Title Page

NOTE: Sample size - 3 to be conducted per quarter (3 Lifting & Cranage CCVs)

-

Work Order Number

-

Job Description

-

Location

-

Conducted on

-

Conducted by

-

CMW's involved in lift and task (crane operator, rigger, fitter etc.)

Lift Plans

Dropped and Swinging Loads Risk Scope: Significant exchange of kinetic energy as a result of a dropped load or crane tip.

Dropped and Swinging Loads Critical Control Objective: Appropriate assessment of the lift to be made to ensure that an appropriate Lift Plan is developed, signed off and implemented.

Dropped & Swinging Loads Critical Design Standard: The design of the control is based on industry standard practice, OEM crane design and recognised training standards for crane operation and configuration. SOP011 Lifting and Cranage sets the minimum expectations for safety factors and categorises lifts based on complexity. The SOP details the requirements for documentation and site authorisation to conduct lifts based on these defined complexity levels. Every lift conducted on site is assessed in line with the requirements of SOP011.

-

For all Category of Lifts:<br>Interview the Supervisor and understand the assessment process that was conducted. <br>Identify whether the lift was deemed to be Level 1, 2 or 3.<br>The following questions must be asked to ensure that the correct assessment has been made:<br>CAT 1<br>A. Is the load <80% of the cranes rated capacity in its current rigging method?;<br>B. Does the lift involve basic slinging only?<br>CAT 2<br>A. Does the lift involve multiple equipment? Is the load <80% of rated capacity?<br>B. Can the centre of gravity change during the lift?<br>C. Is the lift in tight spaces or does the crane operator loose site of the load?<br>CAT 3<br>A. Is the load >80% of the rated capacity of the crane?<br>Is the lift conducted on site assessed and in line with SOP011 and the category of lift determined.

-

Add comments:

-

<br>For all Category of Lifts:<br>Obtain copies of the Pre Lift Hazard Assessment and check for completeness.<br>Was the assessment made by a competent Crane/Forklift Operator?

-

Attach photo evidence of Take 5, JSA or Pre Lift Hazard Assessment.

-

Add comments:

-

For Category 2 Lifts: <br>Obtain the Lift Plan, go out and observe the lift for compliance on the day.<br>Has the Lift Plan been completed?

-

Attach photo evidence of Cat 2 Lift Plan.

-

Add comments:

-

For Category 2 Lifts: <br>Check LMS for appropriate training records for Coal Mine Workers involved in the Lift.<br>Has the Lift Plan been reviewed and signed by Crew Member (competent Crane/Forklift Operator) and Supervisor?

-

Attach photo evidence of LMS reocrd.

-

Add comments:

-

For Category 3 Lifts: Obtain the Complex Lift Plan, go out and observe the lift for compliance on the day.<br>Has a Complex Lift Plan been completed?

-

Attach photo evidence of Complex Lift Plan.

-

Add comments:

-

For Category 3 Lifts:<br>Check LMS for appropriate training records for Coal Mine Workers involved in the Complex Lift.<br>Has the Complex Lift Plan been signed by an Independent Competent person and SSE (or delegate).<br>

-

Attach photo evidence of LMS record.

-

Add comments:

Exclusion zones

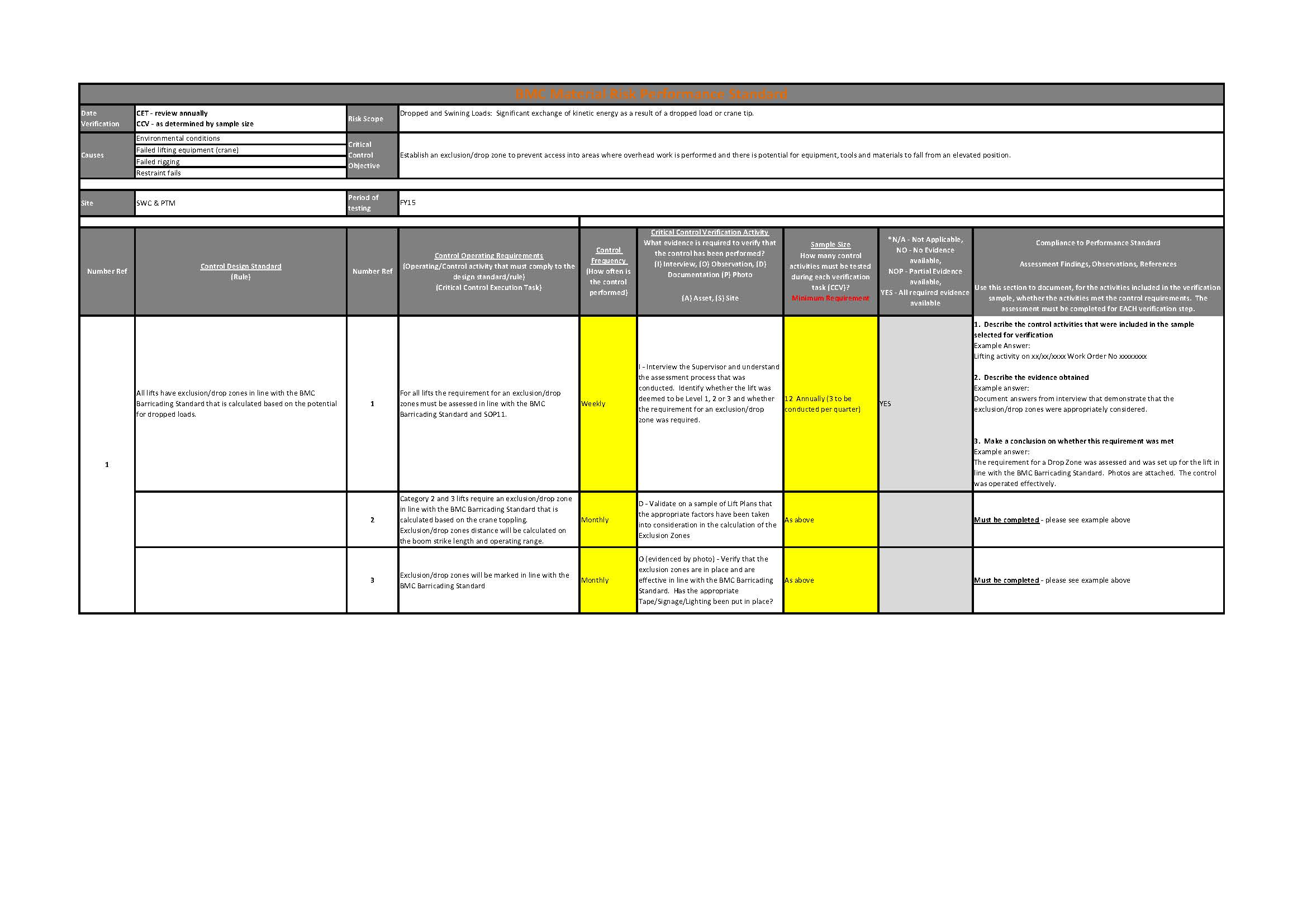

Dropped and Swinging Loads Risk Scope: Significant exchange of kinetic energy as a result of a dropped load or crane tip.

Dropped and Swinging Loads Critical Control Objective: Establish an exclusion/drop zone to prevent access into areas where overhead work is performed and there is potential for equipment, tools and materials to fall from an elevated position.

Dropped and Swinging Loads Control Design Standard: All lifts have exclusion/drop zones in line with the BMC Barricading Standard that is calculated based on the potential for dropped loads.

-

For all lifts the requirement for an exclusion/drop zones must be assessed in line with the BMC Barricading Standard and SOP11.<br>Interview the Supervisor and understand the assessment process that was conducted. <br>Identify whether the lift was deemed to be Category 1, 2 or 3 and whether the requirement for an exclusion/drop zone was required.<br>

-

Add comments:

-

Category 2 and 3 lifts require an exclusion/drop zone in line with the BMC Barricading Standard that is calculated based on the crane toppling.<br>Exclusion/drop zones distance will be calculated on the boom strike length and operating range.<br>Considers distance and potential velocity and deflection of falling objects?<br>Are spotters used?<br>Are all accesses barricaded?

-

Take a photo of evidence of Lift Plan & JSA

-

Add comments:

-

Exclusion/drop zones will be marked in line with the BMC Barricading Standard. Could the boom fall on someone during the lift.<br>Verify that the exclusion zones are in place and are effective in line with the BMC Barricading Standard. <br>Has the appropriate Tape/Signage/Lighting been put in place?

-

Take a photo of evidence of exclusion/drop zones.

-

Add comments:

Fit for purpose equipment

Dropped and Swinging Loads Risk Scope: Significant exchange of kinetic energy as a result of a dropped load or crane tip.

Fit for Purpose Equipment Critical Control Objective: The objective this control is to ensure that all Lifting and Cranage equipment is used according to its safe working load and is fit for purpose so as to not fail when in use.

Fit for Purpose Equipment Control Design Standard: All equipment will have defined OEM specifications for operation and be in line with those specifications.

-

Validate that equipment is in line with OEM specifications.<br>Does the crane have a current safety certificate (Crane Safe Sticker)

-

Take a photo of evidence - certification sticker

-

Add comments:

-

For BMC owned equipment validate that if equipment is modified from OEM design specifications that the appropriate Change Management Process has been followed.<br>Verify that for a sample of equipment (forklifts, tyre handlers, overhead cranes) chosen any modifications (design/engineering) have been approved through the change management process.

-

Take a photo of evidence of change management process

-

Add comments:

-

Does the crane operator have the required certification to safely operate and assemble crane?<br>(LMS records or statement from employer)

-

Take a photo of evidence of LMS record.

-

Add comments:

-

Is the crane configuration safe working load matched to the lift category <br>i.e. Load less than 80% of SWL, taking into account all rigging.

-

Take a photo of evidence of safe work load assessment.

-

Add comments:

-

Is the crane maintained as per OEM specifications. <br>Check service records

-

Add comments:

-

Attach evidence of service record, prestart inspection log, rigging within test date record etc.

-

Type in name and sign.

-

Email audit and attach to Notification of Work Order