Information

-

Inspection Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Information and Documentation

Work Activity

-

Provide a brief description of the work being carried out.

-

Add media

-

Are the actions from the previous inspection closed out?

SAFE PLACE OF WORK

-

Is a safe means of access/egress provided for personnel?

-

Is work area firm, level & suitable (free from trip hazard).

-

Is segregation in place?

-

Is the work area tidy (Housekeeping).

PERMITS

-

Permits required?

-

Are there safe systems established for all permits issued?

-

Are permits closed out correctly?

SITE ACCESS & TRAFFIC ROUTES

-

Are vehicles & pedestrians segregated?

-

Are traffic marshals employed to direct traffic on and off site?

GENERAL ITEMS

-

Are there any services within the piling area.

-

If yes to the above are they signed and marked.

STORAGE & MOVEMENT OF MATERIAL

-

Is there a safe clean segregated working area for steel fixers?

-

Are fire extinguishers located around the fuelling station and the correct type?

PPE - PERSONAL PROTECTIVE EQUIPMENT (Is correct PPE in use)

-

Is standard 5-point PPE in use?

-

Are there any site-specific special requirements for PPE?

-

Is the pump operator wearing hearing protection, eye protection, and waterproof gloves?

RIG / FOREMAN DOCUMENTATION

-

Daily / Weekly Plant Inspection Checklist completed. (LOLER PUWER)

-

Are lifting certificates on site and in date?

-

Is rig guarding being used?

-

If guarding can not being used as designed, is there relevant documentation used and are exclusion zone in place?

-

Piling platform certificate completed & available.

-

Toolbox Talks completed.

-

Is the site specific method statement on site and signed by all staff?

-

Is the site specific Risk assessment on site?

-

Is the site specific lift plan on site and signed?

-

Is the COSHH/blowing out procedures pack available for review?

PLANT AND SAFETY EQUIPMENT

-

Safety harness and lanyard in date?

-

Spill Kit(s) available on site?

-

Are drip trays in use?

-

Diesel Storage tank free from leaks?

-

Are blow out cannons in good condition? (free from defects/concrete build up)

-

Is the blow out containing device being used?

PILING RIG AND EQUIPMENT MAINTENANCE

-

What is the condition of augers?

-

Any maintenance related issues?

OCCUPATIONAL HEALTH

-

Adequate montoring of vibration?

-

Adequate monitoring of noise exposure?

-

Suitable control measures for dust exposure

-

Avoid, assess, reduce principle adopted for manual handling?

End of Inspection

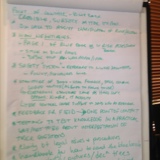

- Observations

-

Media

-

Comments

End of Inspection

Signature of auditor

-

Add signature

Signature of supervisor

-

Add signature