Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

Have you linked existing Asset

General Inspection Guidelines

-

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer’s Instructions for Use: download the instructions at PETZL.COM.

Harness Inspection

Known product history

-

Is there known history of usage conditions or exceptional event/s during use (e.g., fall or fall arrest, use or storage at extreme temperatures, contamination or modification outside manufacturer's facilities..etc)

-

Refer to the attached Harness Inspection Procedure and examples before commencing physical inspection. Refer back to this document to assist with rulings regarding particular elements/components of the harness.

1. Preliminary observations

-

Possible answer types:

Good condition (GC) = Harness is fit for continued use.

To monitor (TM) = Scheduled inspection frequency/interval must be increased/shortened.

To repair (TR) = Harness to be submitted to an approved repair agent to assessment for repairability.

Do not use/retire (R) = Harness is not fit for use it must be removed from service, destroyed & disposed of responsibly.

Not applicable (NA) = Specific question is not relevant. -

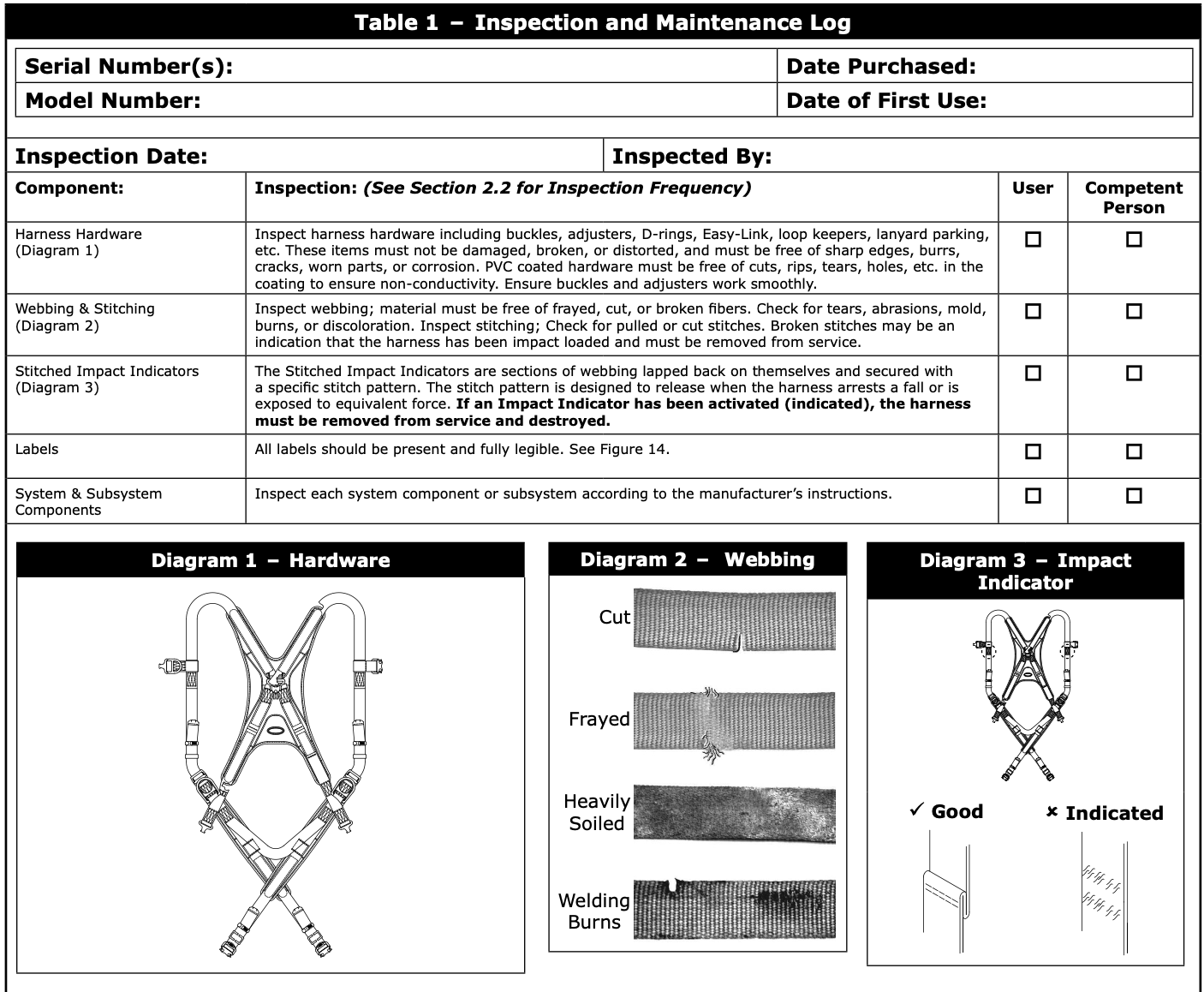

Verify the presence and legibility of the serial number

-

-

Verify that the product lifetime has not been exceeded (10 years from date of manufacture)

-

Compare with a new product to verify there are no modifications or missing parts.

2. Checking the condition of the straps (webbing)

-

-

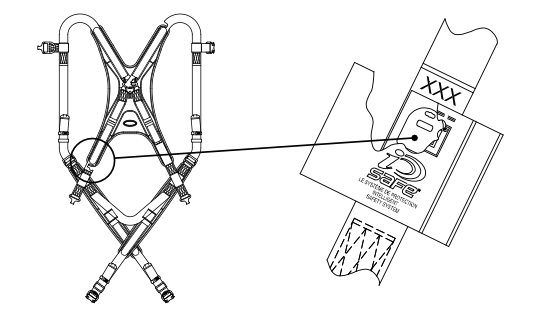

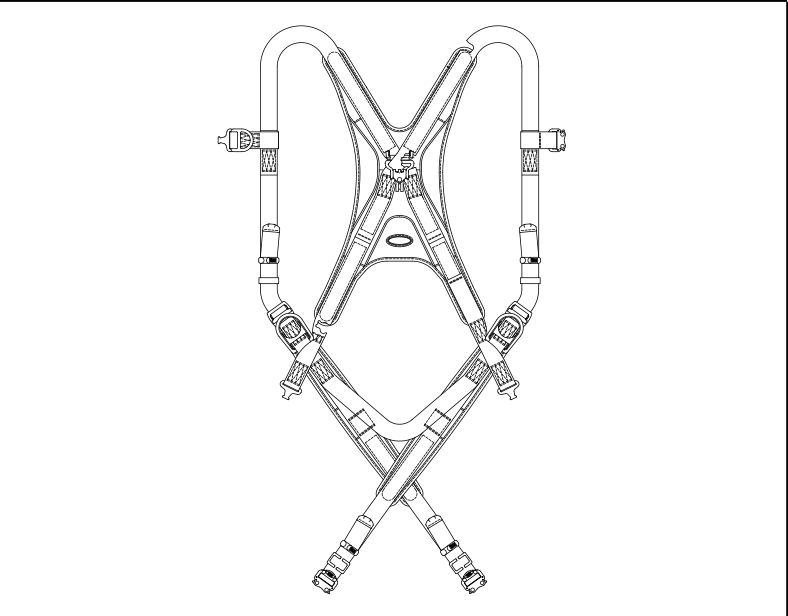

Check for cuts, swelling, damage and wear due to use, to heat, and to contact with chemicals. Check the waistbelt straps, leg loops, leg loop/waistbelt linkage and shoulder straps, if present. Be sure to check the areas hidden by the buckles.

-

Check the condition of the safety stitching on both sides. Look for any threads that are loose, worn, or cut. The safety stitching is identified by thread of a different colour than that of the webbing.

-

Verify that hems are present on the strap ends.

3. Checking attachment points

-

Check the condition of the metal attachment points (marks, cracks, wear, deformation, corrosion...).

-

Check the condition of the textile attachment points (cuts, wear, tears...).

-

Check the condition of the plastic attachment points (cuts, wear, tears...).

-

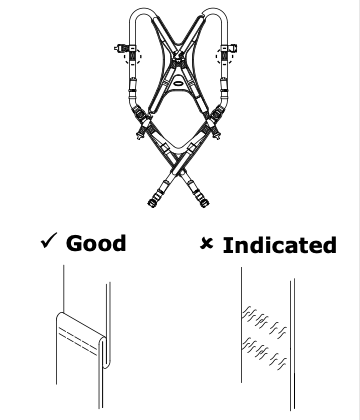

Ensure the impact indicator is not visible.

-

4. Checking the condition of the adjustment buckles

-

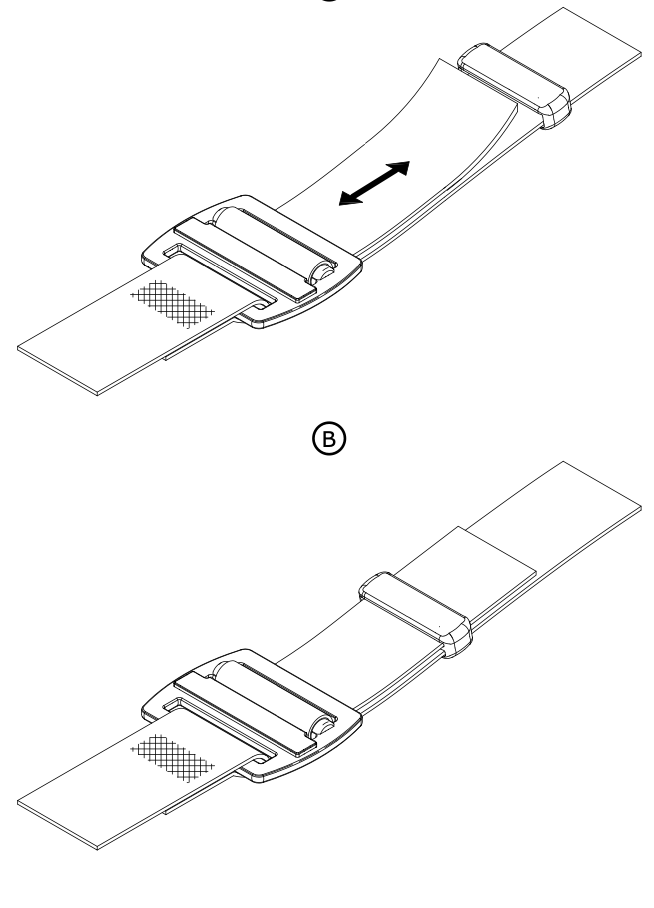

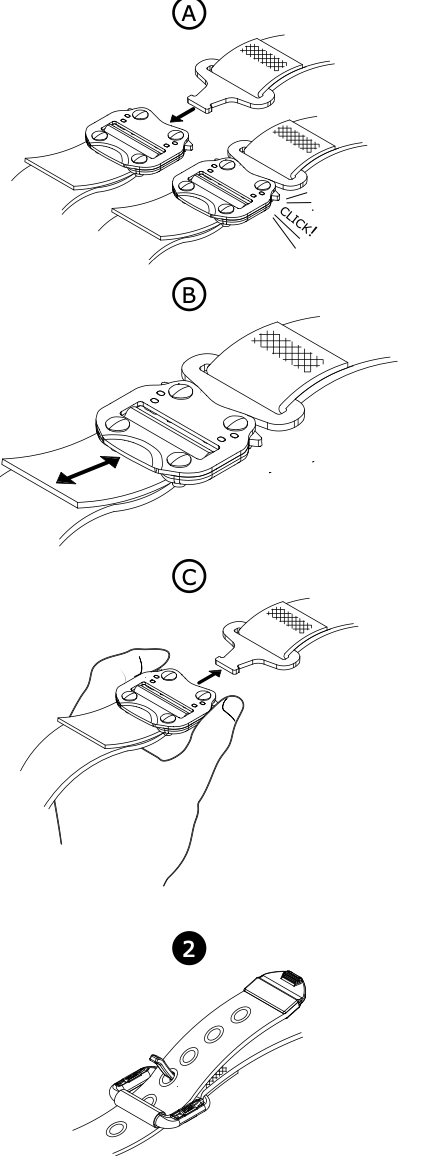

Check the condition of the DOUBLEBACK adjustment buckles (marks, cracks, wear, deformation, corrosion...).

-

-

Check the condition of the FAST adjustment buckles (marks, cracks, wear, deformation, corrosion...).

-

-

Check that the straps are correctly threaded, with no twists.

-

Verify that the buckles operate properly.

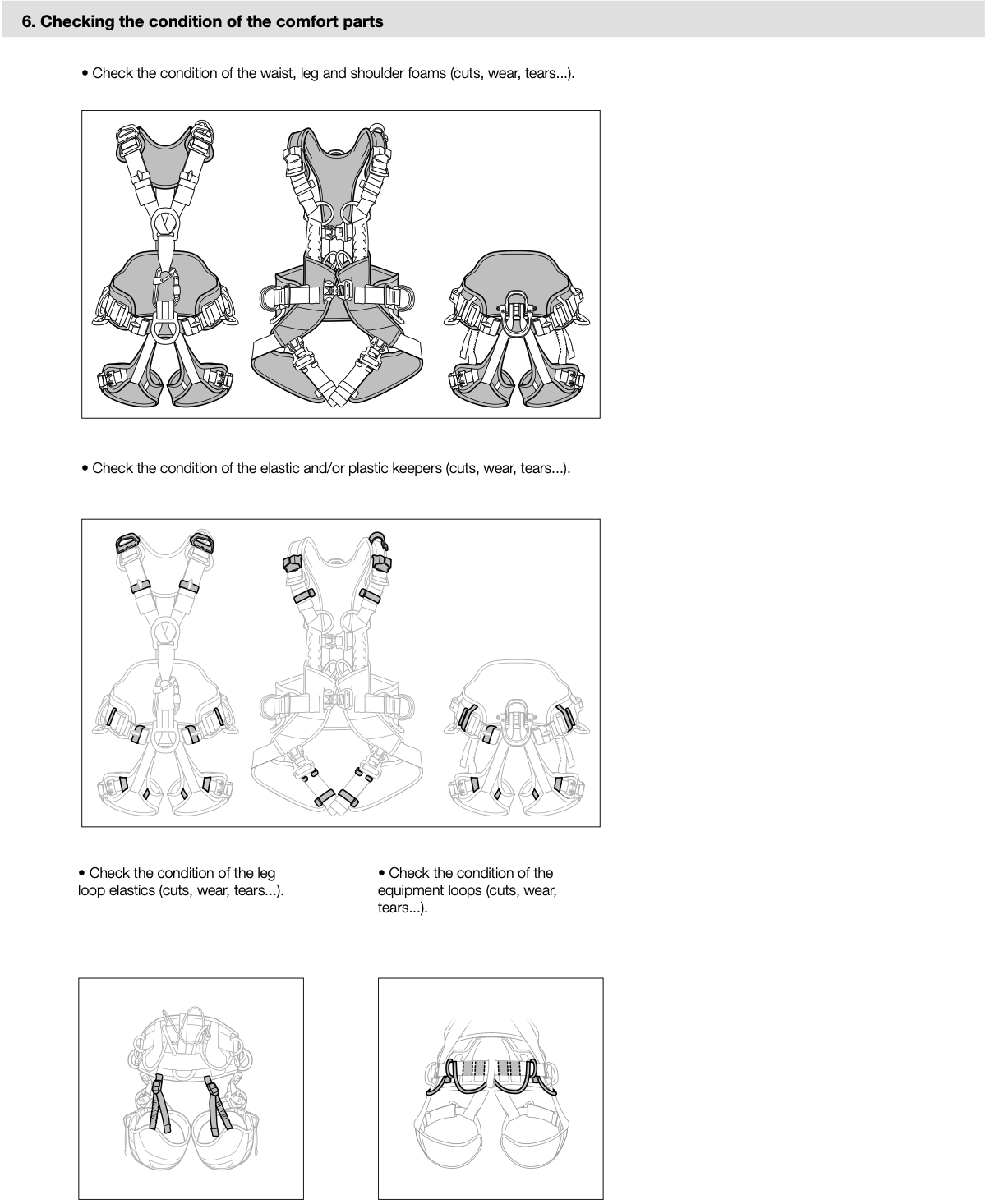

5. Checking the condition of the comfort parts

-

-

Check the condition of the waist, leg and shoulder foams (cuts, wear, tears...)..

-

Check the condition of the elastic and/or plastic keepers (cuts, wear, tears...).

-

Check the condition of the leg loop elastics (cuts, wear, tears...).

-

Check the condition of the equipment loops (cuts, wear, tears...).