Title Page

-

SWMS No

-

Conducted on

-

Prepared by

-

Location

My Company Details

-

Business Name: NRG Industrial Pty Ltd

-

Business Address: 12 Cassam St Yeppoon Qld 4703

-

Business Contact: Narelle Jack

-

ABN: 47139584053

-

Phone No: 49392000

SWMS APPROVAL

-

SWMS APPROVED BY: Grantley Jack (Employer/PCBU/Director/Owner)

-

Date:

-

Name and Signature of person responsible for ensuring compliance with SWMS:

-

Person/s Responsible for Reviewing the SWMS:

-

SWMS amendments must be approved by

Person

-

Name and Signature:

-

ALL PERSONS INVOLVED IN TASK MUST HAVE THIS SWMS COMMUNICATED TO THEM PRIOR TO WORK COMMENCING:

- Daily Tool Box Talks will be undertaken to identify, control and communicate additional site hazards.

- Work must cease immediately if incident or near miss occurs. SWMS must be amended in consultation with relevant persons.

- Amendments must be approved by nominated persons and communicated to all affected workers before work resumes.

- SWMS must be made available for inspection or review as required by WHS legislation.

- Record of SWMS must be kept as required by WHS legislation (until job is complete or for 2 years if involved in a notifiable incident).

Relevant Workers

Relevant workers must be consulted in the development, approval and communication of this SWMS.

-

Workers to be consulted:

Worker

-

Name and Signature:

-

Job Title:

Part 1: Principal Contractor Details

Principal Contractor details

-

The builder or the organisation you are working for.

-

Principal Contractor Company Name:

-

Project Name:

-

Job Address:

-

Project Manager Name and Signature:

-

Date SWMS provided to Principal Contractor:

High Risk Construction Work & PPE

SWMS Scope

-

This SWMS provides guidance on the safe operation of Elevated Work Platforms including scissor lifts, boom lifts and cherry pickers.

High Risk Construction Work

-

This work activity involves the following "High Risk Construction Work"

-

Confined Space

-

Mobile Plan

-

Demolition

-

Asbestos

-

Using explosives

-

Diving work

-

Artificial extremes of temperature

-

Tilt up or pre-cast concrete

-

Pressurised gas distribution mains or piping chemical, fuel or refrigerant lines energised electrical installations or services

-

Structures or buildings involving structural alterations or repairs that require temporary support to prevent collapse

-

Involves a risk of a person falling more than 2m, including work on telecommunications towers

-

Working at depths greater than 1.5 Metres, including tunnels or mines

-

Work in an area that may have a contaminated or flammable atmosphere

-

Work carried out adjacent to a road, railway or shipping lane, traffic corridor

-

In or near water or other liquid that involves risk of drowning

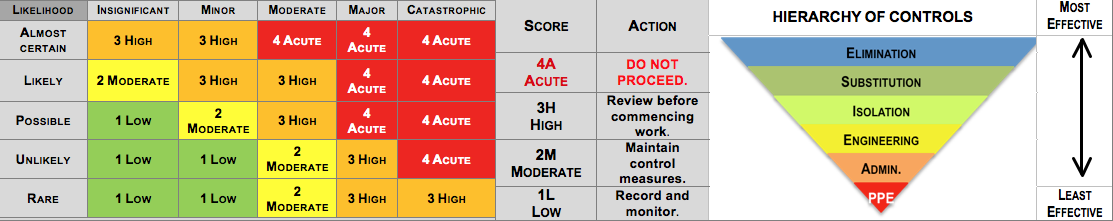

Risk Assessment Matrix & Controls

Personal Protective Equipment (PPE)

-

Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

Foot Protection

-

Hearing Protection

-

High Visibility

-

Head Protection

-

Eye Protection

-

Face Protection

-

Hand Protection

-

Breathing Protection

-

Protective Clothing

-

Fall Arrest

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

Planning & Preparation

Potential Hazard

-

Lack of consultation with potential outcomes for personal injury, property damage &/or environmental incident.

-

Risk-Rating (IR) before control measures have been put in place

Control Measures to Reduce Risk

-

Liaise with Principal Contractor to establish the following on-site systems and procedures are in place and take note of:

· Health and Safety rules

· Induction for all workers – site specific and toolbox meetings

· Supervisory arrangements

· Communication arrangements

· All relevant workers are appraised for required competencies & for any pre-existing medical conditions if working in remote or isolated locations.

· PPE required

· Site plans – showing no go zones for pedestrians

· Traffic Management Plan

· Exclusion Zones

· Risk Assessments

· SWMS and JSA’s

· Injury reporting procedures

· Hazard reporting procedures -

Risk-Rating (RR) after control measures have been put in place<br>

-

Person responsible to implement control measures:

Training & Capabilities

Potential Hazard

-

Lack of training or the assessment of capability may lead to personal injury, property damage &/or environmental incident.

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure all persons entering site have a General Construction Induction Card (white card).

Ensure all relevant workers have undertaken training and/or received instruction in the use of control measures. Including:

· Reporting procedures for incidents

· Correct use of EWP including loading / unloading EWP

· Correct use of fall restraint equipment, use, care of and maintenance

· Correct use of all tools & equipment used

· Use of supervision where required (e.g. new starters or new equipment)

· Ensure supervisors, foremen etc. are suitably experienced in the type work to be conducted. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Implement a Falls Emergency Rescue Plan

Potential Hazard

-

Personal injury from fall<br>Note: A Falls Emergency Rescue Plan is included in this SWMS

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Use of a Spotter:

· Spotter to make visual contact with operator at regular intervals (approx. every 5 minutes)

· Spotter trained in how to lower the EWP in the event of an emergency

· Trained first aid providers must be available

· A reliable means to contact emergency services. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Suspension trauma

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Considerations for rescuing workers who have fallen and are suspended:

· Whenever a person is wearing a harness, a rescue plan must be in place as suspension trauma can occur to persons who fall and remain in the harness for more than 5 minutes

· The rescue must be able to commence immediately

· The victim must be moved from suspension in stages – if moved too quickly from full suspension into a horizontal position serious injury or death can occur

· If a suspension may last up to 5 minutes – foothold straps or other way of placing weight on legs must be provided.

In event of a fall and suspension - Workers should be trained to:

· Use a sit – type harness with padded legs to allow legs to remain horizontal

· Move their legs in the harness to push against any footholds

· Move their legs as high as possible and keep their head as horizontal as possible. Note: The ability for workers to be able to follow these procedures should be a consideration when selecting harnesses for use

· Ensure all workers on-site are trained and familiar with emergency and evacuation procedures

· Ensure EWP is fitted with an emergency retrieval device, controlled descent device and an escape-rescue facility. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Delivery and removal of EWP

Potential Hazard

-

Crush Injuries Entrapment

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure the truck/vehicle and/or trailer used to transport the mobile plant is appropriate –weight and size.

Ramps:

· Suitable load capacity for weight of plant, wide enough, foot boards on the side

· Lock ramps in place, use locking pin/clips if required

· Assess ground conditions at loading/unloading site to determine forward or reverse loading

· Ensure clear of obstructions (tree branches, structures / overhead electric lines etc.)

· Ensure persons are clear of loading/unloading site

· Ensure EWP is in fully lowered position.

To load/unload:

· Apply handbrake and block tow/transport vehicle wheels

· Load / unload as per manufacturer’s instructions

· EWP is loaded/unloaded to and from the vehicle whilst on level ground

· EWP is aligned for loading/unloading and positioned with the vehicle by a suitably qualified, competent and experienced operator

· Use caution during any swivel operation

· Ensure EWP is adequately restrained to prevent movement during transit. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Slips, trips and falls

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Do not climb on EWP while loading/unloading to and from the vehicle

· Do not jump from EWP or vehicle tray

· Wear non slip footwear

· Only access tray of vehicle using manufacturers access points. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Falling objects

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Do not leave any loose items in EWP

· Ensure all fittings and attachments are secure before loading / unloading EWP

Do not stand behind EWP or vehicle when loading/unloading. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Assess onsite conditions

Potential Hazard

-

Lack of a clear assessment may lead to personal injury, property damage &/or environmental incident.

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Assess conditions at site on arrival. Ensure:

· Ensure site-specific induction is undertaken (include location of amenities, first aid facilities, emergency plans and evacuation points, incident reporting, communication, contact persons etc.)

· Assess mobile phone reception’ (alternative emergency communications procedures in place if no reception available)

· Work site is exactly as detailed in Terms of Agreement or contract

· Suitable weather conditions (do not work outside in low visibility, heavy rain, high winds etc.)

· Suitable access for all equipment required

· Suitable ground / track conditions for operation of equipment

· Suitable lighting, including night-works (include flood lighting and operator head lamps as applicable)

· Power lines in close proximity

· Take note of other mobile plant movement -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Working near utilities

Potential Hazard

-

Contact with overhead power lines causing electrocution and property damage

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Do not undertake work in No-Go Zones of electrical power lines unless de-energised/isolated from the power supply and evidence of the continuing isolation of the power supply is obtained.

Where work is undertaken in close proximity to power lines:

· Use trained spotters

· Use adequately insulated EWP

In general:

· 3m above, either side and below power lines is No Go Zone

· Between 3-6.4m of power lines a Spotter is required

· Further than 6.4m of power lines is open area

· No work to be conducted within 10m radius of SWER transformer.

Note: Authorised persons may be permitted to work within minimum safe distance zones for jobs such as tree clearing work, provided requirements of State Energy Authority and owner of electric line are complied with. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

EWP - Pre start check

Potential Hazard

-

Lack of a clear assessment may lead to potential personal injury, property damage &/or environmental incident.

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Inspect before use. Ensure:

· Check that plant is in a mechanically sound condition and operator’s instructions are available

· All required safety equipment is fitted and operational

· Equipment, including labelled controls and safety devices, present and working

· Complete log books

· SWL is displayed.

Do not use if any fault/damage/missing parts. Report immediately and follow tag-out/lock-out procedures. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Work area setup

Potential Hazard

-

Muscular stress / musculoskeletal disorder (MSD)

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Enter and Exit EWP as per manufacturers instruction

· Ensure EWP is as close to work area as possible (avoid leaning out stretching at odd angles). -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Work adjacent to road & public safety

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· If setting up roadside – comply with local laws and permits

· Erect any barriers & signage necessary to keep others safe and aware. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Contact with mobile plant

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Plan travel path. Ensure:

· Ground surface is suitable (assessed by competent person)

· No obstructions (power lines, scaffolding, pipes etc.)

· Clear visibility in all directions

· Do not raise platform on slope or drive onto slope when elevated.

· Ensure placement will not cause traffic congestion

· Adequate lighting (especially during night works)

· Ensure work area is barricaded from other mobile plant. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Plant rollover

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Verify the work ground / floor is suitable for the particular machine. (Smaller mobile plant may have higher bearing pressures than larger machines)

· Ensure the ground / floor is safe and approved for use by a competent person. (E.g. Engineer)

· Ensure the ground / floor is monitored and maintained in good condition for the duration of the work

· Do not commence work in areas where other site activities (e.g. trenching) may have affected the integrity of the ground without visual inspection and/or sign off that it is safe. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

EWP Operation

Potential Hazard

-

Falls from height operation

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure workers operating the platform are trained and instructed in the safe use of fall-arrest equipment and emergency rescue procedures.

Fall arrest system:

· Fall arrest system must comply with relevant Australian Standard

· Formal inspection by competent person per manufacturer (6 monthly or more if exposed to hazardous environment)

· Inspect all fall arrest equipment before each use.

Operate per manufacturer’s instructions and task specific SWMS:

· Only one designated person should operate the controls (except in an emergency)

· Never exceed the Safe Working Load (SWL) of the EWP

· Ensure entry gate is closed before elevating

· All loads must be stored within the platform perimeter

· All occupants must wear approved fall restraint device properly attached to designated platform anchorage points

· No ground-operated controls shall be engaged without permission of elevated operator worker except in an emergency.

Do not exceed working height of the unit. Do not:

· Stand on handrails

· Lean/reach out of platform

· Use ladders in platform

· Exit platform once elevated -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Crush injuries entrapment

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Keep all parts of the body inside platform at all times when moving EWP

· Never allow any part of the body to be under the EWP platform when it is in an elevated position

· Always check under EWP before lowering. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Safety of others from being hit by falling object

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Ensure no tools & equipment can be dropped over the side.

Do not:

· Use EWP to push or pull other objects

· Use lanyard to stop tools falling. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Muscular stress / musculoskeletal disorder (MSD)

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Avoid long periods of repetitive movements

· Avoid working in awkward postures – do not Lean/reach of out platform

· Do not work in static positions for more than 30 minutes at a time

· Ensure regular rest-breaks taken

· Consider stretching before and after work. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

On completion

Potential Hazard

-

Crush injuries / entrapment

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Park EWP in safe area (flat, firm ground, clear of obstructions, traffic)

· Lower platform to ground

· Shut down machine as per manufactures instructions

· Remove keys and apply park brake

· Inspect equipment for any damage/leaks. If damage is detected – report immediately and take out of service

· Ensure all equipment /plant is clean of debris and/or contaminants before leaving site.

Note: The hydraulic system remains pressurized when the engine is not running. Using controls after machine is off may cause sudden/unexpected movements to occur -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Remote and/or isolated work

Potential Hazard

-

Personal Injury from delay in emergency assistance to remote workers

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

A ‘Buddy’ system is utilised for high-risk tasks undertaken in remote locations or working in isolation.

A procedure is developed and in place for regular contact with people working remotely or in isolation, The procedure should identify:

· Travel itineraries, locations, scheduled contact persons and times

· Sufficient supplies of water, food, fuel & supplies needed

· An emergency response

· Appropriate Vehicles

· Safety equipment including first aid. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Site specific hazards

-

Have you identified any further hazards on the job site?

Job Step

-

What job step does this hazard relate to?

-

Potential Hazard

-

Risk-Rating (IR) before control measures have been put in place<br>

Control Measures to Reduce Risk

-

Control measures used to reduce risk

-

Risk-Rating (RR) after control measures have been put in place.

-

Person responsible to implement control measures:

Refuelling on site

Potential Hazard

-

Fire / explosion

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· DO NOT smoke during re-fuelling

· Ensure re-fueling is undertaken in well-ventilated area, clear of ignition sources

· NOTE: Ignition sources include pilot lights, stoves, heaters, cigarettes, matches/lighters, grinding, welding, power points, lighting, light switches, radio transmitters, mobile phones, battery powered forklifts etc.

· Material/Safety Data Sheets (M/SDS) for all fuel products on hand

· Follow manufacturer’s manual/recommendations for re-fuelling

· Ensure fire extinguisher available and in date.

Diesel: Fire extinguisher – Water, foam, dry chemical powder, CO2

Unleaded petrol: Fire extinguisher – Dry chemical powder, foam, CO2. Never use water to extinguish an Unleaded Petrol fire. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Exposure to hazardous chemicals / substances

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Avoid breathing vapours or contact with fuel

· If clothing is splashed with fuel, change immediately

· Do not siphon or swallow fuel as this can be fatal

· Do not eat, drink or smoke during/after-handling fuel until hands are carefully washed. Shower and wash immediately after work. Wash clothes in separate wash from other clothes. -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Muscular stress / musculoskeletal disorder (MSD)

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

Where possible use pump to transfer fuel from container into tank

If using fuel container, and lifting into place:

· Lift smoothly, do not jerk or throw load upwards

· Avoid any twisting and side-bending during lift

· Bend knees, not back.

· Avoid awkward and sustained positions -

Risk-Rating (RR) after control measures have been put in place

Potential Hazard

-

Environment incident

-

Risk-Rating before control measures have been implemented

Control Measures to Reduce Risk

-

· Ensure training in emergency response for chemical spill

· Ensure to have spill kit available onsite.

Emergency response – minor fuel spill:

1. Stop the source of the spill or leak or release

a. If that is not possible & it is safe to do so - stop the spill or release from spreading

2. Turn off any ignition sources if safe to do so

3. Use Spills Kit: (as required)

a. Position socs on a downhill slope or surround spill if on flat ground.

b. Block stormwater inlets with drain sealing mats.

c. Float Booms around the spill if on water. -

Risk-Rating (RR) after control measures have been put in place

-

Person responsible to implement control measures:

Falls Emergency Plan

-

Location of closest medical facility:

-

Approximate response time:

-

Location of closest emergency services:

-

Approximate response time:

-

Can rescue be undertaken onsite by trained personnel?

-

Indicate rescue equipment that will be provided:

-

Fibre rope (meets relevant standards)

-

Karabiner

-

Number required

-

Rescue Knife

-

Auto-stop Descender

-

Triple Lock Karabiner

-

Rescue stretcher

-

Round sling

-

Pre-rigged control descent device

-

Recovery pole

-

Other

-

Specify other rescue equipment

-

Provide details of communication equipment that will be used

-

Provide details of trained rescue personnel (trained within last 12 month period)

-

Trained rescue personnel

Person

-

Name

-

Course Name

-

Date of training

-

Provide details of trained first aiders for rescue (trained within last 12 month period)

-

Trained first aiders

Person

-

Name

-

Course Name

-

Date of training

-

Documented rescue plan developed?

-

Documented rescue plan rehearsed?

-

Documented rescue plan accessible on site?

Emergency Response

-

Emergency Response - CALL 000 IMMEDIATELY.

-

If work is to be conducted on a construction site (or a site controlled by another Employer / PCBU) follow the site-specific Emergency Management Plan. Ensure:

· Adequate numbers of first aid trained staff are on site when working at heights occurs

· First aiders are trained and competent in managing injuries associated with demolition until emergency services arrive

· All rescue equipment is in good condition, available for use and in close proximity to the work site. -

Ensure workers have access to:

· First aid kit/supplies

· First Aid trained personnel familiar with Resuscitation and emergency response for electric shock

· M/SDS

· Communication devices (check mobile phones will have service in area)

· Suitable fire protection equipment.

Training, Permits, Tools, Supervisory Arrangements

Training and Licences Required For Workers Undertaking This Task. Select those relevant

-

Are any training or licences required to complete this task?

-

Licence to Perform High Risk Work (operating certain plant, equipment)

-

Licence details

-

Photo of relevant licences

-

TAFE or other recognised training organisation

-

Licence details

-

Photo of relevant licences

-

Construction Induction Card (or equivalent)

-

Licence details

-

Photo of relevant licences

-

PPE

-

Licence details

-

Photo of relevant licences

-

Traffic Management Plan

-

Licence details

-

Photo of relevant licences

-

Other

-

Licences/training

Licences / Training

-

Licence details

-

Photo of relevant licences

Plant/Tools/Equipment Required For The Job

-

Plant / Tools / Equipment are required to complete this job:

-

Plant / tools / equipment required:

Equipment / Tools / Plant

-

Make & Model

-

Plant/macinery photo

Details of Supervisory Arrangements for Workers Undertaking This Task:

-

Supervisory arrangements for this task:

- Suitably qualified supervisors for job

- Direct on-site supervision

- Remote site - communication systems / schedule

- Audits

- Spot Checks etc

- Reporting Systems

- Not applicable

- Other

-

List other licences/training relevant

Licences / Training

-

Enter relevant information

Details of Regulatory Permits / Licenses / Engineering Details / Certificates / Work Cover Approvals:

-

Are there any Regulatory Permits / Licenses / Engineering Details / Certificates / Work Cover Approvals?

-

Applicable permits / licenses etc

- Local Council Permits

- Authorisation to work

- Confined Space Permit

- Building Approvals

- EPA Approvals / Permits

- Plant to be registered with State Authority

- PPE to comply with relevant Australian Standards

- Other

- Not applicable

-

Item

Licences / Training

-

Item Details

-

Take a photo of relevant licenses / permits where possible

Part 2: Relevant Legislation & Codes of Practice

Relevant Legislation:

-

Note: Retain only the legislation references applicable to your state of operation for this SWMS.

-

Northern Territory

-

· Work Health and Safety (National Uniform Legislation) Act 2011

· Work Health and Safety (National Uniform Legislation) Regulations 2011 -

Commonwealth, NSW, QLD, ACT

-

· Work Health and Safety Act 2011

· Work Health and Safety Regulations 2011 -

SA, Tasmania

-

· Work Health and Safety Act 2012

· Work Health and Safety Regulations 2012 -

Victoria

-

· Occupational Health & Safety Act 2004

· Occupational Health & Safety Regulations 2007 -

Western Australia

-

· Occupational Safety & Health Act 1984

· Occupational Safety & Health Regulations 1996

Codes of Practice

-

Commonwealth, NSW, QLD, ACT, NT, SA, Tas.

-

Safe Work Australia (2011):

· Construction Work

· First Aid in the Workplace

· Managing the Risk of Falls at Workplaces

· Managing the Risk of Plant in the Workplace

· Managing Noise and Preventing Hearing Loss in the Workplace

· How to Manage Work Health and Safety Risks

· Hazardous Manual Tasks

· Managing Risks of Hazardous Chemicals

· Managing Electrical Risks in the Workplace

· Managing the Work Environment and Facilities

· WHS Consultation, Cooperation & Coordination -

Victoria

-

WorkSafe Victoria

(1990): No. 13: Building and Construction Workplaces

(2000): No. 25: Manual Handling

(1995): No. 19: Plant

(1998): No. 23: Plant (Amendment No. 1)

(2004): No. 29: Prevention of Falls in Housing Construction

(2000): No. 24: Hazardous Substances

Compliance Codes: WorkSafe Victoria (2008): Compliance Code:

Communicating OHS Across Languages

First Aid in the Workplace

Prevention of Falls in General Construction

Workplace Amenities and Work Environment

Reference Documents

-

Have you referred to any documents?

-

References referred to:

Part 3: Worker / Employee Sign Off

Overall Risk Rating After Controls

-

Select Risk Rating

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and Personal Protective Equipment described.

Employee

-

Employee/Worker Name and Signature:

-

Job Role/Position

-

Employer/PCBU/Supervisor:

Review & Monitor

-

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation. -

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

• Spot checks

• Consultation

• Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Review Number

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

Name & Initials

-

Date