Title Page

-

Site Conducted

-

Conducted on

-

Prepared by (Name + Last Name)

-

Location

To answer (YES, NO, N/A) in ZONE 2...

-

Every area must be checked daily and its cleaning requirement assessed

-

Ensure all foreign material is delivered to Quality Laboratory

-

All hoses rolled up?

-

Work station wiped down & tools accounted for and stored away?

-

Are cutter heads assembled and stored?

-

All cleaning equipment hanging up & Shadow Boards complete? (note down missing equipment below)

-

Please note the missing equipment

-

OTHER COMMENTS

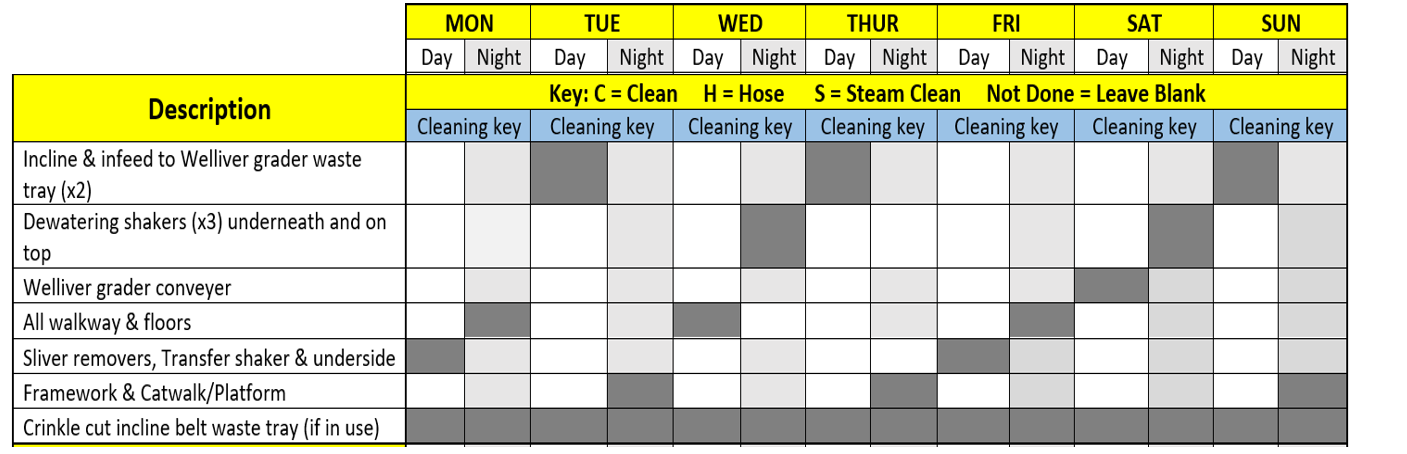

To answer based on the Cleaning Key...

-

Team leaders to inspect areas marked 'clean', Operators to note a comment reason area is 'not done'. Anything which is not up to standard, is to be reported to the Team Leader or Shift Manager at handover. Comments can be add at the bottom of this page.

-

A steam clean of each area MUST be completed at least once a week (shaded section) or as required

-

CLEANING KEY: C = Clean ; H = Hose ; S = Steam ; Clean Not Done = ND

-

Incline & infeed to Welliver grader waste tray (x2)

-

Why are these parts still not clean?

-

Dewatering shakers (x3) underneath and on top

-

Why are these parts not clean yet?

-

Welliver grader conveyor

-

Why is this grader conveyor still not clean?

-

All walkway & floors

-

Why are these spaces not clean yet?

-

Sliver removers, Transfer shaker & Underside

-

Why are these parts still not clean?

-

Framework & Catwalk/Platform

-

Why are these parts not clean yet?

-

Crinkle cut incline belt waste tray (if in use)

-

Why is this tray still not clean?

-

COMMENTS