Title Page

-

Client / Site

-

Conducted on

-

Prepared by

-

Personnel

-

This Inspection is an assessment of the conditions and activities on the project worksite at the time of the visit. The conditions & activities are assessed against agreed expectations between PCBU’s, legislative and regulatory requirements and/or industry best practice.

…

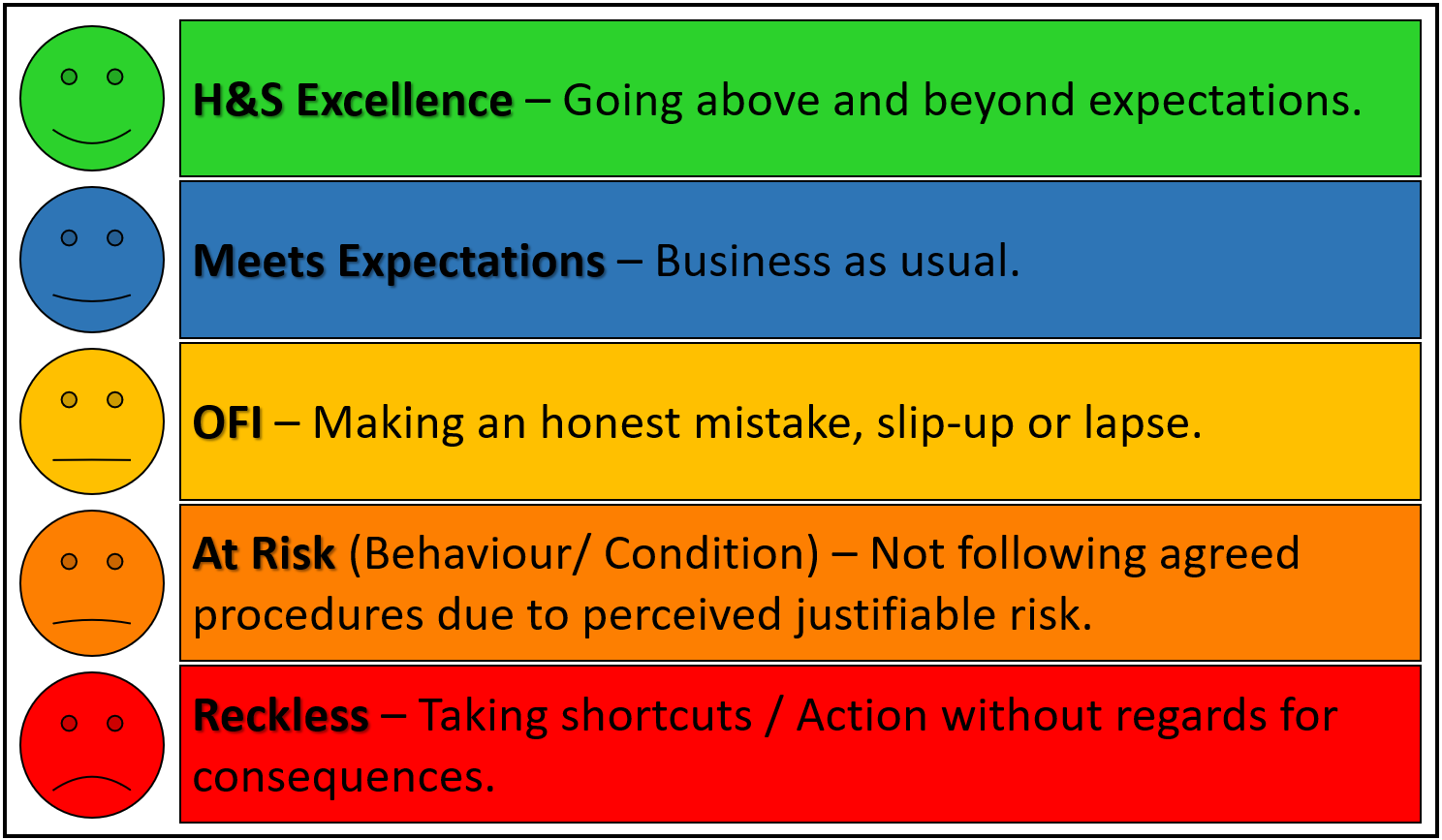

Assessment Criteria:

…

Meets Expectations (ME) = The assessed condition or activity meets current expectations.

...

Opportunity For Improvement (OFI) = The assessed condition or activity does not fully meet current expectations.

...

At Risk (AR) = The assessed condition or activity does not fully meet current expectations and as a result there is an intolerable level of risk of harm to people, the environment and/or the business.

...

Not Checked (NC) = The condition or activity was not checked.

...

Not Applicable (NA) = The condition or activity was not present.

1. Pre-Inspection Planning

-

What is the Focus for the period:

-

Pre-planning Notes:

2. Inspection Criteria

-

Select the criteria that is applicable to your site inspection:

- CASE

- Asbestos

- Confined Space

- Power Tools, RCD's & Leads

- Emergency Preparedness & Response

- Environmental

- Hazardous Substances

- Hotwork

- Housekeeping

- PAT's

- PPE/PPC

- Safety Signage

- Silica and Inhalable Dust

- Site Fencing & Security

- Subcontractor SSSP

- Supervision

- Traffic Management

- Worker Facilities

CASE

-

QR code in place?

-

Signed in using CASE App?

-

Self-induction completed?

-

Current hazard list relevant?

-

Activity Pre-Start completed?

Emergency Preparedness and Response

-

Emergency response plan and site layout plan in place and displayed?

-

Emergency assembly point identified and sign posted?

-

Emergency contact details displayed?

-

Is a trained First Aider on site?

-

Are adequate First Aid kits available (including eyewash)?

-

Are adequate Fire Extinguishers available?

-

Spill kit available?

Supervision

-

Are subcontractor workers adequately supervised?

-

Are PCBU 3 subcontractors adequately supervised?

Safety Signage

-

Is warning signage in place at all access points?

-

Is a site safety board displayed near the site entry?

-

Are the hazards and controls listed on the site safety board relevant?

-

Are worksite 'key contact' details displayed at the site entrance?

-

Are minimum PPE requirements displayed?

PPE/PPC

-

Are minimum PPE requirements complied with?

-

Is the correct PPE being worn relevant to the exposure risks?

-

Is the PPE in good condition?

Housekeeping

-

Is the work area and lay down area clean and free of excess trash or debris?

-

Are materials and equipment properly stored or stacked?

-

Are scrap materials free of protruding nails or other puncture hazards?

-

Are waste bins available and maintained?

-

Are waratah end caps installed and maintained?

-

Are there any trip hazards i.e., hoses, electrical leads etc.

Hazardous Substances

-

Are hazardous substances being used and stored correctly?

-

Are the amounts of hazardous substances on site limited to an "in use" amount?

Asbestos

-

Has ACM been considered as being present on the worksite?

-

Is an ACM plan in place?

-

Is the ACM plan being followed?

-

Have Worksafe been notified of ACM? (>10sqm friable)

-

Are workers handling ACM competent?

Silica and Inhalable Dust

-

Are bricks and concrete saws operating with water suppression?

-

Is the saw waste water contained to minimise runoff?

-

Is the dust from dried waste water being eliminated?

-

Are power cutting tools fitted with an 'at-source' extraction system and is it effective?

-

Is the vacuum system rated for silica dust ('M' or 'H' class)?

-

Are fibre cement sheets cut using the correct tools/ methods i.e. shears or score & snap method?

-

Are workers exposed to dust wearing P2 rated dust masks?

-

Is the site free from excess settled dust?

-

Is a vacuum system used to clean surfaces?

PAT's

-

Are PATs used by competent operators?

-

Are exclusion zones in place?

-

Are warning signs in place?

-

Are misfired charges secured and discarded correctly?

-

Are the PATs secured when not in use?

Portable Electric Equipment, RCD's & Leads

-

Is portable electrical equipment, RCD's and leads in good working order (all guards in place, no damage to casing, no cuts in cable etc.)?

-

Are power tools used in accordance with the manufacturers instructions?

-

Does electrical equipment have a current test & tag?

-

Are temporary power sources fitted with an RCD i.e. Lifeguards?

-

Are electrical leads routed neatly and away from water sources?

Environmental

-

Are silt fences in place?

-

Is the silt fence in good working order?

-

Are silt socks/gutter bags in place at stormwater inlets?

-

Are the silt socks/gutter bags in good working order?

-

Are accessways metalled?

-

Is sediment and run-off fully contained with the site boundary?

-

Are vehicles/ plant tracking mud into the road reserve?

-

Is dust being controlled on the worksite?

Site Fencing & Security

-

Is the worksite fully fenced?

-

Is the fence in good working order?

-

Is site access controlled?

-

Are site gates lockable?

Hotwork

-

Are hot works being correctly managed?

-

Are hot work activities meeting the hot work permit requirements?

Confined Space

-

Is there a TRA in place for confined space activities (proof of regular review and communicated to all workers involved)?

-

Does the emergency response plan cover confined space rescue?

-

Are confined space activities correctly managed and meeting confined space requirements (i.e. permits, competency requirements etc.)?

Worker Facilities

-

Appropriate number of toilets onsite (male/ female), clean and hygienic?

-

Clean, potable water readily available onsite?

-

Smoko shed available for use?

-

Traffic management plan in place, current and approved by Road Corridor Authority?

Subcontractor Review

-

Subcontractor reviewed:

-

Subcontractor SSSP's in place?

-

Subcontractor SSSP evaluated and verified by lead contractor?

-

Worksafe hazardous work notifications submitted (where required)?

-

TA/TRA's in place where required and signed off accordingly?

-

Training and competency register in place?

-

Plant & Equipment register in place for safety critical plant and equipment?

-

Hazardous Substances register in place?

-

SDS's in place for all hazardous substances on site?

3. Other Observations

-

-

What was your Observation?

Click on the "+ button" over here ---->--->

Observation

-

What was your Worksite Observation?<br>(Select one of the following)

4. Inspection Summary/ Comments

-

Inspection Summary: