Information

-

Site

-

Section

-

Conducted on

-

Lead Auditor

-

Auditor Signature

-

Personnel

Task 1 Audit

-

What is the task?

-

Photo of the Task

-

Is a Risk Assessment readily available for the Task?

-

Has the Risk Assessment been reviewed in the last 12months ?

-

Is a MAC Assessment readily available for the Task?

-

Has the MAC Assessment been reviewed in the last 12 months ?

-

Is an SOP readily available for the Task?

-

Has the SOP been reviewed in the last 12 months?

-

Who is performing the task?

-

Is there evidence readily available to show that the employee is competent at the task?

-

Can the employee list 3 hazards associated with the task?

-

Is the employee using Kinetic Handling for the Task?

-

Eye Protection being worn correctly

-

Hearing protection being worn correctly

-

Appropriate Gloves being worn? ( fingerless should only be used for tasks involving labels )

-

Is a dust mask being used for the task?

-

Good donning of a dust mask look like:

-

Is the dust mask donned correctly?

-

Is there evidence of a pre use check this shift?

-

Can the person how signed it off, describe what they did without looking at the preshift check?

-

Does the operative consider to be difficult doing the task?

-

Auditee Signature

Task 2 Audit

-

What is the Task?

-

Take a Photograph of the Task

-

Is there a Risk Assessment readily available for the Task?

-

Has the Risk Assessment been reviewed in the last 12 months?

-

Is a MAC Assessment readily available for the Task?

-

Has the MAC Assessment been reviewed in the last 12 months?

-

In an SOP for the Task readily available for the Task?

-

Has the SOP been reviewed in the last 12 months?

-

Who was performing the task?

-

Is there evidence readily available to show that the employee is competent at the task?

-

Can the employee list 3 hazards associated with the Task?

-

Is the employee using Kinetic Handling for the Task?

-

Is Eye protection worn correctly

-

Is Hearing protection worn correctly? ( eg Ear plugs fully inserted )<br>

-

Are appropriate Gloves being worn?

-

IS RPE being used?

-

This is how a disposable mask should be worn.

-

Is the mask being worn correctly?

-

Is there evidence of a pre use check this shift?

-

Can the person who signed the pre shift check describe what they did without looking at the pre shift check list..... you are looking for operatives just signing the machine off without doing the check.

-

Does the operative consider there to be any difficult aspects to they task?

-

Auditee Signature

Training Management

-

Is there evidence of a training matrix in the Section?

-

Choose two operatives at random. Do both these operatives' names appear on the training matrix?

-

In the opinion of the auditor, does the coverage of training shown on the training matrix allow for non routine situations, like absence. For example if a critical piece of equipment only has 1 person per shift trained then this is likely to encourage non trained personnel to be put on the machine.

LOTO Performance

-

What is the process / machine?

-

Who is running the process / machine?

-

What sources of Energy are applicable?

- Kinetic

- Thermal

- Pnuematic

- Springs

- Electrical

-

Is a LOTO procedure posted?

-

Are all these sources of Energy identified on the LOTO procedure

-

Can the employee explain the purpose of LOTO?

-

Can the employee demonstrate how to LOTO?

Machine Safety

-

Name of Machine / equipment

-

Photo of the Machine / equipment

-

Is the machine meant to be used for the purpose for which it is being used?

-

Does the machine have controls that are readable?

-

Choose 1 emergency stop. Press it .. does it work? Comment if the machine doesn't stop straight away

-

Do the guards appear to be properly in position?

-

Can access to dangerous parts of the machine be obtained?

-

If interlocks are used choose 1 and attempt to gain access when the machine is running

-

Is there anything around the machine that might cause harm?

-

If appropriate is a push stick being used?

-

Has the machine a pre shift check sheet visible?

-

Does the pre shift check specify what to check, how to check it and the frequency of check?

-

Has the preshift check been completed for this shift

Fire Precautions

-

Is an evacuation plan displayed on all exits showing all relevant escape routes and roll call position?

-

Select a Fire Point

-

Are all extinguishers in place and clearly marked for the type of fire?

-

Have these extinguishers been serviced in the last 12 months?

-

Have the extinguishers been checked by JW in the last Month?

-

Is the access to extinguishers free from obstructions?

-

Is there adequate Emergency Exit direction signs from where you are?

-

Can departmental emergency exits be easily opened from the inside

-

Is emergency lighting inside and outside of the exits

-

Is the external route from emergency exits clear?

Emergency Procedures

-

Does the person leading the Team know who is the incident controller?

-

Does the person leading the team have a current roster for this shift?

-

Is there emergency procedures issued by the section telephone?

-

Is the nearest first aider posted in the area?

-

Is the nearest Fire Marshal posted in the area?

5S Deployment

-

Are Safe walkways clearly defined?

-

Are these walkways free of obstruction?

-

Are there clearly marked areas for material used in the process?

Work Bench Safety

-

Name of Bench

-

Photo of bench

-

Clear of rubbish / clutter?

-

Any damaged hand Tools visible?

-

Any damaged powered Tools visible?

Vibration Management

-

Are vibrating tools used in the section

-

Do the vibrating tools have a working trigger time timer?

-

As no timers are on the vibrating tools then the tools must be removed.

-

Can the Manager of the area tell you the maximum trigger time allowed per shift for any one person ? ( 1/2 hr trigger time )

-

Name of current or latest person to used vibrating tools

-

Can the section leader provide evidence to ensure the workplace exposure is below the lower threshold?

Waste Management

-

Is the waste segregated correctly? Provide evidence

-

Bins not full?

-

Waste containers / IBCs / skips appropriately identified whilst being used?

-

Does the are require spill kits

-

Are the spill kits appropriate for the fluids?

-

Are the spill kits full?

-

Is there evidence of the spill kits being checked?

Racking

-

Is there racking in the area ?

-

If there Is evidence of damage above SEMA guidance, has the racking been off loaded?

-

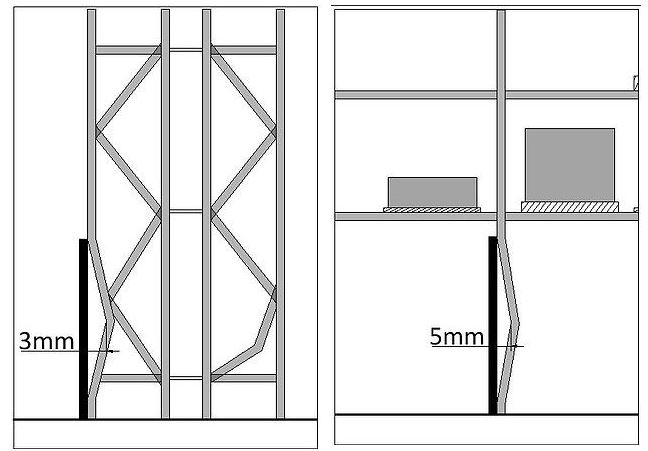

Is there evidence of racking damage

-

-

Is there evidence of local racking inspection within the last month easily available ?

-

Is there evidence of independent racking inspection within the last 12 month easily available?

-

Are appropriate SEMA boards posted?

-

Is there evidence of any missing beam clips?

SQCDI Boards

-

Does the section have its own SQCDI board?

-

Does the S section show the Safety Cross or other means to display incidents happened previous day, toolbox talk delivered?

-

Is the Cross upto date?

-

Are there daily hazards being recorded ?

-

Is there evidence of these hazards being actioned? ( take the biggest issue on the 90day tracker and bif there is no evidence of that issue, the answer is yes )

Electrical Safety

-

Machine / Section ?

-

240v cords using an RCD socket

-

No extension plugged into an extension?

-

No portable items found un PAT tested?

-

No frayed or damaged leads?

-

No trailing leads?

-

No access possible to live circuits

-

Cabinets properly locked?

-

Adequate access to switch gear

-

Wiring from disconnected plant properly terminated?

Ladder Management

-

Is there any ladders in the section?

-

Is there evidence of a pre use check evident?

-

Are the ladders in an acceptable condition?

-

Are unused ladders locked?

First Aid

-

Name a First Aider on shift now?

-

First Aid supplies sufficient and in date?

-

Eye wash stations full and in date?

-

First Aiders identified on the Area notice board?

-

Is there enough First Aiders on shift? 1 FA for every 50 employees?

Fork Lift Trucks

-

Name of FLT Driver

-

Driver wearing a lap belt restraint

-

Evidence that the truck has had a pre shift check?

-

Driving Standard acceptable?

-

Good use of Horn and slowing down at doorways?

Knife Management

-

Were knives observed during the audit?

-

Was the knife fully automatic?

-

Has the operative been trained in the use of knives?

Chemical Management

-

is there a chemical register in the area?

-

Is there a copy of the JW Haz Com program in the register?

-

Are flammable chemicals stored in a suitable flammable cabinet?

-

Are there any secondary containers that have no identification?

-

Choose one chemical used in the area. List the chemical below.

-

is there evidence of the container of the chemical listed above being properly disposed?

-

is there evidence of any waste of the chemical listed above being properly disposed?

Tracking Control

-

Do you have tracking in the audit area?

-

Does the roller tracking have any missing rollers?

-

Does the roller tracking have any clips or wires that protrude causing a cut hazard

-

Do any operatives state that it is hard to push loads on the tracking ?

-

Are there end stops at the end of each roller tracking?

-

Do any end stops look in poor repair?

-

Are there pipes or other trip hazards when pushing along the tracking?

Other observations

-

Are there any other issues that need a comment?

Issue:

-

What is the issue?

-

Is the issue safe or at risk?