Title Page

-

Client / Site

-

Conducted on (Date and Time)

-

Prepared by

-

Location

SUPPORTED SCAFFOLD INSPECTIONS

-

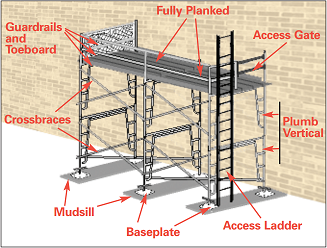

REFERENCE: Scaffolding parts

[This is an example of how you can use iAuditor to include reference images in your templates to assist with inspections] -

Check to see if power lines near scaffolds are de-energized or that the scaffolds are at least 10 feet away from energized power lines.

-

Make sure that tools and materials are at least 10 feet away from energized power lines.

-

Verify that the scaffold is the correct type for the loads, materials, workers and weather conditions.

-

Check footings to see if they are level, sound, rigid, and capable of supporting the loaded scaffold.

-

Check legs, posts, frames, and uprights to see if they are on baseplates and mudsills.

-

Check metal components for bends, cracks, holes, rust, welding splatter, pits, broken welds, and non-compatible parts.

-

Check for safe access. Do not use the cross braces as a ladder for access or exit.

-

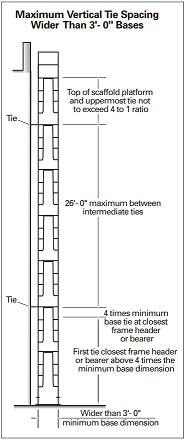

REFERENCE: Maximum Vertical Tie Spacing Wider Than 3'- 0" Bases

[This is an example of how you can use iAuditor to include reference images in your templates to assist with inspections] -

Check wooden planks for cracks, splits greater than 1 /4 inch, end splits that are long, many large loose knots, warps greater than 1 /4 inch, boards and ends with gouges, mold, separated laminate(s), and grain sloping greater than 1 in 12 inches from the long edge and are scaffold grade lumber or equivalent.

-

If the planks deflect 1 /60 of the span or 2 inches in a 10-foot wooden plank, the plank has been damaged and must not be used.

-

Check to see if the planks are close together, with spaces no more than 1 inch around uprights.

-

Check to see if 10-foot or shorter planks are 6 to 12 inches over the center line of the support, and that 10-foot or longer planks are no more than 18 inches over the end.

-

Check to see if the platform is 14 inches or less from the wall or 18 inches or less away if plastering/stucco.

-

Check for guardrails and mid-rails on platforms where work is being done.

-

Check for workers under the platform and provide falling object protection or barricade the area. Make sure that hard hats are worn.

-

Use braces, tie-ins and guying as described by the scaffold’s manufacturer at each end, vertically and horizontally to prevent tipping.

COMPLETION

-

Full Name and Signature of the Inspector