Title Page

-

Meter or NMI number

-

HIRAC number.

-

Conducted on

-

Prepared by

-

Location

-

Contracting company

-

Personnel

1 Initial contact and qualifications

-

Auditor inducted onto worksite

-

Customer consulted prior to work commencing

-

Outage time within advertised planned outage window for NECF?

-

STN form required, or isolation is at hot water meter on same day as planned outage

-

Stop job immediately and review NECF requirements

-

Has THIS installer's qualifications been checked in previous interactions today

-

General induction (white card) all employees

-

Qualified supervisor certificate - installer

-

EE identification (photo ID CSP or contractor) card carried by all employees

-

EE Authority to enter lands card available

-

Comments

2 Documentation

-

Has THIS installer's documentation been checked in previous interactions today?

-

Current Version of Work instructions available

-

Field staff aware of noxious weeds, plant/animal disease controls and implementation, have Weed Guide available

-

Issues and Actions document available

-

Bushfire controls in place and aware of bushfire survival

-

Comments

Tools and Equipment

-

Has THIS installer's Tools and Equipment been checked in previous interactions today?

-

Dangerous goods/hazardous substances correctly stored and restrained

-

Appropriate emergency communication available

-

All vehicles have EE signage

-

Appropriate tools and equipment used, up to date testing and tagging

-

Appropriate safety equipment available and used, up to date testing and tagging

-

SDS available in vehicles and on worksites where required

-

Spill kit available, field staff understand effective clean up, disposal and relevant hazard notification

-

Appropriate PPE, clothing, footwear according to the HIRAC

-

Comments

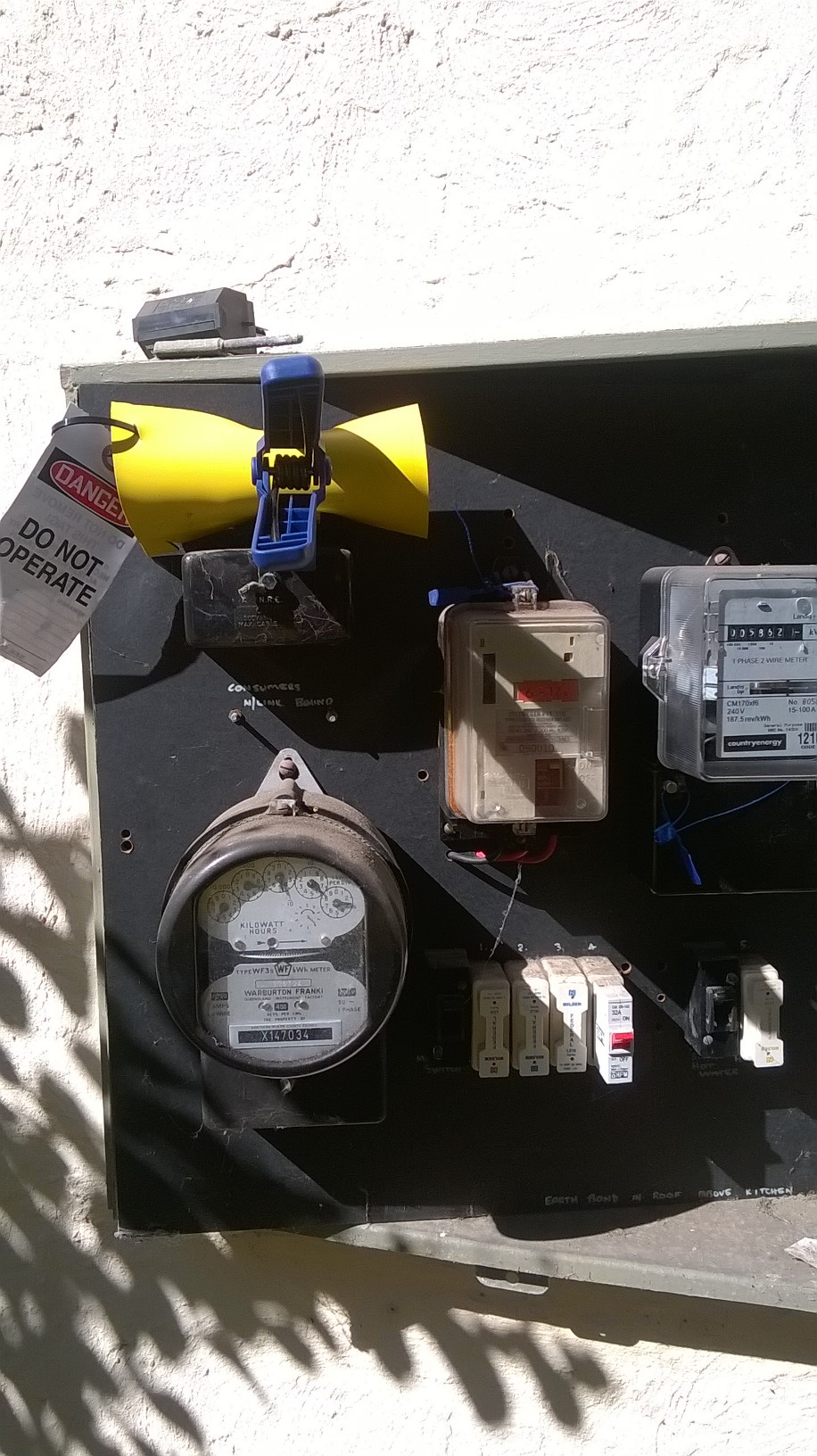

Working at switchboard

-

Perform close approach testing prior to work

-

Completed HIRAC which identifies the site being worked

-

Effective isolation and tagging (if applicable) – method used

- Service fuse

- Barge Board fuse

- Hot Water meter

- Pole/Pit/Pillar

- Point of Attachment

- Active link

-

Insulating mat used

-

Danger tag applied to isolation point

-

Inadvertent contact with energized exposed/covered conductors/terminals controlled (potential difference reduced)

-

Appropriate testing device/s used at FIR terminals, tested before and retested after

-

FIR wired and installed correctly, cables marked or diagram drawn for non-standard installations

-

FIR mounted with 3 bolts

-

Is there obvious reason for not installing 3 bolts

-

FIR re-energised with terminal covers on and tested correctly

-

FIR programmed correctly

-

All service and metering equipment sealed

-

Main switches returned to original position for final test

-

Program file number written on FIR

-

Program file number

-

Comments

3 Asbestos controls

-

Asbestos switchboard

-

Correct PPE and correct usage

-

Segregate/delineate work area and signage

-

Windows/vents/windy conditions considered and controls implemented

-

Suitable switchboard preparation/decontamination if required

-

Equipment, tools and work area effectively decontaminated

-

Removed FIR effectively decontaminated and sticker applied on site

-

Switchboard drilled, vacuumed and wiped clean effectively

-

Effective personal decontamination

-

Asbestos sticker applied to panel

-

Comments

Completion

-

Customer notified on completion of work and/or a correctly documented card has been left

-

Worksheet or similar on a device completed with correct billing details at the completion of work

-

Close out meeting held with installer

-

Photo(s) if required

-

Comments