Title Page

-

CWP

-

Title:

-

Client:

CALTRANS -

Site:

- Segment 1

- Segment 2

- Segment 3

- Segment 4

- Segment 5

- Segment 6

- Segment 7

- Segment 8

-

Conducted on:

-

Location:

-

Superintendent:

- Roland Sarimento (619) 719-7993

- Jim Baxter (760) 600-1543

- Barney Stenlake (951) 830-0324

- Mike Strachota (760) 497-4505

- Luis Ruiz (909) 721-9775

-

Foreman:

-

Add drawing

CWP Plan

-

Cost code:

-

Plan Number:

-

Start Date:

-

Select date

-

Expiration Date:

-

Select date

-

Plan Creator:

-

Engineer:

- Andy Schalitz (602) 316-8392

- Ryan Adams (951) 232-7285

- Chad Cornwell (858) 776-8998

- Abraham Aceves (760) 446-8167

- Kat La Chapelle (909) 322-4972

- Garrett Stephens (951) 202-3586

- Tim Sorrick (951) 202-6847

- Nate Morrisoe (248) 891-9676

- Victor Sevilla (909) 208-9084

-

EHS Professional:

Site Specific Hazards and Controls

-

This section is designated for Site Specific Hazards & Controls, meaning hazards that are present for every task on the project. Therefore, the entered information will appear on all plans for the jobsite.

-

A typical example would be biological hazards at a sewage treatment plant job. All plans at this job site should address the health risk for working near sewage, and how to address.

-

Further detailed information would be found in the hazard analysis section. This area allows you to bring to everyone's attention some key concerns on the front page of the plan. Please note that unused spaces can be left blank.

Revision Notes

-

Notes

Access to Area

-

This access section is for existing safe pathways to the work area. if access needs to be created, then that work should be put in the Scope of Work ( below ) of this plan or a separate plan.

-

Add media

PPE & Safety Equipment

-

- Power drill

- Impact drill

- Punch drill

- Cut off saw

- Skill saw

- Chain saw

- Saw zaw

- Table saw

- Chop saw

- Jack hammer

- Rivet buster

- Impact wrench

- Grinder

- Percussion hammer

- Router

- Welding machine

- Cutting torch

- Wacker

- Vibrator compactor

- Vacuum truck

- Vibrator

- Pressure Washer

- Power broom

- Leaf blower

- Weed eater

- Post pounder

- Electrical cords

- Chipping gun

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Specific PPE

-

- Hard Hat

- Safety Glasses

- Work Boots

- Safety Vest

- Task Appropriate Glasses

- Safety Harness

- Double Retractable Harness

- Face Shield

- Goggles

- Chaps

- Hearing Protection

- Forearm Protection

- Ear Muffs

- Ear Plugs

- Respirator

- P100 Filter

- Hot Gloves

- Hot Sticks

- Tripod

- Self Retracting Lifeline

- Burning Gloves

- Burning Jacket

- Cutting Gloves

- Welding Shield

- Disposable Coveralls

- Use PPE per Sds

- Clear Safety Glasses

- Halo Light

- Neck Shades

- Cooling Devices

- Full Brim Hard Hat

- PPE or be determined

Emergency Action Plan

-

Superintendents Name:

- Roland Sarimento (619) 719-7993

- Jim Baxter (760) 600-1543

- Barney Stenlake (951) 830-0324

- Mike Strachota (760) 497-4505

- Luis Ruiz (909) 721-9775

-

For medical attention, alert supervisor. Call 911 if needed.

-

EHS Manager's Name:

-

Engineer's Name:

- Chad Cornwell (858) 776-8998

- Abraham Aceves (760) 446-8167

- Garrett Stephens (951) 202-3586

- Tim Sorrick (951) 202-6847

- Kat La Chapelle (909) 322-4972

- Andy Schalitz (602) 316-8392

- Ryan Adams (951) 232-7385

-

Muster Points:

- Jobsite Office

- Manchester Yard

- Loop Ramps

- Work Berm

-

Clinics Name:

- Dunnum Occupational Care

- Scripps Memorial Hospital

-

EMERGENCY CONTACT INFORMATION:

4510 Executive Drive #107,

San Diego, CA

(858) 457 4717 -

EMERGENCY CONTACT INFORMATION:

354 Santa Fe Drive

Encinitas CA

(760) 633-6501

Scope of Work

-

Step

-

Describe the step-by-step sequence of work that will accomplish the task at hand. Keep the text simple and direct. Include work needed to: Create access to the work area and other prep work Make the area safe at the end of each day Leave the area in its final state Don't leave gaps in your work plan. Have another person read the plan to see if they can follow the steps without questions. If you need more than 5 steps, consider whether the task may require more than one plan.

Scope of Work Categories

-

- Excavation

- Exterior Finishes

- Grading and Hauling

- Hazardous Materials

- Interior Fit Out

- Liquid Fuels - Spill

- Marine Work

- Steel Erection

- Storm water - SWPP

- Structures

- Traffic Control and Circuits

- Underground

- Utilities

Triggers

-

Task Environment

- Asbestos

- Bird Droppings

- Chemical Spills / Leaks

- Cold Weather

- Confined Space

- Elevated Work

- Enclosed Area

- Excavation

- Fugitive Dust

- Hot Weather

- Lead Paint

- Lightning

- Low Lighting

- Pedestrian Traffic

- Scaling Rock

- Snow / Ice

- Train Car

- Underground Work

- Utilities - Above Ground

- Utilities - Below Ground

- Vehicular Emissions

- Vehicular Noise

- Vehicular Traffic

- Wet Ground

-

Equipment

- Aerial Lift

- Scissor Lift

- Carry deck Crane

- Cherry Picker Crane

- Crawler Crane

- Gantry Crane

- Mobile Crane

- Mobile Floor Crane

- Overhead Hoist Crane

- Tower Crane

- Drill Rig

- Excavator or Loader with Boom

- Helicopter

- Concrete Buggy

- Concrete Pump

- Concrete Truck

- Backhoe with Hammer

- Bobcat

- Brokk

- Crane with Wrecking Ball

- Excavator with Thumb or Sheer

- Hydraulic Hammer

- Vermeer

- Aggregate Crushing Machinery

- Backhoe

- Bulldozer

- Conveyor Aggregate Delivery Truck

- Excavator Rubber Tires

- Excavator Tracks

- Conveyor Belt Hopper

- Scraper

- Forklift

- Skid Steer

- Rubber Tire Loader

- Track Loader

- Telescopic Handler

- Boom Truck

- Asphalt Paving Equipment

- Pneumatic Tires Compactor

- Vibratory Roller Compactor

- Motor Grader

- Pavement Milling Machine

- Attenuators Truck

- Boomlift Truck

- Dump Truck

- Flatbed Truck

- Pickup Truck

-

Tools

- Baker Scaffold

- Banding Machine

- Bolt Cutter

- 60lb Breaker

- 90lb Breaker

- Broom

- Bucket

- Chain Fall

- Chain Wrench

- Chainsaw

- Chemical Sprayer

- Chisel

- Chop Saw

- Come-A-Long

- Concrete Bucket

- Concrete Mixer

- Concrete Saw

- Concrete Vibrator

- Cutting Torch

- Double Drum Vibratory Roller

- Air Drill

- Electric Drill

- Electric Chipping Gun

- Extension Chord

- Fire Extinguisher

- Float

- Garden Hose

- Gas Cylinder Carts

- Generator

- Georgia Buggy

- GFCI

- Grinder

- Hacksaw

- Hammer

- Pneumatic Hammer

- Hammer Drill

- Hand Saw

- He'll Dog

- High Pressure Spray Gun

- Hoe Rake

- Compressed Air Hose

- Manifold Hose

- Water Hose

- Whip Check Hose

- Hydraulic Wrench

- Jackhammer

- Knife

- Ladder

- Level

- Light Plant

- Line Bar

- Measuring Tape

- Nail Gun

- Nolan Cart

- Check Valves

- Current Probe

- Flash Arresters

- Regulators

- Tip Cleaner

-

Materials

- Asphalt

- Backfill

- Barriers

- Blankets

- Bolts

- Burlap

- Cement

- Concrete

- Concrete Barrier

- Concrete Curing

- Concrete Form Oil

- Concrete Plank

- Cones Box

- Connecting Bar

- Concrete Debris

- Garbage Debris

- Rock Debris

- Soil Debris

- Steel Debris

- Wood Debris

- Drywall

- Dumpster

- Elevator Counterweight

- Elevator Rails

- Chain Link Fence

- Fence Panels

- Flaming Lights

- Forms

- Garbage Pail

- Gas Cylinder

- Gasoline

- GeoTextile

- Geogrid

- Glass

- Grass

- Grout

- Halon

- Hay Bale

- Hydraulic Oil

- Ice Melt

- Lumber

- Masonry Blocks

- Masonry Bricks

- Metal Studs

- Moisture Proofing Material

- Mortar

- Nails / Screws

- Oxy - Acetylene

- Paint

- Concrete Pipe

- Metal Pipe

- Plastic Pipe

- Steel Pipe

- Plants

- Plastic Sheets

- Polyethylene

- PVC Cement

- PVC Primer

- Rebar

- Refrigerant

- Road Plate

- Sand

- Sealant

- Shotcrete

- Silt Fence

- Snow Fence

- Stay form

- Steel Beams

- Misc. Steel

- Steel Plates

- Stone

- Styrofoam

- Super Plasticizer

- Tie Wire

- Tie Wraps

- Timber

Hazard Awareness Acknowledgment

Risk Control Adequacy Statement

-

SUPPORT - Is the type / amount / capability / condition of support adequate to carry out the activity?

-

Personnel

-

Supplies

-

Equipment & Materials

-

STANDARDS - Is guidance adequately clear / practical / specific to control the hazards?

-

TRAINING - Is training adequately thorough and recent to control the hazards?

-

LEADERSHIP - Is the project management team ready, willing, and able to enforce the standards required to control the hazards?

CWP Acceptance

-

Project Manager

-

Superintendent

-

EHS Professional

-

Foreman

Crew Members

-

Crew Member

-

Add signature

Hazards Identified

-

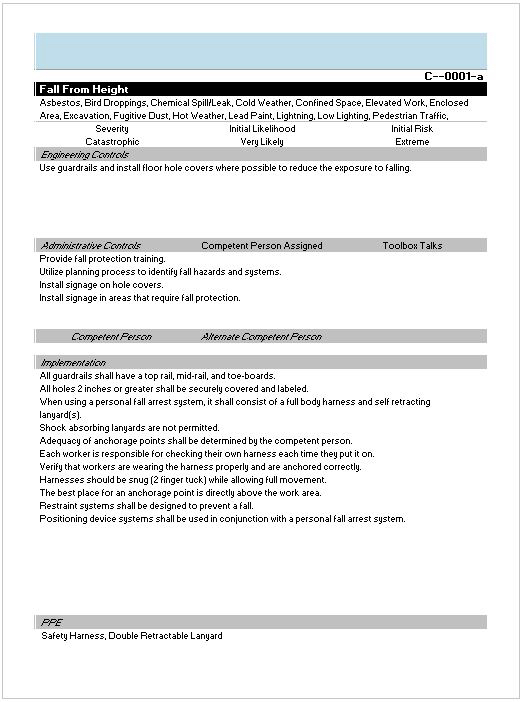

- Fall From Height

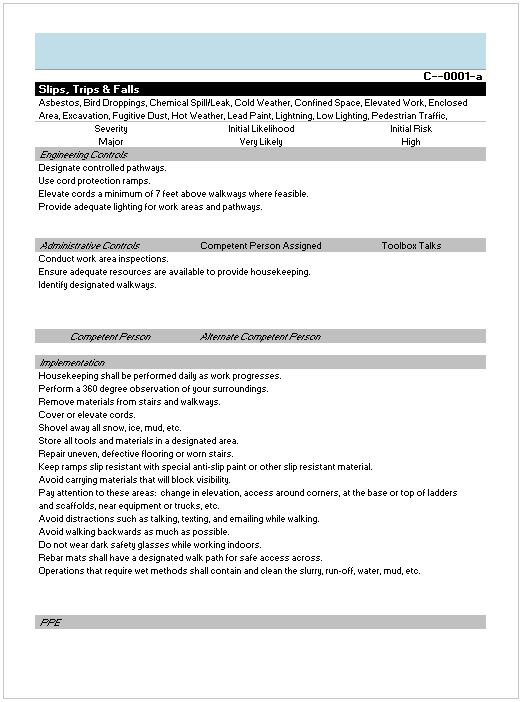

- Slips, Trips, & Falls

- Stains & Pulled Muscles

- Power Hand / Tool Injuries

- Struck By / Caught Between

- Flying Objects

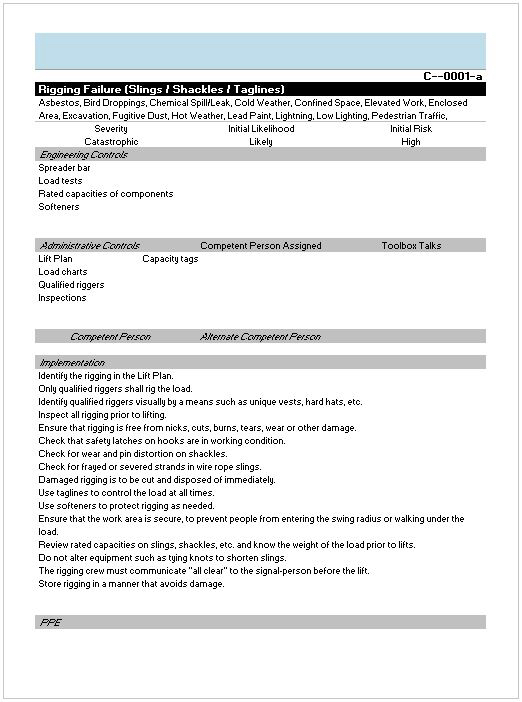

- Rigging Failure ( Slings / Shackles / Taglines )

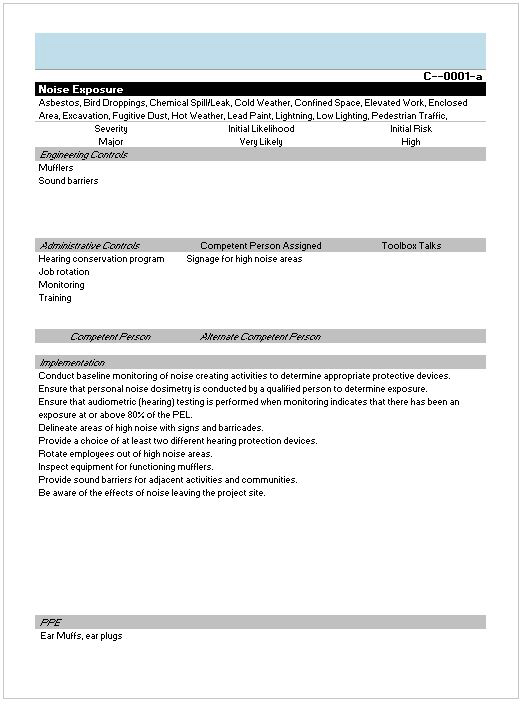

- Noise Exposure

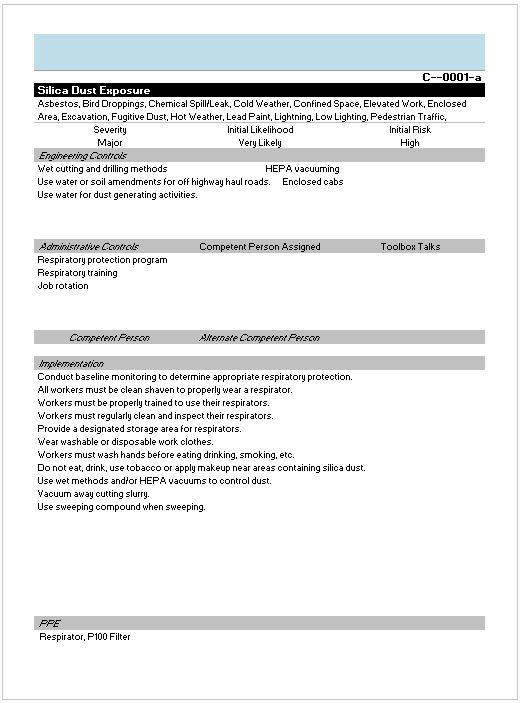

- Silica Dust Exposure

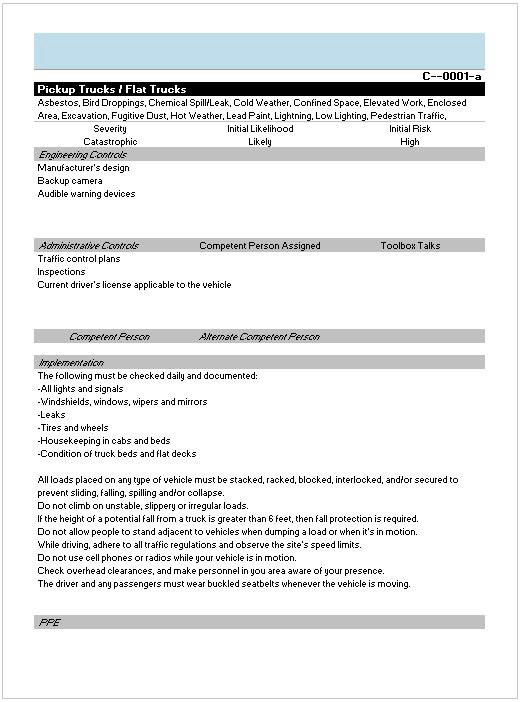

- Pickup Trucks / Flat Trucks

- Electrocution/ Shock

- Confined Space

- Aerial Work Platform

- Hotwork ( Burning / Welding / ETC. )

- Lead Exposure

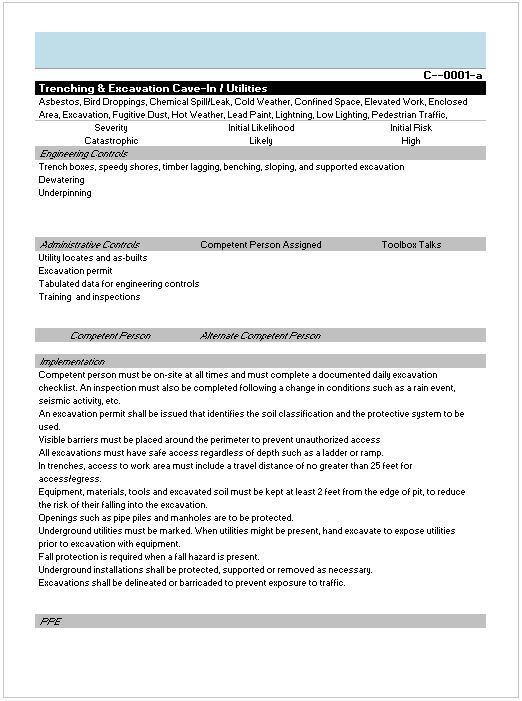

- Trenching & Excavation Cave-In / Utilities

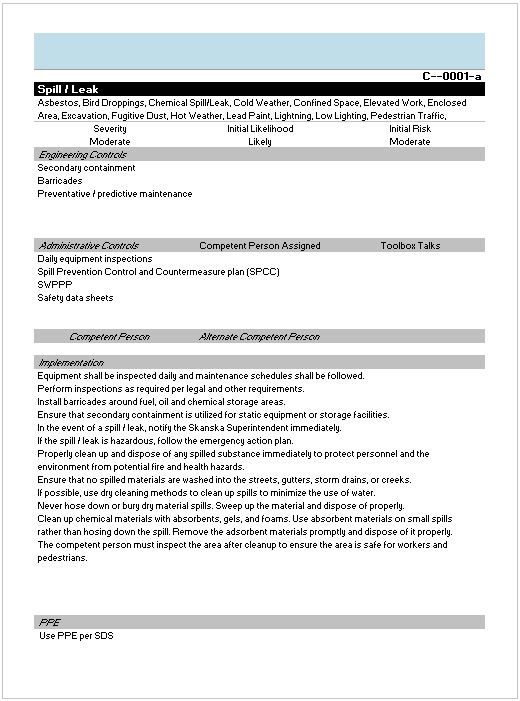

- Spill / Leak

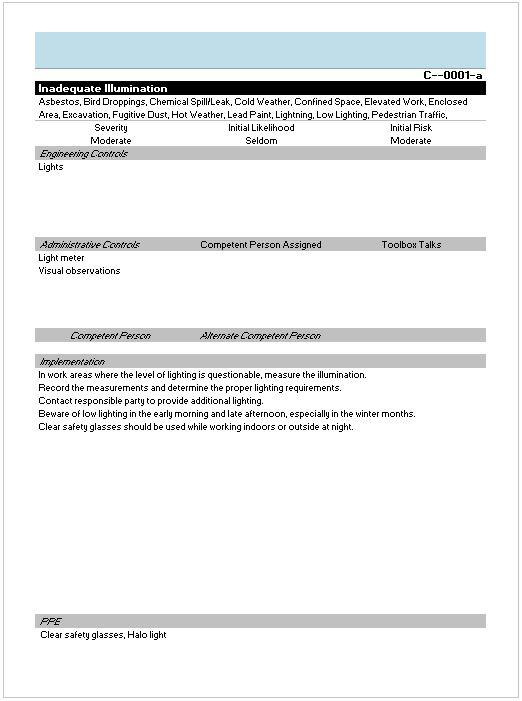

- Inadequate Illumination

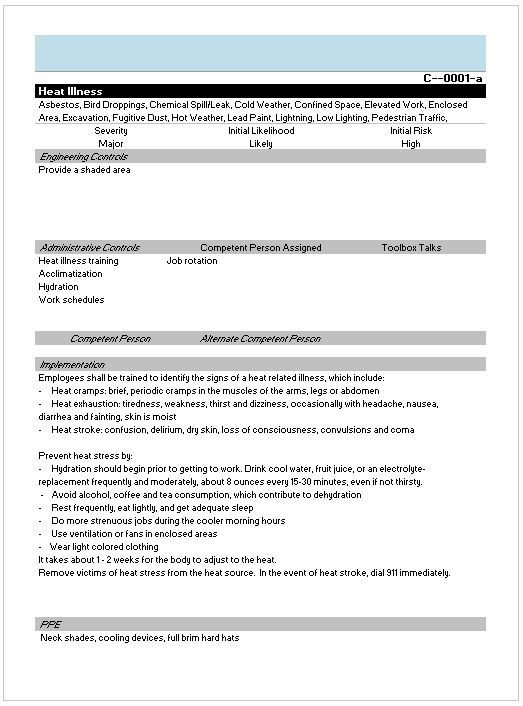

- Heat Illness

- Compressor / Air Pneumatic Tools

- Hazardous Soil

- Scaffolds / Temporary Works

- Stairway / Ladders

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Environmental Aspects

-

- Archaeological, Cultural and Historic

- Community Impacts: Transportation, Traffic Circulation & Economic

- Community Impacts: Utilities

- Dewatering

- Flora, Fauna and Habitat Areas (Wetlands)

- Hazardous Materials and Waste Management

- Indoor Air Quality

- Materials and Waste Management

- Noise and Vibration

- Outdoor Air Quality

- Potential & Unforeseen Upset Conditions ( Spills / Leaks )

- Soil Erosion and Sediment Control

-

-

-

-

-

-

-

-

-

-

-

Unforeseen Conditions

New Job Steps

-

Step

-

Describe the step-by-step sequence of work that will accomplish the task at hand. Keep the text simple and direct. Include work needed to: Create access to the work area and other prep work Make the area safe at the end of each day Leave the area in its final state Don't leave gaps in your work plan. Have another person read the plan to see if they can follow the steps without questions. If you need more than 5 steps, consider whether the task may require more than one plan.

Triggers

Additional PPE

-

Additional Controls Checklist

- First Aid

- Evacuation

- HazCom

- Nearest Safety Shower / Eyewash

- Access / Egress

- Material Storage

- Equipment Inspection

- Signs / Signals / Barricades

- Weather

- Nearest Fire Extinguisher

- Combustible Materials Removed

- Spark Containment

- Fire Extinguisher

- Trained Fire Watch

- Fire Blanket

- Proper Body Position

- Proper Lifting Methods

- Lifting Devices Needed

- Adequate Personnel

- Forklift

- Cherry Picker

- Load Chart

- Position

- Angle

- Crane

- Chain fall

- Proper Rigging

- Condition of Equipment

- Proper Tools Used

- Tool Used Properly

- Ground Fault System

- Color Coding

- Daily Inspection

- Lockout / Tagout

- Try Start / Stop Switch

- Disconnected (if required)

- Properly Grounded

- Ladder Tags

- Proper Footing

- Tie Off Rope

- Hoist Rope

- Handrails

- Mid rails

- Toeboards

- Scaffold Tags

-

Additional Controls Checklist

- Competent Person Onsite

- Excavation Inspection Form

- Guard Rail Removal Permit

- Hot Tap / Pressurized / In-Service Lines / Vessels Form

- Hot Work Permit

- Lift Plans - Critical, Personnel, ETC.

- Lockout / Tagout Evaluation Form

- Lockout / Tagout Shutdown Equipment Form

- Lockout / Tagout Evaluation Form

- Lockout / Tagout Shutdown Equipment Form

- Lockout / Tagout Removal Form

- Material Handling Inspection Log

- Notice to Commence Steel Erection

- Ready to Work Form

- Safety Data Sheets

- Work Site Safety Inspection Form

- Daily Inspection Documented

- Soil Class Documented

- Entry Permit Required

- Shored / Sloped Properly

- Access / Egress

- Air Monitoring

- Rigging

- Taglines

- Floor Requirements

- Lifting Plan

- Erection Plan

- Slings Inspected

- Checklist Performed

- Hot Work Permit

- Systems Drained

- Water Hose

- Flash back Arrestor

- Fire Watch

- Welding Screens in Place

- Welding Leads in Good Condition

- Fire Extinguisher

-

Approvals

If conditions exist beyond the printed plan which are written here, each employee involved in the job will review and sign this analysis before beginning work.

Crew Member

-

Add signature

Lessons Learned

-

Things Done Well - - Keep Doing

-

Things That Didn't Contribute - - Stop Doing

-

Things We Could Do Better - - Start Doing