Title Page

-

Prepared by:

-

Location:

-

Date:

-

Brief Description of Task/Activity

-

Document Number:

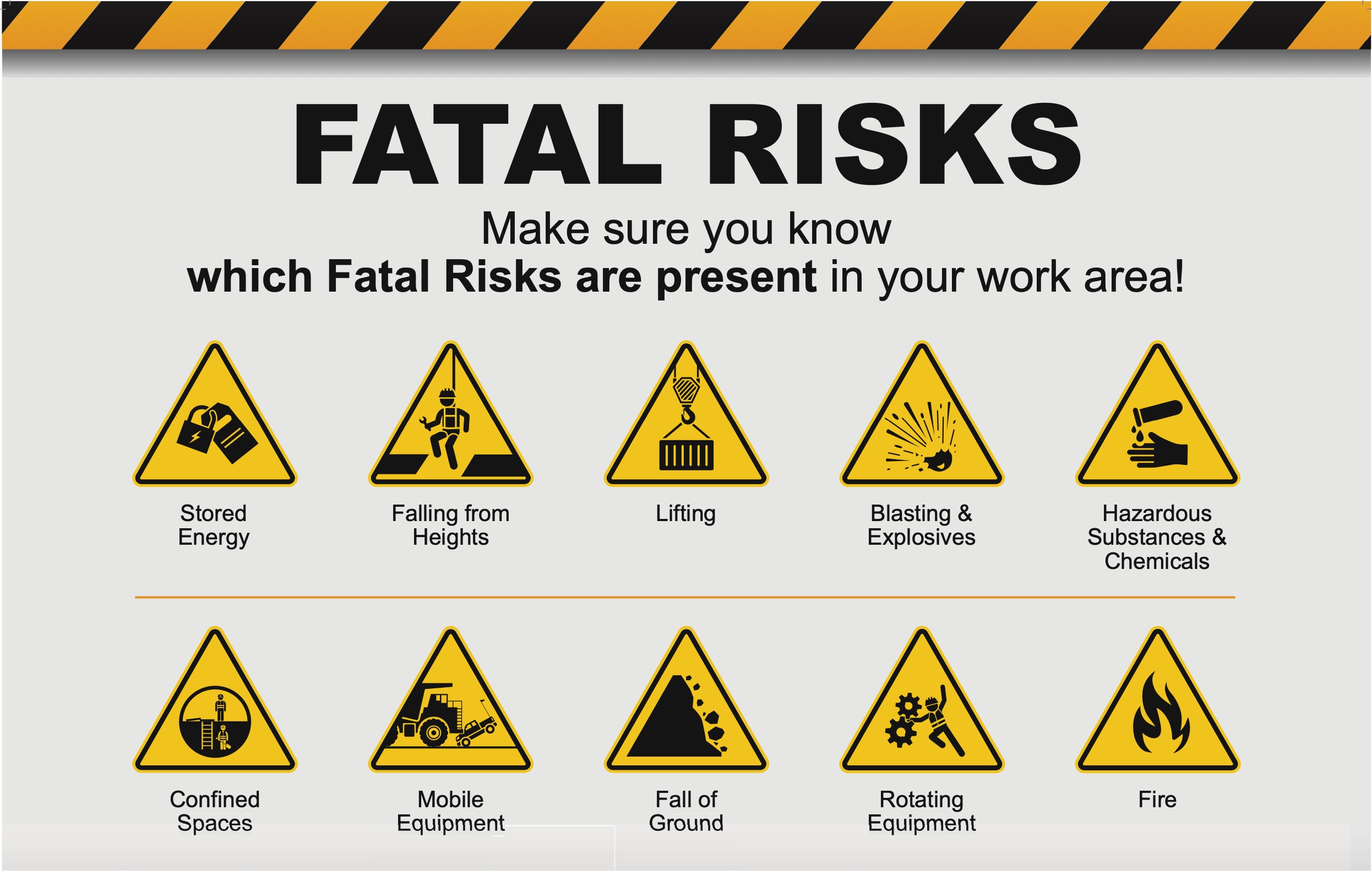

Fatal Risk Control

-

Make sure you know which Fatal Risks are present in your work area!

-

If any fatal risk controls are not effectively implemented or maintained the task/activity should be stopped immediately and the related risks needs to be re assessed by a competent person.

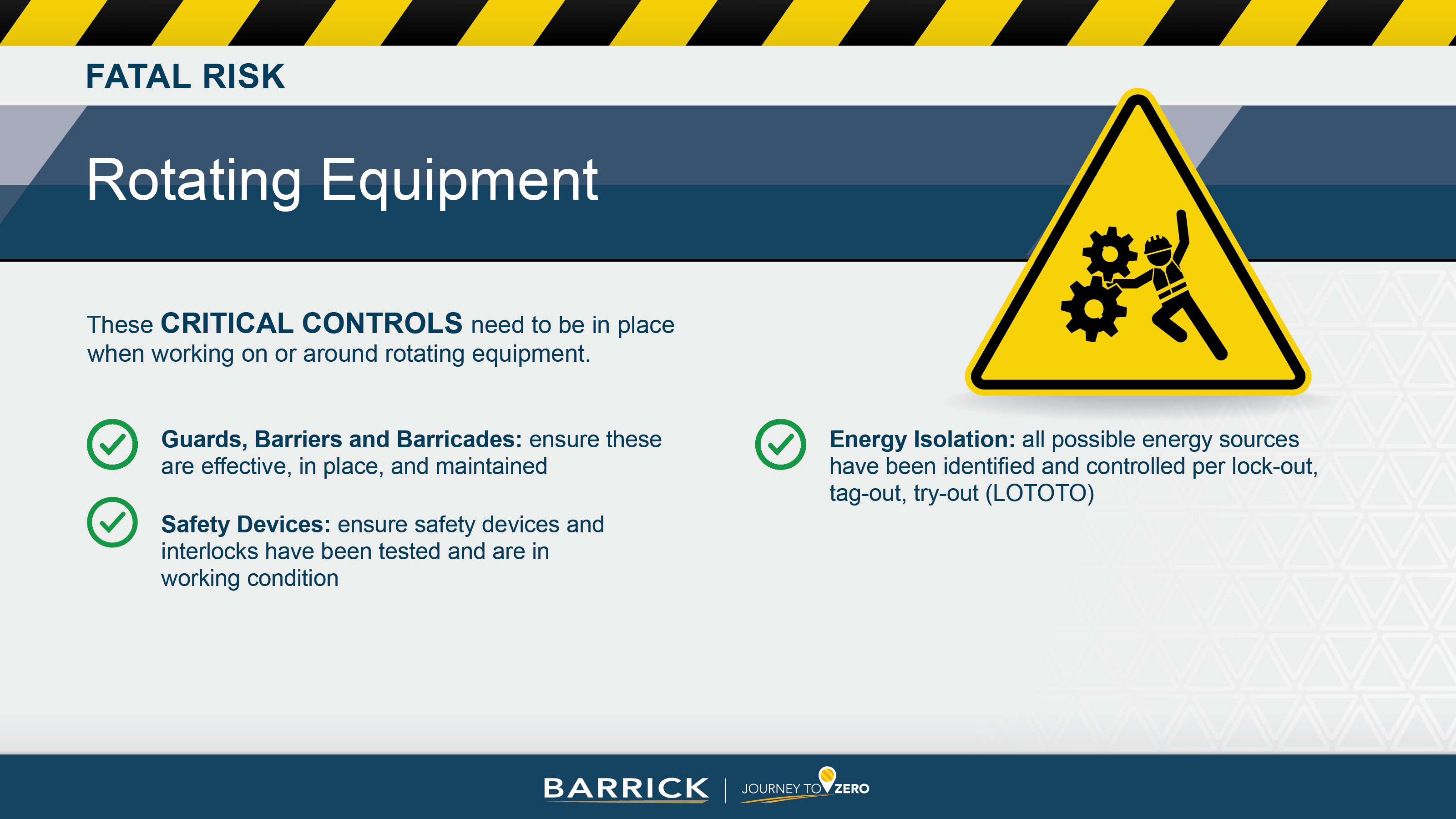

Rotating Equipment

-

These CRITICAL CONTROLS need to be in place when working on or around rotating equipment.

-

Does the activity present rotating equipment risks.

Competency

-

Has the worker been trained and authorized, and does the worker understand the components of working around rotating equipment?

Guarding and Safety Devices:

-

Is guarding and/or a barrier present and meets the standard?

-

If an authorized bypass needs to occur, has communication been made to all affected personnel?

-

Is the exclusion zone demarcated with the hazard and precautionary actions identified?

-

Is there an authorized process in place for removal of guards, when necessary, in order to perform live testing?

-

Is the emergency shut-off device visible, accessible, and properly maintained?

-

If removed, have all guards and safety systems been restored when the work is completed?

-

Is worker clear of potential line of fire situations?

-

Are there designated covered walkways under conveyor belts?

-

Are barricades in place where there is the potential for falling objects?

Block Against Movement

-

Have individuals performed effective mechanical blocking? Are the mechanical blocks approved and safe for use?

-

Are jacks and blocks designed, adequate, and positioned correctly for the task?

-

During maintenance, are the articulation and bed locks in place to block against movement?

Sign off

-

Person Conducted Fatal Risk Critical Control Verification.