Title Page

-

Final inspection ... Inspection Sheet Must be used with the Work Order

-

Body Only

-

Conducted on

-

Prepared by: Veasna Thach

-

Manufactured for:

-

Stock Number matches work order and body serial number

-

Gate serial number

-

Rear door serial number

-

VIN Number (scan)

-

-

-

-

Radio / Antenna

- Radio

- Antenna

-

Pictures <br>

-

Decals/ Inspected Waiting Decals<br>

-

Add signature

-

Sign completed inspection _________________________________________________________________________________________________

-

Add media

-

Body Only, On Chassis

-

Cutaway, Dump box, Freight, Platform, Reefer

Cab

-

Damages if none "Pass"<br>Check Wind shield, side windows, mirrors, and rear window, front bumper

-

Window sheet matches serial tag and chassis Vin number

-

Check interior (dash, headliner, seats, door panels, windows, radio, for damages or missing.

-

Ensure material removed off rear window

-

Remove mounting material from cab

-

Gate stickers in cab

-

Platform Cab issues

Platform

-

Damages if none "Pass"

-

Serial tag installed on lower front passengers side (below headboard)

-

Headboard installed as per work order (headboard window to line up with cab window)

-

Sliding winches installed as per work order (operation of winches are not to interfere with wheels, mudflap brackets or mid turn lights (when required)

-

Two screws in each floor board<br>properly recessed in board

-

All welds neatly and properly done

-

Platform headboard issues

Underbody

-

Tie downs in place

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

Side steps

-

Visually check all step welds

-

Physically check welds (stand on steps)

-

Midturns

-

Brackets welded in place

-

Wires for mid turns pass over frame rails NOT UNDER)

-

Angle of deflection

http://www.visualtrig.com -

Angle of deflection in degrees

-

Platform Underbody issues

Rear

-

Damages if none "Pass"

-

All welds proper and neatly done

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Check all welds at the end of the walkramp stop areas

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Bumper, Liftgate, Railgate

-

Reinforcement brackets installed

-

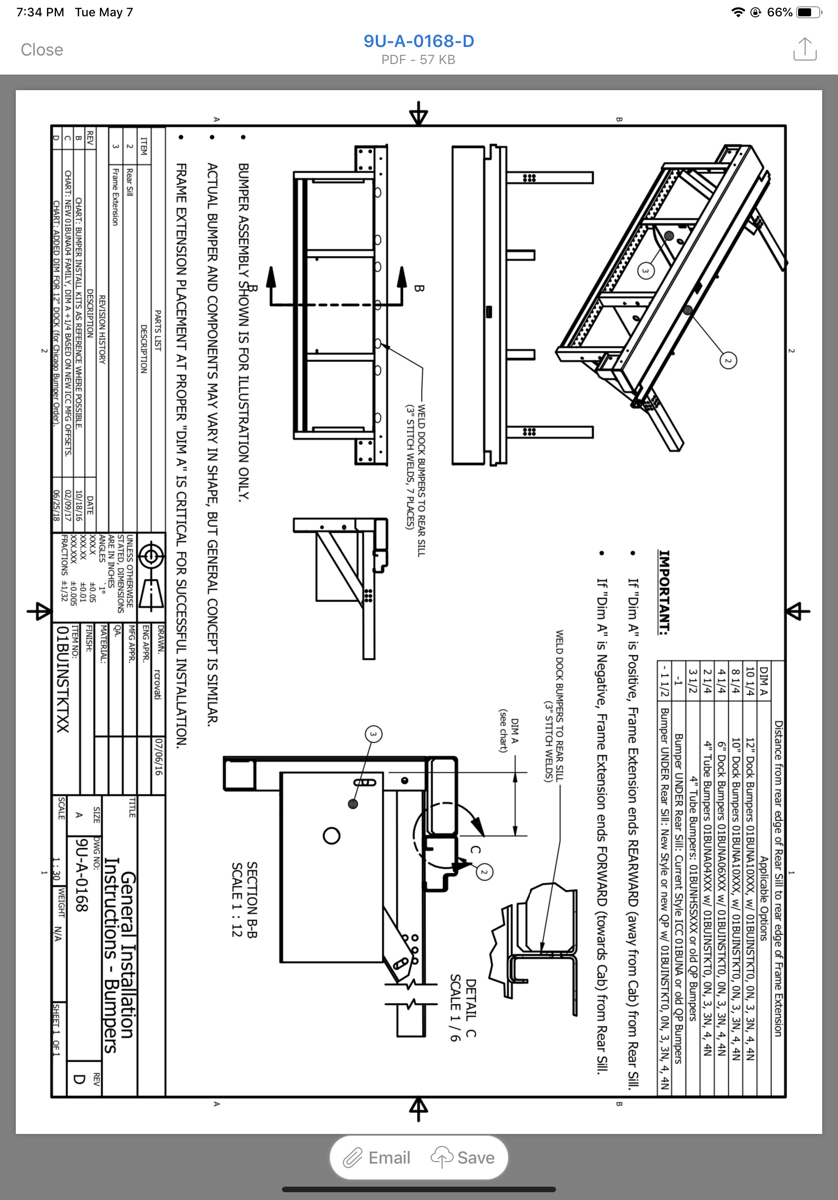

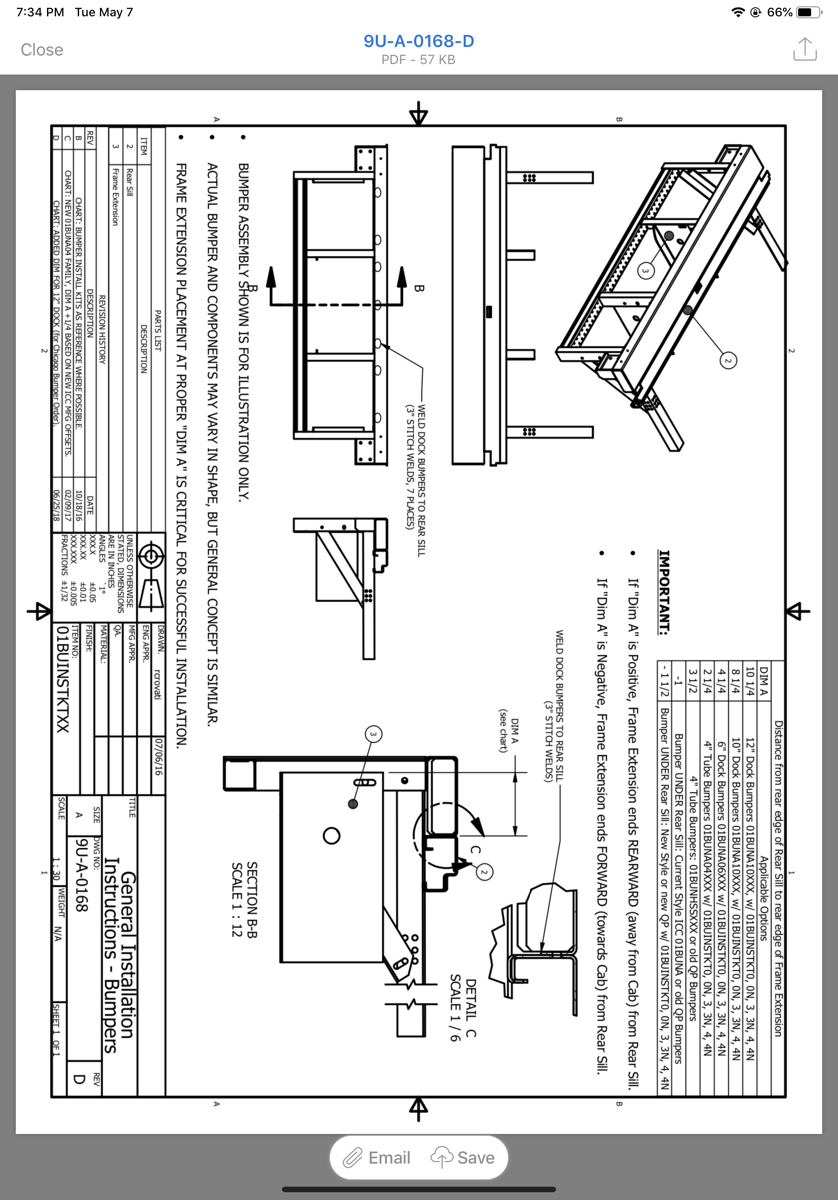

Welds properly done and located as per installation instructions

-

Railgate operates properly ... fully cycle gate

-

All gate wires tied up not wrapped around or hitting any moving parts

-

Platform railgate issues

-

Liftgate operates properly<br>Fully cycle gate

-

Weld splatter removed

-

All welds properly done and located as per manufacturers instructions

-

All bolts in gate fully installed and tight

-

Gate braces are angles NOT flat bar

-

Hydraulic fluid filled to proper levels as per installation instructions

-

Gate wires tight neatly tied up

-

Grommets used in wire holes on frame rails

-

Platform Liftgate issues

-

Reinforcement brackets installed

-

All welds completed as per engineering drawings

-

Dock bumpers installed

-

Tail lights not covers by mid steps on either side of bumper

-

All weld splatter removed

-

All bolts tight and properly installed

-

If ICC bumper installed ... vertical end plates installed

-

License plate fits properly on bracket

-

Platform Bumper issues

-

Platform bumper issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Check license plate (must be seen from all angles)

-

Spot lights

-

Light issues

General information

-

Maximum width of a body is 102"

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit required

-

Sign when completed

Cab

-

Damages if none "Pass" <br>Check wind shield, side windows, mirrors, front bumper,

-

Window sheet matches serial tag and chassis Vin number

-

Check interior (dash, headliner, seats, door panels, windows, radio, remove mounting material from cab

-

No daylight seen lower cab rear corners

-

Gate stickers in cab

-

Cutaway Cab issues

Front wall

-

Damages if none "Pass"

-

Nose cone

-

Damages if none "Pass"

-

All glue squares removed (nose cone clean)

-

Mono bolts spaced and installed correctly

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking .... Sides of Body and Cab roof

-

Front wall issues

Body sides

-

Damages if none "Pass"

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Ford E Series need to cut the rub rails over the rear tires (Arch)

-

Side door

-

Damages if none "Pass"

-

Door seals on all sides

-

Bar hardware<br>check upper and lower cams in keepers

-

Hold back installed

-

Door hinge bolts installed and tight

-

Protection plate installed

-

Rubber door stopper

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Body side issues

-

Body side issues

Rear

-

Damages if none "Pass"

-

All welds proper and neatly done

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Roll up door, Barn door

-

Require door number

-

Damages if none "Pass"

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Green inspection sticker applied

-

Bumper, Liftgate, Railgate

-

Reinforcement brackets installed

-

Welds properly done and located as per installation instructions

-

Railgate operates properly ... fully cycle gate

-

All gate wires tied up not wrapped around or hitting any moving parts

-

License plate fits properly on bracket

-

Railgate issues

-

Liftgate operates properly<br>Fully cycle gate

-

Weld splatter removed

-

All welds properly done and located as per manufacturers instructions

-

All bolts in gate fully installed and tight

-

Gate braces are angles NOT flat bar

-

Hydraulic fluid filled to proper levels as per installation instructions

-

Gate wires tight neatly tied up

-

Grommets used in wire holes on frame rails

-

License plate fits properly on bracket

-

Reinforcement brackets installed

-

Dock bumpers installedu

-

Tail lights not covers by mid steps on either side of bumper

-

All weld splatter removed

-

All bolts tight and properly installed

-

License plate fits properly on bracket

-

If ICC bumper installed ... vertical end plates installed

-

Bumper issues

-

Rear body issues

-

Damages if none "Pass"

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware (4" grab handles installed on both doors .. center area)

-

Protection plates installed (hold backs and rubber door bumpers installed)

-

Barn door issues

-

Barn door issues

Interior

-

Damages if none "Pass"

-

2 screws installed in each floor board

-

No cracks/gaps in floor seam areas

-

Cargo track installed (as per work order)

-

All screws installed in plywood recessed

-

Scuffliner not wavy against side wall

-

Scuffliner installed, no gaps between floor and side wall (maximum gap 1/4")

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Check clearance light wires (interior header area)

-

Cutaway Interior issues

-

Cutaway Interior issues

Underbody

-

Tie downs in place

-

No more than 2 1/2” of thread past bolt

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

Side steps

-

Visually check all step welds

-

Physically check all welds (stand on side step)

-

Cutaway Underbody issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Check license plate (must be seen from all angles)

-

Spot lights

-

Light issues

General information

-

Maximum width of a body is 102"

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit

-

Pictures of unit taken Window sheet Front RS side CS side Rear Rear with gate down door open Interior Underbody (looking up all four corners)

-

Sign when completed

Cab

-

Damages if none "Pass"

-

Window sheet matches serial tag and chassis Vin number

-

Check interior (dash, headliner, seats, door panels, windows, radio

-

Ensure material removed off rear window

-

Dump box Cab issues

Dump

-

Multi vans serial tag installed on passenger side front lower corner box area

-

Lift box fully ... (no binding, not hitting piston)

-

Tail light wires not binding (check rear plug with dump fully up)

-

Box sides open/close easily

-

All paint missed areas in fold down sides, inside corners (touched up)

-

All grease points (greased)

-

Box safety arm installed

-

Mudflap brackets installed on angle (flip down sides not hitting angle when in lower position)

-

Fuel filler hose installed on an angle <br>(Flip down sides not hitting angle when in down position)

Electrical

-

All clearance light wires tied up (all lights working)

-

Brake lights

-

Indicators

-

Backup lights

-

Spot lights

-

Check license plate (must be seen from all angles)

-

Trailer plug tested and working properly

Rear

-

Trailer hitch plate bolted/welded in place

-

Trailer hitch as per work order

-

Pintle hitch installed as per work order

-

Safety chain hooks in place

Tarp

Dump box safety decals

-

Tarp windup winch attached and working properly ... required with dump boxes

-

All safety decals as per instruction manuals (2 packages)

-

Safety decal on rear gate handle area

-

Dump box issues

-

Sign when completed

Cab

-

Damages if none "Pass"

-

Window sheet matches serial tag and chassis Vin number

-

Check interior (dash, headliner, seats, door panels, windows, radio

-

Ensure material removed off rear window

-

Exhaust stack not hitting body (tight and straight)

-

Gate stickers in cab

-

Reefer Cab issues

Front wall

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Rub rail bolts tight

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking ... Rub top edge

-

Check catwalk (level, attached to front wall) all bolts tight<br>NOTE... IF CAB OVER STYLE CHASSIS (CATWALK TO BE INSTALLED ON CAB)

-

Reefer Front wall issues

Body sides

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Side door

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Door seals on all sides

-

Hold back installed

-

Door hinge bolts installed and tight

-

Protection plate and rubber stopped installed

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Reefer Body side issues

Rear

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Gussets installed

-

All welds proper and neatly done

-

License plate can be seen from all angles

-

License plate fits properly on bracket

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Bumper, Liftgate, Railgate

-

Reinforcement brackets need to be installed

-

Mono bolts in rear frame on 4” centres

-

Railgate operates properly ... fully cycle gate

-

Welds properly done and located as per installation instructions

-

Stainless steel flat bar installed on roof rails to rear corner posts (6000 Lb gates or as per work order)

-

All gate wires tied up not wrapped around or hitting any moving parts

-

Liftgate operates properly

-

Weld splatter removed

-

All welds properly done and located as per manufacturers instructions

-

On 102” wide bodies weld dock plate ends

-

All bolts in gate fully installed and tight

-

Gate braces are angles NOT flat bar

-

Hydraulic fluid filled to proper levels as per installation instructions

-

Gate wires tight neatly tied up

-

Grommets used in wire holes on frame rails

-

Make sure ...<br>Plate is welded between gate mounting brackets and long sill

-

Reefer Gate issues

-

License plate properly installed on bracket

-

Reinforcement brackets installed

-

7 welds installed on dock plate (2 - 3" welds evenly spaced per side, … 1 - 3" weld in the centre) Minumum

-

Welds as per engineering drawing

-

Dock bumpers installed

-

Tail lights not covers by mid steps on either side of bumper

-

Check welds at ends of dock plate (When required)

-

All weld splatter removed

-

All bolts tight and properly installed

-

If ICC bumper installed ... vertical end plates installed

-

License plate properly installed on bracket

-

Reefer Bumper issues

-

Rear Issues

-

Roll up door, Barn door

-

Require roll up door serial number

-

Damages if none "Pass"

-

No insulation on rear panels

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Inspection sticker applied to door interior

-

Reefer Roll up door issues

-

Damages if none "Pass"

-

No insulation on rear panels

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware (4" grab handles installed on both doors .. center area)

-

Protection plates installed when applicable (hold backs and rubber door bumpers installed)

-

Reefer Barn door issues

Interior

-

Damages if none "Pass"

-

Ceiling trim sealed (neatly done)

-

Dome lights installed straight (in line with each other)

-

Cargo track installed (as per work order)

-

Reefer hole fully trimmed and sealed

-

Door pocket installed (not interfering with rollup door)

-

Curtain installed as per work order

-

Scuffliner sealed top edge

-

Scuffliner not wavy against side wall

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Floor welds properly done (no holes, high areas ground)

-

Check interior clearance light wires (header area)

-

Reefer Interior issues

-

Reefer Interior issues

Underbody

-

Insulated as per work order

-

Check for voids, loose kemlite; Aluminum end plates... check by tapping on areas (check centre areas between lose sills)

-

Tie downs (as per work order #)

-

Check J bolts/U bolts (Not crooked, threads fully through bolts, Welds fully done on J bolts)

-

If items in the way (air tanks, exhaust system; add J bolts to area) call engineering to verify.

-

Tie downs torqued to 60 Lb Ft.

-

Chassis clips welded

-

Minimum clearance between tire and cross members (5")

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

-

Midturns

-

Brackets welded in place

-

Wires for mid turns pass over frame rails NOT UNDER)

-

Mud flaps installed on brackets properly welded in place

-

Mud flaps installed on bracket (with nuts and bolts)

-

Mudflaps fully cover tires

-

Reefer Under body issues

Side steps

-

Check all welds

-

Visually check all welds

-

Physically check welds (stand on steps)

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Check license plate (must be seen from all angles)

-

Spot lights

-

Light issues

General information

-

Maximum length of body is 41’ from bumper to bumper

-

Maximum width of a body is 102"

-

Maximum height of a body and chassis together is 13'6"

-

Maximum overhang from the middle of the rear wheel (center of tandem wheel area) to rear bumper is 14'

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit required

-

Sign when completed

Cab

-

Damages if none "Pass"

-

Window sheet matches serial tag and chassis Vin number

-

Check interior (dash, headliner, seats, door panels, windows, radio

-

Ensure material removed off rear window

-

Exhaust stack not hitting body (tight and straight)

-

Check chassis lights for backup alarm in cab (need to reinstall alarm on chassis if found in cab)

-

Straps loose in cab (state amount, need picture)

-

Gate stickers in Cab

-

Freight Cab issues

Front wall

-

Damages if none "Pass"

-

Nose cone

-

Damages if none "Pass"

-

All glue squares removed (nose cone clean)

-

Mono bolts spaced and installed correctly

-

Rub rail bolts tight

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking ... Rub top edge

-

Freight Front wall issues

Body sides

-

Damages if none "Pass"

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Freight Body side issues

-

Side door

-

Damages if none "Pass"

-

Door seals on all sides

-

Hold back installed as per work order

-

Door hinge bolts installed and tight

-

Protection plate installed

-

Rubber bumper installed

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Freight Body side issues

-

Single Sided curtain slider, Double Sided curtain sider

-

Lower angles installed

-

Pelment the installed on roof rails (mono bolted to front and rear corner posts)

-

Curtain stop bolts installed on curtain/roof rail front end

-

Tarps installed as per work order

-

Curtain stop bolts installed on curtain/roof rail front end

-

Rear corner post (lower pipe locking plate) (pipe holder at top to hold curtain pipe in place

-

Center braces installed (centred between front and rear corner posts

-

Curtain Sider issues

-

Lower angle installed

-

Pelment installed on roof rail (mono bolted to front and rear corner posts)

-

Plywood properly installed (all screws recessed)

-

Tarp installed as per work order

-

Rear corner post (lower pipe locking plate) (pipe holder at top to hold curtain pipe in place

-

Center brace installed (centred between front and rear corner posts

-

Freight Body side issues

-

Side wall issues

Rear

-

Damages if none "Pass"

-

All welds proper and neatly done

-

Rear Camera

-

Working with safety line seen when reversing

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Walk ramp issues

-

Bumper, Liftgate, Railgate

-

Reinforcement brackets need installed

-

Mono bolts required on 4” centres (rear frame)

-

Welds properly done and located as per installation instructions

-

Railgate operates properly ... fully cycle gate

-

Stainless steel flat bar installed on roof rails to rear corner posts (6000 Lb gates or as per work order)

-

All gate wires tied up not wrapped around or hitting any moving parts

-

License plate fits properly on bracket with light centred over plate (Holes line up on license plate)

-

Angle of deflection

http://www.visualtrig.com -

Freight Rail gate issues

-

Liftgate operates properly

-

Take picture of inspection tag (location CS Dock area)

-

Weld splatter removed

-

All welds properly done and located as per manufacturers instructions

-

On 102 wide bodies need to weld dock plate to rear frame ends

-

All bolts in gate fully installed and tight

-

Gate braces are angles NOT flat bar

-

Hydraulic fluid filled to proper levels as per installation instructions

-

Gate wires tight neatly tied up

-

Grommets used in wire holes on frame rails

-

Check license plate (must be seen from all angles)

-

License plate fits properly on bracket

-

Does the work order call for cart stops to be installed on the gate (if so are they installed)

-

Angle of deflection

http://www.visualtrig.com -

Freight Liftgate issues

-

Reinforcement brackets installed

-

Seven welds installed under dock extension (2 - 3" welds evenly spaced, 1 3" weld in the centre)

-

Welds as per engineering

-

Dock bumpers installed

-

Tail lights not covers by mid steps on either side of bumper

-

All weld splatter removed

-

All bolts tight and properly installed

-

License plate fits properly n bracket

-

If ICC bumper installed ... vertical end plates installed

-

Angle of deflection

http://www.visualtrig.com -

Freight Bumper issues

-

Roll up door, Barn door

-

Required door serial number

-

Damages if none "Pass"

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Damages if none "Pass"

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware (4" grab handles installed on both doors .. center area)

-

Protection plates installed

-

Hold backs and door bumpers installed

-

Freight Barn door issues

Dolly Legs

-

Installed as per dolly legs instructions

-

No brackets welded onto legs

-

Crank handle installed

-

Handle holder installed

-

Freight Roll up door issues

-

Rear issues

Interior

-

Damages if none "Pass"

-

2 screws installed in each floor board

-

No cracks/gaps in floor seam areas

-

Cargo track installed (as per work order)

-

All screws installed in plywood recessed

-

Scuffliner not wavy against side wall

-

Scuffliner installed, no gaps between floor and side wall (maximum gap 1/4")

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Check clearance light interior wires on header area

-

Rear camera wires in header (sticking to header) wires not loose

-

Freight Interior issues

-

Freight Interior issues

Underbody

-

Check angle of deflection for each Bumper/gate/dolly legs ( internet "Trigcal" Trigonometry Calculator - Carbide Depot) add number

-

Tie downs in place,

-

As per Work order (Check amount stated #)

-

Tie downs torqued to 50 Lb Ft.

-

Chassis clips welded

-

Minimum clearance between tire and cross members (5")

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

-

Midturns

-

Brackets welded in place

-

Wires for mid turns pass over frame rails NOT UNDER)

-

Mud flaps installed on brackets properly welded in place

-

Mud flaps installed on bracket (with nuts and bolts)

-

Mud flaps fully cover tires

Side Steps

-

Visually check each weld

-

Physically check welds (stand on each step)

-

Tool Box installed

-

Keys for tool box (placed in cab on key ring)

-

Mounting bolts installed on plate

-

All plastic removed off all sides of box

-

Is the fuel line hooked up and attached to the tank (Isuzu especially)

-

Freight Underbody issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Dome lights installed and working

-

Check license plate (must be seen from all angles)

-

Spot lights

-

Light issues

General information

-

Maximum width of a body is 102"

-

Maximum height of a body and chassis together is 13'6"

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Sign when completed

-

Pictures of unit taken Window sheet Front RS side CS side Rear Rear with gate down door open Interior Underbody (looking up all four corners)

-

Cutaway, Freight, Reefer

Front wall

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Rub rail bolts tight

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking ... Rub top edge

-

Check catwalk (level, attached to front wall) all bolts tight<br>NOTE... IF CAB OVER STYLE CHASSIS (CATWALK TO BE INSTALLED ON CAB)

-

Reefer front wall issues

Body sides

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Side door

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

Door seals on all sides

-

Hold back installed

-

Door hinge bolts installed and tight

-

Protection plate (When applicable) rubber bumper stopper installed

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Reefer side door issues

Rear

-

Damages if none "Pass"

-

No insulation protruding from (rivets, seam areas, mono bolts, or overspray on panels)

-

All welds proper and neatly done

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Roll up door, Barn door

-

Damages if none "Pass"

-

No insulation on rear panels

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Reefer rollup door issues

-

Damages if none "Pass"

-

No insulation on rear panels

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware (4" grab handles installed on both doors .. center area)

-

Protection plates installed (when applicable), hold backs and rubber door bumpers installed

-

Reefer rear barn door issues

Interior

-

Damages if none "Pass"

-

Ceiling trim sealed (neatly done)

-

Dome lights installed straight (in line with each other)

-

Panels not wavy in wall or ceiling

-

Reefer hole fully trimmed and sealed

-

Cargo track installed (as per work order)

-

Door pocket installed (not interfering with rollup door)

-

Curtain installed as per work order

-

Scuffliner sealed top edge

-

Scuffliner not wavy against side wall

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Floor welds properly done (no holes, high areas ground)

-

Ship loose parts installed

-

Reefer interior issues

-

Reefer interior issues

Underbody

-

Insulated as per work order

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

-

Reefer underbody issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Check license plate (must be seen from all angles)

-

Spot lights

General information

-

Maximum length of body is 45' from bumper to bumper

-

Maximum width of a body is 102"

-

Maximum height of a body and chassis together is 13'6"

-

Maximum overhang from the middle of the rear wheel (center of tandem wheel area) to rear bumper is 14'

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit required... interior ship loose parts

-

Sign when completed

Front wall

-

Damages if none "Pass"

-

Rub rail bolts tight

-

Nose cone

-

Damages if none "Pass"

-

All glue squares removed (nose cone clean)

-

Mono bolts spaced and installed correctly

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking ... Rub top edge

-

Freight front wall issues

Body sides

-

Damages if none "Pass"

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Freight side wall issues

-

Side door

-

Damages if none "Pass"

-

Door seals on all sides

-

Hold back installed

-

Door hinge bolts installed and tight

-

Protection plate and rubber stopped installed

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Side door issues

-

Single Sided curtain slider, Double Sided curtain sider

-

Lower angles installed

-

Pelment the installed on roof rails (mono bolted to front and rear corner posts)

-

Curtain stop bolts installed on curtain/roof rail front end

-

Tarps installed as per work order

-

Rear corner post (lower pipe locking plate) (pipe holder at top to hold curtain pipe in place

-

Center braces installed (centred between front and rear corner posts

-

Freight side wall issues

-

Side Wall issues

-

Side Wall issues

-

Single sided curtain

-

Lower angle installed

-

Pelment the installed on roof rail (mono bolted to front and rear corner posts)

-

Plywood properly installed (all screws recessed)

-

Curtain stop bolts installed on curtain/roof rail front end

-

Tarp installed as per work order

-

Rear corner post (lower pipe locking plate) (pipe holder at top to hold curtain pipe in place

-

Center brace installed (centred between front and rear corner posts

-

Curtain Sider issues

Rear

-

Damages if none "Pass"

-

All welds proper and neatly done

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Roll up door, Barn door

-

Damages if none "Pass"

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Rear rollup door issues

-

Damages if none "Pass"

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware when applicable (4" grab handles installed on both doors .. center area)

-

Protection plates installed (hold backs and rubber door bumpers installed)

-

Barn door issues

-

Rear body Issues

Interior

-

Damages if none "Pass"

-

2 screws installed in each floor board

-

No cracks/gaps in floor seam areas

-

Cargo track installed (as per work order)

-

All screws installed in plywood recessed

-

Scuffliner sealed top edge

-

Scuffliner not wavy against side wall

-

Scuffliner installed, no gaps between floor and side wall (maximum gap 1/4")

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Check interior clearance light wires (header area)

-

Ship loose parts installed

-

Interior issues

-

Interior issues

Underbody

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

-

Underbody issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Spot lights

General information

-

Maximum width of a body is 102"

-

Maximum height of a body and chassis together is 13'6"

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit required

-

Sign when completed

Front wall

-

Damages if none "Pass"

-

Nose cone

-

Damages if none "Pass"

-

All glue squares removed (nose cone clean)

-

Mono bolts spaced and installed correctly

-

Rub rail bolts tight

-

Caulking ... Radius lower edge<br>Caulking ... Corner post edges<br>Caulking ... Rub top edge

-

Cutaway front wall issues

Body sides

-

Damages if none "Pass"

-

Rub rail bolts tight

-

Rub rail straight not wavy

-

Fasteners properly installed in front and rear corner posts

-

Side door

-

Damages if none "Pass"

-

Door seals on all sides

-

Hold back installed

-

Door hinge bolts installed and tight

-

Protection plate (when applicable) rubber stopped installed

-

Eavestrough

-

Reinforcement bolts installed by door frame (all corners ... 8 bolts total)

-

Body only side wall issues

-

Body only side wall issues

Rear

-

Damages if none "Pass"

-

All welds proper and neatly done

-

Walkramp

-

Walkramp installed as per work order

-

No weld splatter or undercoating on ramp

-

Walkramp slides easily

-

Ramp hooks, latch into holes in bumper/sill

-

Ramp latch hole cut neatly

-

Front and rear stops in place

-

Rear spring lock latches easily (not interfering with gate)

-

Reinforcement angles installed on either side of front and rear of mono rail

-

Carriage welds painted

-

Walkramp support angle slider bolts recessed

-

Roll up door, Barn door

-

Damages if none "Pass"

-

Door panels not delaminated

-

Side seals installed

-

Rear door installed as per work order

-

Door seals top header area and bottom sill

-

Door latches easily in sill

-

Inspection sticker applied to interior of door

-

Body only rear issues

-

Damages if none "Pass"

-

Door open/closes smoothly

-

Door(s) sealed on all sides

-

Braces on each door, properly installed

-

If plunger style bar hardware (4" grab handles installed on both doors .. center area)

-

Protection plates installed when applicable (hold backs and rubber door bumpers installed)

-

Body only rear issues

Interior

-

Damages if none "Pass"

-

2 screws installed in each floor board

-

No cracks/gaps in floor seam areas

-

Cargo track installed (as per work order)

-

All screws installed in plywood recessed

-

Scuffliner sealed top edge

-

Scuffliner not wavy against side wall

-

Scuffliner installed, no gaps between floor and side wall (maximum gap 1/4")

-

All door track fasteners installed (mono bolts/screws .... check track for looseness

-

Check clearance light interior wes on header area.

-

Ship loose parts installed

-

Body only interior issues

-

Body only interior issues

Underbody

-

Tie downs in place

-

Wheel pans centered over wheels

-

Gussets in place and welded

-

Long sills welded to sill (welded front and rear areas of sill)

-

Body only underbody issues

Lights

-

All clearance lights

-

Brake lights

-

Indicators

-

Backup lights

-

Spot lights

General information

-

Maximum width of a body is 102"

-

Maximum height of brake light/turn signal is 72" (center of light) off the ground

-

Pictures of unit required ... ship loose parts

-

Sign when completed

-

Pictures of unit required