C Street Annual Facility Inspection (SPCC Plan)

-

C Street Annual Facility Inspection (SPCC Plan)

-

C Street

-

Conducted on

T-1

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

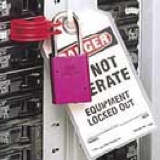

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-2

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-3

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-4

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-5

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-6

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-7

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-8

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-9

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-10

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

T-11

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

Concentrate Tank

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

Additive Tank

Tank Construction

-

Tank is free of dents?

-

Tank is free of missing paint and/or rust?

-

Seams are tight and free of rust?

-

Tank surfaces are clear of snow, trees/vegetation, and debris?

-

Tank support elements are structurally secure?

-

Does tank foundation exhibit signs of settlement, pitting, cracking, or spalling?

-

Check function of level gauges

-

Valves open and close freely?

-

Vents are structurally sound and allow gases to escape?

-

Does overfill basin contain water or products?

-

Inspect the o-ring/gasket on emergency vent(s)?

-

Tank vents are visible and free of dents?

-

Tank overfill alarms?

-

Test automatic overfill shut-off mechanism

-

Test day tank transfer pump, alarms, and level controls

-

UST leak detection test (per UST regulations)

-

Date

-

Tank tightness test (annual for T11, per UST regulations for others, as appropriate)

-

Date

Interstitial Space Monitoring (Double-Wall Tanks)

-

Valve/access orifice closed prior to monitoring?

-

Valve free from rust or missing paint?

-

Interstitial space is free of fluid?

-

Inner compartments appear secure?

-

Test leak detection sensors and alarms

-

Valve/access orifice closed and tank secure when done?

Dispenser And Transfer Controls

-

Dispenser nozzle is secure and properly stored?

-

Dispenser hose is stored off the ground?

-

Starter control is locked and in proper working order?

-

Test emergency shutoff switches

Piping

-

Piping is properly braced and supported (emphasis on joint support)?

-

Piping/hoses are free of deterioration, rips, and tears?

-

Piping is free of rust, corrosion, and missing paint?

-

Joints/connections to tanks are secure?

-

Verify proper function of anti-siphon valves?

Containment Area

-

Area is free of water/snow?

-

Area is free of product or indication of a release?

-

Dikes are secure?

-

Drain valves closed/locked?

Indication of Releases

-

Pooled Product?

-

Stained soil or snow?

-

Distressed vegetation?

-

Sheen on ponded water?

Security

-

Lighting works (verify operation of security lights)?

-

Locks are functional with keys/combos available?

-

Fence is secure?

Maintenance

-

Replace fuel filters

-

Replace gaskets on flanged connections as necessary

-

Restore painting, coatings, or other corrosion protection

-

Calibrate product transfer gauges

-

Restock spill response kit as necessary

Miscellaneous

-

Review inventory records

-

Other

Summary

-

Did you document any unsatisfactory inspection?

-

Did you notify supervisor of any unsatisfactory inspection?

-

Did you describe any corrective action taken or that will be performed?

-

Print and Sign