Information

-

Audit Title

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Health & Safety Inspection

Fire Safety

-

Are emergency exits clearly marked and unobstructed?

-

Fire Exit working as indented (Moving easily)

-

Fire Extinguisher are easy accessible? Not blocked, stored in designated area

-

Flammable materials stored as indented (inside flammable designated cabinets where is possible)

-

Ventilation (LEV) - working

-

Dust cleared from the working areas? (Asses the level of dusts)

-

Ovens are clean inside to prevent accumulation of combustibles inside?

FLOOR

-

Are walkways clear of obstruction?

-

All items are removed from the floor (Everything on wheels easy to be moved from the walkway)?

-

Are the equipment/materials stored in the correct locations?

-

Are work areas clean and free of rubbish and dry? (no spillages, water or other liquids on the floor etc)

-

Are warning signs posted for wet floors or uneven surfaces?

-

Are pallets/ pallet trucks stored correctly? (No pallet trucks left in the middle of the walkways, working areas)

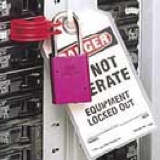

EQUIPMENT/MACHINERY

-

Are machines properly guarded to prevent injuries? (Are guards in good condition and working or closed?)

-

Are emergency shut-off switches readily accessible for all equipment?

-

Are the cables, cables from the equipment stored correctly? Not posing any threat (Trips hazards eliminated)

-

Are machines free from visual damage?

-

Are ladders- serviceable/stored correctly?

-

Are tools & fixtures stored correctly/safely?

GENERAL SAFETY OF THE AREA

-

Are scissors, knives and sharp tools stored correctly?

-

Are hazardous materials stored correctly?

-

Are lights clean & working?

-

Areas free from any broken glass or any broken hard plastics?

-

Safety Signage in place and in good condition

-

Areas are free from other observed issues?

BEHAVIOURAL

-

Are appropriate personal protective equipment (PPE) such as gloves, googles, ear defenders, hairnets, and overalls worn by employees?

-

Employee demonstrates general awareness of job hazards?

-

The employee is demonstrating safe work procedures (SSoW)?

-

Employee worksite is not causing environmental issues to building occupants? (Noise, smell, dangerous behavior)

-

The employee using available resources (tools, machines) as indented?

-

Employee is demonstrating proper ergonomic movements during activities? (Lifting, bending, twisting etc.)

-

The employee does not pose a threat with their behavior when using machines?

-

Workers does transport the goods safely?

DOCUMENTS, TRAINING, PRESTARTUP CHECKS

-

Pre-start up check completed and documented?

-

Training Records completed for workers using equipment or process in that area?

Summary

-

Have any close calls been raised from the audit

-

Have any improvement been identified

-

The employee stopped working when he noticed a threat that could be dangerous?

-

Auditors