Title Page

-

Prepared by:

-

Location:

-

Date:

-

Task/Activity:

-

Brief Description of Task/Activity

-

Document Number:

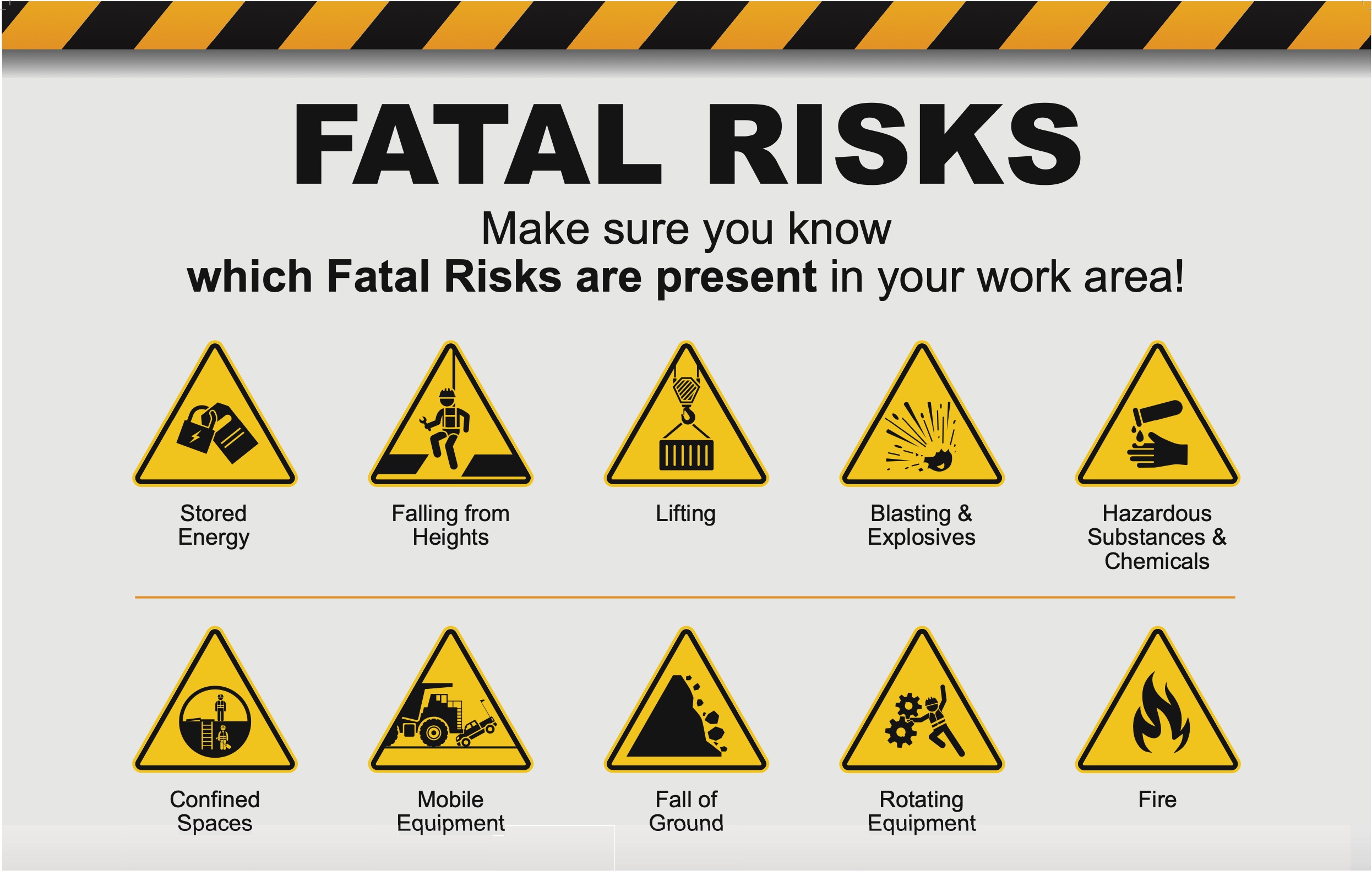

Fatal Risk Control

-

Make sure you know which Fatal Risks are present in your work area!

-

If any fatal risk controls are not effectively implemented or maintained the task/activity should be stopped immediately and the related risks needs to be re assessed by a competent person.

Stored Energy

-

These CRITICAL CONTROLS need to be in place to prevent exposure to stored energy.

-

Does the activity present stored energy risks.

-

De-energise: Identity sources of energy and ensure they are at zero-state

-

LOTOTO: Remember to always lock out-tag out-try out

-

Guards, Barriers and Barricades: Ensure they in position are effective

-

Lock Out Device: Use the appropriate lock-out device to isolate the energy source

-

Personal Lock and Tag: Have your own lock and tag, with unique key

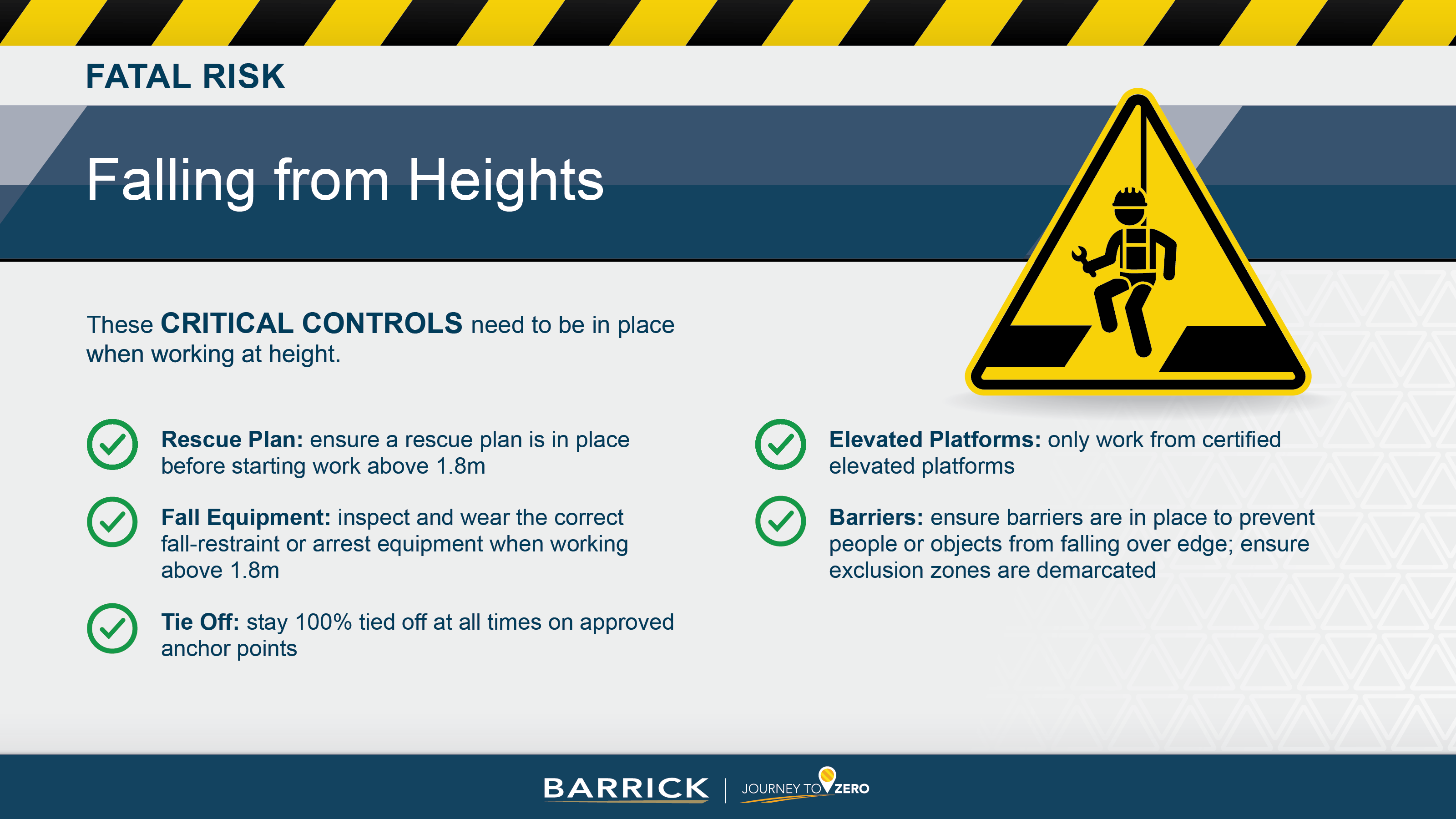

Falling from heights

-

These CRITICAL CONTROLS need to be in place when working at height.

-

Does the activity present falling from height risks.

-

Rescue Plan: Ensure a rescue plan is in place before starting work above1.8M

-

Fall Equipment: Inspect and wear the correct fall-restraint or arrest equipment when working above 1.8M

-

Tie Off: Stay 100% tied off all times on approved anchor points

-

Elevated Platforms: Only work from certified elevated platforms

-

Barriers: Ensure barriers are in place to prevent people or objects from failing over edge, ensure exclusion zones are demarcated

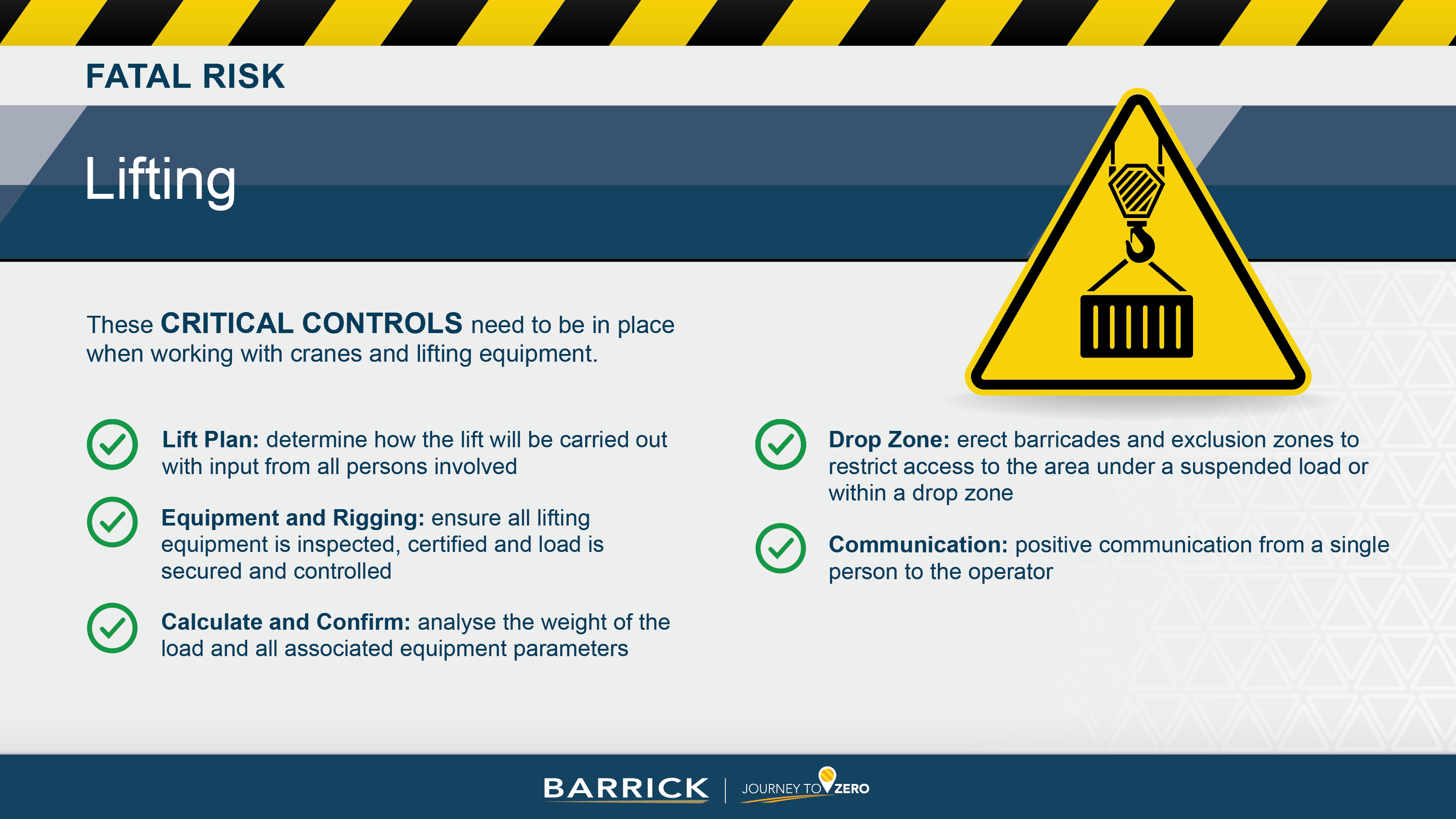

Lifting

-

These CRITICAL CONTROLS need to be in place when working with cranes and lifting equipment.

-

Does the activity present lifting risks.

-

Lift Plan: Determine how the lift will be carried out with input from all persons involved

-

Equipment and Rigging: Ensure all lifting equipment is inspected, certified and load is secured and controlled

-

Calculate and Confirm: Analyse the weight of load and all associated equipment parameters

-

Drop Zone: Erect barricades and exclusion zone to restrict access to the area under a suspended load or within a drop zone

-

Communication: Positive communication from a single person to the operator

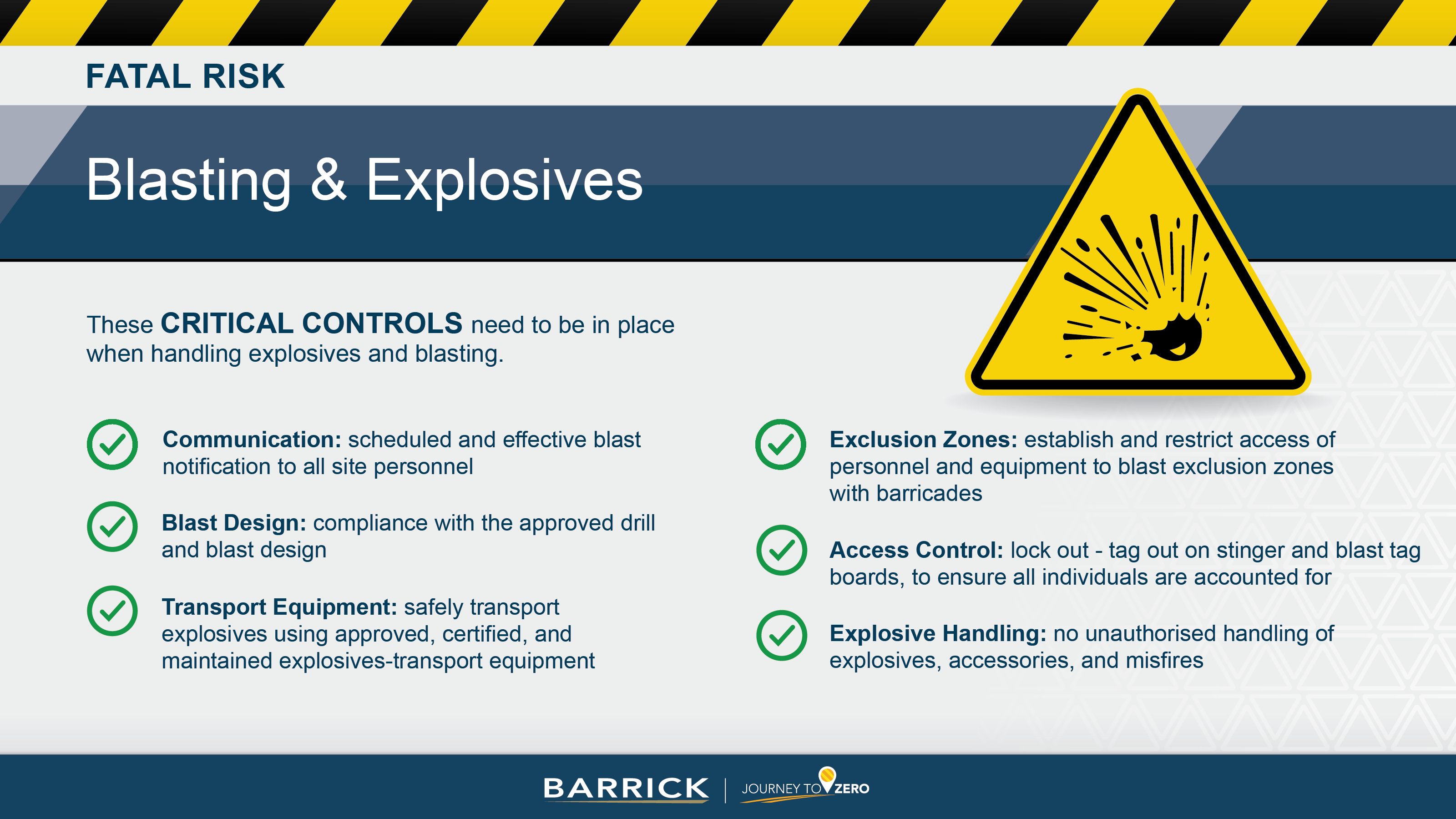

Blasting & Explosives

-

These CRITICAL CONTROLS needs to be in place when handling explosives & blasting

-

Does the activity present blasting or explosive risks.

-

Blast Designs: Compliance with the approved drill and blast designs

-

Transport Equipment: Safely transport explosives using approved, certified and maintained explosives transport equipment

-

Exclusion Zones: Establish and restrict access of personnel and equipment to blast exclusion zones with barricades

-

Access Control: Lock-out tag out on stinger and blasting tag boards to ensure all individuals are accounted for

-

Explosive Handling: No unauthorised handling of explosives, accessories and misfires

Hazardous Chemicals

-

These CRITICAL CONTROLS needs to be in place when handling Hazardous Chemicals

-

Does the activity present hazardous chemical risks.

-

PPE: Wear correct hazardous - materials PPE in line with Safety Data Sheet (SDS)

-

Access: Restrict access to authorised and trained personnel only.

-

Emergency Response: Containment and exposure measures must be on hand and working according to SDS guidance.

-

Detection and Alarm Systems: Correct detection devices and alarms are in place and fully functional.

-

Handling & Transfer: Protection protocols are in place when handling and transferring chemicals based on SDS.

Confined Space

-

These CRITICAL CONTROL needs to be in place when working in confined space.

-

Does the activity present confined space risks.

-

Rescue Plan: Formulate a rescue plan and ensure that a spotter is in place at all times

-

Permit: Ensure you have a signed and completed permit at access entry point

-

Energy Isolation: All possible energy sources have been identified and controlled per lock out, tag out, try-out(LOTOTO)

-

Access Control: Test and Confirm atmosphere is Life-sustaining and continue monitoring

Mobile Equipment

-

These CRITICAL CONTROLS need to be in place when operating and interacting with equipment.

-

Does the activity present mobile equipment risks.

-

Pre-use Inspection: Confirm functionality of brake, Steering and safety devices

-

Parking: Follow safe, secure and stable parking practices in designated parking areas

-

Traffic Management Plan: Adhere to road designs, rules, signage and segregation of equipment and pedestrians

-

Berms and Windrows: Ensure that berms and windrow are installed to standard and maintained

-

Communication: Ensure positives communication is maintained at all times

-

Mobile Devices: do not use phones, Smart Watches or tablets when driving

Fall of Ground

-

These CRITICAL CONTROLS needs to be in place to minimize fall of ground.

-

Does the activity present fall of ground risks.

-

Workplace Inspection: Inspected, Properly scaled down and made safe

-

Geotechnical Inspection: Ensure that Inspections are completed and workplaces are continually monitored

-

Ground Control Management: Ensure that plan is implemented and communicated

-

Barricading and Exclusion Zones: Ensure exclusion zones have been identified and maintained

-

Water Management: Establish a water management plan

Rotating Equipment

-

These CRITICAL CONTROLS need to be in place when working on or around rotating equipment.

-

Does the activity present rotating equipment risks.

-

Guards, Barriers and Barricades: Ensure these are effective in place and maintained

-

Safety Devices: Ensure safety devices and interlocks have been tested and are in working condition

-

Energy Isolation: All possible energy sources have been identified and controlled per lock out, tag out, try-out(LOTOTO)

Fire

-

These CRITICAL CONTROLS need to be in place to prevent fire and response.

-

Does the activity present fire and response risks.

-

Combustible Materials Storage: Store combustible/flammable materials separately

-

Ventilation: Ensure adequate ventilation in working areas, and that systems are functioning and maintained

-

Fire Detection, Alarm and Suppression:

-

Ensure fixed and mobile equipment has functional fire detection and suppression

-

Evacuation Plan:

-

Be prepared and know your emergency plan, egress, refuge, self rescuer and muster point

-

Hot Work Permit: Obtain a permit and implement the associated controls before starting work

-

Hazardous Substances & Chemicals

Sign off

-

Person Conducted Fatal Risk Critical Control Verification.