Title Page

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Personnel

-

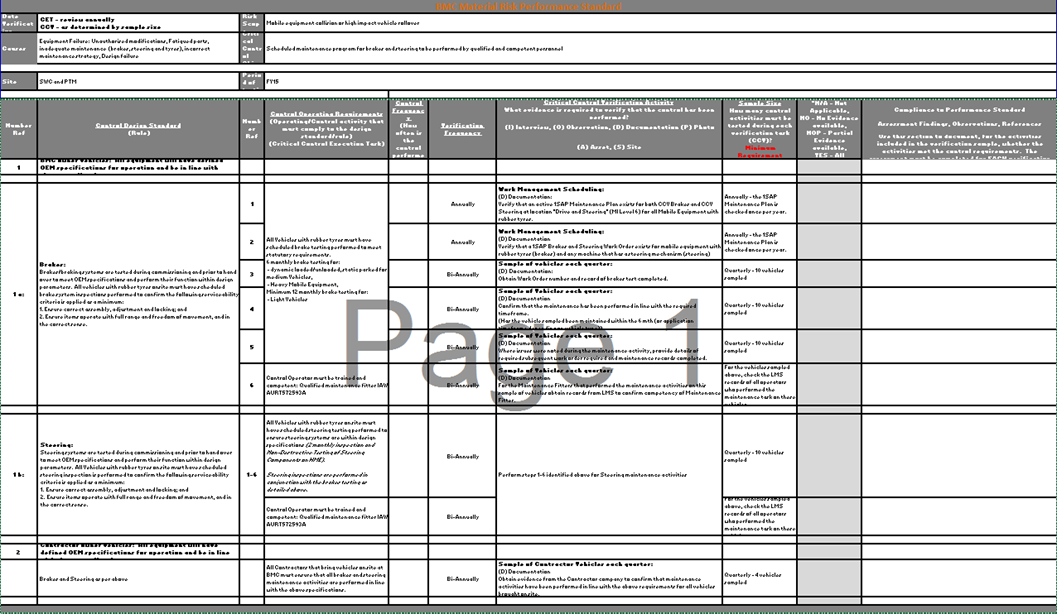

BMC SWC MGT Performance Std - Mobile Equipment - Maintenance

BMC Owned Equipment - Brakes Brakes/braking systems are tested during commissioning and prior to hand over to meet OEM specifications and perform their function within design parameters. All vehicles with rubber tyres onsite must have scheduled brake system inspections performed to confirm the following serviceability criteria is applied as a minimum: 1. Ensure correct assembly, adjustment and locking; and 2. Ensure items operate with full range and freedom of movement, and in the correct sense. All Vehicles with rubber tyres must have scheduled brake testing performed to meet statutory requirements. - 6 monthly statutory brake testing for heavy/medium vehicles - 12 monthly statutory brake testing for light vehicle Statutory requirements include dynamic brake testing of service brakes. Appropriate testing of emergency and park brakes (Refer to BMC Braking Systems Standard).

-

Select 10 statutory brake tests for the last quarter. Do all 10 work orders have the statutory brake tests attached to the notification?<br><br>Attach all 10 brake test documents.

-

For all 10 brake tests performed in line with the required interval? (Has the vehicle sampled been maintained within the applicable timeframe depending on vehicle type)

-

Where issues were noted during the maintenance activity, was subsequent work completed? If applicable, provide evidence of subsequent work orders being raised.

-

Were all brake tests completed by a competent and qualified maintenance fitter, must be trained and competent: Qualified maintenance fitter IAW AURT572593A?<br>Obtain records from LMS to confirm competency of maintenance worker.<br>

Contractor Equipment - Brakes Brakes/braking systems are tested during commissioning and prior to hand over to meet OEM specifications and perform their function within design parameters. All vehicles with rubber tyres onsite must have scheduled brake system inspections performed to confirm the following serviceability criteria is applied as a minimum: 1. Ensure correct assembly, adjustment and locking; and 2. Ensure items operate with full range and freedom of movement, and in the correct sense. All Vehicles with rubber tyres must have scheduled brake testing performed to meet statutory requirements. - 6 monthly statutory brake testing for heavy/Medium vehicles - 12 monthly statutory brake testing for light vehicle Statutory requirements include dynamic brake testing of service brakes. Appropriate testing of emergency and park brakes (Refer to BMC Braking Systems Standard).

-

For all major contractors - Please provide an example of a brake test. 4 or more examples required. <br>

-

For all brake tests performed in line with the required interval? (Has the vehicle sampled been maintained within the applicable timeframe depending on vehicle type)

-

Where issues were noted during the maintenance activity, was subsequent work completed? If applicable, provide evidence of subsequent work orders being raised.

-

Were all brake tests completed by a competent and qualified maintenance fitter, must be trained and competent: Qualified maintenance fitter IAW AURT572593A?<br>Obtain records from LMS to confirm competency of maintenance worker.<br>

BMC Owned Equipment - Steering Steering systems are tested during commissioning and prior to hand over to meet OEM specifications and perform their function within design parameters. All Vehicles with rubber tyres on site must have scheduled steering inspection is performed to confirm the following serviceability criteria is applied as a minimum: 1. Ensure correct assembly, adjustment and locking; and 2. Ensure items operate with full range and freedom of movement, and in the correct sense. All Vehicles with rubber tyres on site must have scheduled steering testing performed to ensure steering systems are within design specifications. - 6 monthly integrity inspection of steering components on SME - 3 monthly non-destructive testing of steering components on SME where applicable

-

Select 10 steering integrity or NDT checks for the last quarter. Do all 10 work orders have the documentation attached to the notification?

-

For all 10 steering checks performed in line with the required interval? (Has the vehicle sampled been maintained within the applicable timeframe depending on vehicle type)

-

Where issues were noted during the maintenance activity, was subsequent work completed? If applicable, provide evidence of subsequent work orders being raised.

-

Were all steering tests completed by a competent and qualified maintainer?<br>Obtain records from LMS to confirm competency of maintenance worker.<br>

Contractor Equipment - Steering Steering systems are tested during commissioning and prior to hand over to meet OEM specifications and perform their function within design parameters. All Vehicles with rubber tyres on site must have scheduled steering inspection is performed to confirm the following serviceability criteria is applied as a minimum: 1. Ensure correct assembly, adjustment and locking; and 2. Ensure items operate with full range and freedom of movement, and in the correct sense. All Vehicles with rubber tyres on site must have scheduled steering testing performed to ensure steering systems are within design specifications. - 6 monthly integrity inspection of steering components on SME - 3 monthly non-destructive testing of steering components on SME where applicable

-

For all major contractors, provide steering checks for the last quarter. Has at least 4 examples been provided? <br>Steering Integrity or NDT inspections.

-

For all steering checks performed in line with the required interval? (Has the vehicle sampled been maintained within the applicable timeframe depending on vehicle type)

-

Where issues were noted during the maintenance activity, was subsequent work completed? If applicable, provide evidence of subsequent work orders being raised.

-

Were all steering tests completed by a competent and qualified maintainer?<br>Obtain records from LMS to confirm competency of maintenance worker.<br>