Information

-

Audit Title

-

Document No.

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Material management

-

Is the material packaged in a manner to prevent physical damage?

-

Are the materials in the EPA in packing that prevents static electricity building up? (do not be guided by the colour, the packing should exhibit the ESD protective symbol)

-

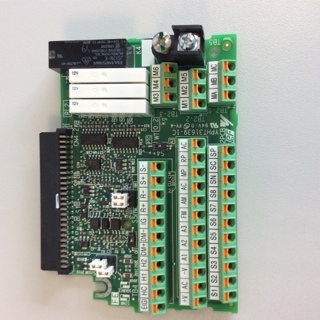

Circuit boards (PCB/PCA) should be stored in a sealed static shielding package

-

Circuit boards ready to use are stored in a dissipative PCB holder/tray. Are these trays grounded or located on a grounded surface?

-

Are material kitting boxes free from all static generating materials?

-

Are static sensitive components and assemblies are correctly packaged?

-

Are shielded bags used to protect the material in good condition?

-

Are the shielded bags marked with the ESD shield symbol?

-

Is ESD compatible tape used to seal protective packaging?

EPA's (electrostatic protected area)?

-

Is access limited to personnel who have completed ESD training?

-

Are the EPA's clearly identified?

-

Is the demarcation between EPA and non-EPA clearly defined?

-

Has the EPA been tested?<br>(EPA should be clearly marked as being tested)

-

Has the EPA been tested by a competent person?

-

Are the EPA surfaces clean and free from dirt?

-

Are the EPA's free from static generating materials?

-

Documentation is contained in appropriate ESD folders.

-

Waste bins are suitable for use in the EPA and are not fitted liners.

-

Are the records of the tests to the EPA work surfaces maintained and up to date?

-

Are the records of the tests to EPA flooring maintained and up to date?

-

Visually check the grounding wires on the work benches in the EPA are connected and free from damage?

-

Visually check the earth termination blocks in the EPA's are free from damage?

-

Make sure that all cleaning materials (solvents) in the EPA are suitable for use in the EPA.

-

Visitors in the EPA are wearing the designated clothing. Any one who is not grounded should be more than 1 meter from a workstation where static sensitive components are being used.

Grounding and Bonding systems

-

Are all conductive / dissipative surfaces connected to a common earth?

-

Has the connections of the local grounding points been verified?

-

Are all the bonding points in good condition?

-

Are all bonding connections easily identifiable?

-

Are there adequate bonding points for the connection of moveable / temporary EPAs?

Personal Grounding

-

Personnel in the EPA are using wrist straps when seated in the EPA

-

Personnel working the EPA standing up are grounded by either a wrist strap, disposable heal grounders or ESD footware

-

Are wrist strap, heal grounders or ESD footware tested on a daily basis.<br>Note heal grounders and ESD footware are to tested every time the person enters the EPA

-

All tests of personal grounding is recorded in the test log<br>

-

Wrist straps are being worn correctly

-

Heal grounders are worn in both shoes

-

Personal grounding used is clean and good condition.<br>Note: when checking the condition of the wrist strap the strap and the cable must be inspected. Any damaged or non functional grounding devices must be replaced before entering or working in the EPA.

-

When not in use are the wrist straps and grounding cables stored in a manner to prevent damage and deterioration

Training

-

Have the staff requiring ESD training been identified?

-

Has the frequency and level of refresher training been identified?

-

Have the staff requiring ESD training received training / refresher training as required?

-

Have new staff in the EPA received training before working in the area?

-

Are the training records maintained and up to date?

Test and Verification Equipment

-

Is all the equipment used to verify the EPA / grounding working and in good condition?

-

Is all the equipment used to verify the EPA / grounding calibrated.

-

Are there procedures in place to define the processes for testing the EPA / grounding?

-

Are the test instruments / fixtures defined in the procedures / process documents?

-

Are wrist band / heal strap checkers in working order and good condition?

-

Are wrist band / heal strap checkers calibrated?