Information

-

Client / Site

-

Date

-

Prepared by:

-

Site Engineer

Site Check

-

Is plant area clean and tidy

-

Tap to enter information

-

Tap to enter information

-

Are there any signs of oil on equipment or floor area.

-

Tap to enter information

-

Tap to enter information

-

Are real zero caps fitted to all plant access points

-

Tap to enter information

-

Are PRV,s in date and tagged. Must not be more than 5 years old

-

Tap to enter information

-

Tap to enter information

-

Are there any visible alarm lights on electrical panels

-

Tap to enter information

-

Tap to enter information

-

Are refrigerant liquid levels marked.

-

Tap to enter information

-

Are there any empty refrigerant cylinders onsite. If so please note serial numbers and email fgas@arcus-engineering.com

-

Tap to enter information

-

Tap to enter information

-

Are all coldstore evaporators free from ice build up

-

Tap to enter information

-

Are cold store doors fully operational

-

Tap to enter information

-

Are all product dividers fitted (where required and without damage)?

-

Tap to enter information

-

Are there any water leaks on the shop floor

-

Tap to enter information

-

Tap to enter information

-

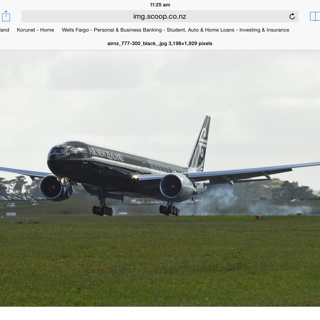

Remove 1 x random honeycombe and photograph.

-

Tap to enter information

-

Tap to enter information

-

Are all condensers clean and fans fully operational

-

Tap to enter information

-

Are all trim heaters working

-

Tap to enter information

-

Check all frozen food doors close correctly

-

Tap to enter information

-

Night blinds fitted and working correctly?

-

Tap to enter information

-

Are all kick plates fitted

-

Tap to enter information

-

Are all cabinets correctly loaded, please raise with store manager if not

-

Tap to enter information

-

Are all electrical panels securely closed

-

Tap to enter information

Sign Off

-

Inspected and signed on behalf of Arcus Engineering Ltd

-

Store Manager

-

On behalf of: