Title Page

-

Document No.

-

MR-Linac Feasibility Study & Site Inspection #1

-

Client / Site Name:

-

Site Address:

-

Primary Customer Contact Info:

-

Date of Inspection:

-

Personnel Involved in Inspection: (Include name & role)

-

Prepared by

-

Introduction to MR linac Feasbility study and site inspection #1.

Purpose

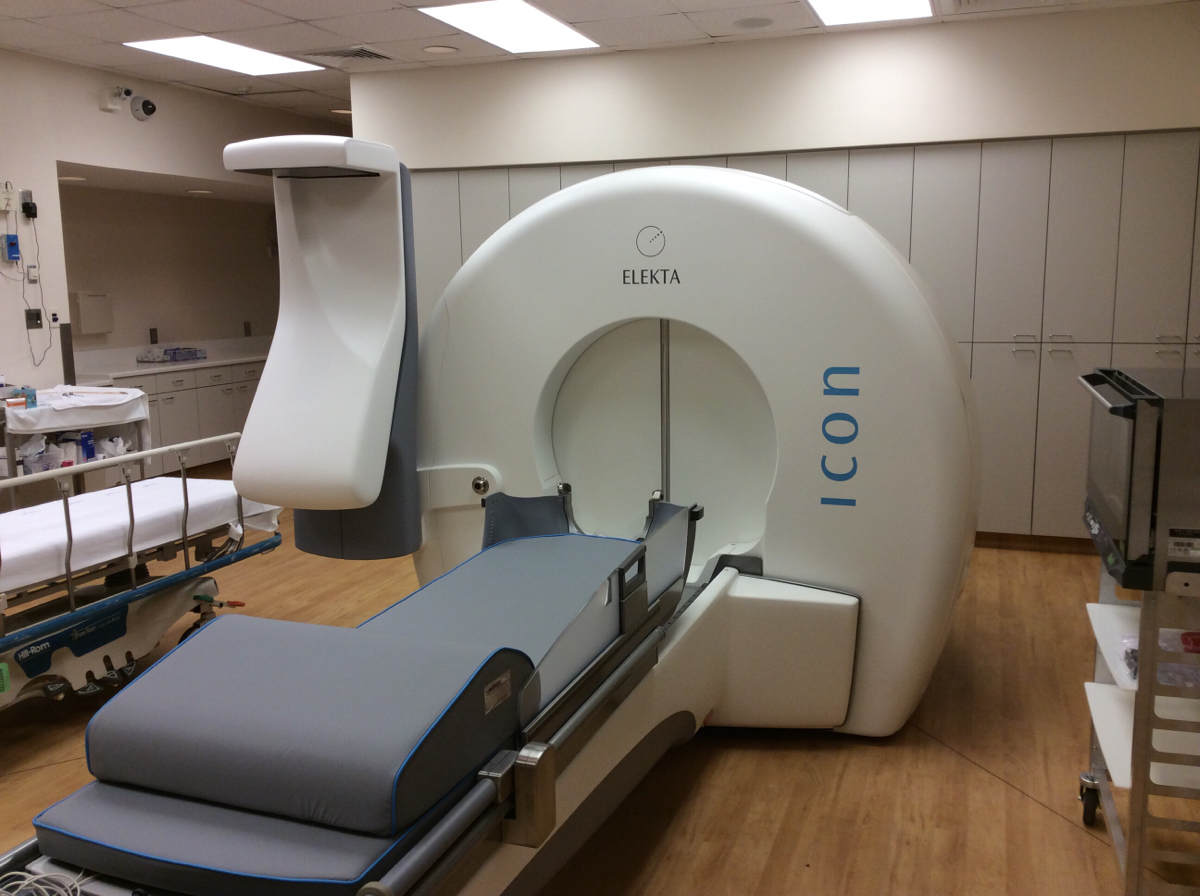

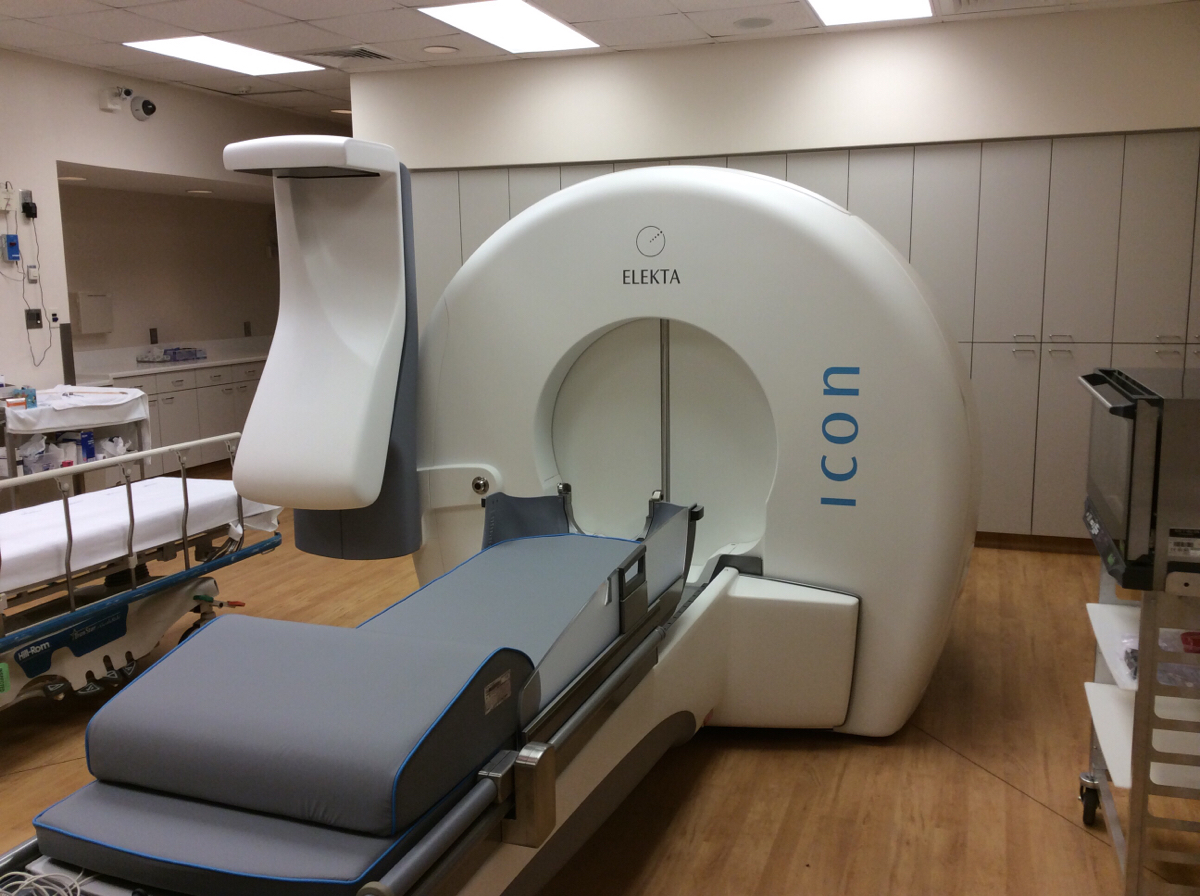

• To examine the suitability of a customer’s site for the delivery, installation and performance of the MR linac

• To record objective evidence of the study results.

• To conclude and recommend the next action.

Approach –following is a template with a proposed sequence of examination. The Project Manager and site coordinator are responsible for making an initial assessment. Based on this assessment the priority and sequence of the feasibility can be determined for a particular site.

It is recommended to include the site facility manager in visits and examinations. -

Feasbility study status and summary:

Requirements satisfied.

Recommend to proceed with project

Feasibility study is not full complete.

Recommend continue study

Feasbility study has identified a specific issue.

Recommend discuss with customer.

Feasibility does not satisfy requirements.

It is recommended to seek alternative location.

Yes/ no

Summarise next action

Record issue and next action

Summarise reason

The feasibility study shall answer these questions

#

Area Question

Guidance

Results -

Feasibility Study Status

- Requirements Satisfied

- Feasibility Study Incomplete

- Feasibility Study has identified a specific issue

- Site does not satisfy equirememts

1. Minimum Dimensions

-

-

-

-

Additional Comments:

2. Identify Obvious Obsticals

-

-

-

-

Additional Comments:

3. Radiation Shielding

-

Request a written assessment from the customers appointed Radiation Protection Officer or Radiation Safety Officer.

-

Has a shielding report been requested from Site?

-

Has a report been returned to Elekta?

-

Does existing bunker provide shielding to specification?

-

Additional Comments:

4. Product Delivery Route

-

Refer to the SPG for dimensions of delivered parts.

Rigging contractor.

A rigging contractor shall be appointed by the principal logistics partner.

The site coordinator or project manager shall arrange a site visit with the rigging contractor.

A detailed inspection and report shall be produced by the rigging contractor. This shall identify the rigging tasks from the delivery point through to the bunker.

Risks shall be identified and mitigations proposed. -

Can the product be delivered to site and rigged into bunker?

-

Is it necessary to cut an opening in the wall or roof of the bunker?

-

An initial assessment can be made by the site coordinator during a site visit. This shall be followed by a detailed analysis sand report by the rigging contractor.

-

Has a site visit been arranged by Rigging Contractor?

-

Has a site visit been performed by Rigging Contractor?

-

Is there space for temporary storage?

-

Pictures of temp storage area/s:

-

What is the floor loading along the route?

-

Additional Comments:

5. Quench Pipe

-

Refer to MR Planning Reference Data

Review the site and relevant existing drawings with the customer. Identify the route of the pipe. -

Is there a viable route for the Quench pipe to safe area?

-

Check outside – is there an area where the pipe can vent safely?

-

Record - make a sketch, mark up existing drawings:

-

and take photos of pipe route

-

Additional Comments:

6. Fringe Field

-

Check the projected magnetic fields do not extend into controlled areas containing magnetically susceptible objects.

Reference Philips specifications and the Site Planning Guide.

Review the site floor plan and determine the extent of the fringe field.

7. Structural Integrity

-

For refurbishment projects:

The appointed contractor shall asses any changes to the building structure.

Consider new wall and roof openings required to deliver large components -

what structural changes need to be made and will this impact on the integrity of the building?

-

Additional Comments:

8. Helium Supply

-

Is there a local supplier of Helium for future?

-

Record supplier information:

-

Additional Comments:

9. Unigue to this Site

-

Record unique or specific issues related to this site that could influence the bunker design, construction or installation. -

Is there occupied space below or above the intended bunker location?

-

Are there adjacent rooms in clinical use?

-

Is the space for storage of material during installation phase?

-

Are there any unusual problems to overcome for this site?

-

Additional Comments:

10. Environmental

-

Reference MR Planning Reference Data.

-

Has a B0 survey plan been completed?

-

Instruct a B0 surveying vendor?

-

Is the magnetic and vibration environment suitable for MR?

-

Additional Comments:

11. 3D Scan (Optional)

-

If appropriate and useful acquire a 3D scan (point cloud). The data shall be analysed offline.

-

Is a 3D Scan Appropriate?

-

What date has 3D scan been scheduled for:

-

Date 3D Scan info sent in for analysis:

-

Synopsis of info from 3D Scan: