Information

-

Quality Control Inspector

-

Title

-

CONDUCTED FOR

-

Customer

- Malaysia Airlines (MH)

- Emirates (EK)

- British Airways (BA)

- KLM Royal Dutch Airlines (KL)

- Air Astana (KC)

- Air China (CA)

- Air Mauritius (MK)

- Biman Bangladesh Airlines (BG)

- China Airlines (CI)

- Shanghai Airlines (FM)

- China Southern Airlines (CZ)

- Etihad Airways (EY)

- EVA Air (BR)

- Flynas (XY)

- Garuda Indonesia (GA)

- Iraqi Airways (IA)

- Japan Airlines (JL)

- Korean Air (KE)

- Lucky Air (8L)

- Myanmar Airways International (8M)

- Nepal Airlines

- Oman Air (WY)

- Regent Airways (RX)

- Royal Brunei Airlines (BI)

- Royal Jordanian (RJ)

- Shenzhen Airlines (ZH)

- SriLankan Airlines (UL)

- US-Bangla Airlines (BS)

- Uzbekistan Airways (HY)

- VietJet Air (VJ)

- Vietnam Airlines (VN)

- XiamenAir (MF)

-

Flight Number

-

Aircraft Registration Number

-

Conducted on

-

Location

-

Vendor

-

Shift Leader

-

Prepared by

1.0 Flight Information / Data

1.0 FLIGHT INFORMATION / DATA

-

Instructions: Audit to be completed by QUALITY CONTROL INSPECTOR. This audit officially signs off the TRANSIT, Pre-Departure Check (PDC), or NIGHT STOP cleaning. Please fill out completely.

-

1.1 Type of Audit:

- Compliance Regulation Audit

- Process Based Audit

- Contractor Audit

- SOP Audit

- Ad-Hoc Audit

- Internal Audit

- On site Audit

- Stock Take Audit

- Corrective And Preventive Action (CAPA) / Observation Audit

- Others

-

Please specify:

-

1.2 Airline:

- Malaysia Airlines (MH)

- Emirates (EK)

- British Airways (BA)

- KLM Royal Dutch Airlines (KL)

- Air Astana (KC)

- Air China (CA)

- Air Mauritius (MK)

- Biman Bangladesh Airlines (BG)

- China Airlines (CI)

- Shanghai Airlines (FM)

- China Southern Airlines (CZ)

- Etihad Airways (EY)

- EVA Air (BR)

- Flynas (XY)

- Garuda Indonesia (GA)

- Iraqi Airways (IA)

- Japan Airlines (JL)

- Korean Air (KE)

- Lucky Air (8L)

- Myanmar Airways International (8M)

- Nepal Airlines

- Oman Air (WY)

- Regent Airways (RX)

- Royal Brunei Airlines (BI)

- Royal Jordanian (RJ)

- Shenzhen Airlines (ZH)

- SriLankan Airlines (UL)

- US-Bangla Airlines (BS)

- Uzbekistan Airways (HY)

- VietJet Air (VJ)

- Vietnam Airlines (VN)

- XiamenAir (MF)

-

1.3 Airline Representative / Officer (if any):

-

1.4 Aircraft Registration Number:

-

1.5 Flight Number:

-

1.6 Aircraft Sector:

-

1.7 Date:

-

1.8 Standard Time Arrival, STA:

-

1.9 Actual Time Arrival, ATA:

-

1.10 Standard Time Departure, STD:

-

1.11 Estimated Time Departure, ETD:

-

1.12 Actual Time Departure, ATD:

-

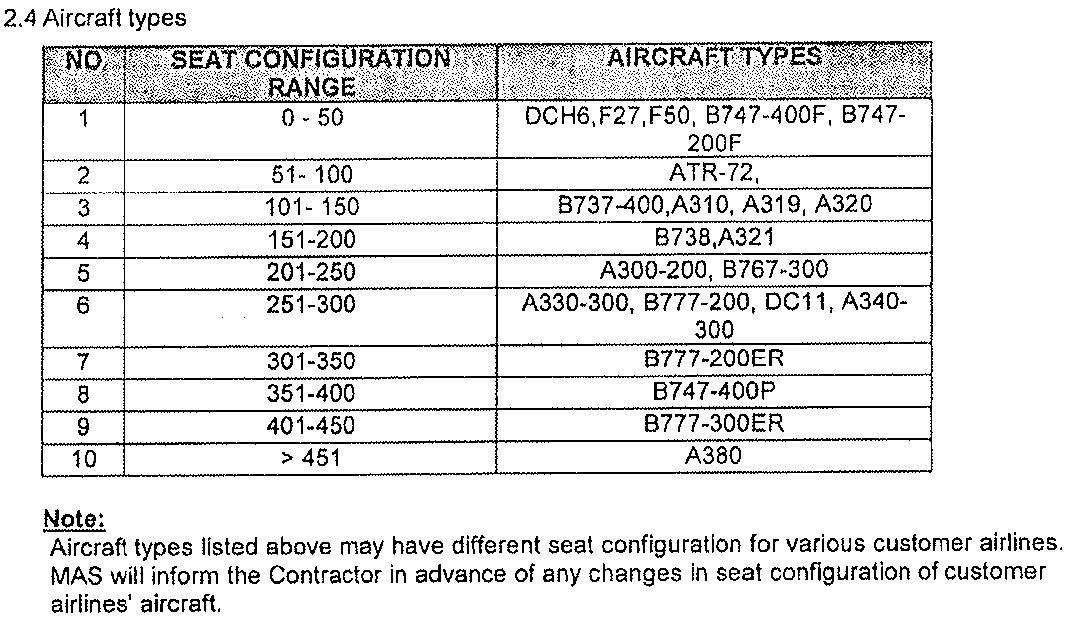

1.13 Aircraft Type:

- B777

- B747

- DC10

- A320/330

- B737-400

- F50

- DH6

- B738

- A380

- B787 Dreamliner

- Others (Please State):

-

Please state Aircraft Type:

-

-

Types of Cleaning:

a. Transit Cleaning - requires contractor (vendor) to carry out the required cleaning tasks within the Precision Timing as specified for the specific aircraft type and available aircraft on ground time. Applicable for aircraft with layover of less than 6 hours.

b. Short Transit/Quick/Pit-Stop Cleaning - is similar to transit cleaning, but with shorter cleaning duration due to shorter aircraft ground time.

Access to the aircraft is via Passenger Step. In the event Passenger Step is unavailable, cleaners are to enter the aircraft via Passenger Loading Bridge (PLB) steps.

c. Deep/Detail/Night Stop Cleaning - cleaning requirement is similar to transit cleaning but with the longer cleaning duration depending on night stop ground schedule. Contractor (vendor) is to give more attention to every area / checkpoints in the aircraft that requires cleaning.

d. Pre-Departure Checks are to be carried out 2 hours prior to Scheduled Time of Departure (STD). Applicable for aircrafts with a layover of 6 hours or more.

Access to the aircraft is via Passenger Step. In the event Passenger Step is unavailable, contractor are to communicate immediately to AIC Department ADS. -

1.14 Sector (Meal or Juice)

-

1.15 Type of Cleaning:

- Deep/Detail/Night Stop Cleaning (NS)

- Transit Cleaning (TR)

- Pre-Departure Check (PDC)

- Pit-Stop/Short Transit Cleaning (STR)

-

1.16 Bay:

2.0 Manpower Details

2.0 MANPOWER DETAILS

-

2.1 Vendor:

-

2.2 Shift Leader(s):

-

2.3 Group(s):

- 01 staff

- 02 staffs

- 03 staffs

- 04 staffs

- 05 staffs

- 06 staffs

- 07 staffs

- 08 staffs

- 09 staffs

- 10 staffs

- 11 staffs

- 12 staffs

- 13 staffs

- 14 staffs

- 15 staffs

- 16 staffs

- 17 staffs

- 18 staffs

- 19 staffs

- 20 staffs

- 21 staffs

- 22 staffs

- N/A

-

2.4 Boy(s):

- 01 staff

- 02 staffs

- 03 staffs

- 04 staffs

- 05 staffs

- 06 staffs

- 07 staffs

- 08 staffs

- 09 staffs

- 10 staffs

- 11 staffs

- 12 staffs

- 13 staffs

- 14 staffs

- 15 staffs

- 16 staffs

- 17 staffs

- 18 staffs

- 19 staffs

- 20 staffs

- 21 staffs

- 22 staffs

- N/A

-

2.5 Pillow/Blanket(s):

- 01 staff

- 02 staffs

- 03 staffs

- 04 staffs

- 05 staffs

- 06 staffs

- 07 staffs

- 08 staffs

- 09 staffs

- 10 staffs

- 11 staffs

- 12 staffs

- 13 staffs

- 14 staffs

- 15 staffs

- 16 staffs

- 17 staffs

- 18 staffs

- 19 staffs

- 20 staffs

- 21 staffs

- 22 staffs

- N/A

-

2.6 Officer(s):

-

2.7 Quality Control Inspector(QCI):

- Iman Arzman

- Zuriyati

- Hanif

- No QCI On-board

-

2.8 Total Manpower:

- 01 staff

- 02 staffs

- 03 staffs

- 04 staffs

- 05 staffs

- 06 staffs

- 07 staffs

- 08 staffs

- 09 staffs

- 10 staffs

- 11 staffs

- 12 staffs

- 13 staffs

- 14 staffs

- 15 staffs

- 16 staffs

- 17 staffs

- 18 staffs

- 19 staffs

- 20 staffs

- 21 staffs

- 22 staffs

- N/A

-

2.9 Enough manpower for this type of aircraft?

-

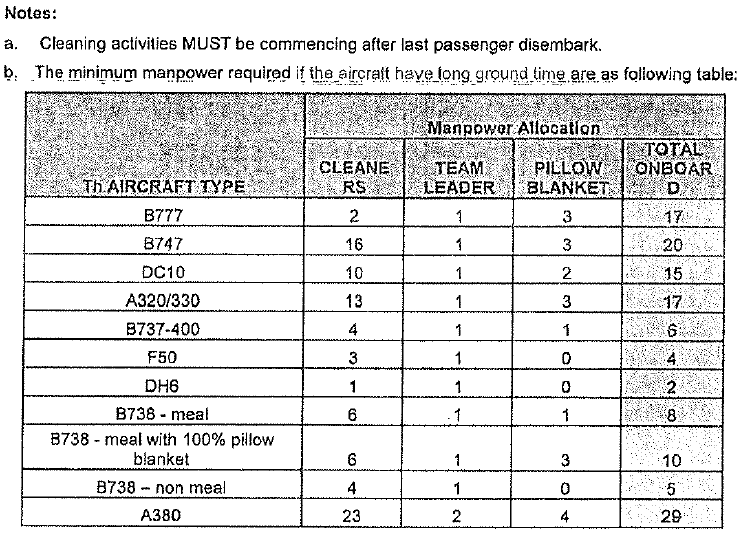

2.9.1 Minimum Manpower:

3.0 Aircraft & Passengers Movement Details

3.0 AIRCRAFT & PASSENGERS MOVEMENT DETAILS

-

3.1 Aircraft's On-chocked:

-

3.2 Door 1L Open:

-

3.3 Door 2L Open:

-

3.4 Last Pax Disembark Time:

-

3.5 CCIC Inbound:

-

3.6 Pax Movement Duration (From Door Open until Last Pax Disembark Time):

-

3.7 Wheelchair(s):

-

3.8 Cabin Wheelchair(s):

4.0 AIC Activities, Timing & Details

4.0 AIC ACTIVITIES, TIMING & DETAILS

-

4.1 Staffs at Bay:

-

4.1.1 AIC Staffs standby 10 minutes before aircraft's arrival?

-

4.2 AIC Staffs wear approved PPEs?

-

4.3 Security check before and/or after cleaning?

-

4.4 Commenced Cleaning Time:

-

4.4.1 All manpower commenced cleaning together and not staggered?

-

4.5 Completed Cleaning Time:

-

4.6 CCIC Signed Time:

-

4.7 CCIC Outbound:

-

4.8 Cleaning Duration:

-

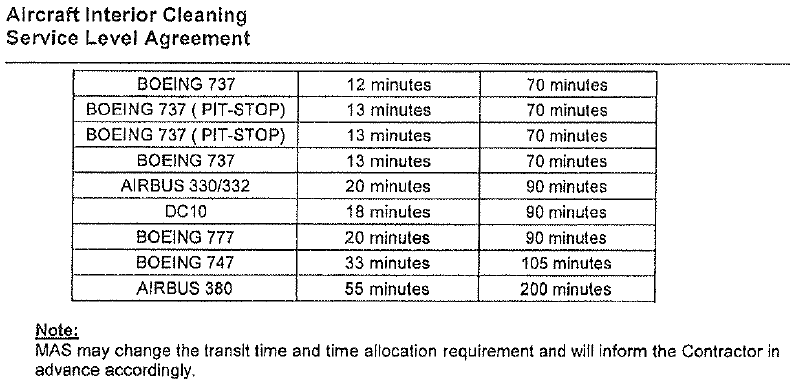

4.8.1 Cleaning duration within Precision Timing?

-

4.8.2 Precision Timing for Transit and Night Stop:

-

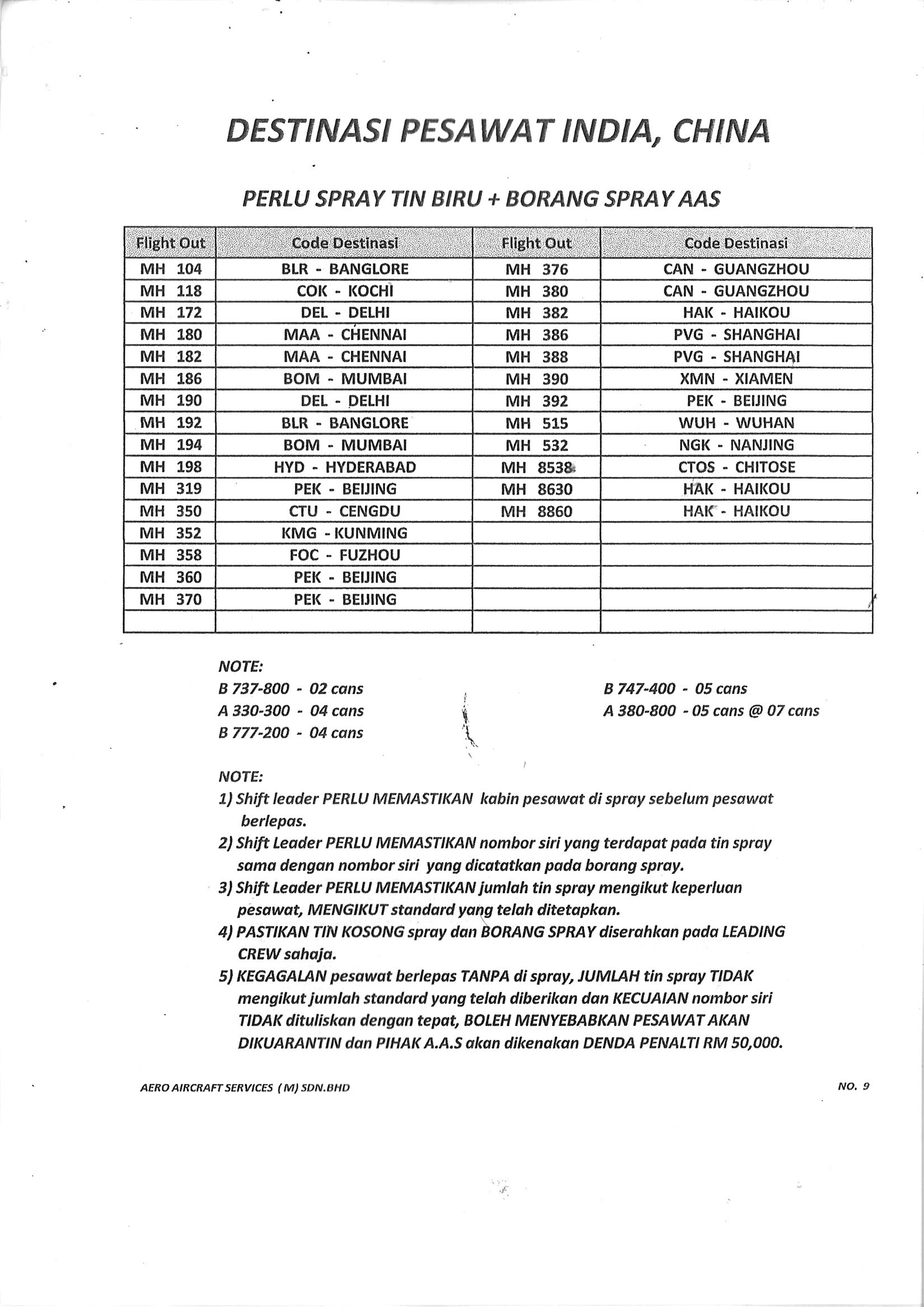

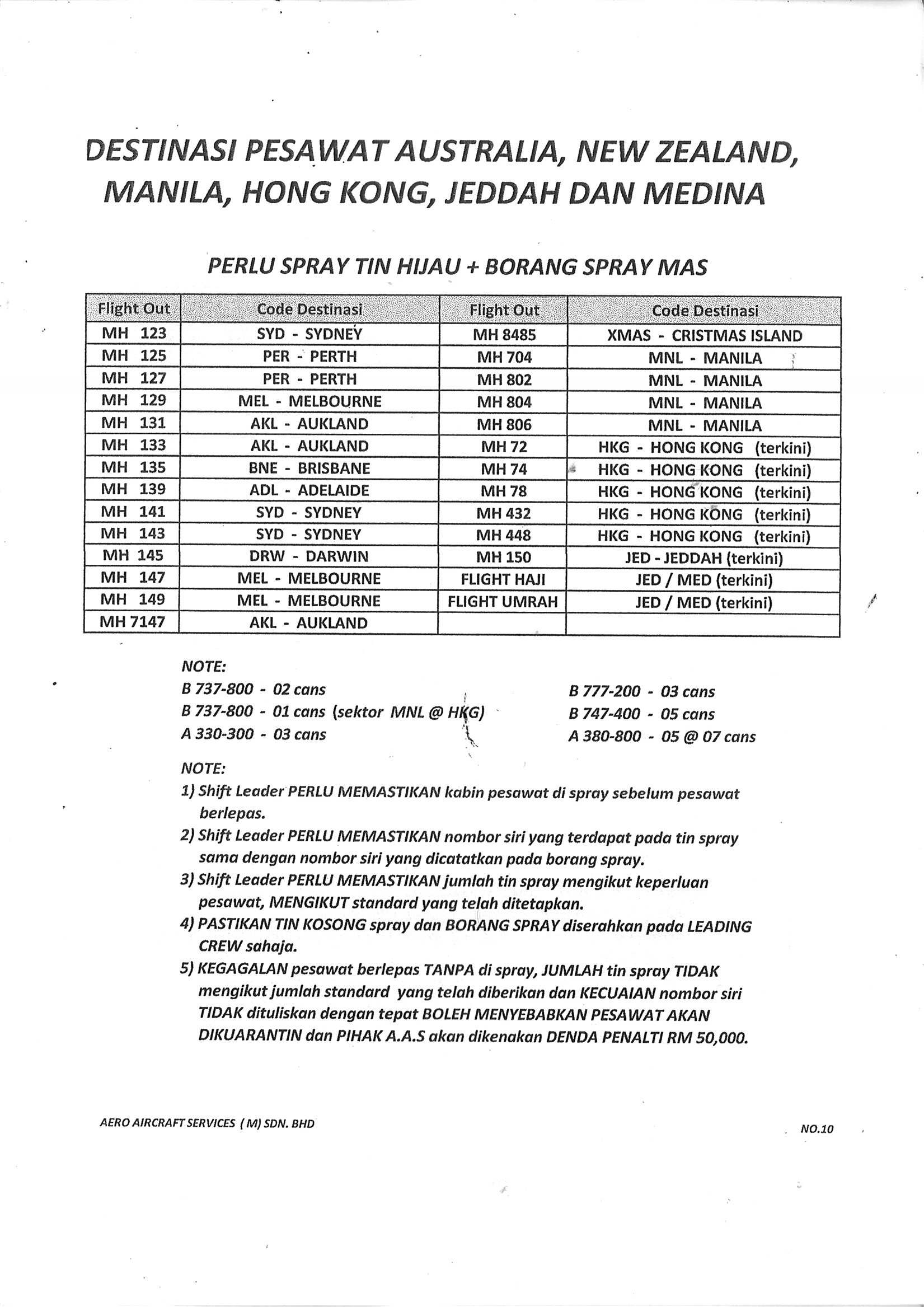

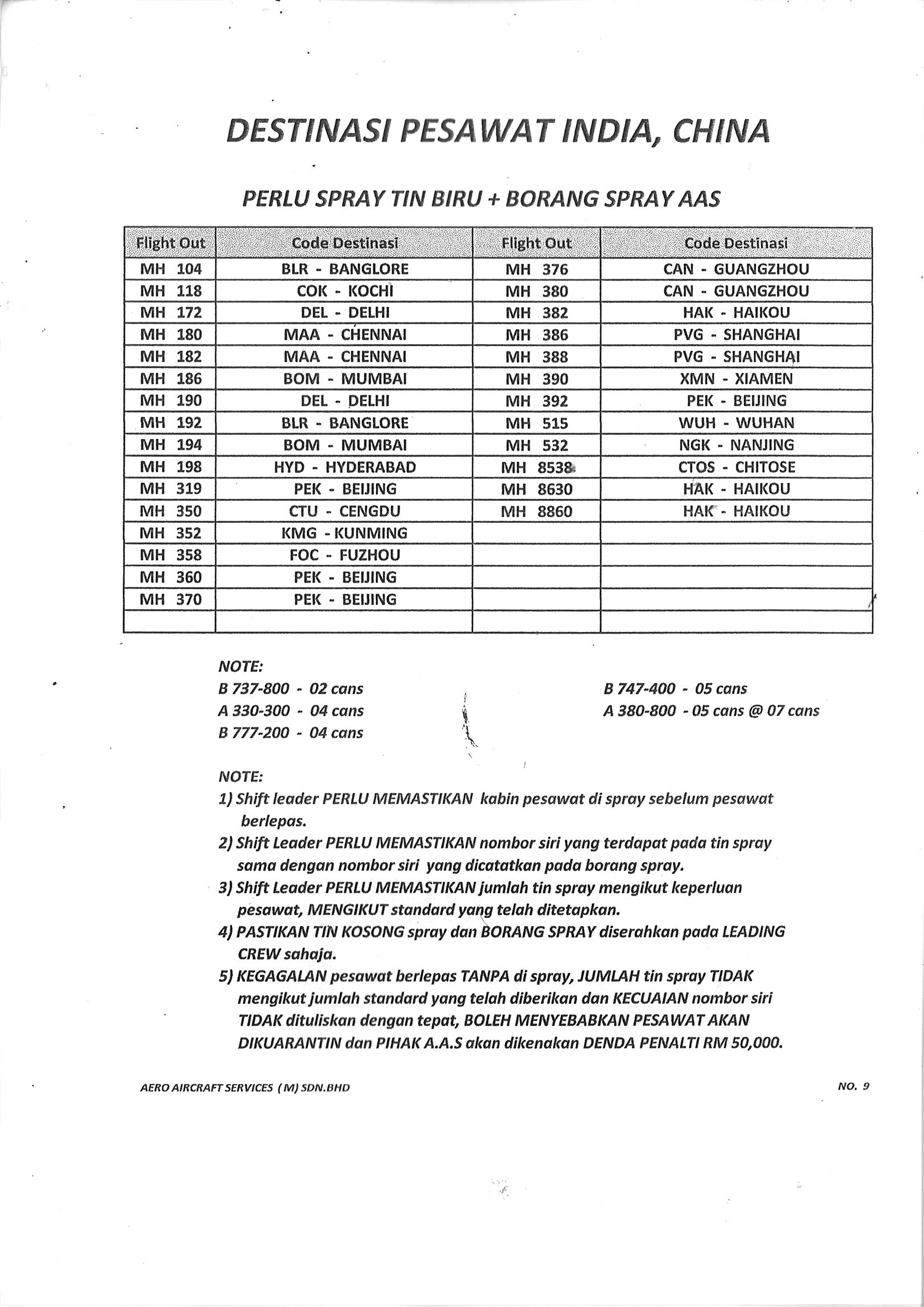

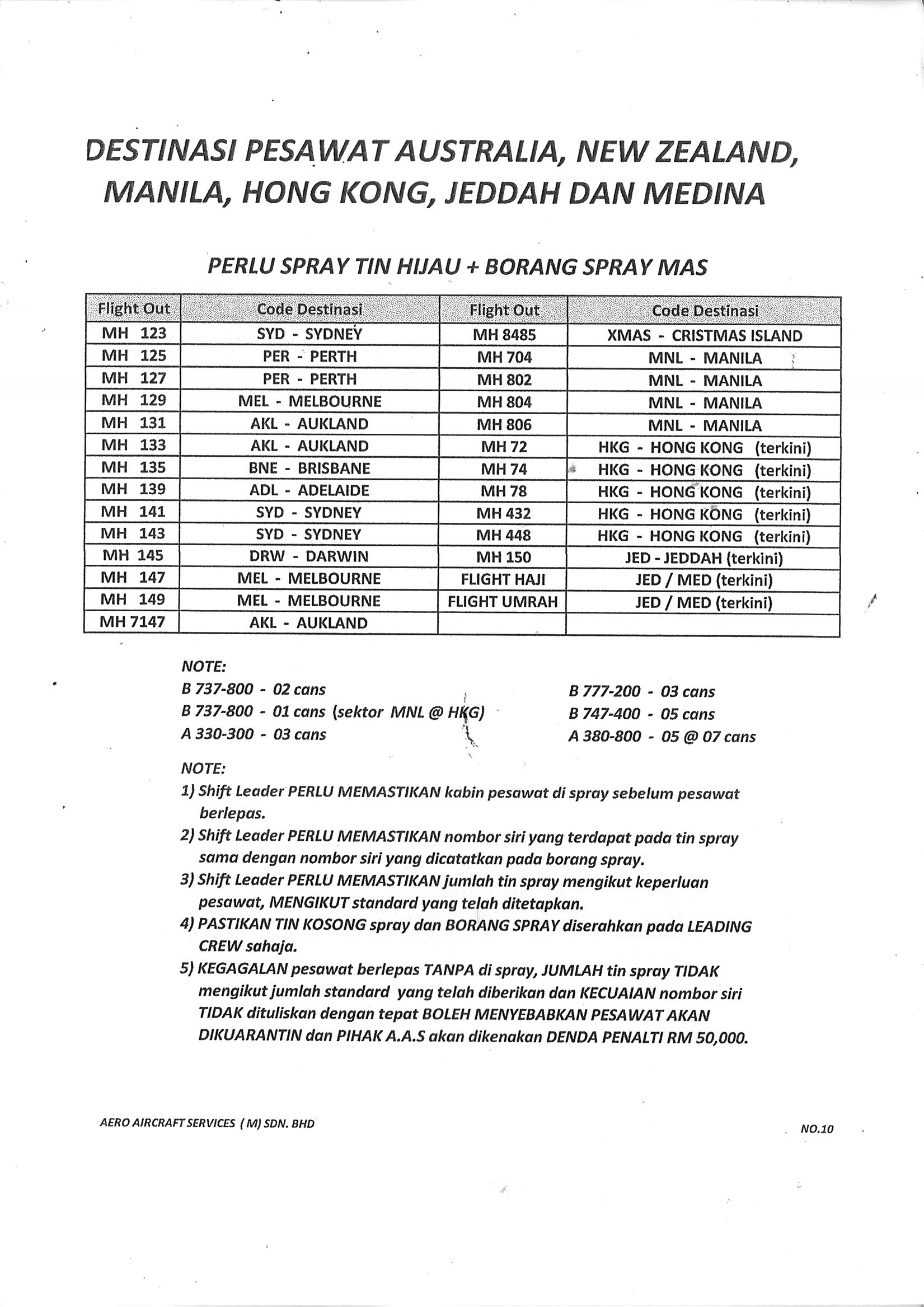

4.9 Fumigation / Aerosol Spray?

-

4.9.1 Aerosol Spray Color and Quantity?

-

Callington Top Of Descent Spray (Blue Cap):

-

Callington Aircraft Pre-Spray Insecticide (Green Cap):

-

4.10 Pax Boarding Time (if available):

-

4.11 Shift Leader or Officer standby at PLB until pax boarding commenced / aircraft's door closed?

-

4.12 Last Pax Boarding Time (if available):

-

4.13 Aircraft's Door Closed Time (if available):

-

4.14 Attach any support document(s). Example OCC Form, JDS, Spray Form, etc. (if available).

5.0 Audit - Cleaning by Sections / Areas

-

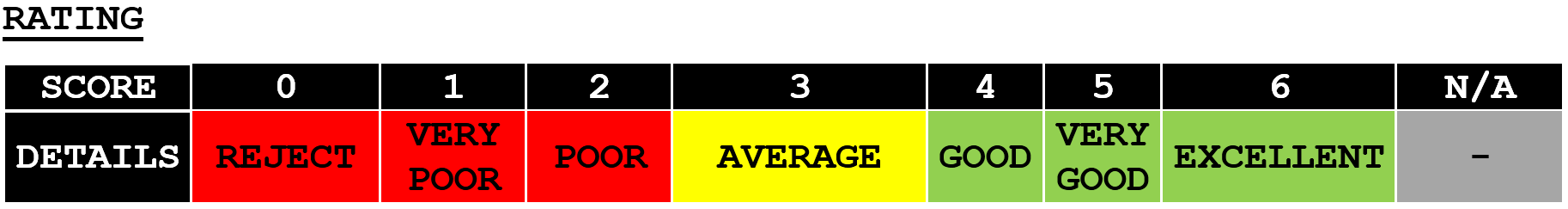

Ratings are based on AIC Department Audit Form - MH and Customer Airlines.

5.1 COCKPIT

-

A cockpit or flight deck is the area, usually near the front of an aircraft, from which a pilot controls the aircraft.

-

Cleaners may enter and clean the cockpit area as per request by Tech Crews, or Engineers.

-

5.1.1 Cockpit Waste Bin.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.1.2 Cockpit Ash Tray.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.1.3 Cockpit Floor.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.1.4 Additional Comments:

5.2 SEATS

-

Ensure to follow cabin dressing setting (SOP) for MH or others Customer Airlines Cabin Dressing.

-

5.2.1 Seats Ash Tray.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.2.2 Seat Pocket.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.2.3 Seat Cover.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.2.4 Seats Head Rest.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Ensure to change any crumple or dirty Head Rest Cover.

-

5.2.5 Seats Arm Rest.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.2.6 Seat Belt.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

All seat belts must be open and crossed over for MH flights.

-

5.2.7 Seats Pocket Item.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

For MH Seat Pocket, Items in the seat pocket in the following order: From front: Safety card, Air sickness bag, Temptation Magazine, In-flight Sales Promotional Leaflet, Going Places.

-

5.2.8 Seats Meal Table.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Ensure Meal Table properly cleaned and not wet or smelly.

-

5.2.9 Headset.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

AIC to distribute EY headsets for MH:-

*B737-800 only, effective from 01 March 2017,

*All Sectors except Peninsular Malaysia, Singapore and Medan(KNO) - flying hours more than 90 minutes. -

5.2.10 Seats Compartment.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Ensure around the screen properly cleaned and no stains.

-

5.2.11 Seats PTV Screen.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Ensure properly cleaned and no fingerprints.

-

5.2.12 Additional Comments:

5.3 CABIN

-

5.3.1 Window.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.2 Cabin Side Wall.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.3 Cabin Dado Panel.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.4 Cabin Overhead Compartment / Hat rack.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Ensure no finger prints and properly cleaned.

-

5.3.5 Cabin Bassinet.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

5.3.6 Cabin Closet.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.7 Cabin Carpet.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Remarks:

-

Add media

-

5.3.8 Seat.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.9 Doghouse.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.10 Air-vent.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.3.11 Additional Comments:

5.4 GALLEY

-

5.4.1 Galley Waste Bin.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.2 Oven.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.3 Fridge.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.4 Galley Compartment.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.5 Galley Sink.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.6 Galley Work Top.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.7 Galley Floor.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.4.8 Additional Comments:

5.5 TOILET / LAVATORY

-

5.5.1 Toilet Waste Bin.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.2 Toilet Wash Basin.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.3 Toilet Bowl.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.4 Toilet Mirror.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.5 Toilet Floor.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.6 Toilet Wall.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.7 Toilet Changing/Nursing Table.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.8 Toilet Items.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.9 Toilet Spare Items.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.5.10 Additional Comments:

5.6 CREW BUNK

-

5.6.1 Crew Bunk - Pillow / Blanket / Bed-sheet / Floor.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.6.2 Additional Comments:

5.7 SPARE ITEMS

-

5.7.1 Spare Items - Seat Covers/Blanket/Pillow/Magazines/Safety Card/Air Sickness Bag, etc.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.7.2 Enough spare items?

-

5.7.3 Additional Comments:

5.8 OTHERS

-

5.8.1 Pillow / Blanket.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

Enough spare pillow/blanket?

-

5.8.2 Cabin Crew Seats.

- Excellent

- Very Good

- Good

- Average

- Poor

- Very Poor

- Reject

- N/A

-

Remarks:

-

Add media

-

5.8.3 Complaint by Rep or Cabin Crew?

-

Remarks:

-

Add media

-

5.8.4 Any visible aircraft cabin related issues that need to be addressed for maintenance? For example - torn leather seats, cracked setbacks, ripped carpet, etc. If so, please take and attach a picture.

-

Remarks:

-

Add media

-

5.8.5 Additional Comments:

6.0 Safety, Security and Health

6.1 SAFETY

-

6.1.1 Contractor (Vendor) to conduct safety briefing prior aircraft's arrival.

-

Remarks:

-

Add media

-

6.1.2 Contractor (Vendor) to wear Personal Protective Equipment (PPE) - Approved Safety Vest, Approved Safety Shoes, Ear Plug, Approved and Designated Uniform, Approved Hand Gloves and Google.

-

Remarks:

-

Add media

-

6.1.3 For driver,following additional permit is needed:<br>a. Valid airfield driving permit (ADP) issued by MAHB.<br>b. Valid Malaysia driving permit/license.<br>c. To have serviceable vehicles for logistic.<br>d. Valid vehicle airfield permit issued by MAHB.<br>e. Safety equipment such as Fire Extinguisher.<br>f. Beacon Light.<br>g. To have serviceable communication device.

-

Remarks:

-

Add media

-

6.1.4 No AIC staff open the aircraft's door (should be open by Crew or Engineer only).

-

Remarks:

-

Add media

-

6.1.5 No rubbish left unattended at PLB and Pax Step?

-

Remarks:

-

Add media

-

6.1.6 Pax Steps and Surrounding areas are free from FOD?

-

Remarks:

-

Add media

-

6.1.7 No rubbish / blankets / toilet items left unattended at bay?

-

Remarks:

-

Add media

-

6.1.8 No items placed at PLB Control Panel?

-

Remarks:

-

Add media

-

6.1.9 Implementation to insert / collect Quarantine Disease Areas (ZIKA) Templates to / from ICN sector.

-

6.1.9.2 Remarks: FINE will be MYR 39,000 for every failure.

-

Add media

-

6.1.9.1 Quarantine Risk Area Template.

-

6.1.10 Safety Cards were distributed correctly by the type of aircraft?

-

Remarks:

-

Add media

-

6.1.11 Cabin compartment had been sprayed with aerosol Callington Pre-Spray Insecticide (AUSTRALIA, NEW ZEALAND, MNL, HKG, & SAUDI ARABIA SECTOR) and Top of Descent (INDIA & CHINA SECTOR).

-

Remarks:

-

Add media

-

Callington Top Of Descent Spray (Blue Cap):

-

Callington Aircraft Pre-Spray Insecticide (Green Cap):

-

6.1.12 No AIC transportation parked at hammerhead or near aircraft.

-

Remarks:

-

Add media

-

6.1.13 Additional Comments:

6.2 SECURITY

-

6.2.1 Contractor (Vendor) to wear and display valid COMPANY ID and AIRPORT PASS (MAHB ID) before enter the aircraft.

-

Remarks:

-

Add media

-

6.2.2 Dangerous item such as sharp object, cigarette lighter, and chemical (liquid/gel) is not allowed near or within or into the aircraft.

-

Remarks:

-

Add media

-

6.2.3 Cash not more than MYR50.

-

Remarks:

-

Add media

-

6.2.4 No hand phone is allowed near or within or into the aircraft.

-

Remarks:

-

Add media

-

6.2.5 No AIC staffs attempting to steal Pax belongings?

-

Remarks: TERMINATION and POLICE REPORT if NON-COMPLIANT.

-

Add media

-

6.2.6 Additional Comments:

6.3 HEALTH

-

6.3.1 AIC staffs use approved chemical for cleaning.

-

Remarks:

-

Add media

-

6.3.2 AIC staffs wear approved PPE when handling/using chemical.

-

Remarks:

-

Add media

-

6.3.3 AIC staffs implement proactive ergonomics to prevent or reduce musculoskeletal<br>injuries.

-

Remarks:

-

Add media

-

6.3.4 Additional Comments:

6.4 HAZARDS

-

The main hazards of the job are related to ergonomics, and the tight working schedule and congested work space underlie most of the hazards.

a. Musculoskeletal problems - Cabin cleaning work is quite physically demanding and associated with some high risk postures and high risk activities. In fact, a survey of cabin cleaning workers of a major contractor in Hong Kong found one sixth of them had experienced occupational injuries in the past and about one third of them experienced bodily discomfort during and after work in the seven days before the interview. The main areas affected were: back, elbow, shoulder, neck, knees, and wrists and hands. In addition to the major problems associated with working postures and working pace, cabin cleaners are also subjected to other health hazards in the workplace.

b. Physical hazards - Noise exposure can occur when they are staying in the ramp area on standby. Noise from vacuum cleaners may also post a hazard if they are not properly maintained. High temperature can be a problem if the air-conditioning system of the aircraft is turned off during cleaning.

c. Chemical hazards - Common household cleansing agents are used for cleaning various surfaces and the toilets; some of them may contain chemical irritants that are harmful to the skin of the workers. Some airline companies require ‘‘disinsection’’ (spraying of residual insecticide) of aircraft on certain international flights. Although professional pesticide sprayers equipped with personal protective equipment do the spraying, cabin cleaners may still be affected by the residual insecticides if they are forced to enter the cabin (due to the tight time schedule) to perform cleaning duties without an adequate washout period being allowed for. The pesticides used belong to the pyrethroid class of compounds and should usually present no major harm to humans except for subjects with hypersensitivity. However, many pesticides also contain organic solvents, and the residual concentration without an adequate washout period may pose a hazard to the cabin cleaners.

d. Psycho-social hazards - Night work and shift work, sometimes with irregular hours, is part and parcel of cabin cleaning work, and may result in sleep disturbance, social isolation, and other undesirable psycho-social consequences.

6.5 MEASURES TO PROTECT WORKERS

-

As the constraint of the workplace probably contributes most to the poor working postures of the workers, the best solution should stem from the redesign of the workplace. This necessitates modification and redesign of the aircraft seat plan and space, and should be brought to the attention of cabin designers. From the perspective of the cabin cleaning contractor, the strategies to be adopted for reducing stressful postures include: administrative measures, provision of ergonomic aids, and training and education of the workers.

a. Administrative measures - Cabin cleaning is composed of tasks with different levels of physical exertion; the management should consider a good mix of tasks assigned to each individual worker, such that the amount of stressful work postures can be reduced by combining less physically demanding tasks with high demand tasks. It may be worthwhile to consider a systematic daily job rotation scheme. The scheme should be formulated according to the demands of each work task and the time that the workers would be exposed to the same demands, such as ‘‘stressful positions’’ of the back or upper limbs. Such a scheme can minimize the continuous exposure of a worker to a particular stressful position within a work shift. As many of the work related musculoskeletal injuries are cumulative in nature, early reporting of problems will enhance ratification and recovery. Policies and procedures for reporting problems/injuries should be made clear to all staff members and such reports should be closely monitored. Regular surveys on the feedback from workers should be conducted to evaluate the effects of changes made or solutions introduced to ameliorate the problems.

b. Provision of ergonomic aids - The management should consider possible use of ergonomic aids to reduce the chances of stressful postures. For instance, a tool that can assist in lifting up the footrest (in first or business class) could be beneficial by reducing the frequency of forward bending position. Using a tool with a long handle may also help to reduce stress when cleaning footrests. The vacuum harness/straps may need to be redesigned such that the vacuum cleaner can be secured appropriately on the back and the shoulders while working in different working postures.

c. Training and education of the workers - While training in itself should not be regarded as a substitute for job redesign or the use of ergonomic aids, it should be an integral part of the whole preventive strategy. As the effects of stressful postures are likely to be cumulative, the cabin cleaners should be educated about the concept of good postures, and the supervisors should be given the responsibility of reminding their subordinates of the proper ways to perform the tasks. It is also recommended to institute regular breaks and regular in-house exercise classes during the break or lunchtime in order to engage workers in structured stretching exercises for reinforcing the prevention component at the workplace. Train the trainer approach can be adopted, and the team leaders should receive proper training in occupational health and safety related to the job.

Prevention of other hazards - Regular maintenance of vacuum cleaners may help to cut down noise generation, and better insulation of transportation vehicles will also help to reduce noise exposure while workers are staying on the ramp. Rubber and/or plastic gloves should be worn when handling chemicals or cleaning with chemicals, and the cabin should be adequately ventilated with fresh air after pesticide spraying before cabin cleaners are allowed to work inside.

Medical surveillance - It is worthwhile to have regular medical surveillance, which may be in the form of a standardized questionnaire, for detecting and monitoring the work related health problems of the employees.

7.0 Conclusions & Recommendations

-

7.1 Conclusions:

-

7.2 Recommendations:

8.0 ACKNOWLEDGMENTS

8.0 ACKNOWLEDGMENTS

-

Prepared By:

-

Checked By:

-

Verified By:

-

Approved By: