Title Page

-

Conducted on

-

Prepared by

-

Location

-

Employees Name

-

Date Completed

Start Up

-

Firstly, twist the emergency stop button to release it, this should make a loud beep, then press the green button to start the compressor.

-

Then turn on the boiler by pushing the middle white switch down and pressing the reset button down on the left. This will fire up the boiler.

The boiler will take between 45 minutes to an hour to heat up to optimal temperature. -

When temperature reaches between 60 and 70 degrees, turn on the agitator and bed from the control panels. This will ensure all components are running at the correct temperature for production.

When temperature is between 70 and 80 degrees you are ready to introduce the raw material. -

When optimal temperature has been reached you can now turn on all functions on the bed dryer controls, the blowing fan, vibrating sieve, feeding fan, crusher.

-

Sign to acknowledge understanding

First Pass

-

To run first pass you must ensure the switch is turned to first pass.

-

The first pass gate must be checked to ensure correct positioning for optimal flow of material. This will affect the weight of the product at the end of the process.

When running grey/carbon the gate is normally set between 1 and 2, you can always adjust the gate to obtain correct weights,

When running white this can be opened to between 2 and 3 depending on weight outcome. -

The octabin must be loaded on to the stand using a forklift only by someone who is capable to do so, Then using the pallet truck, the stand and octabin are pushed into the correct position

-

-

Cut the carboard section down on the front of the bin, then make a small insertion with the metal chute, the raw material will then load the hopper, Always make sure the hopper does not over fill on to the floor.

-

When the raw material is in the hopper you then need to turn on the feed which in turn feeds through the first pass gate and then into expander , this is automatic so the bead will feed into the expander every couple of minutes.

-

It my take up to 30 minutes from first feed for you to see any bead coming from the expander

-

The path of the bead exiting the bed must be checked to make sure it is reaching its desired location. First pass will always be put into silo 1. Check the piping is all attached and the gate to the correct silo is in the correct position.

-

-

When the drying bed begins to fill up it will pour on to the crusher , the feeding fan will then pass the bead into silo via the over head ducting.

Measuring and surveilance of product

-

The product must be monitored hourly to ensure quality and weight are correct and meet the standards required. This is done using the digital scales and sieves.

Pass 1 only requires the weights to be documented on an hourly basis. The product type and batch numbers must be recorded. These are found on the label on the box of each bin of raw material.

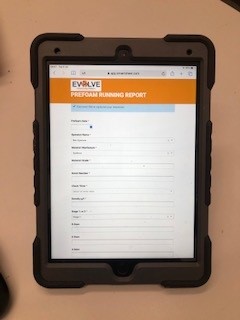

This along with the name of the operator, date of production and time of each measurement are recorded on the Ipad provided. -

-

To weigh the beads the 10 litre jug must first be placed on the scales to set the default weight. When jug is steady on the scales press the Tare button to get the weight to zero. Now fill the jug with beads from the bed and weigh again. Divide the result by 10 and record. This is to be done on an hourly basis.

-

-

When performing pass 2, the size of the beads must be recorded also.

This is done by filing the smaller measuring jug and emptying into the sieves. Make sure the sieves are stacked in the correct order first. Largest at the top.

Shake the sieves to allow beads to fall and then empty each sieve in turn back into the small measuring jug. This will enable you to get a correct percentage reading to record in the log.

This is to be completed on the Ipad hourly along with the weight of the bead to ensure correct quality of bead. -

-

Sign to acknowledge understanding

Second Pass

-

To perform second pass, follow steps on pass1 up to feeding the hopper.

The material will now be coming in from silo 1 to pass through the process.

When machinery is ready and up to temperature (70 -80 degrees) you can begin.

First turn second pass switch on from the control panel. Make sure all piping is fixed and secure and route the direction of the bead. This will be going into one of the other silos.

Check all gates on the ducting and walk the route to the silo you are filling. -

When all is correct you can start the second pass fan from the control panel.

This will fill the cage with beads and introduce them to the agitator.

The gate on the bottom of the cage determines the speed of entry and is marked with corresponding lines. -

-

This gate can be adjusted to obtain correct weights on pass 2

-

Once again the drying bed will fill up, pour on to the crusher and the feeding fan will send the bead to the required silo.

-

Sign to acknowledge understanding

End of process procedure

-

When all the material, whether it be first or second pass, has been entered into the agitator you must wait at least 20 minutes for the product to expand. When little or no material is exiting the agitator you can begin the shutdown procedure.

-

When no bead is falling from the expander chute, you then need to open the small hatch found at the bottom of the main door, this will then empty the expander You do this by turning the 2 large bolts.

-

REMEMBER THE BEADS AND THE EXPANDER WILL BE HOT SO WEAR HEAT PROTECTIVE GLOVES AT ALL TIMES

-

The beads that are left in the drying bed can be manual passed down through to the fan using the large scoops, When ready, material can be cleared from the cage if doing second pass using the compressed air. The second pass fan can be turned off via the control panel at this stage. The beads that are left in the bed can be blown to the end to be pumped out. When the bed is empty, the silo fan can be turned off. When all is empty, agitator, feeds and silo fan can be turned off. When completed, make sure everything is turned off via the control panels.

-

Sign to acknowledge understanding

Routine checks and maintenance

-

The boiler must be blown down once a week to ensure optimal performance. This is done by following the instructions on the taps. Each section will show you what taps to turn and in what order. These are turned for 10 seconds and then returned to original positions.

-

-

Diesel must be checked routinely to avoid running the boiler low. This is checked by the plug in fuel indicator next to the fuse board. When indicator reads 3 bars or less, diesel is to be ordered.

-

-

After each run, the agitator must be cleaned out to prepare for the next run. This is done via the trap door, when machine has had time to cool down. Brush out remaining material and using a vacuum cleaner, remove product from feed and steam entry points. All machinery is to be blown clean using the air compressor. When ever a different material is run, a full clean down must be completed, please revert to 'product change over' on the iAudit to carry out this.

-

Sign to acknowledge understanding