Title Page

-

Prepared by:

-

Location:

-

Date:

-

Brief Description of Task/Activity

-

Document Number:

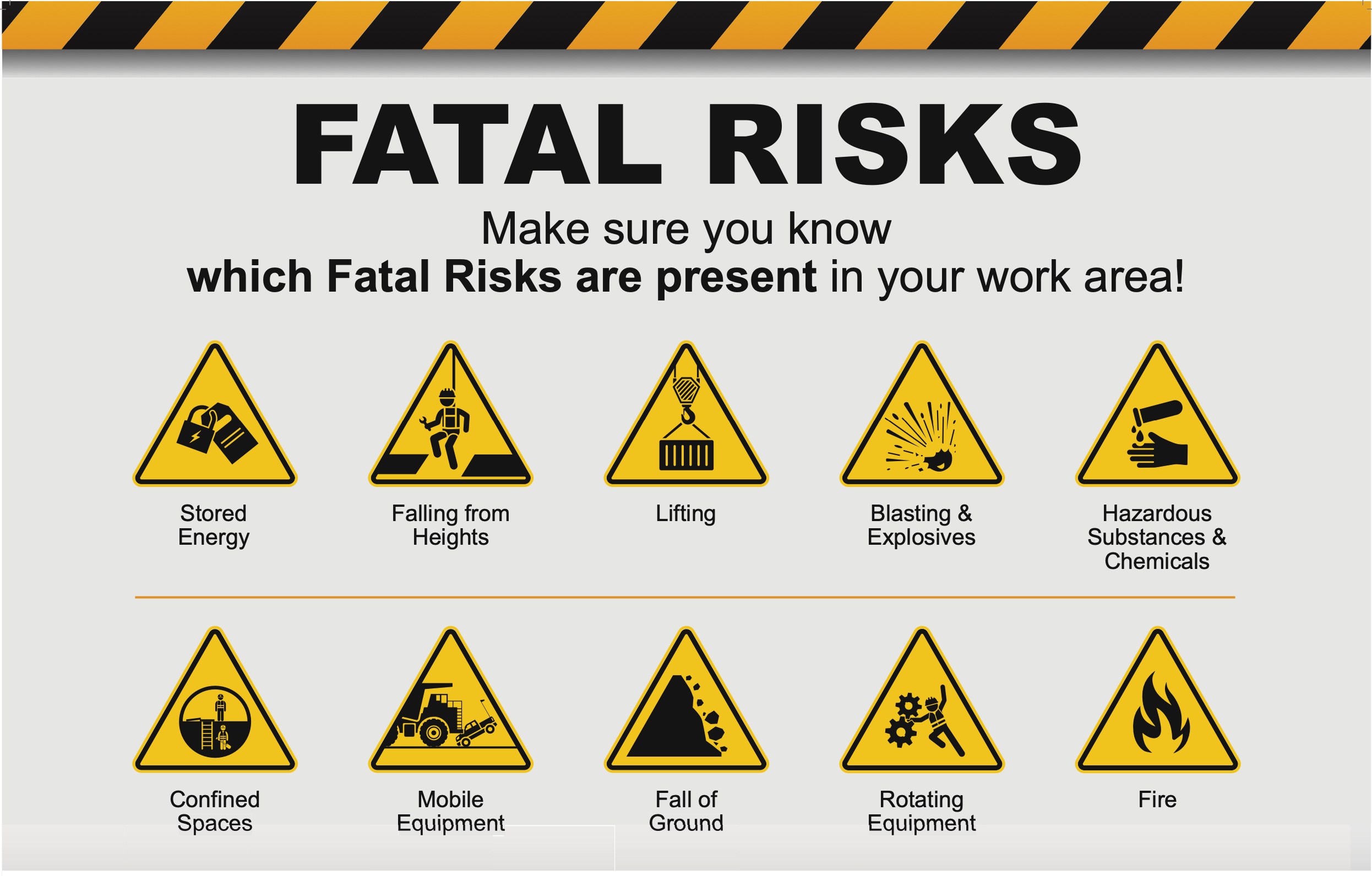

Fatal Risk Control

-

Make sure you know which Fatal Risks are present in your work area!

-

If any fatal risk controls are not effectively implemented or maintained the task/activity should be stopped immediately and the related risks needs to be re assessed by a competent person.

Mobile Equipment

-

These CRITICAL CONTROLS need to be in place when operating and interacting with equipment.

-

Does the activity present mobile equipment risks.

Safe Driving

-

Is the team member alert, rested, and free of distractions?

-

Are electronic devices secured and put away?

-

Is team member aware of and complying with posted speed limits and changing road conditions?

Safety Devices

-

Are visibility accessories (i.e., strobe lights, reflective tape, buggy whip, etc.) installed, functional, and maintained?

-

Are all safety critical items installed and functioning properly prior to operating equipment? (i.e., tires, brakes, steering, horn, ala cameras, maintenance up-to-date, Fatigue Monitoring, etc.)

-

Have all seatbelts been inspected for damage (tears, cuts, frays, etc.), and determined to be in good operable condition and worn correctly?

Vehicle / Pedestrian Segregation

-

Has interaction between vehicles and pedestrians been minimized by physical barriers, designated walkways/travel ways, work area exclusion zones?

-

In parking areas and other congested traffic areas, are berms installed and maintained to minimize vehicle interactions?

-

Are vehicles operating at the required separation distance per Traffic Management Plan?

-

Do employee(s) avoid entering equipment blind spots unless positive communication is established, equipment is shut down, secured from movement i.e., chocks in place and blades/buckets are lowered into the ground?

Berms

-

Are berms built with competent material to the mid-axel height of the largest vehicle travelling the area to prevent vehicles from falling over the edge or overturning (i.e., dumps, stopes, travel ways, TSF, etc.)?

Stable Parking and Secured Loads

-

Is the vehicle or equipment parked in a designated or segregated parking area?

-

Is the park / service brake set, other suitable brakes applied, and the vehicle is blocked against movement? (wheel chocks, parking ditches, equipment bermed/ribbed, implements - blades/buckets/rippers/etc. are lowered into the ground)

-

Are loads and loose items that could become a hazard or risk secured?

Communication

-

Are radios installed, present, and operational in vehicles/equipment in required areas (i.e., active mining area, hauls, stockpiles, restricted areas, etc.)?

-

Is positive two-way communication made when passing equipment or when entering exclusion zones?

Engineered Fire Detection and Suppression System

-

Is the equipment fitted with the appropriate fire suppression system and/or fire extinguisher? (LV exempt unless otherwise noted)

-

Has the employee inspected the fire suppression system and/or fire extinguisher(s) prior to operation?

Sign off

-

Person Conducted Fatal Risk Critical Control Verification.