Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Incident Investigation

-

NOTE: Do not move anything prior to the investigation. Take pictures from all appropriate angles.

-

Take as many photos of the scene as possible.

-

Describe, in detail, what occurred. Include the exact task being done (include any tools, machinery or equipment being used and comment on condition):

-

What type of incident occurred?

- Fire

- Spill

- Injury

- Illness

- Near Miss

- Property Damage

-

Date and time of incident

-

Date and time injured employee began work

-

Affected Employee and Position:

-

Location of near miss/injury incident:

-

Employment Status of Injured Person

-

Severity

- Near miss

- First Aid

- Medical Only

- Restricted Work

- Lost Time

- Fatality

-

Nature of Injury

- Amputation/avulsion

- Fracture/dislocation/crush

- Cut/scrape/puncture

- Sting/bite

- Bruise/contusion

- Irritation

- Hernia/rupture

- Sprain/strain

- Burn-chemical

- Burn-thermal or electrical

- Suffocate/drown/asphyxiated

- Concussion/unconscious

- Poisoning-acute

- Ergonomic issue (sprain, strain)

-

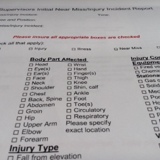

Body Parts Affected

- Head

- Eye(s)

- Ear(s)

- Face

- Neck

- Shoulder

- Chest

- Back, Spine

- Abdomen

- Groin

- Hip

- Upper Arm

- Elbow

- Forearm

- Wrist

- Hand

- Fingers(s)

- Thigh

- Knee

- Shin, calf

- Ankle

- Foot

- Toe(s)

- Circulatory

- Respiratory

-

Injury Type

- Fall from elevation

- Fall, same level

- Slip or trip without fall

- Struck against object

- Struck by object

- Caught in, under, or between

- Overexertion

- Public or contracted transportation

- Motor vehicle

- Drowning, buried

-

Injury Type (Contact by):

- Chemical(s)

- Electricity

- Temperature Extremes

- Noise

- Other physical agents

- Animal, insect

-

Injury Company/Involved Equipment

- Fired vessel-boiler, incinerator

- Chemical Process

-

Stationary Powered Equipment

- Gas or liquid handling

- Solids handling

- Mechanical power transmission

- Portable equipment

- Hoist, cranes, lifting equipment

- Power presses, brakes, shears

- Powered saws

- Drills, screw machines, boring bar

- Fastening equipment

-

Vehicles

-

Miscellaneous

- Piping hoses, valves & fittings

- Drums, boxes, pails, cylinders

- Ladders, scissor lift, scaffolding

- Floor, stairs, working surfaces

- Tools-hand (knives, wrenches)

- Electrical distribution systems

- Office Equipment

- Lab equipment

- Machine/maintenance shop

- Unknown

- Other

-

Procedures

- Failure to follow written procedures or rules

- Confined space procedure not followed

- Hot work procedure not followed

- lockout/Tagout procedure not followed

- Written procedures not available

- Incomplete/outdated procedures

- Other

-

Personal Protective Equipment

- Failure to use appropriate PPE

- Appropriate PPE not specified

- Appropriate PPE not available

- Employee improperly trained on PPE

- PPE not used properly

-

Ergonomic Considerations

- Static work

- Direct pressure

- Duration

- Position

- Type of grip

- Force

- Vibration

- Tool design/Weight

- Repetition

- Physical characteristics

-

Was on-site first aid treatment given?

-

Who administered first aid?

-

What first aid was performed? (Ice, bandage, anti-bacterial cream, etc.)

-

Is the employee requesting/in need of medical attention? Tap Here to enter details.

-

Immediately Contact Jeff Schlagel (920) 344-3420, Shelly Cupery (920) 296-0307, and Department Manager.

-

Date:

-

Start Time:

-

End Time:

-

Name of Person Reporting Spill:

-

HAZMAT First Responders:

-

Location of spill:

-

Source of spill:

-

Contact Tim Rivers and or Department Manager.

Safety Precautions

-

Sources Removed That Could Cause Fire or Explosions:

-

Evacuated Spill Area

-

Barricade Spill Area

-

Warning Signs Placed

-

What material Spilled?

- 1642 SOLVENT -04R08UNTA1642- 7.2 LBS-GAL

- 1042 EA SOLVENT -04R08HYTA1042- 7.5 LBS-GAL

- 1497 EXT/PAPER - Foil -04R17CR0A1497- 8.06 LBS-GAL

- 1512 LAC -04R09SNPA1512- 8.4 LBS-GAL

- 1675 SOLVENT -04R08UNTA1675- 7 LBS-GAL

- 1899 LAM WHITE -04R17CRQC1899-

- 1855 GPF EXT -04R17CROC1855- 7.4 LBS-GAL

- FOIL WHITE -04R17CRQA2047-

- 1308 SOLVENT -04R08UNTA1308- 6.8 LBS-GAL

- DB ADH (PB6370) -04R06PSKD1257-

- 1104 SOLVENT -04R08UNTC1104- 6.7 LBS-GAL

-

~ 2 minutes / 1 Pump Stroke_104SA_ETHYL ALCOHOL (ETHANOL)_20%_1000 ppm_3300 ppm_55 deg F_19.0%_3.3%

~ 1.5 minutes / 1 Pump Stroke_111U_ETHYL ACETATE_40%_400 ppm_2000 ppm_24 deg F_11.5%_2.0%

~ 1.5 minutes / 1 Pump Stroke_151U_N-PROPYL ACETATE_40%_200 ppm_1700 ppm_55 deg F_8.0%_1.7% -

~ 1.5 minutes / 1 Pump Stroke_111U_ETHYL ACETATE_100%_400 ppm_2000 ppm_24 deg_11.5%_2.0%

-

~ 1.5 minutes / 1 Pump Stroke_111U_ETHYL ACETATE_60-90%_400 ppm_2000 ppm_24 deg F_11.5%_2.0%

~ N/A NITROCELLULOSE_5-10% -

~ 2 minutes / 1 Pump Stroke_124SA_TOLUENE_39%_100 ppm_500 ppm_40 deg F_ 7.1%_1.1%

~ XYLENE_6%_100 ppm_900 ppm_90deg F_6.7%_9.0%

~ 1.5 minutes / 1 Pump Stroke_150U_N-PROPYL ALCOHOL (N-PROPANOL)_3%_200 ppm_800 ppm_72 deg F_13.7%_2.2%

~ ETHYL BENZENE_1%_100 ppm_800 ppm_55deg F_6.7%_0.8%

-

~ 1.5 minutes / Pump Stroke_111U_ISOPROPYL ACETATE_9-47%_250 ppm_1800 ppm_36 deg F_8%_1.8%

~ 2 minutes / Pump Stroke_104SA_ETHYL ALCOHOL (ETHANOL)_9-44%_1000 ppm_3300 ppm_55deg F_19%_3.3%

~ 1.5 minutes / Pump Stroke_151U_N-PROPYL ACETATE_9.25%_200 ppm_1700 ppm_55 deg F_8.0%_1.7% -

~ 1.5 minutes / Pump Stroke_111U_ETHYL ACETATE_10-30%_400 ppm_2000 ppm_24 deg F_11.5%_2.0%

~ 1.5minutes / Pump Stroke_151U_N-PROPYL ACETATE_5-10%_200 ppm_1700 ppm_55 deg F_8%_1.7%

~ N-PROPYL ALCOHOL (N-PROPANOL)_3.7%_200 ppm_800 ppm_72 deg F_13.7%_2.2% -

~ 1.5 minutes / Pump Stroke_151_ISOPROPYL ACETATE_40%_200 ppm_1700 ppm_55 deg F_8%_1.7%

~ 2 minutes / Pump Stroke_104SA_ETHYL ALCOHOL (ETHANOL)_30%_1000 ppm_3300 ppm_55deg F_19%_3.3%

~ 1.5 minutes / Pump Stroke_150U_N-PROPYL ACETATE_30%_100 ppm_800ppm_72 deg F_13.7%_2.2% -

~ 1.5 minutes / Pump Stroke_111U_ISOPROPYL ACETATE_10-30%_250 ppm_1800 ppm_36 deg F_8.0%_1.8%

~ 1.5 minutes / Pump Stroke_151U_N-PROPYL ACETATE_10-30%_200 ppm_1700 ppm_55 deg F_8%_1.7%

~ NITROCELLULOSE_10-30%

1.5 minutes / Pump Stroke_150U_ISOPROPYL ALCOHOL_3-7%_400 ppm_2000 ppm_53% F_12.7%_2.0% -

~ 2 minutes / Pump Stroke_104SA_ETHYL ALCOHOL (ETHANOL)_9-43%_1000 ppm_3300 ppm_55 deg F_19.0%_3.3%

~ 1.5minutes / Pump Stroke_151U_N-PROPYL ACETATE_9-25%_200 ppm_1700 ppm_55 deg F_8%_1.7%

~ 1.5 minutes / Pump Stroke_150U_ISOPROPYL ALCOHOL_9-33%_400 ppm_2000 ppm_53 deg F_12.7_2.0%

~ ALIPHATIC HYDROCARBON MIXTURE_9-13% -

~ 1.5 minutes / 1 Pump Stroke_111U_ETHYL ACETATE_99%_400 ppm_2000 ppm_24 deg_11.5%_2.0%

-

~ 2 minutes / Pump Stroke_104SA_ETHYL ALCOHOL (ETHANOL)_85%_1000 ppm_3300 ppm_55 deg F_19.0%_3.3%

~ 1.5minutes / Pump Stroke_150U_ISOPROPYL ALCOHOL_14%_400 ppm_2000 ppm_53 deg F_12.7%_2.0%

~ 1.5 minutes / Pump Stroke_151U_N-PROPYL ACETATE_1%_200 ppm_1700 ppm_55 deg F_8.0%_1.7% -

Review MSDS For Hazards and Exposure Limits:

Selected PPE

-

Tryhem Suit

-

Boot Covers

-

Nitrile Gloves

-

Goggles

-

Face Shield

Air Monitoring - Initial Readings

-

Time:

-

Temperature:

M40 Multi Gas Monitor

-

CO:

-

H2S:

-

O2:

-

LEL:

Sensydine Gas Detector

-

Ethyl Acetate ppm:

-

Reading:

-

Ethyl Alcohol ppm:

-

Reading:

-

Isopropyl Acetate ppm:

-

Reading:

-

Isopropyl Alcohol ppm:

-

Reading:

-

N-Propyl Acetate ppm:

-

Reading:

-

N-Propyl Alcohol ppm:

-

Reading:

-

Toluene ppm:

-

Reading:

-

Nitrocellulose ppm:

-

Reading:

-

Clean

-

Exhaust

-

Call Outside HAZMAT

Exhaust

-

Ventilation Blower

-

Intrinsically Safe Fan

-

Foam Extinguisher

-

How Was The Spill Exhausted?

Air Monitoring - After Exhausting

-

Time:

-

Temperature:

M40 Multi Gas Monitor

-

CO:

-

H2S:

-

O2:

-

LEL:

Sensydine Gas Detector

-

Ethyl Acetate ppm:

-

Reading:

-

Ethyl Alcohol ppm:

-

Reading:

-

Isopropyl Acetate ppm:

-

Reading:

-

Isopropyl alcohol ppm:

-

Reading:

-

N-Propyl Acetate ppm:

-

Reading:

-

N-Propyl Alcohol ppm:

-

Reading:

-

Toluene ppm:

-

Reading:

-

Nitrocellulose ppm:

-

Reading:

-

Clean

-

Call outside HAZMAT

Clean

-

Employees Cleaning Spill:

-

Time:

-

Temperature:

-

Good way Vacuum

-

Absorbent Pads

-

Spill Booms

-

Rags

-

LSS Spill Kit

-

Battery Acid Spill Kit

-

How Was Spill Contained and Cleaned?

-

lbs. Of Waste Cleaned:

-

LBS-GAL

- 1642 SOLVENT -04R08UNTA1642- 7.2 LBS-GAL

- 1042 EA SOLVENT -04R08HYTA1042- 7.5 LBS-GAL

- 1497 EXT/PAPER - Foil -04R17CR0A1497- 8.06 LBS-GAL

- 1512 LAC -04R09SNPA1512- 8.4 LBS-GAL

- 1675 SOLVENT -04R08UNTA1675- 7 LBS-GAL

- 1899 LAM WHITE -04R17CRQC1899-

- 1855 GPF EXT -04R17CROC1855- 7.4 LBS-GAL

- FOIL WHITE -04R17CRQA2047-

- 1308 SOLVENT -04R08UNTA1308- 6.8 LBS-GAL

- DB ADH (PB6370) -04R06PSKD1257-

- 1104 SOLVENT -04R08UNTC1104- 6.7 LBS-GAL

-

A Waste

-

# of Barrels:

-

B Waste

-

# of Barrels:

-

C Waste

-

# of Barrels:

-

Location of Waste Drums:

Air Monitoring - Continuous

-

M40 readings should be recorded every 20 minutes. Toxicity should be checked and recorded every 1 hour with the Sensidyne Gas Tubes, unless conditions change that warrent immediate attention

-

1 hour period

Air Monitoring

-

Time:

-

Temp:

M40 Multi Gas Monitor

-

CO:

-

H2S:

-

O2:

-

LEL:

-

Time:

-

Temp

M40 Multi Gas Monitor

-

CO:

-

H2S:

-

O2:

-

LEL:

-

Time:

-

Temp:

M40 Multi Gas Monitor

-

CO:

-

H2S:

-

O2:

-

LEL:

-

Time:

-

Temp:

Sensydine Gas Detector

-

Ethyl Acetate ppm:

-

Reading:

-

Ethyl Alcohol ppm:

-

Reading:

-

Isopropyl Acetate ppm:

-

Reading:

-

Isopropyl Alcohol ppm:

-

Reading:

-

N- Propyl Acetate ppm:

-

Reading:

-

N-Propyl Alcohol ppm:

-

Reading:

-

Toluene ppm:

-

Reading:

-

Nitrocellulose ppm:

-

Reading:

Review of Spill Area

-

Refer to ESOP-6012 EPCRA to determine if regulatory reporting is required)

-

Is there any indication that the spill leaked or penetrated into the soil?

-

Comment:

-

Is there any indication that the spill has leaked into the storm sewer?

-

Comment:

-

Additional Comments:

-

Date and Time:

-

Witness Statement

-

Witness name?

-

Telephone Number

-

Occupation

-

Date and time of injury

-

Location where injury occurred.

-

Description of what you saw.

-

Who or what caused the accident/injury?

-

In your opinion what body parts were injured?

-

Was there anything that could have been done to prevent injury?

-

What could have been done?

-

Did anything appear suspicious about the incident?

-

What was suspicious?

Root Cause

-

What was the root cause of this incident?

Immediate Corrective Actions:

-

Enter corrective actions taken to prevent immediate reoccurrence. Enter suggestions for future corrective actions.

Finalization

-

Employee Signature

-

Preparers Signature