Title Page

-

Audit Title

-

Which site is audited?

-

Which customer is audited?

- Sony

- Module D (Otterbox, ASUS, Dolby..)

- Sonova

- Cardinal health

- Harman

- Rituals

-

Which department is audited?

- All departments

- Inbound

- Assembly / Production

- Pick / Pack / Ship

- Replenishment

- Returns

- Outbound

- Quality

-

What zone is audited?

- Zone A

- Zone B

- Zone C

- Zone D

- Zone E

- Zone F

- Zone W

- All Zones

-

What zone is audited?

-

What zone is audited?

- Zone 1

- Zone 2

- Zone 3

- Zone 4

- Zone 5

- Zone 6

- Zone 7

- Zone 8

- Zone 9

- Zone 10

- All zones

-

What zone is audited?

- Zone 1

- Zone 2

- Zone 3

- Zone 4

- Zone 5

- Zone 6

- Zone 7

- Zone 8

- Zone 9

- Zone 10

- All zones

-

Which customer is audited?

-

Which department is audited?

- All departments

- Inbound

- Assembly / Production

- Pick / Pack / Ship

- Replenishment

- Returns

- Outbound

- Quality

-

Which department is audited?

- Boxing

- Inbound / Outbound

- NLA3, NLA4, RMA

-

Which customer is audited?

-

Which department is audited?

- All departments

- Inbound

- Assembly / Production

- Pick / Pack / Ship

- Replenishment

- Returns

- Outbound

- Quality

-

Date of audit.

-

Auditor

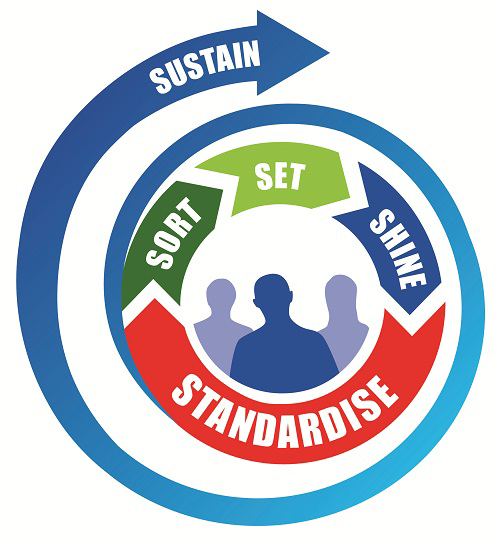

SUSTAIN

-

5S tasks are shown on 5S board and in use.

-

5S tasks are achievable.

-

5S tasks have an owner and due date.<br>

-

Action log is shown on the 5S board<br>

-

Actions that follow up the last 5S audit are shown, have an owner and due date.<br>

-

Actions marked as “Done” are not failed this audit.<br>

-

Success stories are celebrated and being displayed (i.e. before and after pictures).

STANDARDISE

-

All visual color coding is visually at the department (cone colors, line colors and work clothes colors).

-

Zones are defined on the lay-out.

-

Employees (ass. Supervisor, Supervisor and zone leaders) are trained in 5S.

-

All employees wear the handed out Arvato working clothes or vests.

SORT

-

If not in use, all MHE used during the operation process are parked on designated places.

-

Only equipment needed to fulfill the job is present and stored correctly. (cleaning material not included)

-

There is only equipment present which is used daily/weekly. <br><br>

-

Why not?

-

Please take a picture from the unused equipment.

-

Please place the equipment in a red tag area or attach a red tag to the equipment.

-

All consumables have a defined minimum and maximum quantity.

-

All consumables have the minimum and maximum required quantity.

-

Waste disposal bins / containers are indicated and if not used on designated place

-

Places for empty pallets are indicated and there are no empty pallets on other places

STRAIGHTEN

-

Personal belongings are properly stored.

-

Make a picture

-

All equipment and tools have a designated place, which is marked (e.g. consumables, tape roller, etc.)

-

After using equipment/tools they are put back on designated place.

-

If not in use cleaning materials are present and are placed on a shadow board / designated place

-

Floor markings are in good condition. (Markings not broken more than 50%)

-

Walking path and red marked areas are free.

-

Why not and make a picture

-

Work area is free of obstacles.

SHINE

-

Waste separation is done correctly (until 3 incorrect bins).

-

Confidential information (personal/customer) around the work area is stored/disposed correctly.

-

The area ‘looks clean’ (until 3 unclean examples).

-

The racking protection is clean

-

The MHE and Tools are clean.

-

Additional comments:

-

Additional photos: