Title Page

-

Conducted on

-

Prepared by

-

Job Number

-

Location

-

Equipment within calibration dates?

-

MSA monitors bump tested and calibrated

Dry Film Thickness Gauge

Psychrometer (Atmospheric conditions meter)

Jeep -

Environmental conditions required for coating applications verified?

-

Plastic down to collect sandblast media

Environmental Conditions Required for Coating Applications

Prepare surfaces and apply all coatings under the following range of ambient conditions, unless the coating

manufacturer specifically allows variations. Measurement of air temperatures, humidity, and dew point shall be made

in accordance with ASTM E337.

11. Air Temperature: Between 50F and 100F.

12. Surface Temperature: Between 50F and 100F and at least 5F above the dew point.

13. Relative Humidity: Not over 85%.

14. Surface Conditions: Clean, dry, and free of dust and oil.

15. Work Area: Free of airborne dust that would contaminate prepared surfaces or freshly applied

coatings. -

ISN Net Card and OQ Card available and valid for coating operations.

-

30/60 Sandblast media and check the expiration on coating prior to work.

-

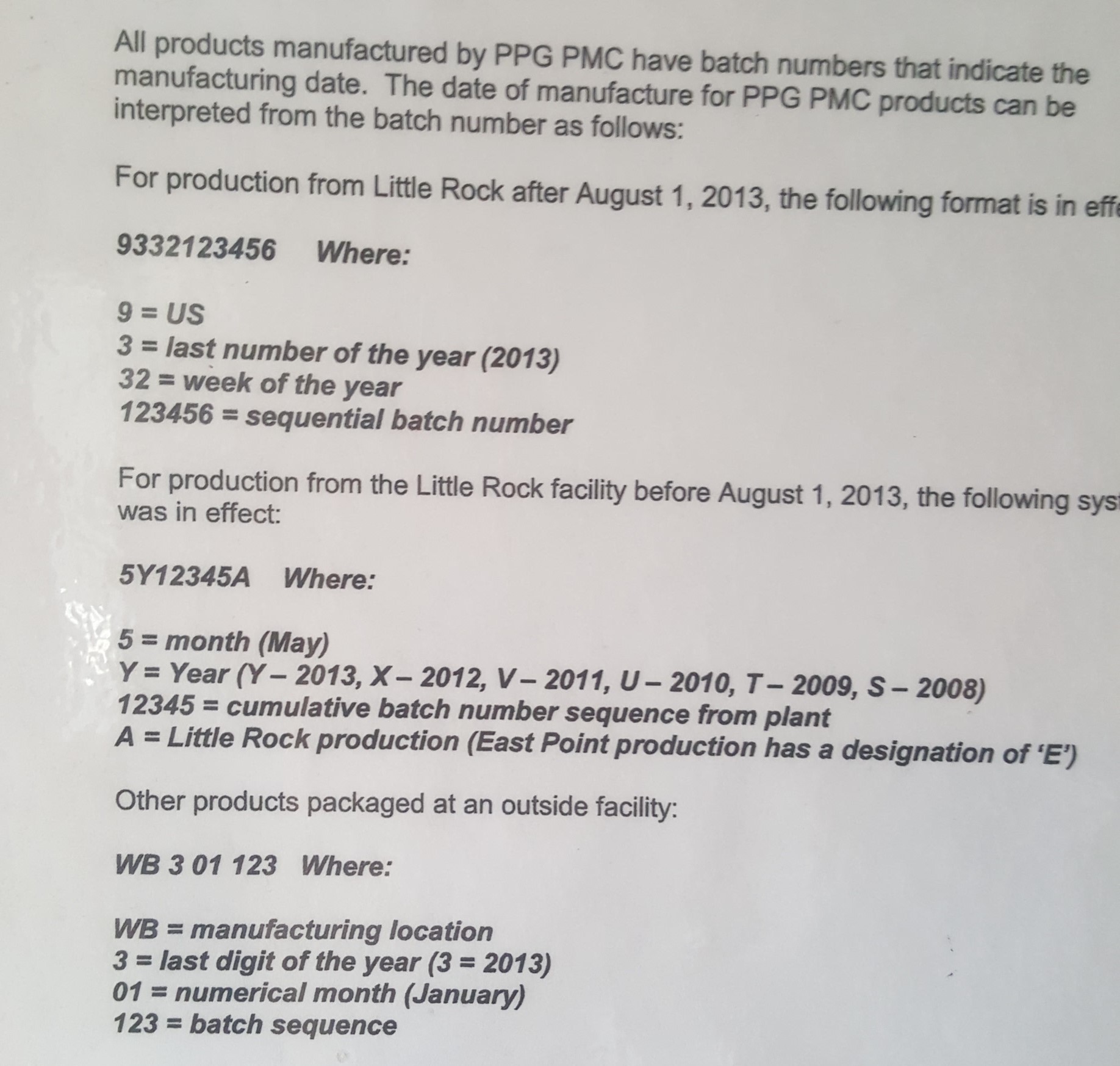

Amerlock and PSX do not have an expiration on the cans, see below for breakdown

-

Expiration breakdown PSX

-

Safety:<br>Carbon Monoxide monitor is present in sand blast hood?<br>Inspect all equipment prior to use (Whip checks, connections tight, fittings)<br>Hot Work Permit (Ask about PM number paul)

-

Pipe blasted to near white?

-

Check Profile, 1.5 anchor minimum, 4 anchor maximum

-

Is new coating compatible with existing coating?

-

Is existing coating being tied into pre-1978 or unknown?

-

Has existing coating been tested for lead?

-

Verify ambiance based on the type of coating used.

-

Amerlock or PSX?

-

Is dry film thickness between 4mm minimum to 8mm maximum?

-

Is dry film thickness between 3mm minimum to 7mm maximum?

-

Visually Inspect coating:<br>Any missed spot<br>A sag<br>A drip

-

Final inspection: thickness between 7mm minimum and 15mm maximum?

-

Fill out daily coating log.