

- All chains must be tagged with correct load rating

- All chains must have annual inspection -

Does all chain meet the applicable standards?

-

Which part of the chain does not meet standard?

- Grade

- Not Tagged with Weight Rating

- Inspection Out of Date

- Other

-

Are all vehicles being serviced with lifted dump beds using a secondary locking device? Wood blocks are not approved as a secondary locking device.

Lighting

-

Does the department have adequate lighting?

-

Does the branch have fluorescent bulbs?

-

Is the branch disposing of fluorescent bulbs?

-

Do they have an approved Waste Management recycling box?

-

Is it properly labeled with an accumulation start date that is less than 1 year from today?

-

Are there records showing that a vendor is properly disposing of fluorescent bulbs?

-

Are all light bulbs working (no lights out)?

-

Is the department free of all metal, caged drop lights?

Lock Out/Tag Out

-

-

Lock Out/Tag Out Standard

All vehicles in the shop will have:

- Key on floorboard

- Tag hung from turn signal -

Is the LOTO program in effect and properly administered per the work instruction?

-

Which part(s) of the LOTO Program does not meet standard?

- Key Not on Floorboard

- Tag not Hung from Turn Signal

- Other

Parts Cleaner (Solvent-Based Basin)

-

Is the parts cleaner free of all flammable products?

-

Are parts cleaners being used for their intended purpose and not as a work station?

Parts Washer (Automatic Steamer Cabinet)

-

Does the department have an automatic parts steamer cabinet?

-

Steamer Cabinet Standards

- Must have signage stating "Caution/Hot"

- Power cord must be free from all defects -

Does the parts steamer cabinet meet all applicable standards?

-

Which part of parts steamer cabinet does not meet standard?

- Signage

- Power Cord

Personal Protective Equipment

-

Are safety glasses being worn by employees in the shop at all times?

-

Is the visitor safety glasses bin stocked and safety glasses readily available?

-

Are all visitors, vendors, and other MHC employees wearing safety glasses in the shop?

-

Are steel-toed or composite-toed boots being worn by all employees in the shop at all times?

-

Are all employees handling any tools, parts, or materials wearing cut resistant gloves?

-

Does this department have bump caps?

-

Is hearing protection (ear plugs) available for all employees?

Rotary/Die Grinders

-

MHC Grinding and Cutting Standards

- All rotary/die grinders including personal grinders must be equipped with the proper guards

- The maximum revolutions per minute (rpm) rating of each abrasive wheel must be compatible with the rpm rating of the grinder motor

- The power cord must free of damage including missing ground prong -

Does the department meet all the grinding and cutting standards?

-

Which part of the cutting and grinding standards are not being followed?

- Missing Guard

- Wheel not Rated for Grinder

- Power Cord

- Other

-

Are all employees using cutting wheels or grinders wearing safety glasses AND face shields?

Service Pit

-

Does the department have a service pit?

-

Service Pit Standards

- Must be clean without trash, rags, or spills

- Must have a barrier around or over the the open pit

- Must be well lit with all lights working -

Does the service pit meet all applicable standards?

-

Which part of the service pit does not meet standard?

- Housekeeping

- No Barrier

- Lighting

- Other

Spill Control

-

Does the branch have a Spill Prevention Control Countermeasure (SPCC) Plan developed and available?

-

Is spill containment (Green Stuff, oil dry) material present and readily available?

-

What is the branch using for spill containment?

-

Does the department have a spill kit for larger spills?

Tool Room

-

Is the tool room organized and free of slips, trips, and falls?

-

Does it meet the MHC housekeeping standard?

-

Is it free of homemade tools?

-

Are all tools and equipment free of broken or fractured handles and in good working condition?

-

Are the striking ends of all seal drivers in good condition?

-

Are the power cords of all tools and equipment free from damage, including missing ground prongs?

Wash Bay

-

Does the department have a wash bay?

-

Is the wash bay organized and does it meet MHC housekeeping standards?

-

Do all electrical outlets have the proper weather covers?

-

Is the wash bay free from storage of excess barrels?

-

Is the wash bay free from any barrels containing flammables?

Waste Lubricants

-

Are all oils and lubricants cleaned up and disposed of in the designated area?

-

Are all the spent oil materials (including mats, absorbent, socks) being disposed of properly?

-

Are all used oil, antifreeze, and fuel tanks labeled properly?

-

Per state regulations, is the department disposing of oil filters properly?

Oil Water Separator

-

Does the department have an oil water separator?

-

Is there paperwork showing the separator has been cleaned in the last year?

-

Take a picture of the paperwork.

-

Are all drain grates in place, free from damage, and serving their original purpose?

Vehicles

-

Does this department have a vehicle?

-

Vehicle Inspection

Vehicle

-

Asset Number

-

Take multiple pictures of the vehicle's exterior and interior condition.

-

Vehicle Safety Sticker

-

Does the vehicle have 3 of the stickers above?

-

No Phone Sticker

-

Does the vehicle have 1 of the stickers above on the pillar next to the driver's side door?

-

Max Speed Sticker

-

Does the vehicle have 1 of the stickers on the back bumper?

-

Is this a DOT or non-DOT vehicle?<br>- DOT vehicles have a GVWR over 10,00 lbs (anything bigger than F250)<br>- Non-DOT vehicles have a GVWR of 10,000 lbs and under (F250 and smaller)

-

Does the vehicle have proper daily DVIRs and weekly MHC inspections?

-

Take a picture of the inspections.

-

Does the vehicle have all required paperwork? Includes: <br>- Valid Registration<br>- Valid insurance card<br>- Collision Assistance Kit<br>- Annual DOT inspection (paperwork & legible sticker on vehicle)

-

Which required paperwork is missing?

- Insurance Card

- Valid Registration

- Vehicle Collision Assistance Guide

- Annual DOT Vehicle Inspection

-

Take a picture of the paperwork.

-

Does the vehicle have all required safety items?<br>- Functioning DriveCam<br>- First Aid Kit<br>- Reflective Vest and Hi-Viz Seatbelt Covers <br>- Cargo Securement<br>- Bluetooth<br>- Spill kit<br>- Safety Glasses<br>- Cut Resistant Gloves<br>- Phone Mount <br>- Lock Out Tags<br>- Extra Fuses<br>- Triangles or Flairs<br>- Secured Fire Extinguisher<br>- Wheel Chocks

-

Which safety items are missing?

- DriveCam

- First Aid Kit

- Reflective Vest

- Cargo Securment

- Hazmat Spill Kit

- Safety Glasses

- Cut Resistant Gloves

- Phone Mount

- Secured Fire Extinguisher

- Hi-Viz Seat Belt Covers

-

Does the vehicle’s condition meet MHC standards? Includes: <br>- Must be clean inside/out and present a world-class appearance<br>- Asset number must be displayed - DOT # must be displayed on both sides in 2-inch bold letters<br>- Logos must be in good condition and free from peeling or tears<br>- Mirror and dash must be clear of all obstructions and items<br>- Vehicle must backed in or parked in a pull through manner <br>- Tires must not be damaged & have 1/8th of an inch tread<br>- Vehicle must be free from all damage, including tailgate<br>- Windshield must be free from all damage, including chips/cracks

-

What part of the vehicle’s condition and image does not meet standard?

- Vehicle Cleanliness

- Asset Number

- Logos

- Parked Properly

- Mirror/Dash Not Clean

- Windshield

- Tailgate

- DOT Number

-

Does the vehicle proper weekly inspections?

-

Does the vehicle have all of the required paperwork? Includes: <br>- Valid Registration<br>- Valid Insurance Card<br>- Collision Assistance Kit

-

Which required paperwork is missing?

- Registration

- Insurance Card

- Collision Assistance Kit

-

Does the vehicle have ALL required safety items? Includes: <br>- Functioning DriveCam<br>- First Aid Kit<br>- Hi-Viz Seatbelt Covers <br>- Cargo Securement <br>- Bluetooth<br>- Spill Kit<br>- Safety Glasses<br>- Cut Resistant Gloves<br>- Phone Mount<br>- Lock Out Tag<br>- Secured Fire Extinguisher

-

Which safety items are missing?

- DriveCam

- First Aid Kit

- Reflective Vest

- Cargo Securment

- Hazmat Spill Kit

- Safety Glasses

- Cut Resistant Gloves

- Phone Mount

- Secured Fire Extinguisher

- Hi-Viz Seat Belt Covers

-

Does the vehicle’s condition meet MHC standards? Includes: <br>- Must be clean inside/out and present a world-class appearance<br>- Asset number must be displayed <br>- Logos must be in good condition and free from peeling or tears<br>- Mirror and dash must be clear of all obstructions and items<br>- Vehicle must backed in or parked in a pull through manner <br>- Tires must not be damaged & have 1/8th of an inch tread<br>- Vehicle must be free from all damage, including tailgate<br>- Windshield must be free from all damage, including chips/cracks

-

What part of the vehicle’s condition and image does not meet standard?

- Vehicle Cleanliness

- Asset Number

- Logos

- Parked Properly

- Mirror/Dash Not Clean

- Windshield

- Tailgate

- DOT Number

Parts

Parts

-

Does the branch have a Parts Department?

Parts

General

-

Is the department free from any plastic or non-OSHA approved fuel cans? <br>

-

Are there empty barrels outside?

-

Are they labeled and capped?

-

Are they in an excessive amount?

-

When asked can an employee name the FOS 4 States of Mind?

-

Educate the employee on FOS and the importance behind it.

-

How often is the department holding Safety Huddles?

-

How often is the department holding Crew Meetings?

-

Did this department have a new hire?

-

Was the employee onboarded correctly and was it completed through Safety Culture?

-

Provide employees Name and Number.

Batteries

-

Battery Storage Standards

- No MHC vehicle should transport more than 1000lbs of batteries

- Battery cores must be stored on a containment pallet

- Batteries that do not have a handle must be transported by battery carrier - Eye wash station must be within 75 feet of batteries

- Batteries must be stacked in an orderly fashion and ready for collection (not in a pile or out of order) -

Is the department meeting all battery storage standards?

-

Which part of storing batteries does not meet standard?

- Batteries not stored on containment pallet

- Batteries not being moved by a handle or carrying device

- Eye wash station not within 75 feet

- Not being stacked correctly

- Other

Bullpen

-

Does the department have an outdoor bullpen?

-

Bullpen Standards

- Must be clean, organized, and free from all trash and debris

- Must be properly secured to prevent theft

- Fencing must be free from all damage -

Does bullpen meet all standards?

-

Which part of the bullpen does not meet standard?

- Housekeeping

- Securement

- Fencing

- Other

Chop Saw

-

Does the department have a chop saw?

-

Chop Saw Standards

- Must be in good working condition

- Work area must be clean and orderly with no used parts or waste

- Face shield & leather gloves must be at the station and worn when in use

- Power cord must be free from defects and have a ground prong

- Must be secured/anchored to work area -

Does the chop saw meet all standards?

-

Which part of the chop saw does not meet standard?

- Condition

- Work Station Housekeeping

- PPE Missing

- PPE Not Being Used

- Power Cord

- Unit Not Anchored/Secured

- Other

Egress & Exits

-

Do all lighted exit signs and emergency lighting work when tested?

-

MHC Egress and Exit Standards

- Walkways must be clean

- Exits must not be obstructed from inside or outside

- Doors must unlocked from the inside during business hours -

Do all exits and egress paths meet MHC standard?

-

Which part of the exit or egress does not meet standard?

- Walkways Not Clean

- Exits Obstructed

- Exit Doors Locked

- Other

Electrical

-

Electrical Outlet Standards

- Outlets must be covered and free from holes or openings

- Outlets exposed to weather (outside or moisture) must have weather covers

- Junction boxes must be covered and free from holes or openings -

Is the department meeting all electrical outlet standards?

-

Which part of the electrical outlets do not meet standard?

- Uncovered/Holes

- Weather Covers

- Junction Boxes

- Other

-

Extension Cord Standards

- Must be free from damage, including missing ground prong & repair with electrical tape

- Must be hung up out of the way when not in use

- Must not be used as permanent wiring (zip tied to conduit or run through walls or doors) -

Is the department meeting all extension cord standards?<br>

-

Which part of the extension cords do not meet standard?

- Damaged Cord

- Missing Prong

- Cord zip tied to conduit

- Runs Through Wall or Door

- Other

-

Electrical Panel Standards

- Panels must be labeled with Danger, High Voltage and Keep Out signage

- All breakers must be properly labeled

- All breaker boxes must be free of open void or holes greater than 1/8th inch

- All breakers must be in proper working condition without tape

- All electrical panels must have clear access and cannot be obstructed -

Is the department meeting all electrical panel standards?

-

Which part of the electrical panel does not meet standard?

- High Voltage Warning Signs

- Breaker Labels

- Open Voids or Holes

- Other

- Panels Obstructed

Eye Wash Station/Bottles

-

Does this department have an eye wash station or bottles?

-

What type?

- Plumbed Eye Wash Station

- Gravity Fed Eye Wash Station

- Eye Wash Bottles

-

-

Plumbed Eye Wash Station Standards

- Caps must be in place.

- Basin must be clean and not broken.

- Station must be clear from all obstructions. -

Is the plumbed eye wash station meeting all standards?

-

Which part(s) of the plumbed eye was station does not meet standard?

- Caps not in Place

- Basin not Clean/Is Broken

- Station is Obstructed

- Other

-

-

Gravity Fed Eye Wash Station Standards