Title Page

-

Audit Title

-

Conducted on

-

Client / Site

-

Location

-

Prepared by

-

Personnel

Equipment/Assured Grounding Inspections

-

All ladders inspected?

-

All electrical equipment connected to GFCI power supply?<br>

-

All extension cords inspected?

-

All corded tools inspected? (Drills, porta band, power pony, etc)

-

All fall protection inspected? (Harnesses, lanyards, retractables, beavers, etc)

-

All rigging equipment inspected?

-

All scissor/aerial/boom lifts inspected daily?

-

Fork lift pre-use inspection completed?

-

Is there a site appointed Designated Safety Coordinator?

-

All equipment in satisfactory condition?

-

Equipment inspection color. Jan/Feb-Red Mar/Apr-Blue May/June-White July/Aug-Brown Sept/Oct-Yellow Nov/Dec-Orange.

Work Area Compliance

-

Work areas organized and free of debris/trip hazards?

-

Chemicals properly stored in approved containers?

-

Scrap/trash/oily rag containers emptied regularly? Not overflowing?

-

Fire extinguisher inspected and secured in correct place?<br>

-

First aid kit in place and inspected weekly? Are all contents up to date?

-

ESCO Group Chemical Inventory (SDS) and Safety Manual in place?

-

All paperwork posted in proper location? (Emergency Numbers, Labor Law, Medical Facilities, OSHA 300 Logs)

-

All ladders are secured properly? (Chained or laid down)

-

All benders properly secured to their cart/bench?

Safe Work Practices

-

Employees have Pre Job Hazard Analysis completed?

-

Employees following safe ladder practices?

-

Employees have all proper permits, forms, and tags in place and used properly?

-

Confined space, hot work, excavation, elevated work, energized work, existing conduit removal, verified de-energized tag in place, ground tags with locks.

-

Employees know where ESCO Group Chemical Inventory (SDS) and Safety Manual are located?

-

Employees know where to go in case of an emergency?

-

Safety Meetings completed weekly?

-

Toolbox talks completed as required?

-

Employees have an adequate supply of potable water in place?

-

Employees provided adequate restrooms?(Stationary crews)

-

Employees provided with hand washing station/hand wipes?

-

Employees wearing all basic PPE requirements?

-

Hard hats, safety glasses/face shields, goggles, gloves, hearing protection, safety footwear, Arc Rated clothing.

-

Employees using proper gloves?

-

Are grinders, band saws, and similar equipment provided with appropriate guards?

-

Employees operating powder-actuated tools? Have they been properly trained?

-

Employees following safe scissor/aerial/boom lift work practices? Have they been properly trained? Are employees properly tied off when needed?

-

Employees following safe fall arrest/restraint practices?

-

Employees wearing harnesses properly?

-

Employees using fall arrest system properly?

-

Employees following customer fall protection requirements?(i.e. 4th step rule)

-

Employees operating forklifts/reach forklift/telehandler? Employees properly trained?

-

Has the ESCO Group client safety exchange taken place?

Voltage Rated Equipment/Electrical Safe Work Practices

-

All voltage rated equipment up to date on testing? (Gloves, grounds, hot sticks, blankets, sleeves)

-

Employees using Voltage Rated PPE correctly? (Check levels and layers of PPE)

-

Employees testing before they touch when working on electrical equipment?

-

Employees have adequately rated meter for detecting voltage?

-

Lockout/Tagout being performed correctly? (LOTO audit form available for reference)

-

Employees using appropriate tools to perform work within electrical equipment?

-

Temporary lighting suspended by nonconductive means and fully protected?

-

Employees have all transformers clear of material/equipment around and on top of?

-

Temporary electrical service panel properly labeled, receptacles labeled, penetrations covered, weather covers in place, NEMA rating, strain relief, properly secured/mounted?

-

Do employees have grounds applied? Did employees apply lock on box for grounds?

-

Voltage rated equipment stored in proper location?

-

Overall summary of the job site safety performance.

-

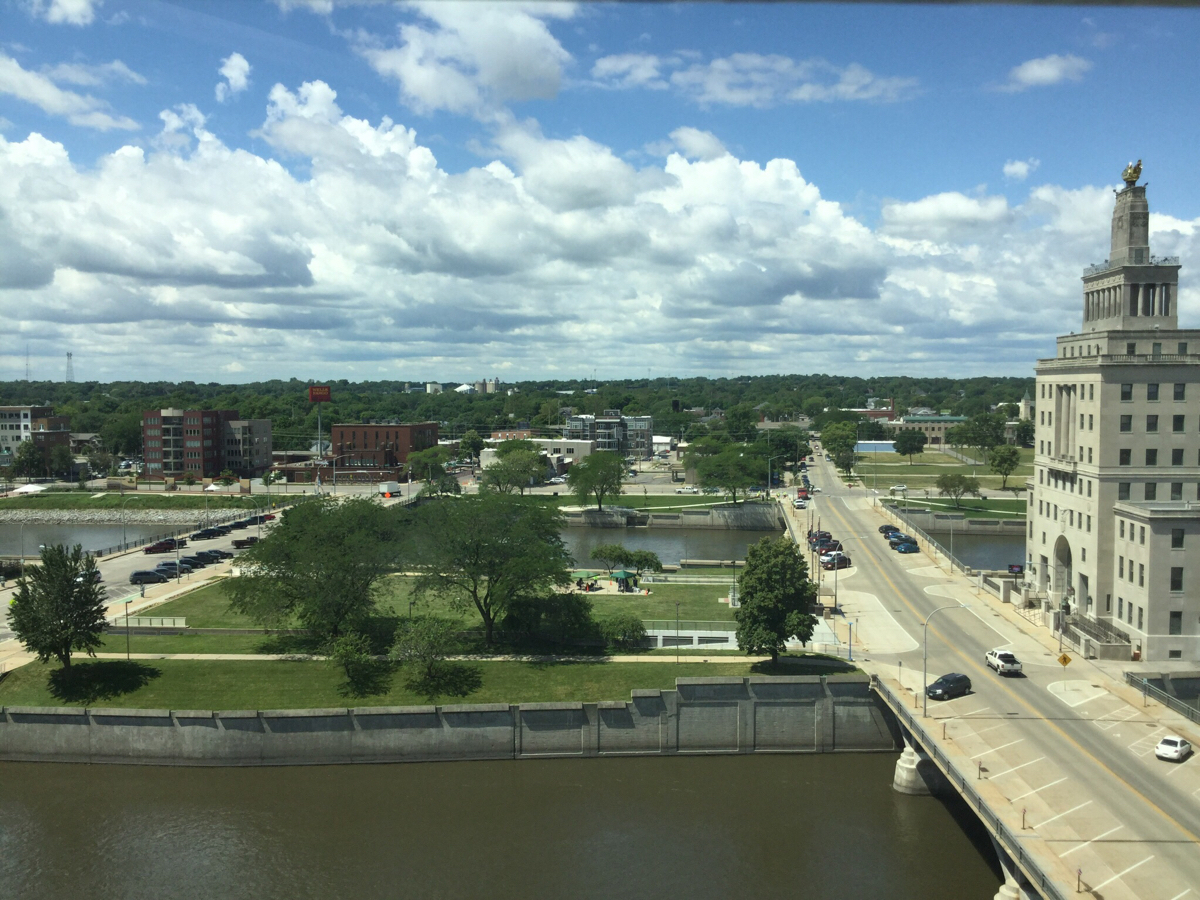

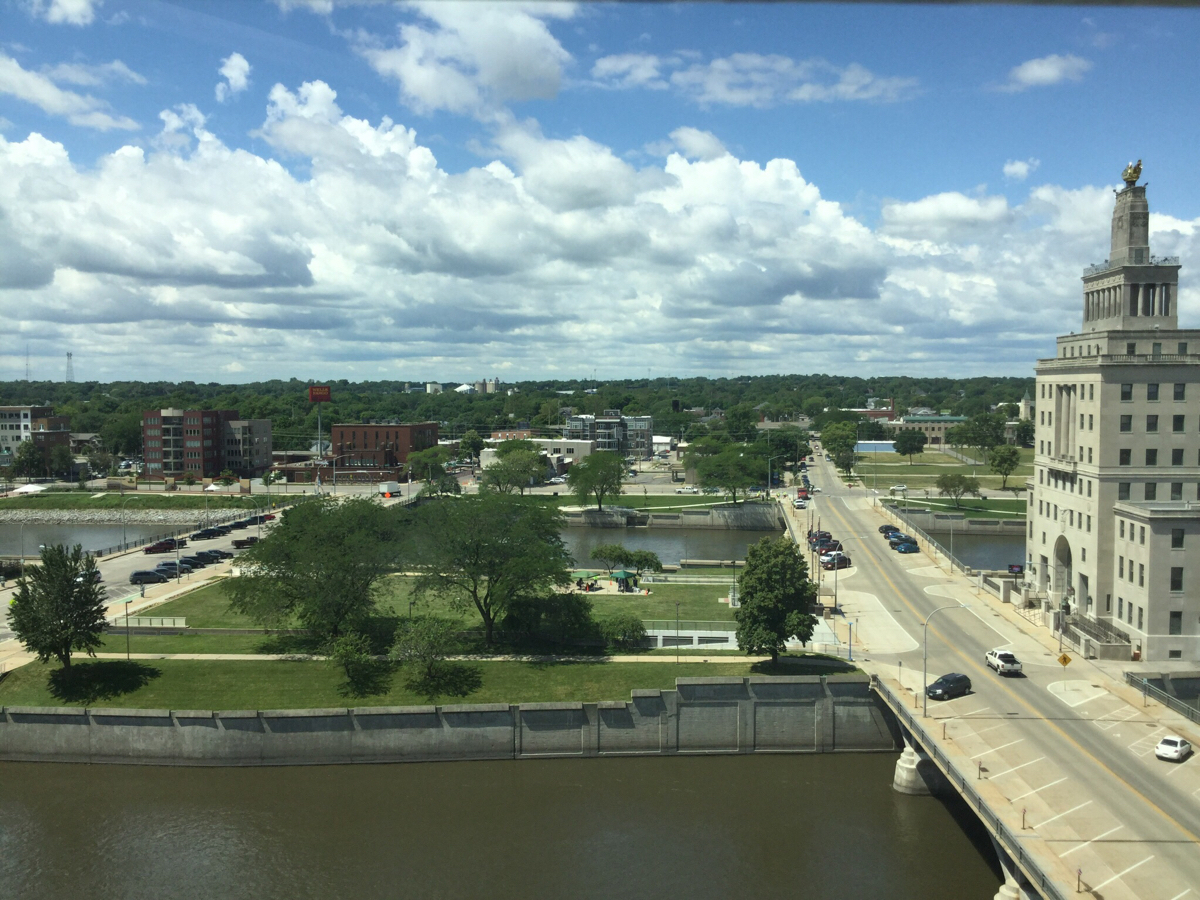

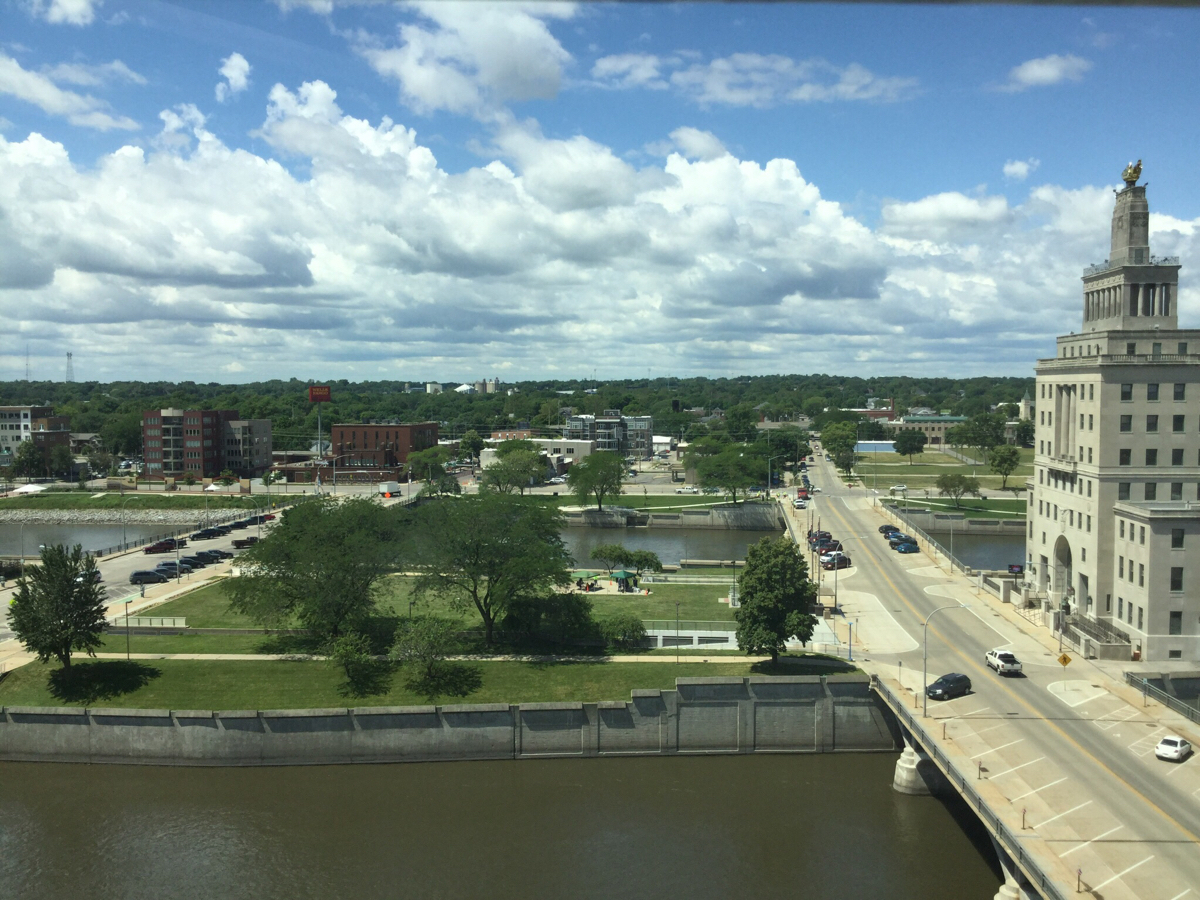

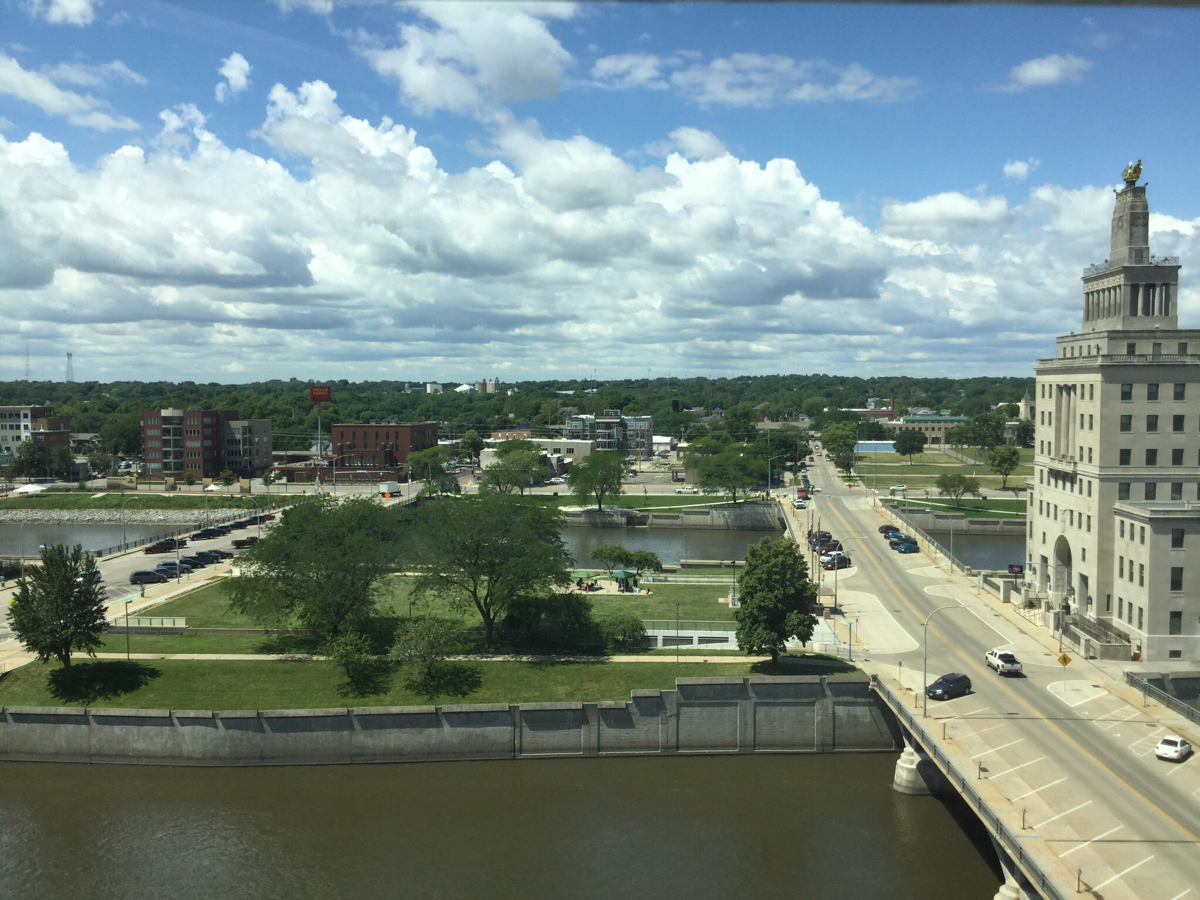

Pictures of overall project status.

-

Signature