Title Page

-

Site Conducted

-

Conducted on

-

Prepared by (Name + Last Name)

-

Location

To answer (YES, NO, N/A) in ZONE 4...

-

Every area must be checked daily and its cleaning requirement assessed

-

Dextrose Filter cleaned x2 per shift & check tubes for signs of mold

-

Check clips/clasps along the catch boxes at the fryer

-

Check & Clean crumb build up at SWECO oil miser reclaim tank, auger and gem belt

-

Dextrose made up & a bag in dosing bin?

-

All cleaning equipment hanging up & Shadow Boards complete? (note down missing equipment below)

-

Please note the missing equipment

-

OTHER COMMENTS

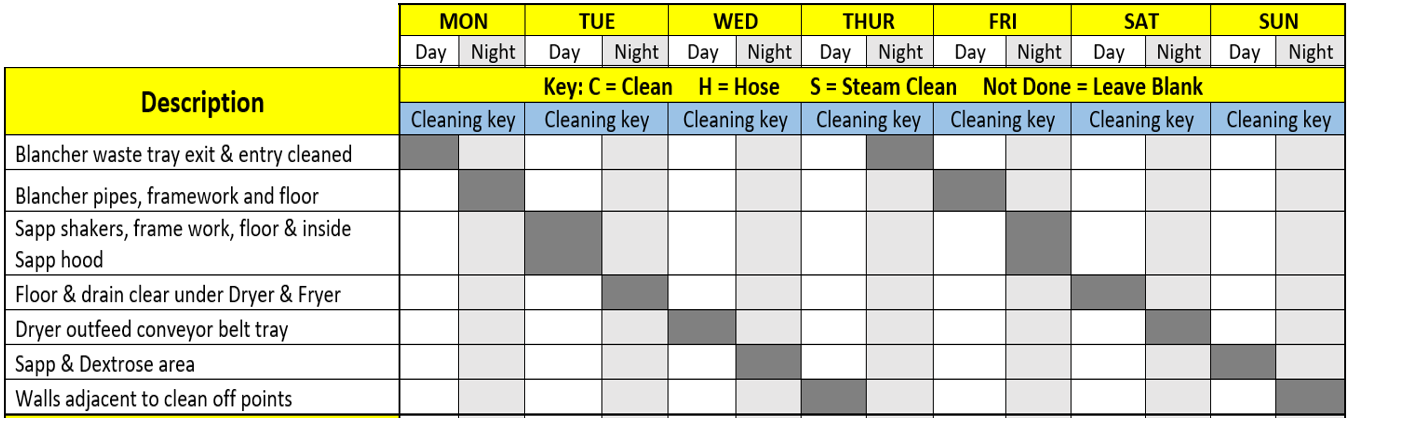

To answer based on the Cleaning Key...

-

Team leaders to inspect areas marked 'clean', Operators to note a comment reason area is 'not done'. Anything which is not up to standard, is to be reported to the Team Leader or Shift Manager at handover. Comments can be add at the bottom of this page.

-

A steam clean of each area MUST be completed at least once a week (shaded section) or as required

-

CLEANING KEY: C = Clean ; H = Hose ; S = Steam ; Clean Not Done = ND

-

Blancher waste tray exit & entry cleaned

-

Why are these parts still not clean?

-

Blancher pipes, framework and floor

-

Why are these parts not clean yet?

-

Sapp shakers, frame work, floor & inside Sapp hood

-

Why are these parts still not clean?

-

Floor & drain clear under Dryer & Fryer

-

Why are these spaces not clean yet?

-

Dryer outfeed conveyor belt tray

-

Why is this tray still not clean?

-

Sapp & Dextrose area

-

Why are these areas not clean yet?

-

Walls adjacent to clean off points

-

Why are these walls still not clean?

-

COMMENTS