Sinomax USA

-

Date of Investigation

-

Completed By

-

Location

-

Incident Type

-

Injury Classification

- Lost Time Injury (1 or more full work days off)

- Medical Treatment Injury

- First Aid Injury

-

Type of Shift

-

Shift Length

Investigation Team

-

Team Member

Investigation

- Statement

-

Reason for Statement

-

Worker Statement

-

Worker Name

-

What task was being performed at the time of the incident?

-

What happened? (e.g. ‘worker tripped over box’ or ‘forklift hit wall’)

-

Was any damage sustained to plant and equipment?

-

Description of the damage and type of damage.

-

Was there any impact or damage to the environment?

-

Description of the impact or damage and type of impact.

Timeline and 5 Why Chart

-

Problem

-

Why?

-

Why?

-

Why?

-

Why?

-

Why?

ICAM (Contributing Factor Analysis)

-

Were there any absent or failed defences?

-

Select all that apply from the list

- Hazard identification

- Communication

- Competence / knowledge

- Supervision

- Work instruction

- Visual warning systems

- Auditory warning systems

- Speed / movement detectors

- Vigilance / fatigue

- Gas / substance detection

- Procedures

- Bypass valves / circuits

- Emergency shutdown

- PPE / clothing

- Firefighting equipment

- Spill response

- Bunding barricading / exclusion zones

- Fencing / guarding

- Safe access / egress

- Emergency planning / response

- Other

-

Describe other absent or failed defences

-

Did individual or team actions contribute to the event?

-

Select all that apply from the list

- Supervisory error or issue

- Work authority error

- Operating speed

- Equipment use error

- PPE use error

- Procedural compliance

- Change management error

- Equipment / materials handling error

- Horseplay / thrill seeking behaviour

- Hazard recognition / perception

- Hazard management error

- Work method error

- Occupational hygiene

- Physical fitness for work

- Psychological fitness for work

- Critical Risk Control error

- Other

-

Describe other individual or team actions

-

Did task / environmental conditions in the workplace contribute to the event?

- Yes

- No

-

Select all that apply from the list

- Task planning / preparation / resourcing

- Hazard analysis / risk assessment

- Availability / suitability of work procedures

- Abnormal operation situation

- Availability / condition of equipment or tools

- Availability / suitability of materials

- Equipment integrity

- Housekeeping

- Weather conditions

- Congestion / restricted access

- Routine / non-routine task

- Fire / explosion hazard

- Lighting

- Condition of equipment / materials temperature

- Noise

- Ventilation

- Gas, dust, or fumes

- Radiation

- Chemical

- Wildlife

- Surface / ground condition

- Reduced / restricted visibility

- Routine / non-routine task

- Other

-

Describe the task / environmental conditions

-

Did the task / environmental conditions from human factors contribute to the event?

-

Select all that apply from the list

- Complacency

- Drugs / alcohol

- Familiarity with task

- Fatigue

- Situational awareness

- Time / productivity pressure

- Physical capabilities

- Mental capabilities

- Confidence level

- Personal issues

- Distraction / pre-occupation

- Knowledge / experience in task

- Competency

- Personality / attitude

- Change of routine

- Reliance on undocumented knowledge

- Other

-

Describe the other human factors

-

Organisational Factors

-

Select all that apply from the list

- Hardware

- Training

- Organisation

- Communication

- Incompatible goals

- Procedures

- Maintenance management

- Design

- Risk management

- Management of change

- Contractor management

- Organisational culture

- Regulatory influence

- Organisational learning

- Plant / vehicle management

- Management systems

- Other

-

Describe the other organisational factors

Root Cause and Key Findings

-

What was the Root Cause? (The root cause is the one factor identified that if changed would have prevented the incident from occurring.)

-

What are the Key Findings?

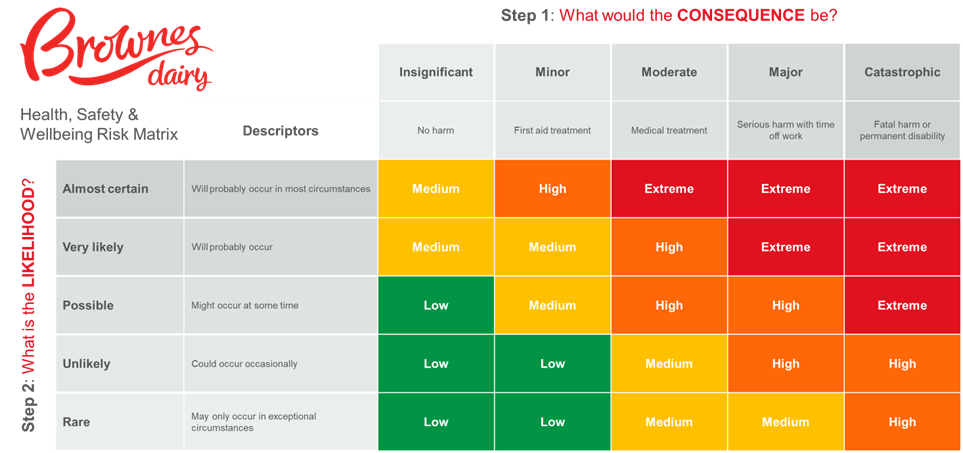

Actual Risk Rating

-

Using the risk matrix, rank the risk based on the actual outcome / outcomes of the incident.

-

Actual Risk

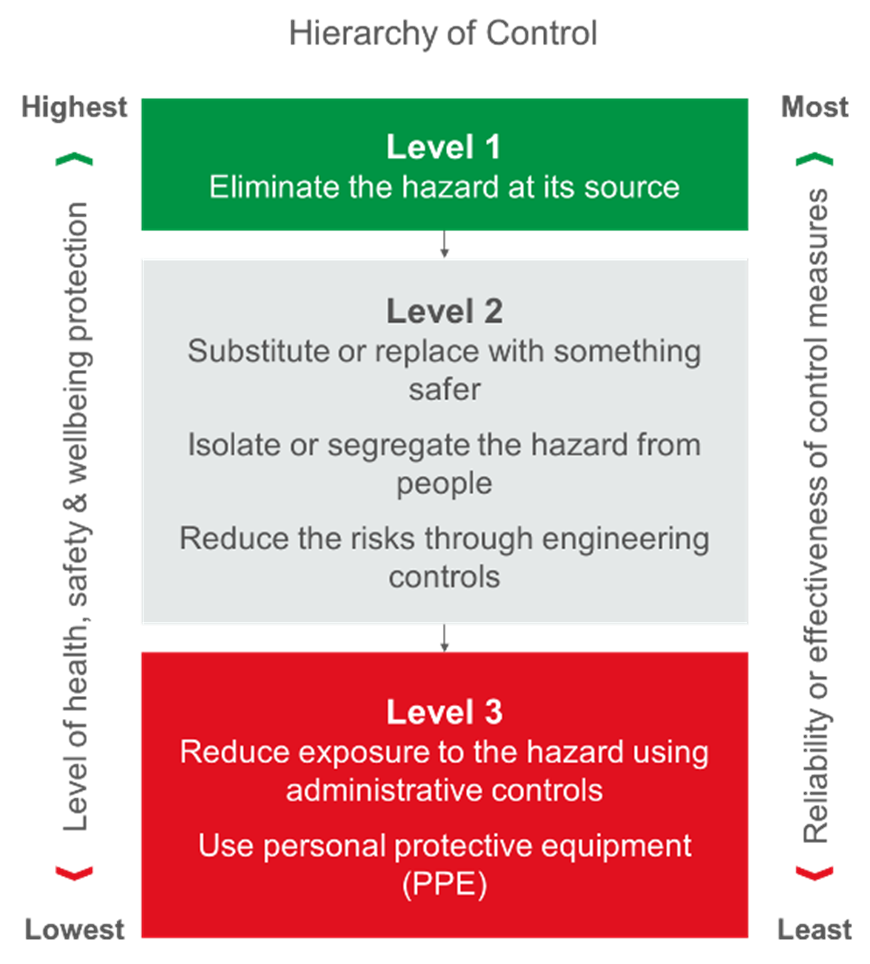

Corrective and Preventative Actions

-

Use the hierarchy of control to ensure effective controls are implemented.

-

Can the hazard be eliminated?

-

Click the 'Action' button and create an action.

-

Can the risk be reduced by substitution, isolation, or engineering controls?

-

Click the 'Action' button and create an action.

-

Can the risk or severity be reduced by Administrative & PPE controls?

-

Click the 'Action' button and create an action.

-

Speak with Steve Reilly.

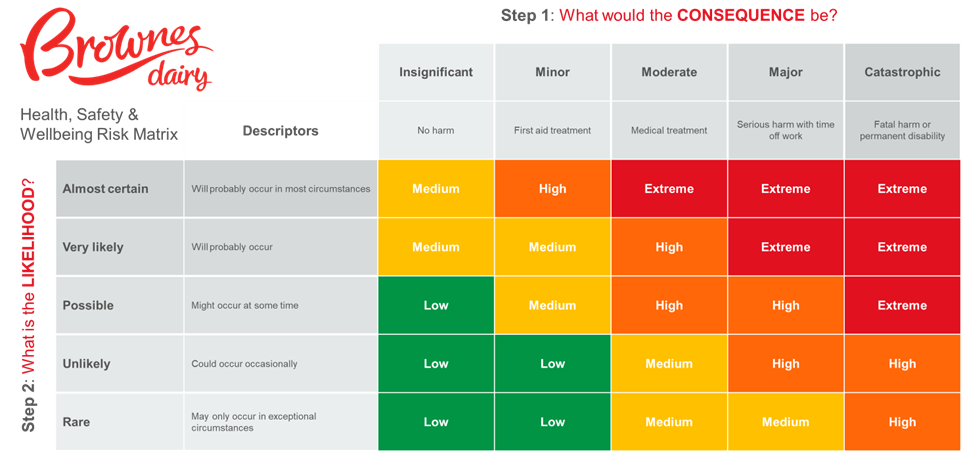

Residual Risk Rating

-

Using the risk matrix, rank the risk based on the new outcome / outcomes of the incident after the controls have been implemented.

-

Residual Risk