Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

-

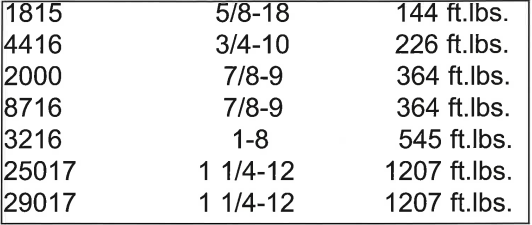

CRANE MOUNT BOLT TORQUE VALUES

-

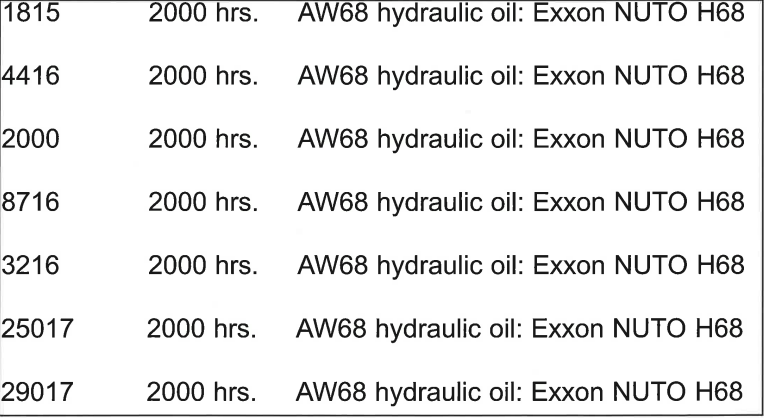

CRANE SERVICE INTERVAL

-

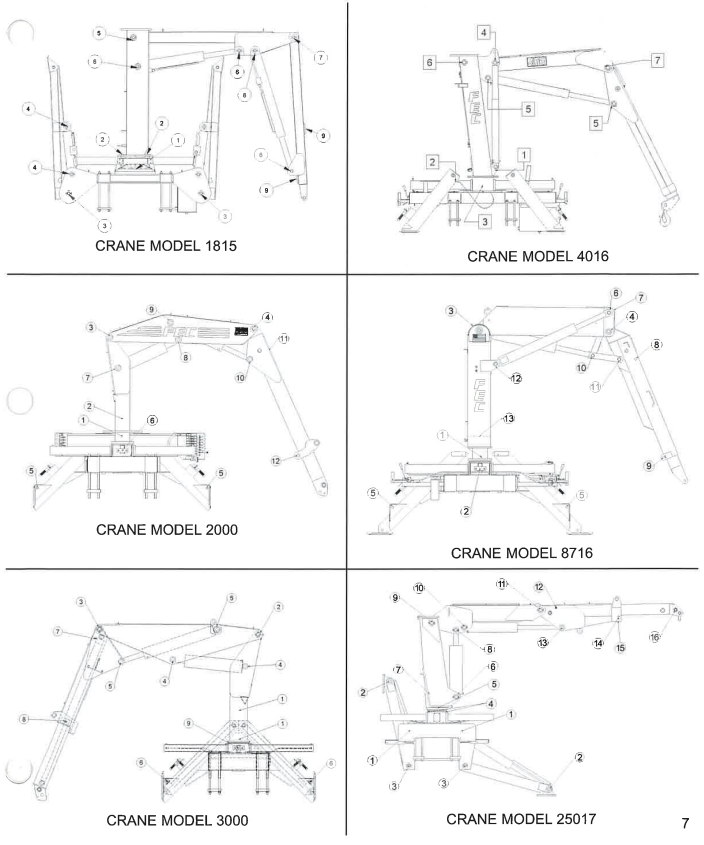

CRANE LUBE POINTS

-

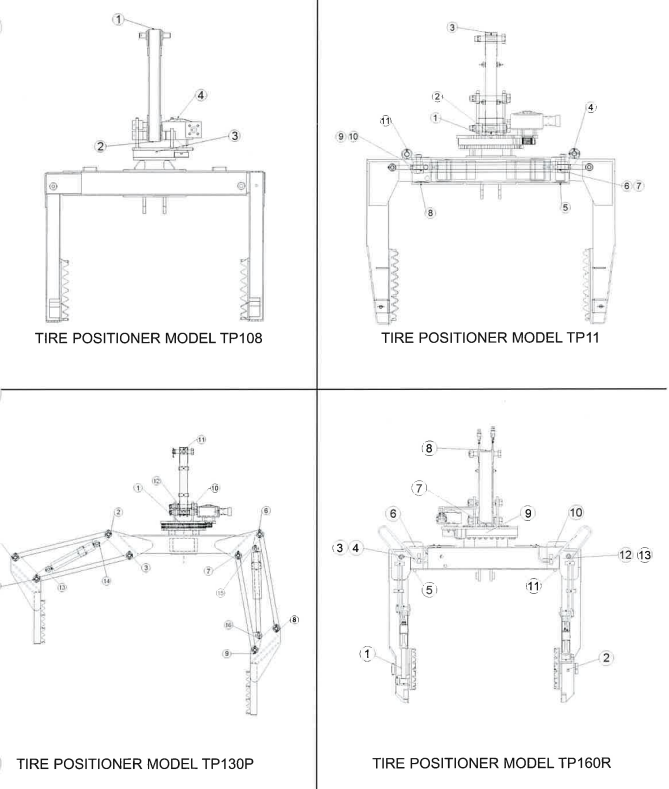

TIRE POSITIONER LUBE POINTS

CRANE INSPECTING

-

-

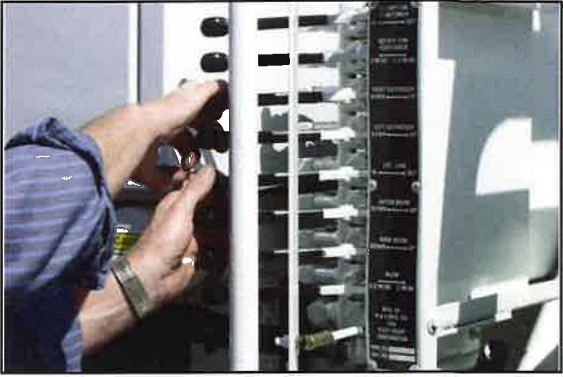

1. Check control levers to make sure all operate smoothly.

-

-

2. Check crane hook, mounting bolt, and safety latch.

-

-

3. Check crane hose routing and fittings for leaks or damage.

-

-

4. Check hydraulic oil in crane tank and check for leaks.

-

-

5. Check hydraulic pressure to make sure pump is operating to specifications.

-

-

6. Check for broken or damaged grease fittings on crane.

-

-

7. Check condition of crane (weld cracks and structural damage).

-

-

8. Check crane boss main boom to mast.

-

-

9. Check crane boss main boom to outer boom.

-

-

10. Check crane mounting bolts and nuts. Hit mounting block with a small hammer to quickly check crane mount¬ing bolts for movement. (Picture shows oversized hammer for illustrative pur¬poses.)

-

-

11. Check safety decal and weight chart make sure all are still on crane.

-

-

12. Check all cylinders for leaks.

-

-

13. Check bushing wear on all pivot points and cylinder ends.

-

-

14. Check pivot link welds and pin condition for any signs of stress. Make sure mount¬ing fasteners are tight.

-

-

15. Check pivot pin retaining device (roll pins, snap rings, and bolts.)

-

-

16. Check Tire Positioner hoses for wear, leaks, loose fittings, and proper mounting.

-

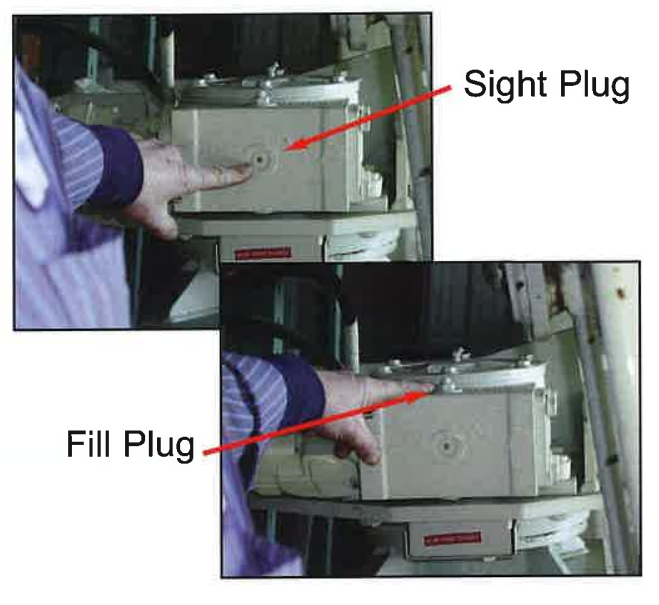

17. Check Tire Positioner gear box oil level.<br><br>1. Stand Tire Positioner up so arms are parallel to crane mast.<br>2. Remove sight plug. Oil should drain out.<br>3. If oil doesn't drain out, remove fill plug and fill with 90W until oil drains out sight plug.

-

-

18. Check for broken or damaged grease fittings on Tire Positioner.

SIGN OFF

-

Name and Signature