Title Page

-

Forklift Type and Number

-

Thorough examination under LOLER valid and not exceeded

-

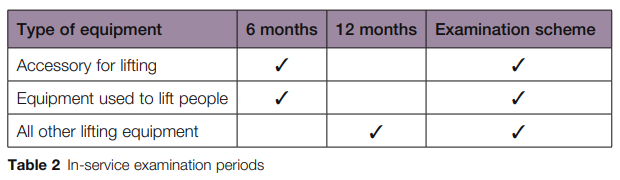

In-service examination periods

-

Select Gigaclear stores location

-

Select Gigaclear Region

-

Conducted on

-

Prepared by

Guidance Page

-

No - item is defective, or does not meet the requirements or standards as determined by the User manual, Gigaclear, Equipment owner or Legislative requirements. Breach may have the potential to cause harm or injury or risk of notices or prosecution from, the HSE. Failed Item(s) must be rectified prior to using the Forklift.

-

Yes - item is compliant, and meets or exceeds the required standards as determined by the User manual, Gigaclear, Equipment owner or Legislative requirements.

-

Useful HSE Guidance:

-

Use lift trucks safely Advice for operators

-

Operator training and safe use

-

A simple guide for employers

HSEQ Forklift Inspection

Daily Checklist

-

Before starting the engine

-

Tires and rims in good condition

-

Engine oil, hydraulic oil, battery fluid, coolant level and hydraulic levels are adequate

-

Are there any leaks under the forklift

-

Are there any cracks, dents or visible damage of any sort

-

Locking mechanism is working correctly

-

Are the Rams damaged or leaking

-

Battery operates correctly

-

Engine bay is clean and its locking mechanism working correctly

-

Load plate is fitted and legible

-

Overhead and back rest guards are free of any damages

-

Seat is working properly

-

Seat belt is in good working condition

-

Controls are clearly marked

-

After starting the engine

-

Controls, pedals and indicators are working correctly

-

Reverse buzzer and beacon are working correctly

-

Lights and flashing strobe are in good working condition

-

Steering wheel turns smoothly from lock to lock

-

Park brake and foot brake work correctly

-

Hydraulic lift, tilt and reach work properly for their full extent?

-

Notes and Observations

Confirmation

-

Is the forklift free of all defects and safe to use?

-

Full Name and Signature of Operator Inspector