Title Page

-

Prepared by

-

Conducted on

-

Location

-

Site conducted

SAFE WORK METHOD STATEMENT (SWMS)

COMPANY DETAILS

-

Subcontractor Name

-

Contact Name

-

ABN/ACN

-

Contact Position

-

Address

-

Contact Phone No.

SCOPE OF WORK DETAILS

-

Project Name

-

Date Submitted

-

SWMS Title

Permit Required

-

Concrete Cutting/Coring

-

Confined Space

-

Hot Work

-

Excavation

-

Lifting

-

Working at Height

-

Not applicable

-

Will powered plant been inspected before use?

-

Have applicable drawings been identified?

- Yes

- No

- N/A (i.e. Dial Before You Dig, Structural Drawings, Tilt-up plans etc.)

-

Materials Used

-

Are hazardous substances involved?

-

Have MSDS's been supplied?

-

Legal Requirements Applicable (Legislation, Permits, Approvals, etc.)

-

Australian Standards, Codes of Practice or Guidance Notes

Plant/Equipment Used

-

Plant:

-

Equipment:

SWMS Developer

-

Name:

-

Signature

-

Date:

Site Approved

-

Name:

-

Signature

-

Date:

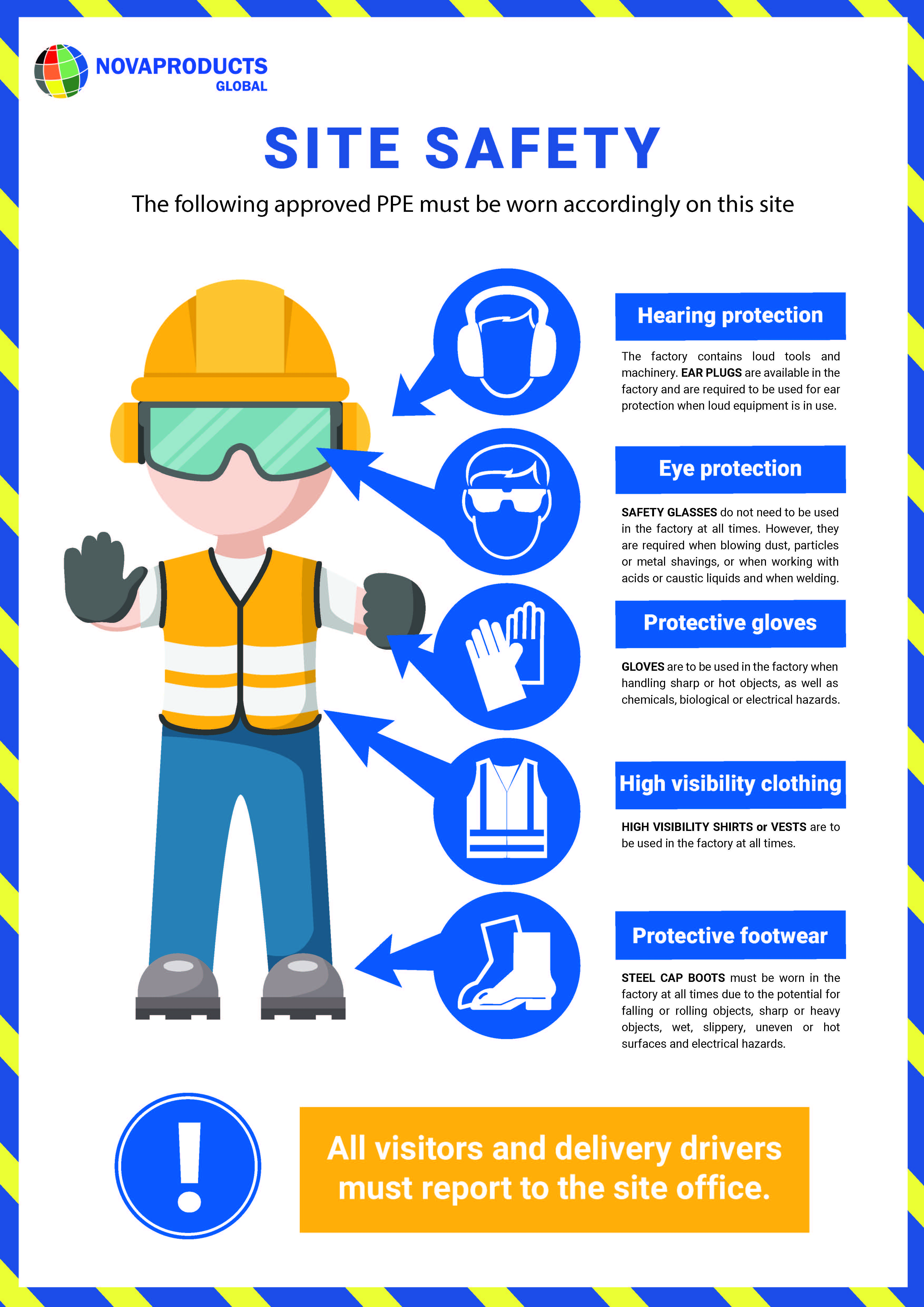

PPE (Personal protective equipment)

-

-

Head Protection/Safety Helmets/Hard Hat

-

Foot Protection/Safety Shoes

-

Protective Clothing/Reflective Vests

-

Eyes and Face Protections

-

Hand Protection

-

Hearing Protection

-

Safety Belts/Safety Harness

-

Respiratory Protection

-

Leg and Foot Protection

-

Skin Protection

-

Personal Fall Protection (i.e Travel-restraint system, Positioning system, Fall-arrest system)

HAZARD IDENTIFICATION (tick all the apply – add additional as necessary)

Hazards

-

Traffic Management

-

Pedestrians / Unauthorised persons

-

Underground / Overhead services

-

Pressuried fluid/Gas

-

Electrical Hazards

-

Confined Space

-

Hazardous Atmosphere

-

Flammable Materials

-

Combustible Materials

-

Hazardous Substances

-

Working at Heights

-

Suspended Loads

-

Plant Hazards

-

Moving machinery – mobile plant

-

Vibration or noise – plant & equipment

-

Temperature Extremes

-

Weather Extremes

-

Air emissions-dust, fumes

-

Steep Terrain

-

Soil disturbance/Erosion

Workplace Hazard

-

Manual Handling

-

Difficult entry/exit

-

Slip/Trip Hazards

-

Falling Objects

-

Fatigue

Environmental Hazard

-

Communications

-

General waste

-

Hazardous waste

-

Noise

-

Other

COMPETENCIES REQUIRED (tick all that apply - add additional as necessary)

-

White Card

-

Electrical Licence

-

Rigging

-

Plumbing Licence

-

Scaffolding

-

Tilt Panel

-

Plant Operation

-

Forklift

-

Other

-

Describe it:

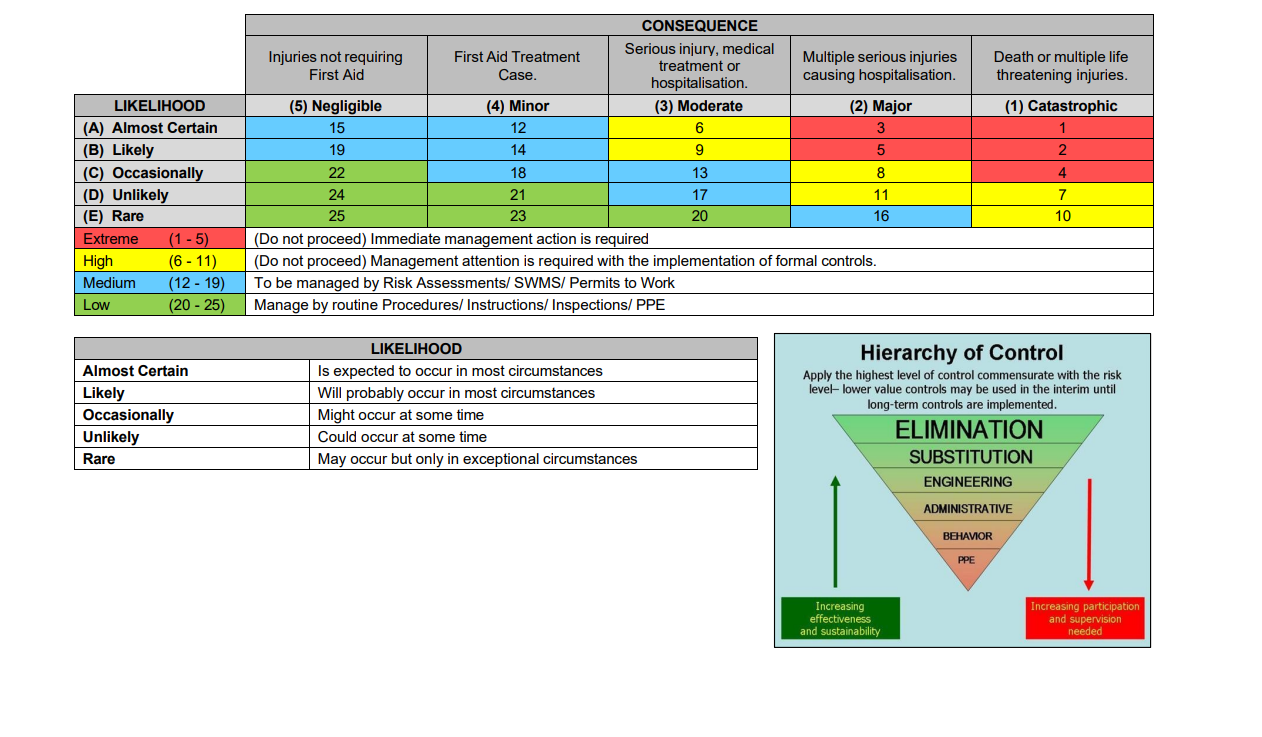

CONSEQUENCE

-

This OHS Risk Matrix is to be used when assessing levels of risk and defining appropriate safety controls to commencing work activities.

Methods of Installation

-

Job Steps

-

Hazards

-

Initial Risk (before controls)

- Catastrophic A1

- Catastrophic B2

- Catastrophic C4

- Catastrophic D7

- Catastrophic E10

- Major A3

- Major B3

- Major C8

- Major D11

- Major E16

- Moderate A6

- Moderate B9

- Moderate C13

- Moderate D17

- Moderate E20

- Minor A12

- Minor B14

- Minor C18

- Minor D21

- Minor E23

- Negligible A15

- Negligible B19

- Negligible C22

- Negligible D24

- Negligible E25

-

Risk Controls

-

Residual Risk (after controls)

- Catastrophic A1

- Catastrophic B2

- Catastrophic C4

- Catastrophic D7

- Catastrophic E10

- Major A3

- Major B3

- Major C8

- Major D11

- Major E16

- Moderate A6

- Moderate B9

- Moderate C13

- Moderate D17

- Moderate E20

- Minor A12

- Minor B14

- Minor C18

- Minor D21

- Minor E23

- Negligible A15

- Negligible B19

- Negligible C22

- Negligible D24

- Negligible E25

-

Qualification or Training Required

-

Name of Person Responsible for Control

Historical Information or Data

-

What incidents have occurred in the past as a result of this activity or similar tasks? Is any information available on illness or disease related to this task?

Environmental Controls (AS/NZS 14001)

-

What environmental risks are involved in the task and how will they be controlled? (i.e. Noise & Vibration, Waste Material, Water Pollution, Fire, Hazardous Substances or Air pollution etc.)

Site Specific Considerations

-

Are there other trades or plant working in the same vicinity as this task? Will this task impact upon other trades? What new conditions do personnel need to be aware of?

Implementation

-

I, ___________________, from Novaproducts have developed this SWMS as the safe system of work governing this task. I will supervise this work, control the identified risks, and require all personnel involved in this task to read, understand, and sign this document before commencing work. Furthermore, I will review and update this SWMS whenever site conditions change and communicate these changes to all personnel involved in this task.

-

Signature

Review

-

The SWMS is to be reviewed every thirty (30) days or when;

• A change in the work activity occurs,

• Conditions change, or;

• A new hazard or control is identified

Changes to the SWMS are to be made by the Work Team Supervisor and signed off by a member of Site Management. All personnel involved in the task are to resign from the SWMS after a revision has been made.

If there are no changes required after a review, the Work Team Supervisor shall write “reviewed – no change” (or R.N.C) in the “Key Changes / New Hazards / Reviews” column. The Work Team Supervisor and member of Site Management will sign it off.

Changes to the SWMS

-

Key Changes / New Hazards Reviews

-

Controls

-

Residual Risk

-

Date

-

Work Team Supervisor (Name)

-

Work Team Supervisor (Signature)

-

Site Management (Name)

-

Site Management (Signature)

Declaration

-

Declaration by those signing below:

• I have been consulted and have assisted in the development of this SWMS.

• I have been given the opportunity to comment on the content of this SWMS.

• I have read and understand how I am to carry out the activities listed in this SWMS.

• I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment.

• I have read and understand the requirements set out in the material safety data sheets for the hazardous substance identified in this SWMS.

Declaration by those signing below:

-

Print Name / White Card No.

-

Signature (I have been consulted and understand this SWMS)

-

Date

![[DRAFTING TEMPLATE] SAFE WORK METHOD STATEMENT (SWMS) [DRAFTING TEMPLATE] SAFE WORK METHOD STATEMENT (SWMS)](/media/d3dd3e34-0608-4ab7-a82e-b3cfae18d26e)