Title Page

-

Site Address

-

Builder work being performed for:

-

Commencement Date

-

Assessment undertaken by

Using the hazard prompts below, please identify site-specific hazards and your intended control measure below.

-

Impaling hazards - Star Pickets, Reo bars or Wooden Stakes

-

Unsafe access to work areas

-

Open Trenches or excavations

-

Plant Operating near were you are working?

-

Site security fence pulled apart?

-

Sediment control damaged

-

Waste enclosure/area installed

-

Unsafe scaffold

-

Visible signs of Fire Ant activity?

-

Excessive dust needing suppresion

COVID-19

-

How many persons are on the worksite (including Loby Earthmoving staff)?

-

Do Not Enter Site and make contact with Site Supervisor

-

Someone appears unwell

-

Do Not Enter Site and make contact with Site Supervisor

-

Trades working in less than 4sqm per person?

-

Make contact with Site Supervisor for further instructions:

Plant Pre-Start Procedure

-

Plant Type: Mustang Skid Steer Loader

-

Registration Number: C90417

-

Ensure that the following are in good working order:

-

Lights, Warning Devices, Signs and Gauges

-

Hydraulics - Leaks, Damage or Loose Connections

-

Components - Damaged or Broken?

-

Wheels - Tyres, Loose Nuts, Wear or Suspension

-

Pins - Pivots, rams, lift arms and bucket pins

-

Quick Hitch - Independent connector secured

-

Guards - In place and secure with all safety devices working

-

Condition of Hooks, Chains, Slings and Sheaves

-

Cabin - Controls, Loose Objects, Seat Belts, Visibility, Rear View Mirrors and seat function

-

BEFORE MOVING, CHECK - Operation of Brakes, Steering Controls, Wipers, Levers, Buckets.

-

Wiring - Check for loose connections.

-

Did all components pass?

-

Please note any failing components:

-

Inspect new sites for FIRE ANT activity before disturbing the site.

-

Fire Ant Activity?

-

Don't enter site and contact site supervisor.

-

Check Surrounding area prior to moving plant

SWMS Powered Mobile Plant - Site Cleaner

SWMS Scope

-

This SWMS covers general hazards associated with the operation of mobile plant associated with earthworks.

This SWMS covers Skidsteer site cleaning work on or adjacent to the road.

High Risk Construction Work

-

This work activity involves the following "High Risk Construction Work" (select all that apply):

-

Mobile Plant

-

Work on, near or adjacent to energised electrical installations or services

-

Working at depths greater than 1.5 Metres,

-

Work carried out adjacent to a road or traffic corridor.

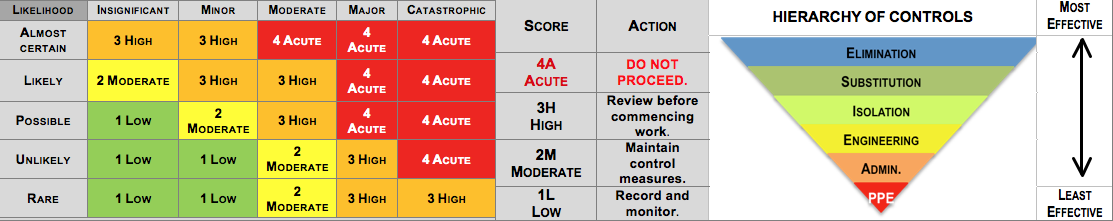

Risk Assessment Matrix & Controls

Personal Protective Equipment (PPE)

-

Ensure all PPE meets relevant Australian Standards. Inspect and replace PPE as needed.

-

Foot Protection

-

Hearing Protection

-

High Visibility Protective Clothing

-

Head Protection

-

Eye Protection

-

Hand Protection

-

Sun Protection: Broad brimmed hat, UV rated clothing, SPF 30+ sunscreen, tinted safety glasses with adequate UV protection

-

Rings, watches, jewellery that may become entangled in machines must not be worn. Long and loose hair must be tied back.

Potential Hazard: Lack of consultation with potential outcomes for personal injury, property damage &/or environmental incident.

-

CONTROL MEASURES TO REDUCE RISK

Liaise with Principal Contractor to establish the following on-site systems and procedures are in place and take note of:

· Health and Safety rules

· Induction for all workers – site-specific and toolbox meetings

· Supervisory arrangements

· Communication arrangements

· All relevant workers are appraised for required competencies & for any pre-existing medical conditions if working in remote or isolated locations.

· PPE required

· Site plans – showing no go zones for pedestrians

· Traffic Management Plan

· Exclusion Zones

· Risk Assessments

· SWMS and JSA’s

· Injury reporting procedures

· Hazard reporting procedures. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Lack of training or the assessment of capability may lead to personal injury, property damage &/or environmental incident.

-

CONTROL MEASURES TO REDUCE RISK

Ensure all persons entering the site have a General Construction Induction Card (white card).

The operator has appropriate licences for the operation of the machine.

Ensure all relevant workers have undertaken training and/or received instruction in the use of control measures.

Include:

· Reporting procedures for incidents

· Correct use of equipment including selecting, fitting, use, care of and maintenance

· Use of supervision where required (e.g. new starters or new equipment)

· Correct use of all equipment

· Ensure supervisors, foremen etc. are suitably experienced in the type work to be conducted

· All workers are trained in this SWMS. -

Risk-Rating after control measures have been put in place = 1L Low

Potential Hazard: Powered mobile plant movement

-

CONTROL MEASURES TO REDUCE RISK

· Follow traffic management plan requirements

· Check constantly for changing hazards while working and monitor work position at all times

· Ensure:

o High visibility clothing worn at all times

o Do not stand behind reversing vehicles

o Allow sufficient distance from plant during operation (allow sufficient room for equipment failures - such as arm/boom failure or plant rollover)

o Do not enter established "no go zones" for pedestrians

o Alertness at all times. Listen for:

- Reversing alarms/beepers

- Calls from Plant Operators

o Safety/warning signs, Spotters, traffic barriers etc. must be obeyed as required

o Work positions should be in clear sight of other plant operators

* NOTE: Some traffic management plans may say that pedestrians have the right-of-way. Never assume this. Make visual and verbal contact with the plant operator as required -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Personal injury, property damage &/or environmental incident.

-

CONTROL MEASURES TO REDUCE RISK

· Suitable weather conditions, do not work outside in low visibility, heavy rain, high winds etc.

· Suitable access for all equipment required

· Suitable ground/track conditions for the operation of equipment

· Power lines in close proximity

· Take note of other mobile plant movements. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Heat stress

-

CONTROL MEASURES TO REDUCE RISK

· Appropriate protective clothing

· Wear hand protection

· Wear non-slip footwear (slippery surfaces)

· Adequate breaks

· Check weather conditions - do not work in extreme conditions

· Heat:

o Sun brim on hard hat

o Safety glasses - UV Rated

o Use 30+ sunscreen on exposed skin areas

o Adequate drinking water. -

Risk-Rating after control measures have been put in place = 1L Low

Potential Hazard: Crush Injuries or Entrapment loading or unloading on Truck

-

CONTROL MEASURES TO REDUCE RISK

Ensure the truck/vehicle and/or trailer used to transport the mobile plant is appropriate –weight and size.

Tie downs:

· Tie-down points are identified by tie-down decals where required

· Use designated tie-down points on the plant if provided (see operations manual)

· Do not attach tie-down accessories around hydraulic cylinders or in any way that may damage hoses or hydraulic components

· Ensure machine is stabilised before travel

· Verify all tie-down equipment (chains, shackles etc.) is rated for the task and fixed in such a way to prevent movement during transit.

Ramps:

· Suitable load capacity for the weight of the plant, wide enough, footboards on the side

· Lock ramps in place, use locking pin/clips if required

· Assess ground conditions at loading/unloading site to determine forward or reverse loading

· Ensure clear of obstructions (tree branches, structures / overhead electric lines etc.)

· Ensure persons are clear of loading/unloading site

· Ensure bucket is in the lowest position possible to remain stabilised.

To load/unload:

· Apply handbrake and block tow/transport vehicle wheels

· Load / unload as per manufacturer’s instructions

· Mobile plant is loaded/unloaded to and from the vehicle whilst on level ground

· Aligned for loading/unloading and positioned with the vehicle by a suitably qualified, competent and experienced operator

· Ensure mobile plant is adequately restrained to prevent movement during transit. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Work adjacent to road & injury to public

-

CONTROL MEASURES TO REDUCE RISK

· If a machine is to be operated on public roads, ensure it is currently registered

· Machine is in roadworthy condition

· Implement traffic control measures to ensure workers, passing motorists and pedestrians cannot come in contact with the mobile plant · Methods of delineation can involve traffic cones around the vehicle allowing for a 1m spillage buffer zone around the truck

· Erect any barriers & signage necessary to keep others safe and aware. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Slips Trips and Falls Entering or Exiting Plant

-

CONTROL MEASURES TO REDUCE RISK

· Do not exit cab while loading/unloading to and from the vehicle

· Do not jump from cabin or vehicle tray

· Wear non slip footwear

· Only access tray of vehicle using manufacturer’s access points. -

Risk-Rating after control measures have been put in place = 1L Low

Potential Hazard: Injury to ground workers

-

CONTROL MEASURES TO REDUCE RISK

· Worker consultation:

o Ensure an effective system of communication between the machine operator and ground workers is established before work commences

o Relevant workers must be trained in the procedures involved prior to the work commencing

o Groundworkers are instructed not to approach machine until the operator has agreed to their request to approach.

o Ensure ground workers are instructed on set distances to maintain from the machine while in operation

o Groundworkers are instructed made familiar with the blind spots of the machine

o Machine operators and ground workers are required to wear high-visibility clothing

· Ensure no persons or obstructions in the vicinity before start-up

· Before moving/operating - Allow engine to run for sufficient time to reach operational temperature

· Ensure no persons in the vicinity before and during operation. Maintain exclusion zone and cease work if approached

· Be aware of swing boom operations or turning sharply with machine

· Follow the manufacturer's instructions, specific safe work method statement/Site rules and traffic control plan.

· Travel at an appropriate speed for conditions. Reduce speeds over unexpected hazards - such as wet conditions, long grass, hill peaks or low visibility.

· Raised load does not impede the view of the operator. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Contact with overhead power lines

-

CONTROL MEASURES TO REDUCE RISK

· Ensure work is not conducted in close proximity to electrical power lines. Check for:

o Overhead power lines (including high and low voltage distribution conductors

o Single-wire earth return (SWER)

o Service cables to premises

o Communications cables

o Electrical transformers (mounted lower than cables)

· Identify the maximum range of equipment and how close equipment or load can come to the asset (known as design envelope) The following dimensions are taken from the closest point of an extended component of the machine e.g. extended long reach boom. In general:

o 3m above, either side and below power lines is No Go Zone

o Between 3-6.4m of power lines a Spotter is required

o No work to be conducted within 10m radius of SWER transformer.

* No work to be conducted within Minimum Clearance Zones without written permission from the power supplier.

* Spotter required where any part of the machine is within 3m of the power line. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Contact with underground services

-

CONTROL MEASURES TO REDUCE RISK

· Contact Dial before you Dig and Local Authorities to obtain utilities maps of intended work area

· Mark intended work site. Provide signage if required

· Control risks from mobile plant/vehicles (establish traffic management plan – include barricades, signs, traffic controllers as required)

· Ensure sufficient time is provided for location before project begins. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Crush injuries to operator, pedestrians and property

-

CONTROL MEASURES TO REDUCE RISK

· Ensure machine does not operate or travel near the edge of an excavation unless the ground support system installed has been designed by a competent person to carry such loads

· Ensure machine stay on existing access tracks and within construction boundaries.

· Ensure heavier end is always higher upslope

· Do not turn on slopes

· Avoid sudden movements and combined movements such as raising attachment whilst starting a forward movement. (Particularly with rubber wheel models where more bounce is generated than a tracked model)

· Do not overload/exceed capabilities. Be aware of reduced lifting capacity when boom or bucket arms are extended

· Attachments kept in lowest working position possible

· Be familiar with the width of equipment to maintain safe clearance near fences, boundaries or other obstacles.

· If the machine begins to side-slip:

o Discard load

o Turn the machine downhill. -

Risk-Rating after control measures have been put in place = 2M Moderate

Potential Hazard: Hearing loss

-

CONTROL MEASURES TO REDUCE RISK

· Wear hearing protection, ensure it is worn by all persons throughout the period of exposure to noise. -

Risk-Rating after control measures have been put in place = 1L Low

Potential Hazard: Eye or hand injury

-

CONTROL MEASURES TO REDUCE RISK

· When changing hydraulic attachments wear gloves and eye protection:

o Turn plant off

o Release hydraulic pressure

o Cover quick connect with rag and disconnect

o Reconnect new attachment

o Check for proper hydraulic connection, hose routing and hose length

o Check for leaks. -

Risk-Rating after control measures have been put in place = 1L Low

-

Have you identified any further hazards on the job site?

Job Step

-

What job step does this hazard relate to?

-

Potential Hazard

-

Risk-Rating (IR) before control measures have been put in place<br>

Control Measures to Reduce Risk

-

Control measures used to reduce risk

-

Risk-Rating (RR) after control measures have been put in place.

-

Person responsible to implement control measures:

-

Establish communication with victims (if applicable) and maintain for entire rescue. Conduct response as required for specific conditions at site.

-

OPERATOR:

- Do not attempt to jump from plant during roll-over – remain in seat with seatbelt on

- After incident has occurred, if able, turn off engine

- Remain in position with seatbelt on until help arrives, unless it is safe to exit cabin

- If it is safe and injuries permit, exit cabin without jumping, and move clear from plant. -

PERSONNEL:

- Clear non-essential persons from area

- Check for fuel and/or fluid leaks. Ensure there are no ignition sources

- Check for fire or fire/explosion risks. Use suitable fire protection equipment to control fire (if safe to do so)

- Do not approach the plant until Emergency Responders attend the scene. -

NOTE: Plant may be unstable and unsafe to approach.

Do not place first responders at risk – await assistance from suitably trained and resourced Emergency Responders. -

Emergency Response - CALL 000 IMMEDIATELY.

-

If work is to be conducted on a construction site (or a site controlled by another Employer / PCBU) follow the site-specific Emergency Management Plan. Ensure:

· Adequate numbers of first aid trained staff are on site when working at heights occurs

· First aiders are trained and competent in managing injuries associated with demolition until emergency services arrive

· All rescue equipment is in good condition, available for use and in close proximity to the work site. -

Ensure workers have access to:

· First aid kit/supplies

· First Aid trained personnel familiar with Resuscitation and emergency response for electric shock

· M/SDS

· Communication devices (check mobile phones will have service in area)

· Suitable fire protection equipment.

Review & Monitor

-

To ensure controls are implemented and monitored effectively:

• Toolbox /pre-work meetings will be undertaken

• Relevant persons will be consulted on hazards and contents of SWMS, work plans and other applicable information

• Control measures will be monitored throughout works:

o Spot checks

o Consultation

o Scheduled audits

• Corrective actions will be recorded and rectified in a timely manner SWMS will be reviewed and updated accordingly (in consultation with relevant persons) -

Ensure all controls are reviewed as per the following:

• If controls fail to reduce risk adequately

• When changes to the workplace or work activity occur that create new / different risks where controls may no longer be effective

• New hazards identified

• After an incident involving work activities relevant to this SWMS

• During consultation with relevant persons indicate review is needed

• A Health and Safety Representative (HSR) requests a review in line with the requirements of the legislation.

Worker Sign-off

-

This SWMS has been developed in consultation and cooperation with employee/workers and relevant Employer/Persons Conducting Business or Undertaking (PCBU). I have read the above SWMS and I understand its contents. I confirm that I have the skills and training, including relevant certification to conduct the task as described. I agree to comply with safety requirements within this SWMS including risk control measures, safe work instructions and PPE described.

Employee

-

Terry Lobegeier

-

Tammy Hewitt