Title Page

-

Site conducted

-

Date and Time

-

Behavioural Tour

-

Audit Location.

-

Carried out by

- Dave Egan

- Dave Simmons

- Jeff Merchant

- Tony Ward

- David Hind

- Michael Robertson

- Steven Mackay

- William Stanley

- Phil Orton

- Mick Dowd

- Nicola Alden

- Paul Rockliffe

- Just Dey

- Chris Cosgrove

- Anthony Lyon

- Mark Egan

- Steve Carson

- Brandon Cuming

- Paul Macpherson

- Greig Marshall

- Steve Allcock

- Ben Hitchen

- Rob Jones

- Nathan Porter

- Bence Bogdan

- Adam Thornton

- Nathan Cullen

- Terry Miller

- Matt Byrne

- Robert Pearson

- Robert Fallows

- Nathan Cullen

- Dave Thacker

- Nathan Porter

- Adam Thornton

- Anthony Lyon

- Chris Cosgrove

- Josh Hodgkinson

- Justyna Igielinska

- Rutuparna Salodkar

- Chris Windsor

- Steven Griffiths

-

Job Number, auditee, specific areas covered.

-

Areas:

- Office

- Workshops

-

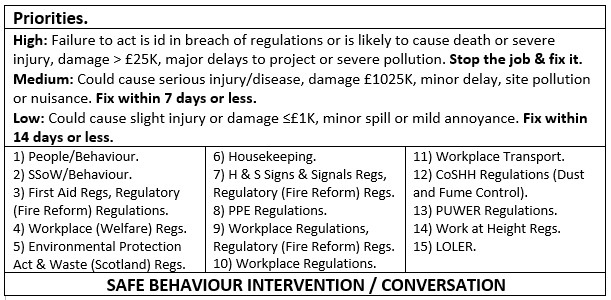

PLEASE REVIEW THE CATEGORIES IN THE IMAGE BELOW AND SELECT THE RELEVANT ONES FOR THIS INSPECTION.

-

Have you read and understood the above image?

Catergories

-

What category are you inspection?

- 1 - People/Behaviour.

- 2 - SSoW/Behaviour.

- 3 - First Aid Regs, Regulatory (Fire Reform) Regulations.

- 4 - Workplace (Welfare) Regs

- 5 - Environmental Protection Act & Waste (Scotland) Regs.

- 6 - Housekeeping.

- 7 - H & S Signs & Signals Regs, Regulatory (Fire Reform) Regs

- 8 - PPE Regulations.

- 9 - Workplace Regulations, Regulatory (Fire Reform) Regs

- 10 - Workplace Regulations.

- 11 - Workplace Transport

- 12 - CoSHH Regulations (Dust and Fume Control).

- 13 - PUWER Regulations.

- 14 - Work at Height Regs.

- 15 - LOLER.

-

Look for positives, praise when seen, query non-compliance.

-

Are they carrying their 60 second risk assessment card and have they read it prior to starting the task?

-

Housekeeping, is their work area clear of trip hazards, cables, tools etc.?

-

If using hand-held power tools, have they carried out pre-use checks for damage to cable or machine, is it within test date, the machine runs smoothly and does not overly vibrate?

-

If they are using chemicals, dye penetrant, pickling paste, are they aware of the CoSHH assessment and where to get access to them to re-cap?

-

Confined space entry, is the permit signed and dated, is it relevant to the day in use, are they aware on the confined space procedure and where to get access to re-cap?

-

Are they wearing the correct PPE?

-

Work procedures, method statements, risk assessments.

-

Are they aware of the work procedures for the tasks they are carrying out, do they know where they are located?

-

Are they aware of the risk assessments for the tasks they are carrying out, do they know where they are located?

-

Is there a job specific method statement or lift plan for the task they are carrying out?

-

Is there a poster showing who the first aiders are?

-

Is the first aid room clean and tidy and the supply list checked and dated?

-

Are the assembly point and emergency exit routes clearly marked?

-

Are fire exit routes clear?

-

Offices

-

Are the messrooms clean; fridges and ovens clean; drinking water available?

-

Are the toilets clean with hot & cold water, soap & towels?

-

Are toilets adequate for number of persons present?

-

Works

-

Are the messrooms clean; fridges and ovens clean; drinking water available?

-

Are the toilets clean with hot & cold water, soap & towels?

-

Are toilets adequate for number of persons present?

-

Is recycling evident throughout the facility?

-

In the stores, are waste transfer procedures known?

-

Is there any evidence of waste accumulating on site?

-

Are spill kits or absorb granules available?

-

Is rubbish, scrap accumulating within the workshop and on work benches?

-

Are power tools stored away tidily, are tower scaffolds dis-assembled when not in use?

-

Are walkways clear of trip hazards?

-

Are signs displayed showing minimum PPE requirements?

-

Are notice boards tidy and up to date?

-

Are fire exits and escape routes marked?

-

In the stores, is there a PPE log and is it up to date?

-

Is PPE worn throughout the workshop to the minimum standard requirements?

-

Is internal lighting adequate in both works and offices?

-

Is external lighting adequate around passageways?

-

Is emergency lighting tested on a monthly basis, is evidence available?

-

Is there any obvious damage to walls, roof or guttering?

-

All doors open and close and are lockable where required?

-

Flooring and passageways are free from potholes, carpets are fitted correctly?

-

Only authorised drivers operate forklift trucks?

-

Banksmen, wearing Hi-Viz are used for reversing vehicles?

-

Deliveries are controlled, unstable loads are assessed/refused?

-

Local exhaust ventilation is available and used?

-

The LEV system has identification and in date for CoSHH regulations?

-

Air fed grinding hoods and air fed welding screens are available and used?

-

Evidence of regular checks to comply with PUWER regulations?

-

Plant and equipment is in good condition with no oil/fluid leaks?

-

Guards and trip switches are fitted and used?

-

Emergency stop buttons fitted and operational?

-

Fuel Gas & Oxy Hoses fitted with flashback arrestors, hoses are not cracked or perished?

-

Gas cylinders are secured vertically. Cylinder Trolley available?

-

Ladders secured, inspection record available, register kept in office?

-

Tower scaffolds have Scaftag system and are signed and dated?

-

Toeboards are fitted to tower scaffold platforms?

-

Standard lift plan for slinging and FLT on the notice board?

-

Well organised equipment storage. Slings free from damage & stored properly?

-

Lifting gear returned to storage area after use?

-

Current period colour code for lifting gear displayed around the workshop?

-

All lifting gear tagged and colour coded for relevant inspection period?

-

Training records available for slinging operations and safe use of overhead cranes?

Tour sign off

-

Sign off