Title Page

-

Conducted on

-

Prepared by

-

Location

Aisle 1

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Emergency exits clear of obstruction?

-

ACM wall in good condition?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Baler pre-start checklist completed & PPE stocked?

Aisle 2

-

Lighting adequate?

-

Cleaning station stocked?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 3

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 4

-

Lighting adequate?

-

Cleaning station stocked?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 5

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Emergency exits clear of obstruction?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 6

-

Lighting adequate?

-

Cleaning station stocked?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 7

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Aisle 8

-

Lighting adequate?

-

Cleaning station stocked?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

-

Pallet stack - secured / within the height limit?

Aisle 9

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

-

Pallet stack - secured / within the height limit?

Aisle 10

-

Lighting adequate?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Battery locations - no excess combustibles, contacts secured?

-

Pallet stack - secured / within the height limit?

Aisle 11

-

Lighting adequate?

-

Cleaning station stocked?

-

Aisle & floors clean, pallets in line, no protruding carton flaps?

-

Emergency exits clear of obstruction?

-

Pallets & loads thoroughly secured - no excess wrap / banding?

-

Broken pallets in use?

-

Battery locations - no excess combustibles, contacts secured?

Goods In Office

-

Any trip hazards from office equipment?

-

Floors clean, dry and free of obstructions & trip / slip hazards?

-

Tier 1 board up to date - review Cell Level Risk Assessment?

Admin Office

-

Any trip hazards from office equipment?

-

Floors clean, dry and free of obstructions & trip / slip hazards?

-

Tier 1 board up to date - review Cell Level Risk Assessment?

Canteen

-

Walkways & floors clean, dry and free of obstructions & trip / slip hazards?<br>(check for personal belongings, waste bins overflowing)

-

Walkways & floors clean, dry and free of obstructions & trip / slip hazards?<br>(check for personal belongings, waste bins overflowing)

-

Emergency exits clear of obstruction?

-

Fridges and drink machines clean?

Employee Behaviours

Powered Device Operator Behavioural Observations Checks

-

Powered device pre-start checklist completed?

-

Device operator looking in the direction of travel?

-

Device operator using horn / warning devices where required?

-

Device operator wearing a seat belt?

-

Device operator traveling at a speed suitable depending on amount of traffic, etc?

-

Device operator adhering to “only Room for One” policy?

-

Device operator vision impaired - clear view over the load?

Employee Behaviour Observation Checks

-

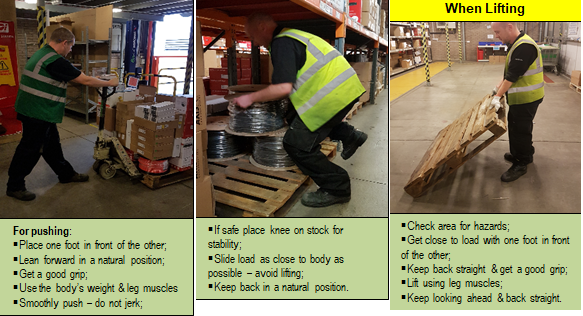

Manual Handling Observations

-

Evidence of heft test / is the employee aware of load contents?

-

Is the employee adhering to a Good Posture / Loads suitable for manual handling?

-

Is the employee over-stretching / twisting?

-

Is the employee holding the load close to trunk?

-

Is the employee wearing hi-visibility clothing, safety shoes (check condition)?

-

Is the employee adhering to Cardinal Rules?

-

Ceramic safety knives used, good working order?

-

Is the employee wearing hand protection when handing pallets?

-

Discuss unsafe observation programme with employee.

-

Discuss evacuation procedure with employee.

-

Discuss accident reporting with employee.

-

Recognition - details below:

-

Any recognition: