Title Page

-

Conducted on

-

Prepared by

-

Location

Have you linked existing Asset

General Inspection Guidelines

-

• In addition to routine checks for each use, PPE should regularly undergo a detailed inspection by a competent person. Petzl recommends an inspection every 12 months and after any exceptional event in the life of the product.

• PPE inspection should be conducted with the manufacturer’s Instructions for Use: download the instructions at PETZL.COM.

I'D S Inspection

1. Known product history

-

Is there known history of usage conditions or exceptional event/s during use (e.g., fall or fall arrest, use or storage at extreme temperatures, contamination or modification outside manufacturer's facilities..etc)

-

Refer to the attached I'D S Inspection Procedure and examples before commencing physical inspection. Refer back to this document to assist with rulings regarding particular elements/components of the device.

2. Preliminary observations

-

Possible answer types:

Good condition (GC) = Devcie is fit for continued use.

To monitor (TM) = Scheduled inspection frequency/interval must be increased/shortened.

To repair (TR) = Device to be submitted to an approved repair agent to assessment for repairability.

Do not use/retire (R) = Device is not fit for use it must be removed from service, destroyed & disposed of responsibly.

Not applicable (NA) = Specific question is not relevant. -

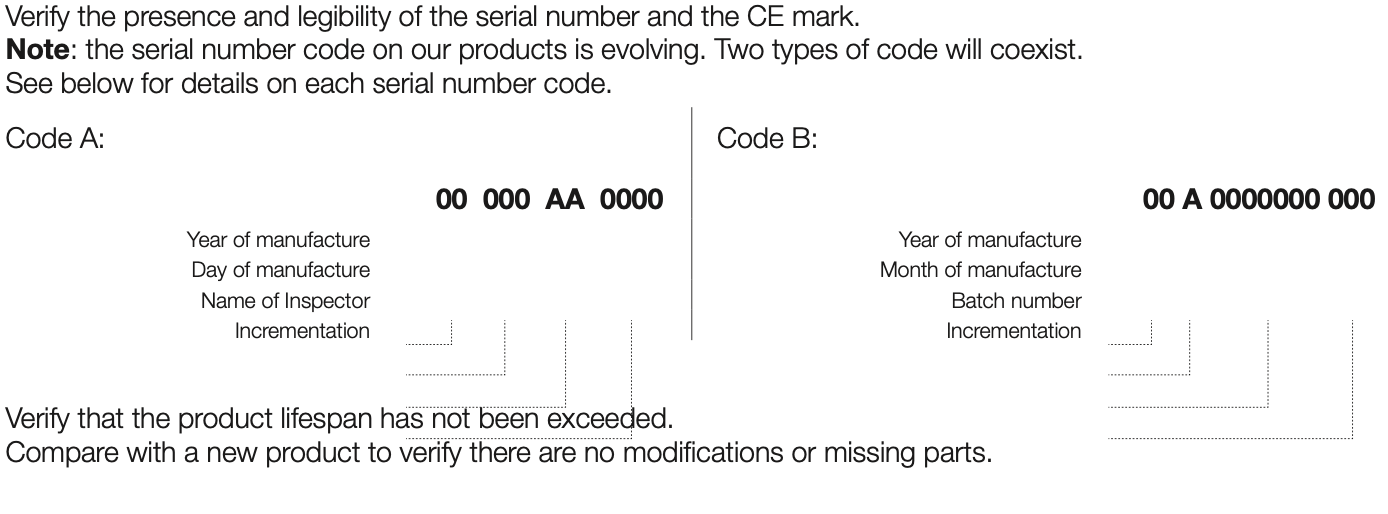

Verify the presence and legibility of the serial number

-

Refer to Serial Number interpretation guide.

-

Verify that the product lifetime has not been exceeded (10 years from date of manufacture) - This does not apply to the Plastic components of the I'D S device

-

Compare with a new product to verify there are no modifications or missing parts.

-

Refer to picture, ONLY if a physical harness is not immediately available. (Always preference checking against a physical example of a new, matching harness).

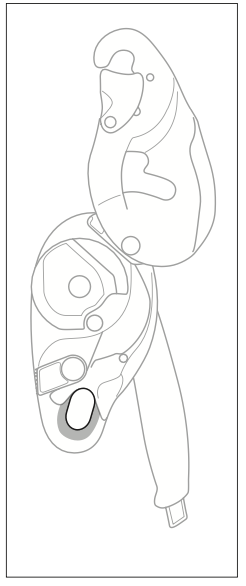

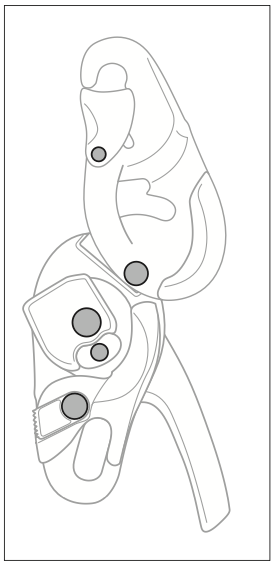

3. Checking the moving side plate

-

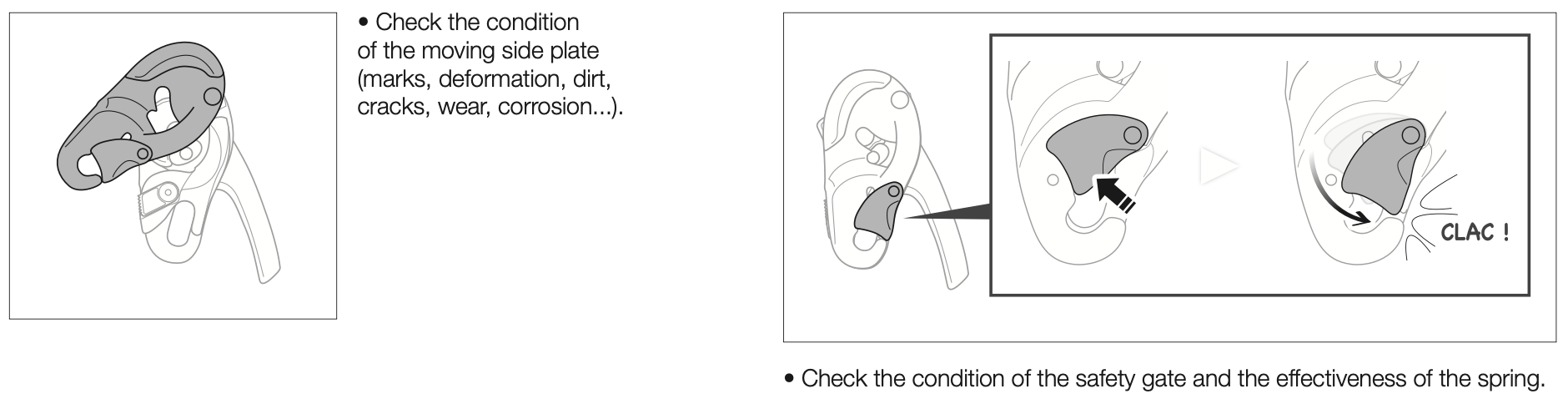

Check the condition of the moving side plate (marks, deformation, dirt, cracks, wear...).

-

Check the condition of the safety gate and the effectiveness of the spring.

-

-

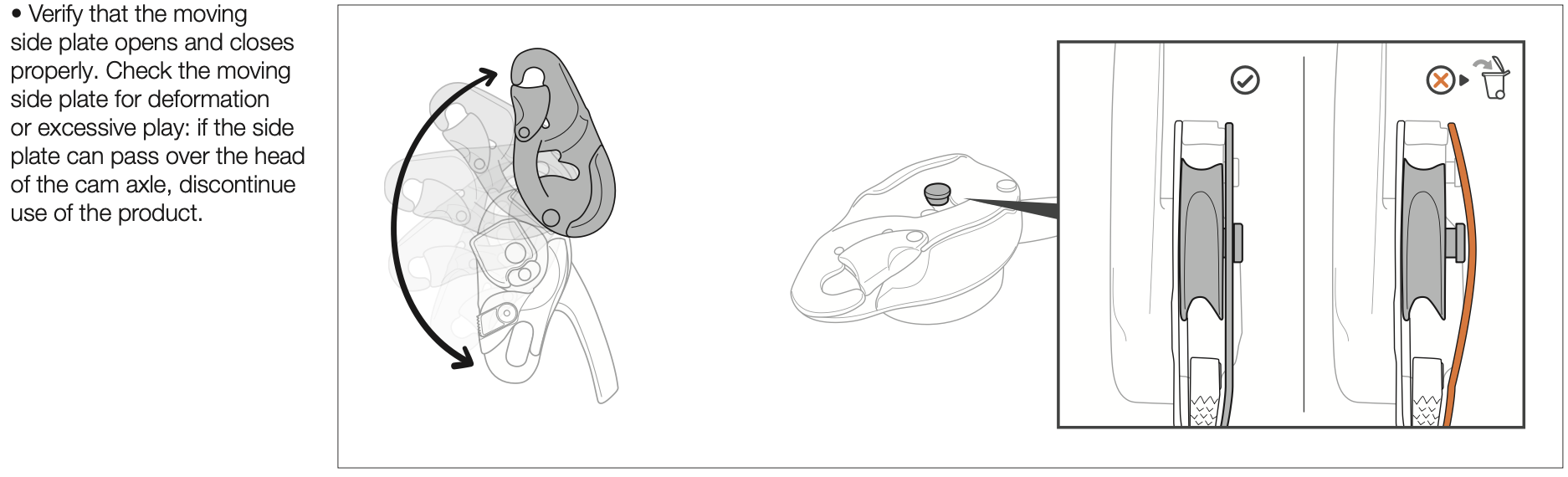

Verify that the moving side plate opens and closes properly. Check the moving side plate for deformation or excessive play: if the side plate can pass over the head of the cam axle, discontinue use of the product.

-

-

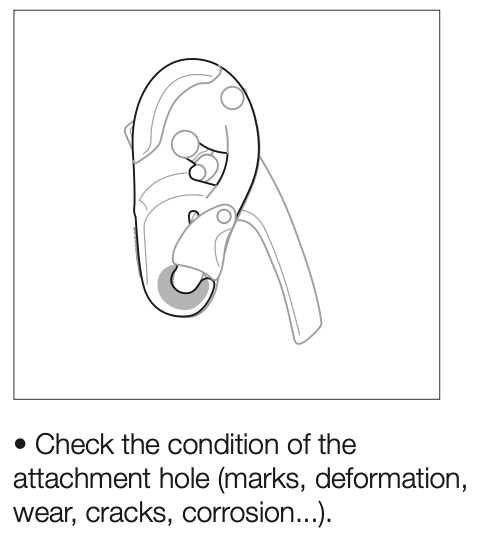

Check the condition of the attachment hole (marks, deformation, cracks, corrosion...).

-

-

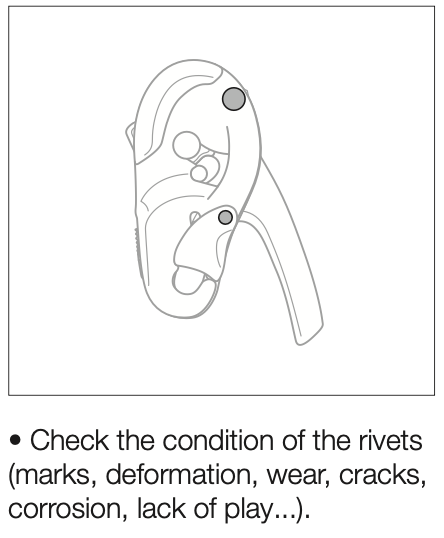

Check the condition of the rivets (marks, deformation, cracks, corrosion, absence of play...).

-

4. Inspecting the Cam

-

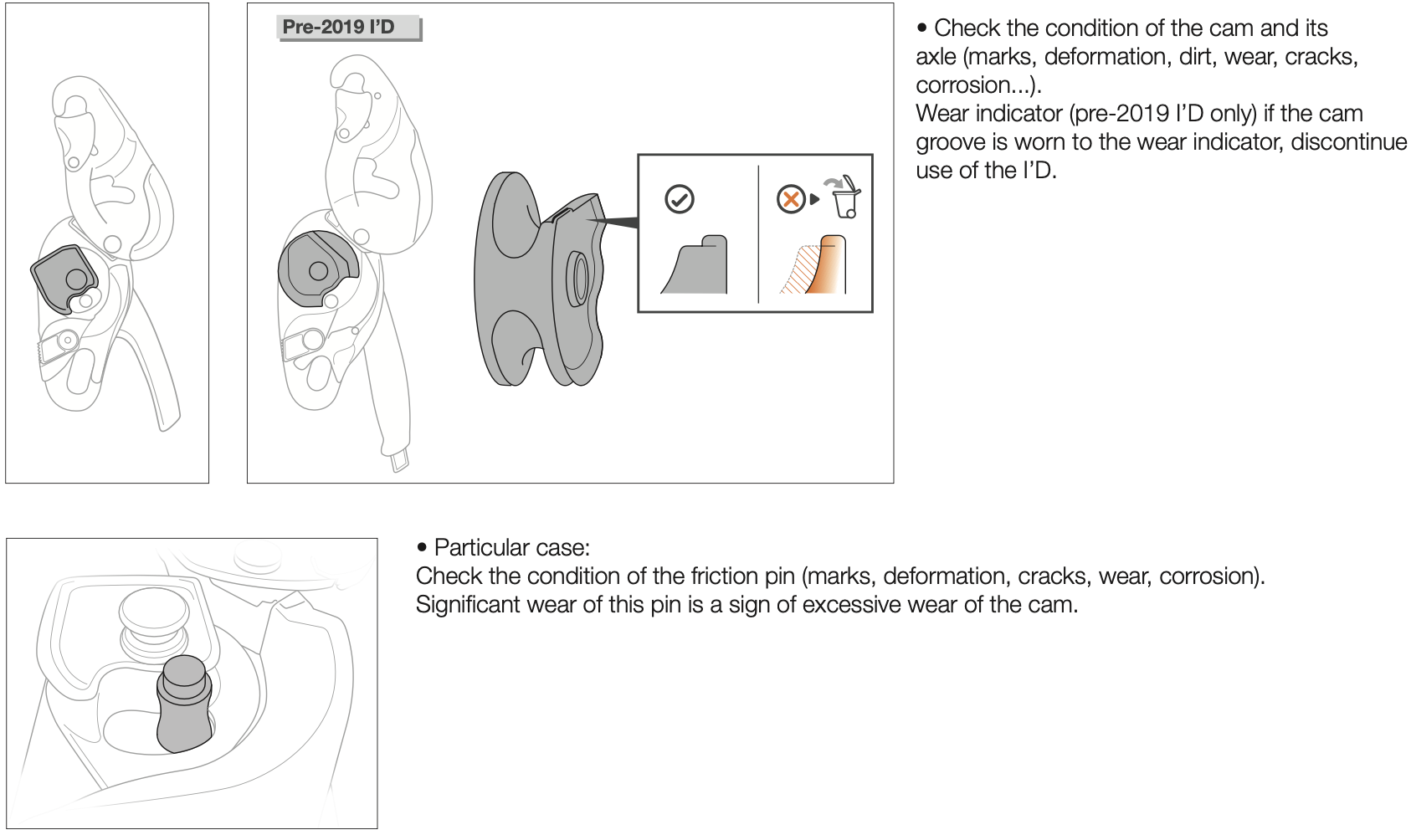

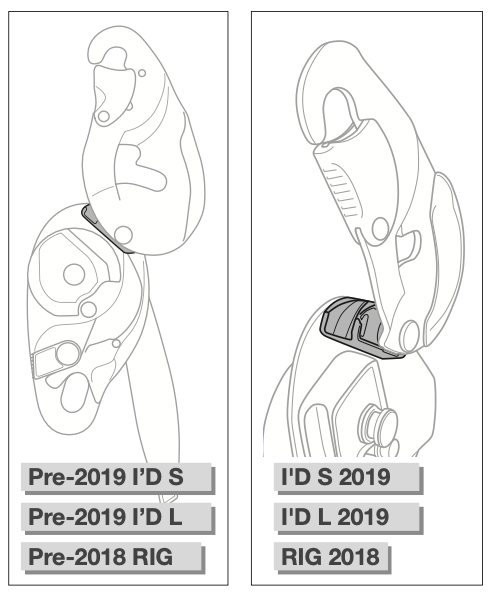

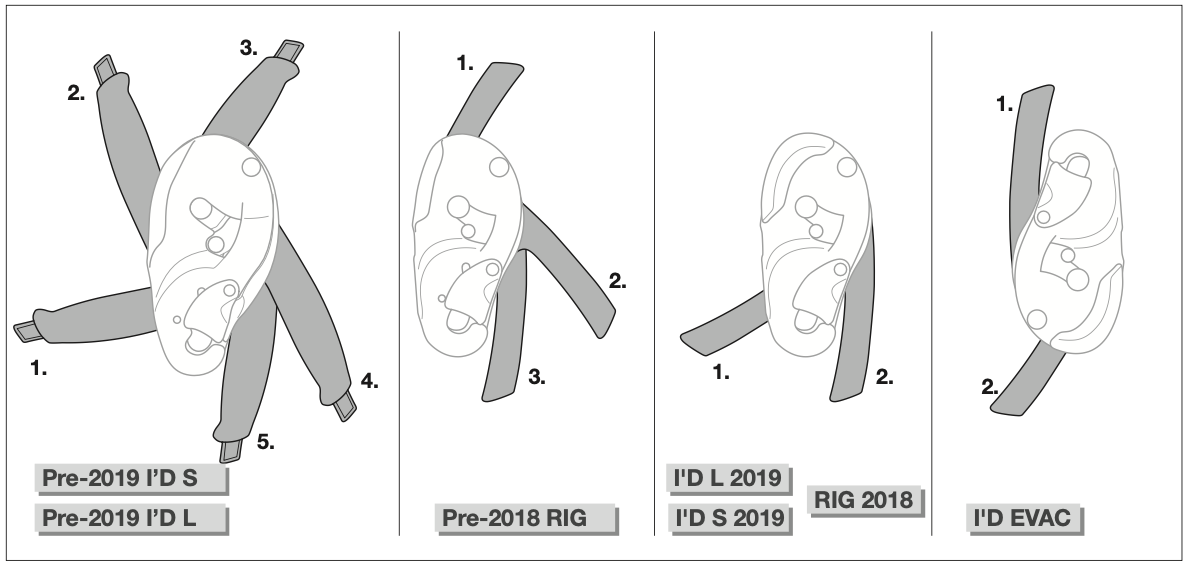

Check the condition of the cam and its axle (marks, deformation, dirt, cracks, corrosion...). Wear indicator (pre-2019 I’D only) if the cam groove is worn to the wear indicator, discontinue use of the I’D.

-

-

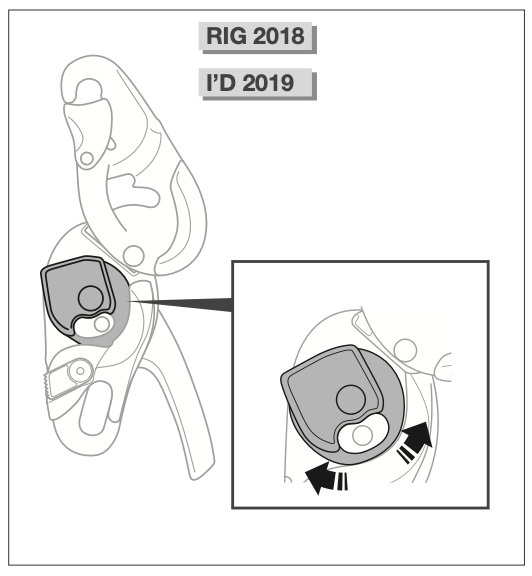

Check the cam’s rotation - Post 2019 I'D S

-

Post-2019 I'D S

-

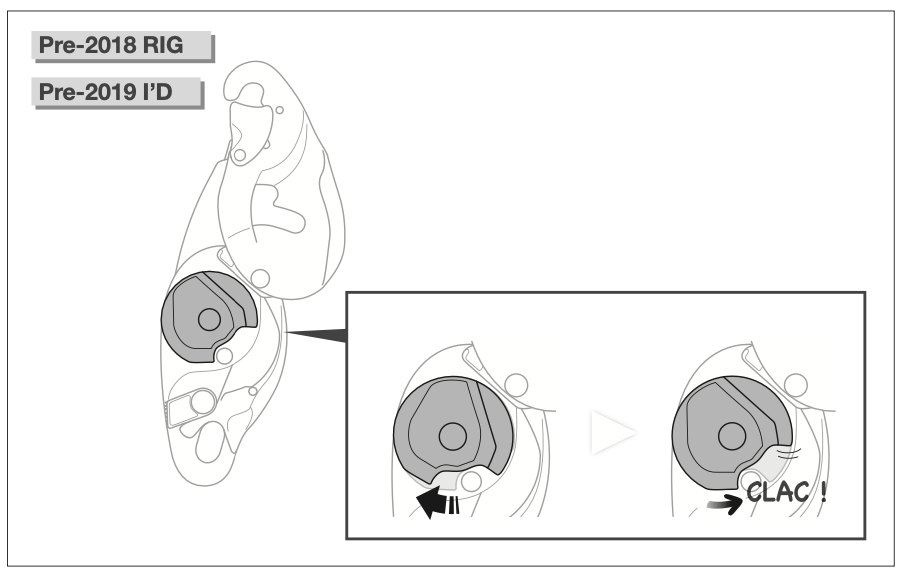

Check the cam's rotation - Pre 2019 I'D S check the effectiveness of the cam return spring.

-

Pre-2019 I'D S

-

Check the condition of the friction plate (marks, deformation, dirt, cracks...).

-

-

Check the condition of the attachment hole (marks, deformation, cracks, corrosion...).

-

-

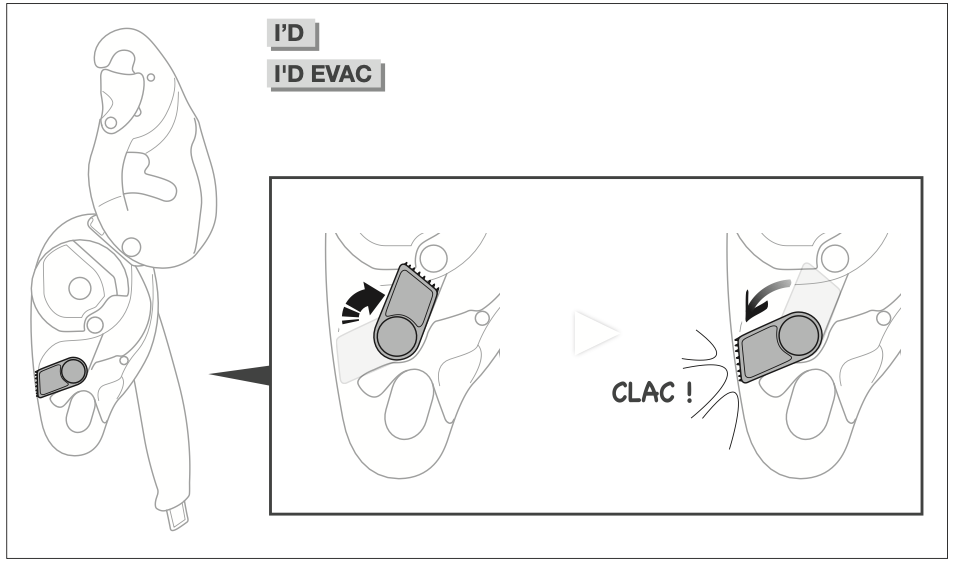

Check the condition of the anti-error catch (marks, deformation, cracks, corrosion...). Check that all teeth are present and check their state of wear. The teeth must not be dirty. If necessary, clean them with a brush.

-

Check the rotation of the anti-error catch and the effectiveness of the return spring.

-

-

Check the condition of the rivets (marks, deformation, cracks, corrosion, absence of play...)

-

5. Checking the condition of the handle

-

Check the condition of the handle (marks, deformation, cracks...).

-

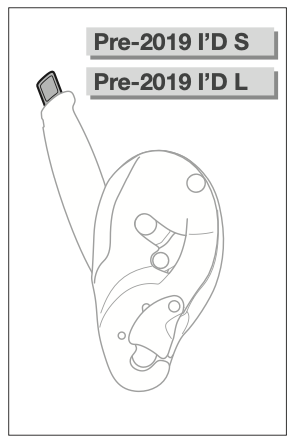

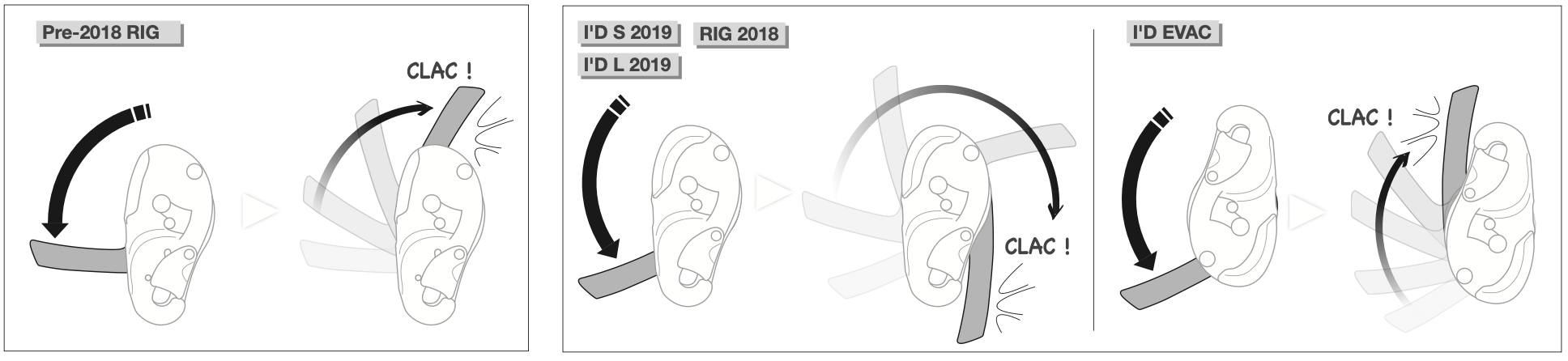

On pre-2019 I’D and pre-2018 RIG, verify that all handle positions are accessible and well defined.

-

-

On the pre-2019 I’D, verify that the horizontal movement button is working properly.

-

-

Check that the handle return spring is working properly.

-

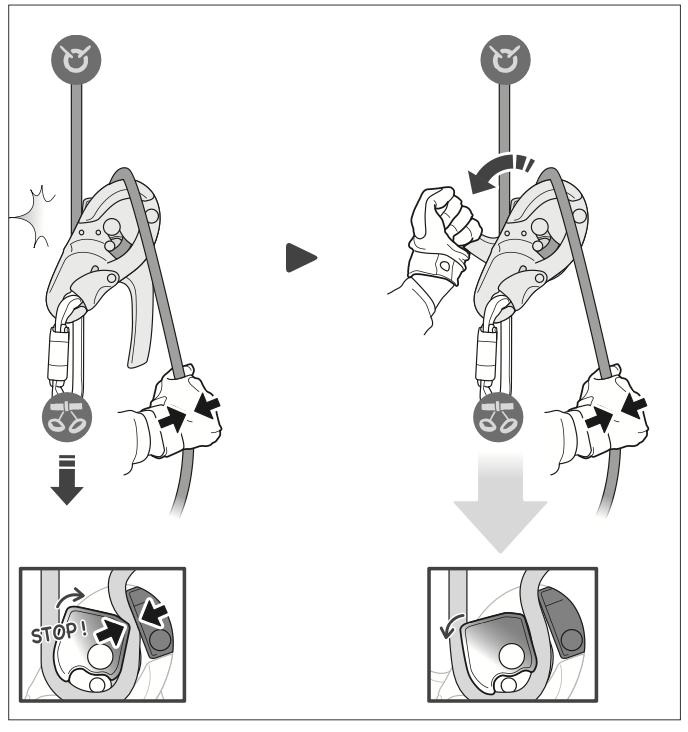

6. Function check

-

Do a function test with the various recommended rope diameters.

-

Suspend yourself at a very low height. The device must lock the rope.

-

Operate the handle to do a very short descent.

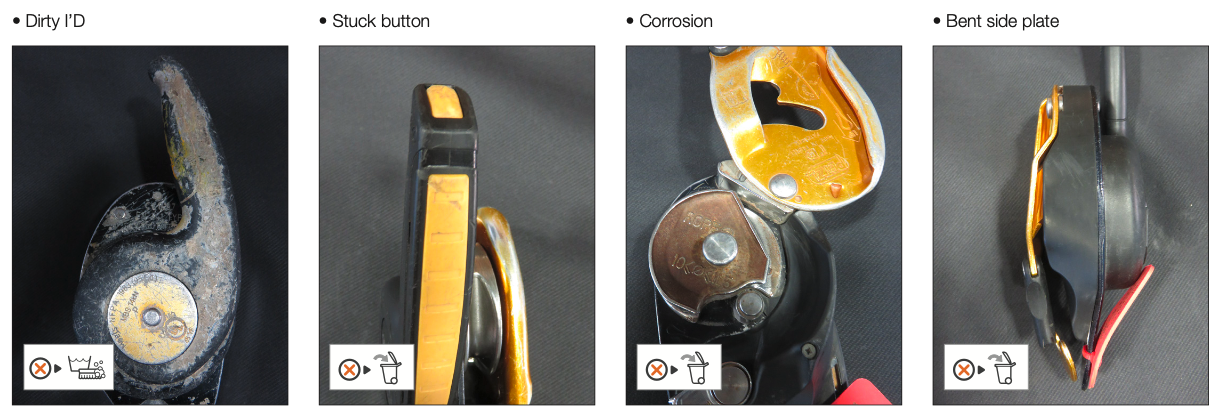

Examples of I'D S wear and tear resulting in device haviung to be Retired

Approval

-

Date and time of approval

-

Approver's signature