Information

-

Gemba Title

-

Department/Area

-

Conducted on

-

Prepared by

GEMBA WALK IS NOT AN AUDIT!!! Go to Where the Actual Work Is Being Done A means of gathering real-time first-hand information on the status of the processes by walking around the site or plant and observing what is happening. Be interactive with the people doing the job, look for areas of improvement. Don't be about just ticking the boxes.

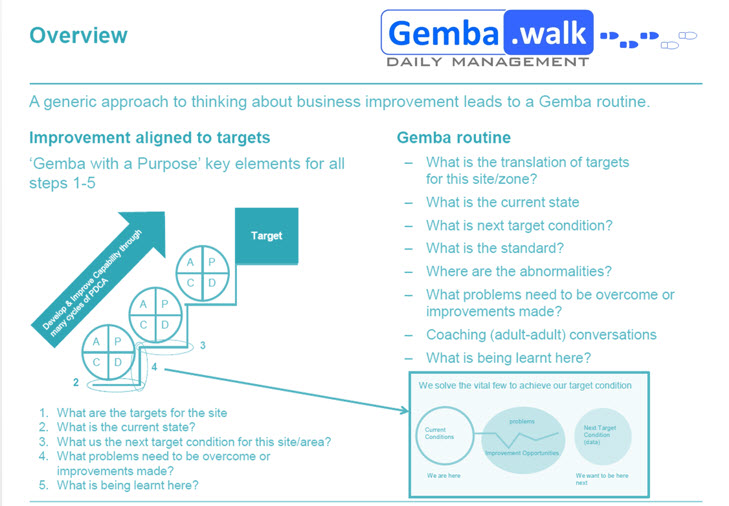

Gemba Overview

"Improvement Aligned to Targets" "Gemba with a purpose" - 5 Key elements

-

-

1.) What are the targets for the area?

2.) What is the current state?

3.) What is the next target condition for this area?

4.) What problems need to be overcome or improvements made?

5.) What is being learned here? -

What is a "Target Condition"?

A Target Condition is an interim goal on the way to the Challenge, described in greater

detail than the Challenge. It usually takes several successive target conditions to

reach a Challenge, so it is sometimes called the “Next Target Condition.”

A Target Condition only describes where you want to be next, not how to get there.

That will be figured out through experimenting in the next step of the IK pattern.

A Target Condition describes a desired future set of circumstances that lie beyond

our current knowledge threshold. We donʼt yet know how we will get there.

A Target Condition has a specified achieve-by date, which is often between 1 week

and 3 months out. Longer than that is often ineffective and should generally be

broken down to smaller Target-Condition increments.

Think of it like eating an elephant, one bite at a time.

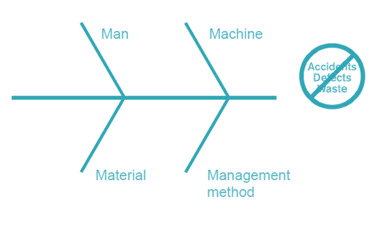

Gemba Coaching - Reducing Accidents Defects and Waste

To improve our zero defects, accidents and waste performance, leading to better cost, quality,service and safety, we have to control the 4M's

-

-

Don’t use the fishbone to solve problems, use it to coach your direct report to identify sources of variation that is impacting Zero Accidents, Defects and Waste:

Observe what the people are doing, and what variation they are introducing into the process that is keeping us from achieving the next target condition.

Observe what the equipment is doing, and what variation it is introducing into the process that is keeping us from achieving the next target condition.

Observe what the material is doing, and what variation it is introducing into the process that is keeping us from achieving the next target condition.

Observe what the management method is doing, and what variation it is introducing into the process that is keeping us from achieving the next target condition

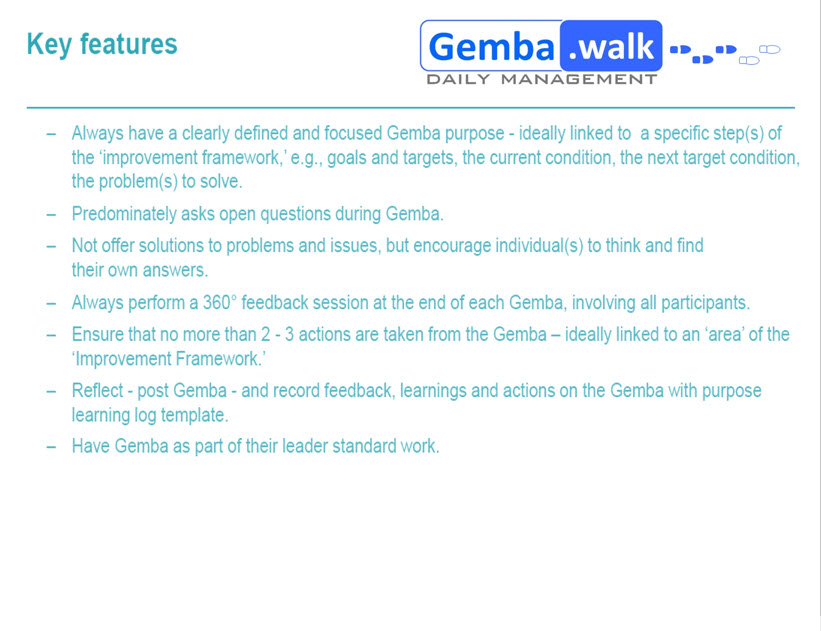

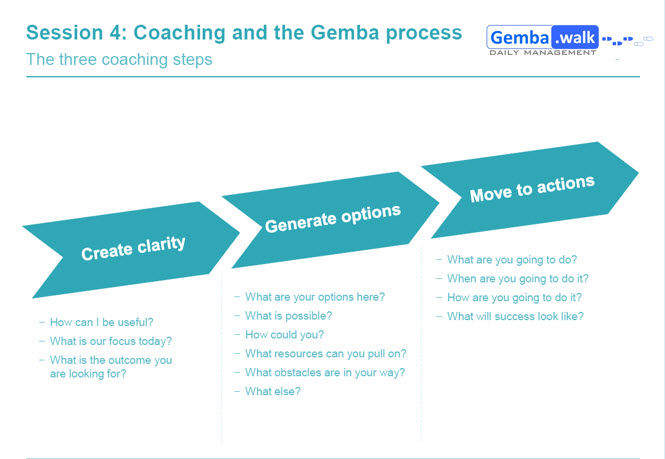

Performing an Effective Gemba! Remember.... The Gemba is the place, the purpose is the coaching.

-

-

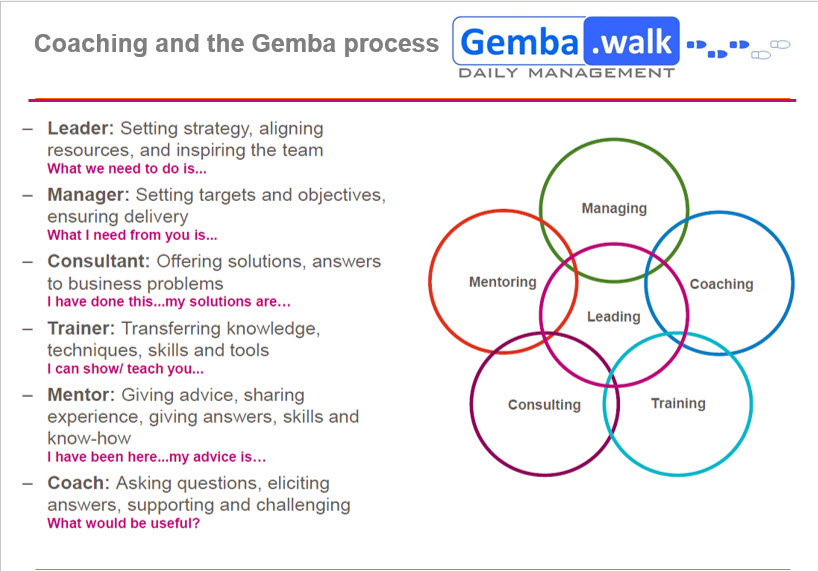

As managers, we all have to wear different hats.

Here is a list of them, and when to put each one on.

1) Sometimes we have to be a leader and inspire.

2) Then there are times we are a manager and drive performance.

3) On occasion we act like a consultant or take the role of an SME

4) There are times we have to be a trainer, and impart knowledge.

5) We could even be asked to be a mentor and share our advice and experiences

6) Finally, we may have to be a coach, by asking questions and challenging the status quo. -

-

Visual Management Board

Gemba walk must always start at the Visual Management Board (VMB). Review the VMB. (Discuss the link between the measures and the organisations strategic goals)

-

Is the Visual Management Board up to date?

-

What is being measured? Do operators/employees understand the KPIs? Do they understand what impact they have on the metrics?

-

How are they doing? How do they know if they are doing good or not?

-

What KPIs are staff most proud of?

Observing Tasks (Learn from the staff)

-

Ask Employee if they have any Safety concerns within their job function or anywhere across the site.

-

Ask the employee if they have a solution to the problem.

-

Ask employees if they have any challenges that keep them from performing their job to the best of their abilities.

-

Ask employee - If they know what the goals are within the area. If they don't know coach them on how they can impact the results.

-

Ask employee - how do they know what they are doing is being done well?

-

What is getting in the way? What barriers do they face? (Underlying causes? use the 5 Whys)

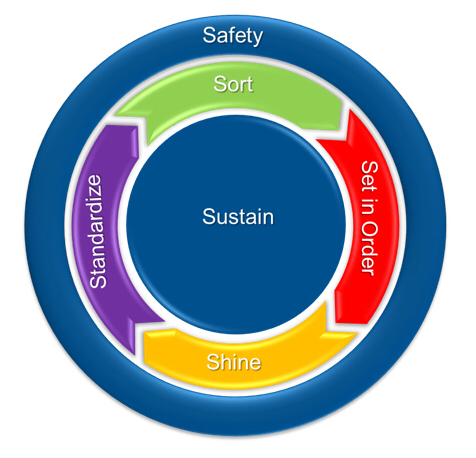

Safety Risks / 6S Improvement opportunities

-

Have there been Incidents/High Potential Incidents reported in the past week/month? Have they been investigated? Have remedial actions been successfully implemented?

-

Ask employee how well Safety risks or issues are fixed after bringing them to management’s attention?

-

Ask employees if they have any 6S or other process improvement ideas they would like to share.

-

Sign off at least one (1) Confirmation Task Card while you are in the area(If it is turned to the green side). This shows the management and BU staff that you care about being part of the team and that we are all in this together "Audit Readiness".

Other Comments / Observations / Commendations (Ensure Feedback is sent to Site Manager/Supervisor)