1.0 - BLANK HOPPER. (Q2400) & ( mb/2 ms)

1.1 All components , present and tight

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

1.2-Hopper central, position, blank fit

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

1.3-stack retainers operation, position

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

1.4- Photoeye operation, position and condition of hopper

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

2.0 - VACUUM PULL DOWN

2.1 - Cups and hoses, condition, position, operation

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

2.2 -vacuum pull down arms, position, condition, timing, lube

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

2.3 - Vacuum release valve condition, timing, operation

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

2.4 VENTURI and filters condition, operation, cleanliness

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

3.0-BLANK PUSHER FEED

3.1-Ensure back dead centre is 0+/-4 on encoder position

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

3.2-- Pusher chain condition, tension and lubrication

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

4.0- HOTMELT

4.1Glue pattern , position, size<br><br><br>

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

4.2- Glue tank condition, charring, overflow, damage, operation

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

4.3 - Guns and hoses, tight, leaks, abrasion, position, guiding

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

4.4- Photoeye condition, position, sensitivity

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.0- FORMING

5.1-Blank position, guiding, movement, & rebound stops

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.2-Mandrel Rack & Pinion condition, Lube, grease points fitted

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.3- chamber, central, wear, operational, all parts present and tight

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.4-Roll over Rack and pinion operation, condition & lubrication

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.5 -Laminator Rack and pinion operation, condition and lubrication

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.6- Mould press condition, operation, speed, mounts , timing

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.7-claw condition, operation, speed, mounts, timing

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

5.8- Expulsors condition, operation, lube, guides, bearings

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

6.0 DRIVE SYSTEMS 7.0- STACKER

7.1- Belt condition, tension, tracking and lubrication

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

7.2 - Elevator cylinder operation, condition, air leaks, lubrication & latches

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

7.3- Stack eject cylinder operation, condition, airleaks and Lube

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

7.4- Electrical cAbinet, controls and PE operation , condition and cleanliness

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.0 -ELECTRICAL

8.1 - Elect cabinet, tidy, clean, locked, main switch lock fitted

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.2 - Contactors, operation, condition

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.3-Push buttons, operation, condition, labelled

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.4- Wiring, condition, tidy, fastened, tagged

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.5- P.L.C battery condition

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.6 glue pattern controller operation, condition

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

8.7 - Hot melt time clock, setting, operation

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

9.0 Pneumatics

9.1. - Cylinders, valves and tubes condition, operation, air leaks

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

9.2 - Air supply unit condition, operation, gauges and auto drains

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

9.3- Pressure settings all regulators ( record values)

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10 - SAFETY

10.1 -Emergency stops condition, operation and labelled

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.2- Guard safety switches operation, condition

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.3- Top FORMING chamber guard condition, operation, correct lift kit

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.4-All fixed guards in place , secure

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.5 - All warnings and labels in place, readable

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.6-Lightening, adequate, turned on

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.7- Clean And safe work area around m/c . PPE available and cond

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

10.8- Only trained operators operating machine

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11- GENERAL

11.1- machine cleanliness condition, over, under, deck, glue overspray

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.2- Machine feet and jacking screws condition, present and tight

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.3- Mounts and fastening present , tight bolts

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.4- Timing of VAC cups, Mandrel and Pneumatics( rectify if necessary)

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.5-Wind DIAL counters equal actual measurements

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.6- Set up sheet and change over procedures available, correct

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.7- Manual and holder , fitted, condition

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.8- MEX I.D tag fitted on all components

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

11.9- Product reject rate square, parallel, damage free, all glue bonded

0- failed

0.5-worn ( out of tolerance)

0.9-slight wear

N/a

1-ok

Sign Off

On site representative

Sign

Auditor's signature

Sign

Select date

Date

link copied

Eugene Raman

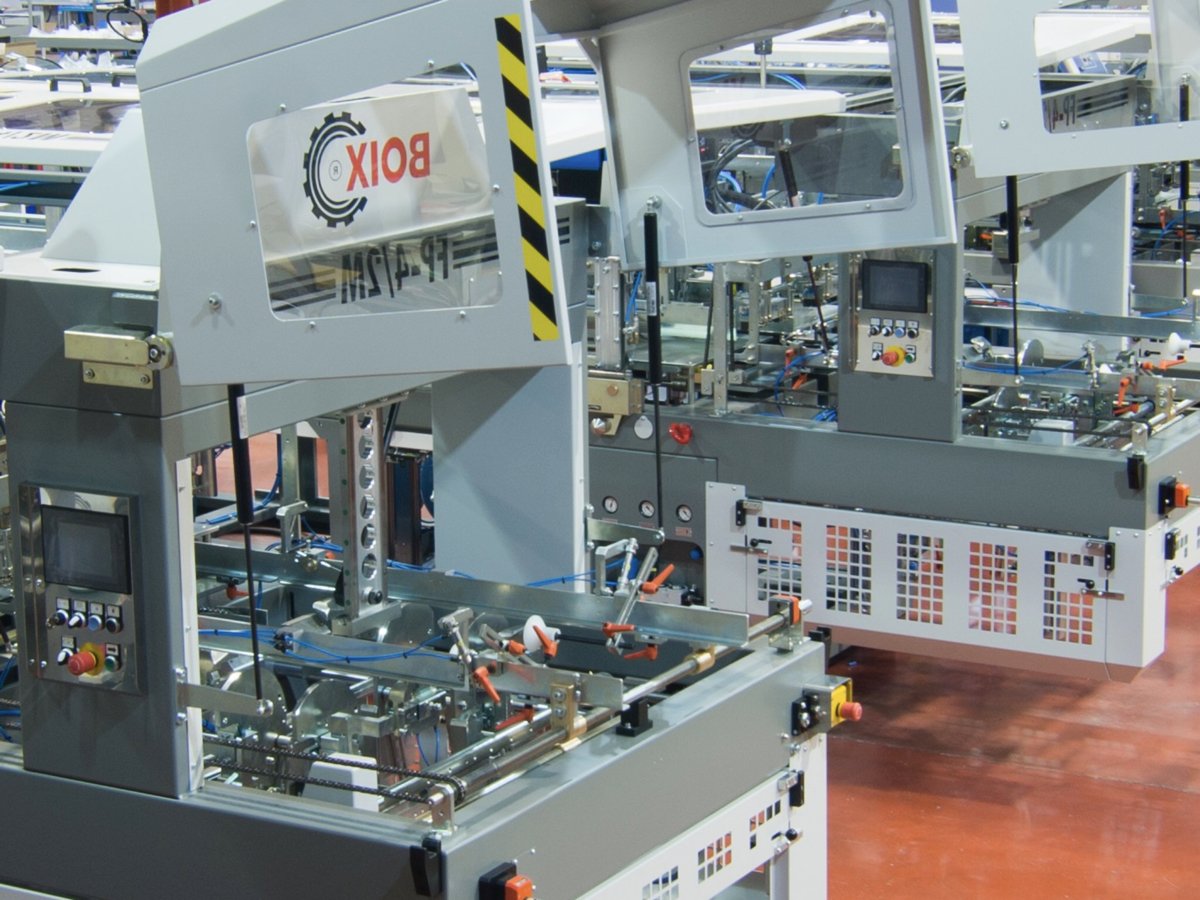

Erecting machine audit - mb/2 ms & Q 2400

The templates available in our Public Library have been created by our customers and employees to help get you started using SafetyCulture's solutions.

The templates are intended to be used as hypothetical examples only and should not be used as a substitute for professional advice.

You should seek your own professional advice to determine if the use of a template is permissible in your workplace or jurisdiction.

You should independently determine whether the template is suitable for your circumstances.