Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Reference number (from the notification e-mail)

-

Incident Summary

Accident report

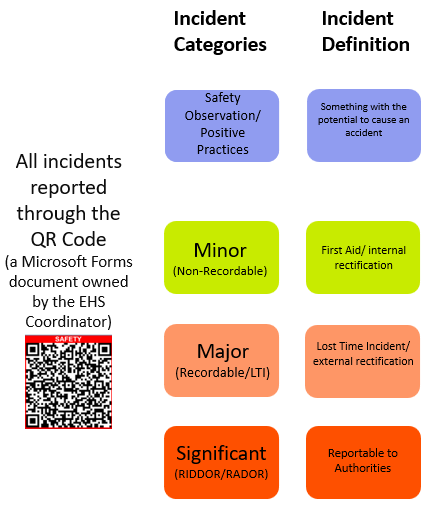

Incident Category:

-

What is the loss category?

-

Incident definitions

-

What is the accident category?

- Minor

- Major

- RIDDOR

- Colleague illness (not work related accident)

-

Has this accident, or one similar to it, occurred on site within the last 30 days?

Define Problem

-

When was the accident?

-

Please describe the accident in detail

-

Where did the accident occur?

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

Where did the accident occur?

-

What equipment was involved in the accident (include photo)

- Blade/ Knife

- Compactors

- Contractor owned equipment

- Products (anything produced and sold by Culligan)

- Display Screen Equipment

- Dock Leveller

- External Building damage

- Fire Equipment (extinguishers, alarms, lights, sounders)

- Hand tools (not including blades)

- Internal Buidling damage

- Manual Handling aids (trolleys, lifting equipment etc)

- MHE (FLT, PPR, etc)

- Office Seating

- Other

- Packaging material

- Pallets

- Racking

- Road Van/ Truck

- Roller Shutter door

- Waste

-

Please describe equipment involved

-

Who was the injured person (please use initials only)

-

What is their employment status?

-

What is their shift pattern?

-

Where on the body was their injury?

- Left side of body

- Right side of body

-

Where specifically on the left side of the body?

- Head

- Face

- Ear/ hearing

- Eye

- Nose

- Mouth

- Neck

- Shoulder

- Arm

- Elbow

- Wrist

- Hand

- Finger

- Torso (inc back injury)

- Hips

- Buttocks

- Thigh

- Knee

- Calf

- Ankle

- Foot

- Toes

-

all head injuries will require a full investigation

-

Circle the body part affected

-

Where specifically on the right side of the body?

- Head

- Face

- Ear/ hearing

- Eye

- Nose

- Mouth

- Neck

- Shoulder

- Arm

- Elbow

- Wrist

- Hand

- Finger

- Torso (inc back injury)

- Hips

- Buttocks

- Thigh

- Knee

- Calf

- Ankle

- Foot

- Toes

-

all head injuries will require a full investigation

-

Circle the body part affected

-

What was the injury type?

- Cut

- Abrasion

- Pain

- Bruising

- Sprain

- Stab

- Burn / Scald

- Fracture

- Crush

- Non-Injury i.e. feeling faint or nausea

-

Is this occurrence related to a previously known medical condition or injury?

-

Has this person received training in the task where the accident occurred?

-

Provide evidence of training such as certificate or attendance record

-

What level of experience does this person have?

-

Was PPE required to be worn?

-

Which PPE was required to be worn?

- Hard hat/ bump cap

- Hearing protection

- Eye protection

- Respiratory equipment

- Hand protection

- Hi-Vis clothing

- Safety footwear

- Fall arrest kit/ Harness

-

Was the correct PPE being worn at the time of the accident?

-

Does CCTV or video footage exist of the accident?

-

Provide link to the footage or still screen shots

-

What was the immediate response?

- First Aid

- Quarantined the area/ equipment

- Walk-in center/ taken to A&E

- Communication to effected parties

-

Who was the first aider? (please use initials only)

-

Was treatment permitted?

-

What first aid treatment was applied?

- Pressure/ elevation to stop bleeding

- Cleaning of wound

- Application of dressing

- Control of the accident area

- Calling emergency services

- Other

-

Please specify first aid treatment applied

-

What time were the emergency services called?

-

What time did the emergency services arrive?

-

Were any witness statements documented?

-

Please attach the documents

-

Was Violence or Aggression involved?

-

The HR department must be involved

Completion

-

Name of person completing report

Define Problem

-

When was the accident?

-

Please describe the accident in detail

-

Where did the accident occour in the facility?

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

What equipment was involved in the accident (include photo)

- Blade/ Knife

- Compactors

- Contractor owned equipment

- Products (anything produced and sold by Culligan)

- Display Screen Equipment

- Dock Leveller

- External Building damage

- Fire Equipment (extinguishers, alarms, lights, sounders)

- Hand tools (not including blades)

- Internal Buidling damage

- Manual Handling aids (trolleys, lifting equipment etc)

- MHE (FLT, PPR, etc)

- Office Seating

- Other

- Packaging material

- Pallets

- Racking

- Road Van/ Truck

- Roller Shutter door

- Waste

-

Please describe equipment involved

-

Who was the injured person (please use initials only)

-

What is their employment status?

-

What is their shift pattern?

-

Where on the body was their injury?

- Left side of body

- Right side of body

-

Where specifically on the left side of the body?

- Head

- Face

- Ear/ hearing

- Eye

- Nose

- Mouth

- Neck

- Shoulder

- Arm

- Elbow

- Wrist

- Hand

- Finger

- Torso (inc back injury)

- Hips

- Buttocks

- Thigh

- Knee

- Calf

- Ankle

- Foot

- Toes

-

all head injuries will require a full investigation

-

Circle the body part affected

-

Where specifically on the right side of the body?

- Head

- Face

- Ear/ hearing

- Eye

- Nose

- Mouth

- Neck

- Shoulder

- Arm

- Elbow

- Wrist

- Hand

- Finger

- Torso (inc back injury)

- Hips

- Buttocks

- Thigh

- Knee

- Calf

- Ankle

- Foot

- Toes

-

all head injuries will require a full investigation

-

Circle the body part affected

-

What was the injury type?

- Cut

- Abrasion

- Pain

- Bruising

- Sprain

- Stab

- Burn / Scald

- Fracture

- Crush

- Non-Injury i.e. feeling faint or nausea

-

Is this occurrence related to a previously known medical condition or injury?

-

Has this person received training in the task where the accident occurred?

-

Provide evidence of training such as certificate or attendance record

-

What level of experience does this person have?

-

Was PPE required to be worn?

-

Which PPE was required to be worn?

- Hard hat/ bump cap

- Hearing protection

- Eye protection

- Respiratory equipment

- Hand protection

- Hi-Vis clothing

- Safety footwear

- Fall arrest kit/ Harness

-

Was the correct PPE being worn at the time of the accident?

-

What were the environmental conditions at the time of the accident?

- Sunny

- Raining

- Windy

- Overcast

- Snow/ Ice

- Extreme heat

-

Does CCTV or video footage exist of the accident?

-

Provide link to the footage or still screen shots

-

What was the immediate response?

- First Aid

- Quarantined the area/ equipment

- Walk-in center/ taken to A&E

- Communication to effected parties

-

Who was the first aider? (please use initials only)

-

Was treatment permitted?

-

What first aid treatment was applied?

- Pressure/ elevation to stop bleeding

- Cleaning of wound

- Application of dressing

- Control of the accident area

- Calling emergency services

- Other

-

Please specify first aid treatment applied

-

What time were the emergency services called?

-

What time did the emergency services arrive?

-

Were any witness statements documented?

-

Please attach the documents

-

Was Violence or Aggression involved?

-

The HR department must be involved

-

RIDDOR Category

- Specified Injury

- Over Seven Day Incapacitation of a worker

- (ROI ONLY) Over Three Day Incapacitation of a worker

- Reportable Disease

- Dangerous Occurrence

- Injury to Non-Worker i.e. Visitor or Member of Public

-

RIDDOR Website England/ Scotland/ Wales: https://www.hse.gov.uk/riddor/report.htm

-

RIDDOR Reference Number (attach a copy of the report to this pack)

-

Who made the RIDDOR report? (print name)

-

This incident does not require an investigation

-

When was the incident?

-

Describe the incident

-

Where did the incident occur in the facility?

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

Who was involved (please use initials only)

-

What is their employment status?

-

What treatment was given?

- First Aid

- Quarantined the area/ equipment

- Walk-in center/ taken to A&E

- Communication to effected parties

-

Who was the first aider? (please use initials only)

-

Has their manager been informed?

Sign off

-

Name of person reporting incident

-

Incident definitions

-

What is the environmental incident category?

- Minor

- Major

- RIDDOR

- Colleague illness (not work related accident)

Investigation Team

-

Team leader

Team Members

-

Name of Team member

Define Problem

-

When was the incident.

-

Where did the incident occur

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

What equipment/infrastructure/products/services/scenario involved.

-

What was the cause of the chemical spill

- Loss of vehicle fuel containment

- Damaged chemical container

- Incorrect use of chemical

- During decanting process

-

Description of the incident in detail

-

What was your immediate response

- Access to site checked/made secure

- Air Con/heating switched off/windows closed.

- Alarm Raised (External)

- Alarm Raised (Internal System)

- Absorbent socks used to prevent spread

- Area cleared of excess water

- Area cleared of litter/dirt

- Bin/Skip covered/sealed

- Building Evacuated

- Customer stock removed from the area.

- Drains blocked with drain covers

- Doors closed in warehouse/temperature controlled areas.

- Equipment and machinery removed from the area.

- Equipment serviced/calibrated.

- Fire fighting/suppression equipment ordered/distributed.

- Fire tackled

- Leak plugged/sealed

- Leaking drum/vessel placed on bunded pallet

- Main site shut off taps closed.

- Nothing

- Spill kit and/or consumables ordered/distributed.

- Storage/spill bund drained of water.

- Storage/spill bund protected against weather

- Unused electrical devices turned off.

- Waste removed and placed in correct bins/skips

- Waste stored elsewhere (Temporary)

- Water outlets turned off

- Weeping/dripping valves/pipes repaired.

- Other

-

Who was involved (Use initials only)

-

What is their employment status?

-

Has this person received training in the task where the accident occurred?

-

Provide evidence of training such as certificate or attendance record

-

What level of experience does this person have?

-

Please describe the accident in detail

-

Does CCTV or video footage exist of the accident?

-

Provide link to the footage or still screen shots

-

Did anyone witness the event?

-

Was a written witness statement(s) taken from the individuals?

-

Attach witness statement to the report here.

-

What was the cause of the waste issue

-

Who was involved (Use initials only)

-

What was the immediate response.

-

Description of the incident in detail

-

Did anyone witness the incident

-

Was a written statement(s) taken from the individuals?

-

Attach statement(s) here

-

Take statement(s) and attach here

-

What was the cause of the utility issue.

- Combination of gas heating, air conditioning or open doors/windows working against each other.

- Electrical machinery/devices left on for excessive periods/overnight when not in use.

- Gas heating systems left on or not moved to tick-over mode when office unoccupied during the evening/weekend.

- Warehouse heating/temperature control systems left on with doors/shutters left open.

- Water outlets for cleaning, vehicle washing or welfare left running unnecessarily.

- Fluid/Fuel leak of a vehicle/plant/tank (3rd party owned)

- Fluid/Fuel leak of a vehicle/plant/tank (DBS Owned)

- Leak from customer owned goods

- Drainage system failure

- Gutting overflowing

- Office flooded - Unable to operate

- Office flooded - Able to operate but with distruptions

- Roof leaking

- Weather damage to doors, gates, roof walls and/or windows

- Yard flooded - Unable to operate

- Yard flooded - Able to operate but with disruptions.

- Arson/deliberate act.

- Carelessness by individual (E.g. discarded smoking materials).

- Electrical fault (fixed wiring)

- Issues during repairs/modifications to equipment/facility (3rd Party Contractors)

- Reactions from hazardous materials

- Stand alone office/warehouse devices creating fumes, overheating or smoking.

- Electrical fault (cables/equipment).

- Extreme wet/windy weather/storm

- Burst Pipes

- Taps/water outlets left running

-

Who was involved (Use initials only)

-

What was the immediate response (ADD DETAILED DROPDOWN)

-

Description of the incident in detail

-

Did anyone witness the event.

-

Was a written witness statement(s) taken from the individual

-

Attach statement(s) here.

-

Take statement(s) and attach to the report here.

-

What was the cause of the fire.

-

Description of the incident in detail

-

What was the immediate response.

-

Did anyone witness the event

-

Was a written witness statement(s) taken from the individuals?

-

Attach the witness statement(s) here.

-

Take statement(s) and attach to the report here.

-

What was the cause of the fire.

-

Who was involved (Use initials only).

-

Description of the incident in detail

-

What was the immediate response

-

Did anyone witness the event

-

Was a written witness statement(s) taken from the individual(s)?

-

Take statements from the individual(s) and attach to the report here.

-

Attach the statement(s) to the incident report here.

-

What was the result of the flood or weather event?

-

The line manager is responsible for completing the online form https://www.gov.uk/report-an-environmental-incident (UK) / https://www.epa.ie/ (IRE). Support can be obtained from the EHS team healthandsafety.ukie@culligan.com and must inform their senior manager of the accident as soon as possible.

-

Has this incident, or one similar to it, occurred on site within the last 30 days

-

This incident requires a level one investigation

Investigation Team

-

Team leader

Team Members

-

Name of Team member

Define Problem

-

When was the incident.

-

Where did the incident occur

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

What equipment/infrastructure/products/services/scenario involved.

-

What was the cause of the chemical spill

- Loss of vehicle fuel containment

- Damaged chemical container

- Incorrect use of chemical

- During decanting process

-

Description of the incident in detail

-

What was your immediate response

- Access to site checked/made secure

- Air Con/heating switched off/windows closed.

- Alarm Raised (External)

- Alarm Raised (Internal System)

- Absorbent socks used to prevent spread

- Area cleared of excess water

- Area cleared of litter/dirt

- Bin/Skip covered/sealed

- Building Evacuated

- Customer stock removed from the area.

- Drains blocked with drain covers

- Doors closed in warehouse/temperature controlled areas.

- Equipment and machinery removed from the area.

- Equipment serviced/calibrated.

- Fire fighting/suppression equipment ordered/distributed.

- Fire tackled

- Leak plugged/sealed

- Leaking drum/vessel placed on bunded pallet

- Main site shut off taps closed.

- Nothing

- Spill kit and/or consumables ordered/distributed.

- Storage/spill bund drained of water.

- Storage/spill bund protected against weather

- Unused electrical devices turned off.

- Waste removed and placed in correct bins/skips

- Waste stored elsewhere (Temporary)

- Water outlets turned off

- Weeping/dripping valves/pipes repaired.

- Other

-

Who was involved (Use initials only)

-

What is their employment status?

-

Has this person received training in the task where the accident occurred?

-

Provide evidence of training such as certificate or attendance record

-

What level of experience does this person have?

-

Please describe the accident in detail

-

Does CCTV or video footage exist of the accident?

-

Provide link to the footage or still screen shots

-

Did anyone witness the event?

-

Was a written witness statement(s) taken from the individuals?

-

Attach witness statement to the report here.

-

What was the cause of the waste issue

-

Who was involved (Use initials only)

-

What was the immediate response.

-

Description of the incident in detail

-

Did anyone witness the incident

-

Was a written statement(s) taken from the individuals?

-

Attach statement(s) here

-

Take statement(s) and attach here

-

What was the cause of the utility issue.

- Combination of gas heating, air conditioning or open doors/windows working against each other.

- Electrical machinery/devices left on for excessive periods/overnight when not in use.

- Gas heating systems left on or not moved to tick-over mode when office unoccupied during the evening/weekend.

- Warehouse heating/temperature control systems left on with doors/shutters left open.

- Water outlets for cleaning, vehicle washing or welfare left running unnecessarily.

- Fluid/Fuel leak of a vehicle/plant/tank (3rd party owned)

- Fluid/Fuel leak of a vehicle/plant/tank (DBS Owned)

- Leak from customer owned goods

- Drainage system failure

- Gutting overflowing

- Office flooded - Unable to operate

- Office flooded - Able to operate but with distruptions

- Roof leaking

- Weather damage to doors, gates, roof walls and/or windows

- Yard flooded - Unable to operate

- Yard flooded - Able to operate but with disruptions.

- Arson/deliberate act.

- Carelessness by individual (E.g. discarded smoking materials).

- Electrical fault (fixed wiring)

- Issues during repairs/modifications to equipment/facility (3rd Party Contractors)

- Reactions from hazardous materials

- Stand alone office/warehouse devices creating fumes, overheating or smoking.

- Electrical fault (cables/equipment).

- Extreme wet/windy weather/storm

- Burst Pipes

- Taps/water outlets left running

-

Who was involved (Use initials only)

-

What was the immediate response (ADD DETAILED DROPDOWN)

-

Description of the incident in detail

-

Did anyone witness the event.

-

Was a written witness statement(s) taken from the individual

-

Attach statement(s) here.

-

Take statement(s) and attach to the report here.

-

What was the cause of the fire.

-

Description of the incident in detail

-

What was the immediate response.

-

Did anyone witness the event

-

Was a written witness statement(s) taken from the individuals?

-

Attach the witness statement(s) here.

-

Take statement(s) and attach to the report here.

-

What was the cause of the fire.

-

Who was involved (Use initials only).

-

Description of the incident in detail

-

What was the immediate response

-

Did anyone witness the event

-

Was a written witness statement(s) taken from the individual(s)?

-

Take statements from the individual(s) and attach to the report here.

-

Attach the statement(s) to the incident report here.

-

What was the result of the flood or weather event?

-

This accident requires a level two investigation

-

When was the accident?

-

Where did the accident occour in the facility?

- Warehouse

- Office

- Production

- Yard/ Car Park

- On the road

- Customer's site

- Other

-

What equipment was involved in the accident (include photo)

- Blade/ Knife

- Compactors

- Contractor owned equipment

- Products (anything produced and sold by Culligan)

- Display Screen Equipment

- Dock Leveller

- External Building damage

- Fire Equipment (extinguishers, alarms, lights, sounders)

- Hand tools (not including blades)

- Internal Buidling damage

- Manual Handling aids (trolleys, lifting equipment etc)

- MHE (FLT, PPR, etc)

- Office Seating

- Other

- Packaging material

- Pallets

- Racking

- Road Van/ Truck

- Roller Shutter door

- Waste

-

Please describe equipment involved

-

Who was involved (please use initials only)

-

What is their employment status?

-

Has this person received training in the task where the accident occurred?

-

Provide evidence of training such as certificate or attendance record

-

What level of experience does this person have?

-

Please describe the accident in detail

-

Does CCTV or video footage exist of the accident?

-

Provide link in the notes to the location of the footage or still screen shots

-

What was the immediate response?

- First Aid

- Quarantined the area/ equipment

- Walk-in center/ taken to A&E

- Communication to effected parties

-

Who was the first aider? (please use initials only)

-

Were any witness statements documented?

-

Please attach the documents

-

Obtain witness statements from the injured person, first aiders and any witnesses.

-

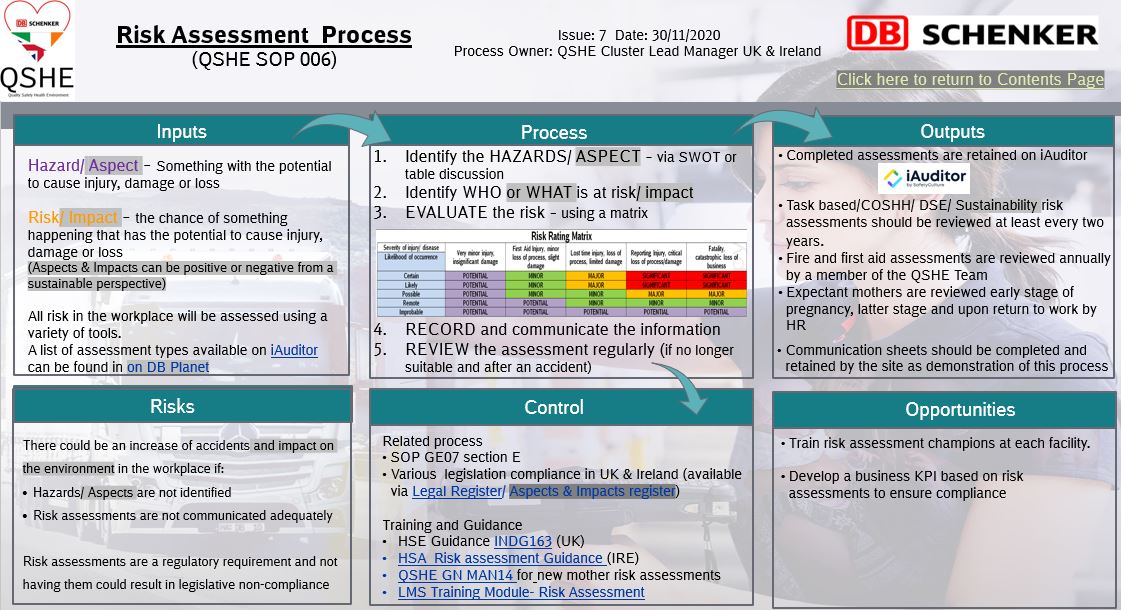

Does a risk assessment exist for this task?

-

Has the risk assessment been reviewed?

-

The risk assessment must be reviewed before closing this investigation

-

What is the risk assessment reference?

-

A risk assessment must be devised and communicated. Please raise an action to complete an assessment as required in QSHE SOP 006

-

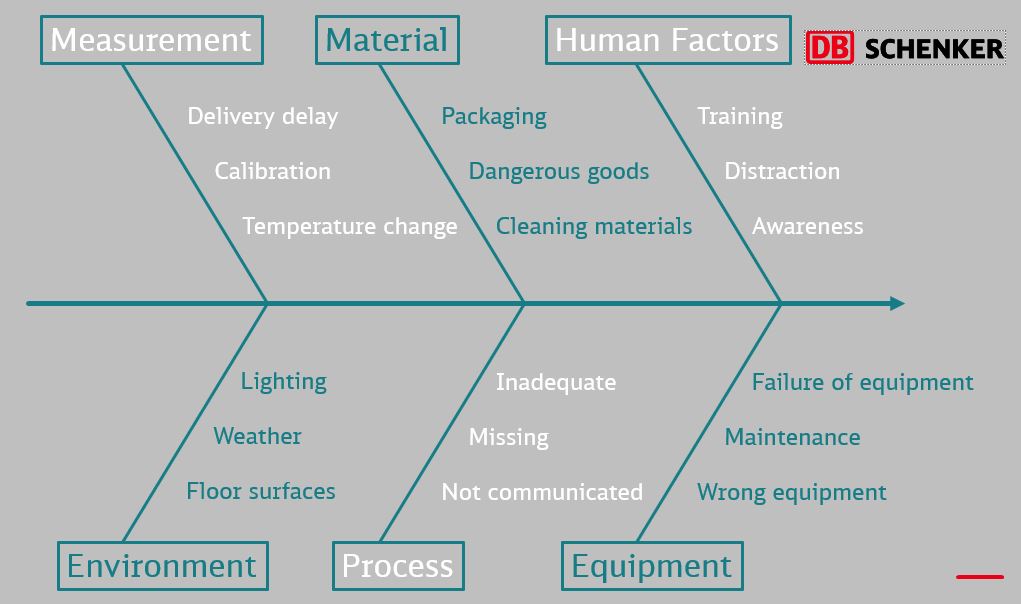

For a level 2 investigation we use a simple Ishikawa principle to determine a potential root cause

-

What was the potential cause of this accident?

- Human factors

- Materials

- Measurement

- Equipment

- Process

- Environment

-

What corrective actions have been implemented to improve the human factor cause of this accident?

- Lessons Learnt communicated

- Re-trianing

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

The investigation can not be closed until the action is completed

-

Provide evidence of the completed action

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the materials used in this accident? (include details in the notes)

- New supplier

- Improved materials

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the measurement aspects of this accident? (include details in the notes)

- Re-calibration

- Delays managed

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Describe corrective action implemented

-

Has this action been completed?

-

What corrective actions have been implemented to improve the equipment used in this accident? (include details in the notes)

- Fixed equipment

- Quarantined equipment

- Disposed of equipment

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Describe the action required to improve the equipment used in the accident

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the process related to this accident? (include details in the notes)

- Process reviewed

- Process written

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the environment associated with this accident? (include details in the notes)

- Improved waste management

- Additional spill equipment

- Controlled work area

- Other

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

Completion

-

Name of person completing report

Investigation of Accident

Interim Containment

-

Describe what has been put in place to stop the issue from escalating?

- Human factors

- Materials

- Measurement

- Equipment

- Process

- Environment

-

What corrective actions have been implemented to improve the human factor cause of this accident?

- Lessons Learnt communicated

- Re-trianing

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the materials used in this accident?

- New supplier

- Improved materials

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the measurement aspects of this accident?

- Re-calibration

- Delays managed

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Describe corrective action implemented

-

Has this action been completed?

-

What corrective actions have been implemented to improve the equipment used in this accident?

- Fixed equipment

- Quarantined equipment

- Disposed of equipment

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Describe the action required to improve the equipment used in the accident

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the process related to this accident?

- Process reviewed

- Process written

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

What corrective actions have been implemented to improve the environment associated with this accident?

- Improved waste management

- Additional spill equipment

- Controlled work area

- Other

-

Please describe the action implemented

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

-

Has this action been completed?

Verify and Determine the root cause

-

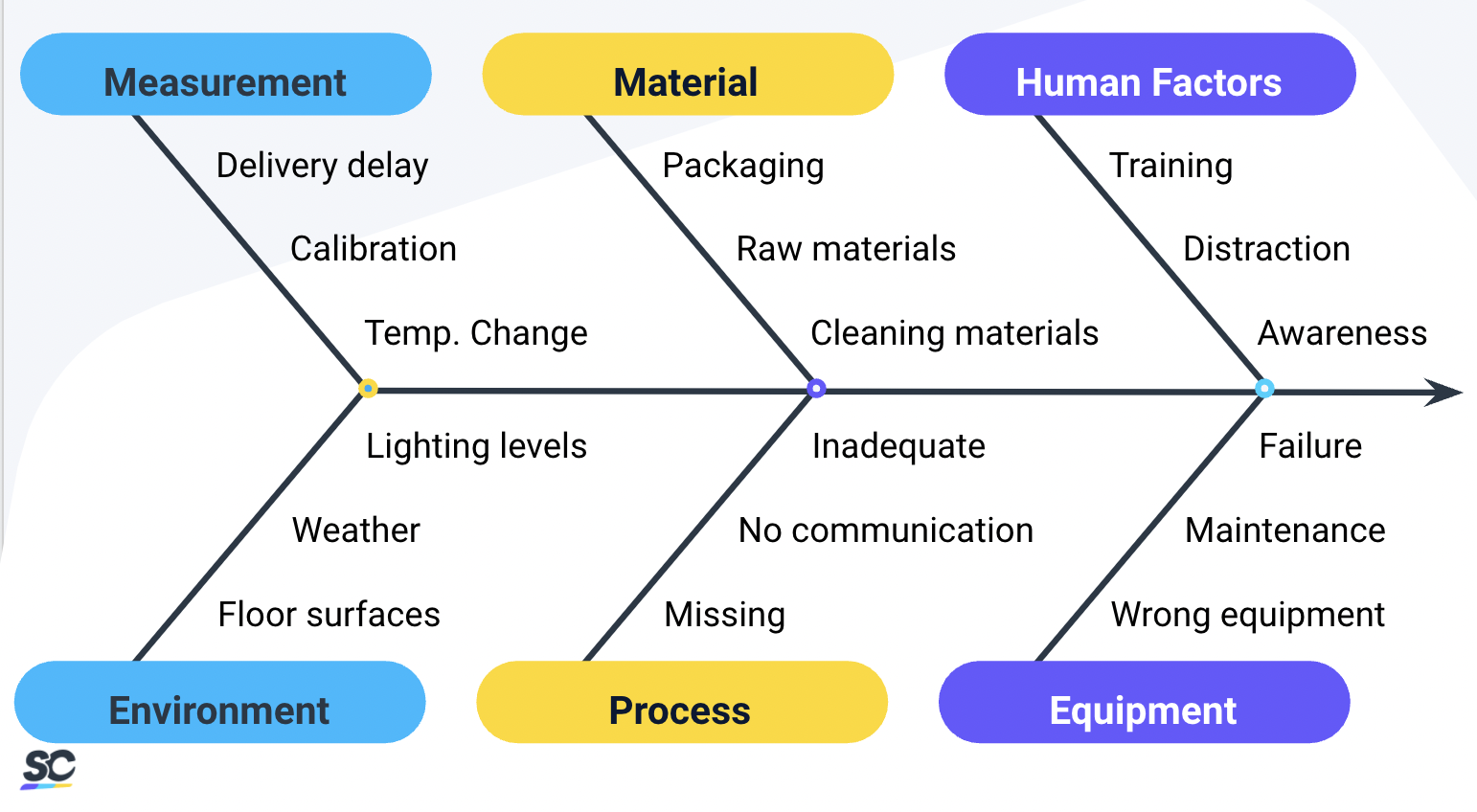

You can use the simple Ishikawa principle to determine a potential root cause as a brain storming tool with the colleagues or the 5 Why process

-

Which root cause analysis will you use?

- 5 Why

- Ishikawa

- Other

5 Why Analysis (click the green + button to complete)

-

What is the problem you are going to root cause analyse

-

Why?

-

Why?

-

Why?

-

Why?

-

Why?

-

As determined by the 5Why above, what are the Immediate/Direct Causes (circumstances that immediately precede the accident)

- Slip

- Trip

- Stab / Puncture

- Cut / Laceration

- Lifting / Carrying

- Pushing / Pulling

- Fall (same level)

- Fall from height

- Unauthorised use of equipment

- Not wearing required PPE

- Not following training

- Struck by moving vehicle

- Equipment Fault or Failure

- Personal attack

- Contact with moving machinery

- Struck by falling / flying objects

- Contact with electricty

- Struck against fixed / stationary object

- Removal of safety guards

- Exposure / contact with harmful substance(s)

- Burns / Scalds from exposure to Fire or Heat

- Trap or Pinch

- Horseplay

- Non- Injury i.e. fainting, nose bleed, black out, rash, bee sting, etc.

-

As determined by the 5Why above, what is the Basic/Root Cause for the accident?

- Personal/ Human Factors

- Job/ System Factors

-

What was the Person/ Human Factor Root cause?

- Lapse (When a person forgets to do something)

- Mistake (When a person does something they are meant to do but should have done something else)

- Violation (when a person decided to act without complying to a known rule/process)

-

Please detail the human factor root cause and create an action to rectify

-

What is the job/ system factor of the root cause

- Process (incorrect documented process)

- Training (incorrect/ lack of training provided)

- Organisational (high workloads/ inadequate resources)

- Equipment (maintenance, availability, suitable for the task)

-

Please detail the system factor root cause and create an action to rectify

Prevent Recurrence

-

Witihn 30 days of the accident, as the problem has reoccurred since implementation of all actions.

-

The root cause analysis should be reviewed and additional prevenatative actions implemented

-

Does a risk assessment exist for this task?

-

Has the risk assessment been reviewed?

-

The risk assessment must be reviewed before closing this investigation

-

What is the risk assessment reference?

-

A risk assessment must be devised and communicated. Please raise an action to complete an assessment as required in QSHE SOP 006

-

Has the procedure/ process been updated?

-

Have the results and improvements been communicated to all affected persons?

-

Has the corrective action been witnessed?

-

If the answer is yes to all of the above in this section, then the investigation is ready to be closed

Sign off

End of Investigation - Sign off

-

What time was lost due to the accident (days)?

-

A RIDDOR report must be completed https://www.hse.gov.uk/riddor/report.htm

-

Team Leader sign off:

-

First Aider sign off: