Title Page

-

Gemba Performer

-

Region

-

Facility Type

-

Facility Name

- FM Johar Town Station

- FM Hall Road Station

- FM IqbalTown Station

- FM Harbanspura Station

- FM Model Town Station

- FM Shah Alam Station

- FM DHA Lahore Station

- FM Saddar Lahore Station

- FM Baghbanpura Station

- FM Township Station

- FM PWD Station

- FM Liaquat Road Station

- FM Blue Area Station

- FM Commercial market Station

- FM Adayala Road Station

- FM North Karachi Station

- FM II Chundrigarh Station

- FM Saddar Station

- FM Shaheed e Millat KHI

- FM AyeshaManzil Station

- FM Gulshan Station

- FM Nazimabad Station

- FM Defence Zamzama Station

- FM Sharah Faisal Station

- FM Defence Phase 2 Station

- FM Garden Station

-

Facility Name

-

Facility Name

-

Facility Name

- LM KLP

- LM DHA-3

- LM SMN

- LM LAX

- LM ISL

- LM RWS

- LM RWP

- LM IST

- LM BDD

- LM CTN

- LM NAZ

- LM KOR

- LM SAD

- LM Malir

- LM Scheme 33

- LM GUL

-

Hub Name

- Abottabad Hub

- Bahawalpur Hub

- Faisalabad Hub

- Gujranwala Hub

- Gujrat Hub

- Hyderabad Hub

- Jhelum Hub

- Multan Hub

- Okara Hub

- Peshawar Hub

- Quetta Hub

- Sahiwal Hub

- Sargodha Hub

- Sheikhapura Hub

- Sheikhapura Hub

- Sialkot Hub

- Sukkur Hub

-

Conducted on

-

Geo Location

Management Gemba Guidelines

-

Please select OK if no observation and NG if any observation.

-

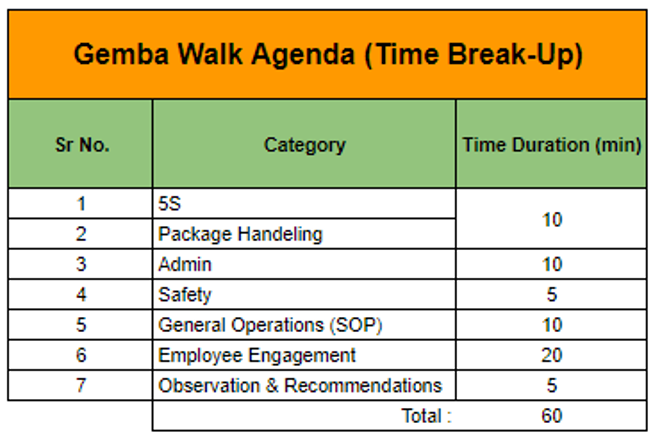

Please ensure to follow the given time allocation for each section:

-

Please adhere to the following guidelines while performing the Gemba:

- Observe and gather information.

- Do not change anything on the spot.

- Do not criticize the employees working.

- Keep record of every observation and attach picture incase of NG.

- Get insights from employees

- Understand the challenges faced by the workers

5S & Package Handling

5S Guidelines

-

While checking for 5S observation please keep in mind the following points.

- Labelling condition of shelves, station and bins.

- Floor demarcation condition.

- Equipment and items placed as per labelling and demarcation.

- 5S champion selected and displayed.

- Dirt, oil or grease on floor, walls or stairs.

- Garbage in working area.

- Gemba checklist being utilized.

- Cleaning checklist being utilized. -

Is there any 5S related observation in the Facility?

-

Please describe the 5S observation.

-

Proposed Action/Counter-Measure for the 5S observation.

Package Handling

-

While checking for Package Handling observation please keep in mind the following points.

- Boxes/carton/package is not kept on floor.

- Boxes are stacked in such a way that they don’t fall off due to imbalance with proper weight

distribution.

- Fragile packages/ LED must be place in separate portion/ Asper policy & stack in Arron direction.

- Sacks are not dragged on the floor.

- No throwing of any sort of package into trolley/carton from distance. -

Is there Package Handling related observation?

-

Please describe the Package Handling observation.

-

Proposed Action/Counter-Measure for the Package Handling observation.

Admin & Safety

Admin

-

While checking for Admin observation please keep in mind the following points.

- Kitchen staff is following all hygiene protocols and kitchen area is clean. No pest intrusion is

observed inside kitchen.

- Building walls and ceilings condition.

- Customer Area condition.

- Operation Area condition.

- Outside Area condition.

- All assets maintain their structural integrity and are free from visible signs of bending, warping, or

deformation.

- Are there any faulty electrical fixtures? Is building wiring in good condition?

- Are washrooms are cleaned and in good condition?

- Is the facility pigeon/bird free? -

Is there any Admin related observation in the Facility?

-

Please describe the Admin observation.

-

Proposed Action/Counter-Measure for the Admin observation.

Safety

-

While checking for Safety observation please keep in mind the following points.

- Is there proper ventilation in the workspace?

- Are the safety equipment and supplies in clear and obstacle free?

- Are there no safety hazards (water/oil/chemicals/open electrical wiring) in the working area? -

Is there any Safety related observation in the Facility?

-

Please describe the Safety observation.

-

Proposed Action/Counter-Measure for the Safety observation.

General Operations (SOP)

-

Facility Type

-

While checking for FM General Operations observation please keep in mind the following points.

- Is self inbounding system operational in designated Model Hubs.(Ensure availability of Scanners,

LEDs & Smooth internet Connectivity, availability of trollies/pallets to keep processed and

unprocessed packages)

- Primary sorting is carried out based on Regular and Irregular Packages or Fragile and Non

Fragile?

- Station Staff will conduct a Smart QC before receiving the item.(Check for physical condition &

Customer Claim in LOP)

- Bar Code are installed on every location where CP package is kept

- For FD Packages, If the seller collects the package within 7 days, a system generated receiving is

given, otherwise the package is marked as Scrap(PSC team will be communicating with the seller).

- RTM/RTC/RTW/SCRAP packages are placed in the standard color bins. -

While checking for Sort General Operations observation please keep in mind the following points.

- Are the docks clear for parking the Inbound vehicle?

- Are the pallets placed at Inbound for unloading the MUs from inbound vehicle?

- Are the pallets placed at Inbound conveyor for placing the MUs (that are to be loaded on Inbound conveyor)?

- Are the pallets placed at the end of Outbound conveyor? (for unloading the out bounded MUs of the machine).

- Parcels greater than BOX003 are being placed at semi-bulky area.

- Irregular shaped parcels (coming inside MUs) are being stopped at Induct stations (Refer to SOP)

- DEX packages are sorted according to 1) based on same city or different city and 2) Based on last mile hub

- 3PL packages are sorted based on 3PL name irrespective of the destination.

- Inbounding is done on package level . In case of high backlog and/or missing packages, Sort Team will initiate the FM Team within 24 hours and Route/Station will be responsible for the loss.

- Are large packages with a Non Bulky Tracking number re-shipped to bulky?(check for Gdoc)

- Is the Inbounding of CB packages done after intimation from CB team(transport team)? -

While checking for FF General Operations please keep in mind the following points.

FF Inbound

- Consignment shall be received only if the vendor has the Purchase order

- Receiver physically checks inbound order and reconcile with item/box level receiving

- Purchase order needs to be stamped after stock receiving

FF Inventory

- Physical stacking location and system stacking location should be the same

- Are the inventory capacity levels maintained? (as defined in the policy)

- B Zone: SKU Limit (5)

- F Zone: SKU Limit (3)

- S Zone: SKU Limit (3), Bin Color (Green, Blue & Red)

- H Zone: SKU Limit (3), Bin Color (Green & Blue)

- P Zone: SKU Limit (3)

- L Zone: SKU Limit (4)

- Troubleshoot Bin must have correct and relatable items

- High Value Entry/Exit log is being maintained

FF Outbound

- Wave is being run by the authorized person

- Single Bin is being used for single Picklist

- Item are getting packed in correct boxes

FF QCC

- QC agent are putting the RTC/ RTM/ RTW Scrap in their respective bin after making logistics closure

- Receiving trollies are marketed with dates, to comply with FIFO

- For Electronics, if complaints are regarding quality issue, QC Agent will perform QC for greater than Rs.1000, else RTC for less than Rs.1000 -

While checking for LM General Operations observation please keep in mind the following points.

- Is Inbounding done at MU Level for Non-Bulky Packages?

- Is Inbounding done at Package Level for Bulky Packages?

- Are the packages that are being reshipped contain dual addresses (L3,L4 Vs Text box)?

- MU are placed based on L3.8 level sorting? i.e. Chute

- At the time of exit, physical packages are checked against the RS to check for any extra or shortage of packages.

- IVR hold, reject and reschedule bins are correctly labelled.

- Reject tape is pasted on the Reject packages before sending it to relevant SC.

- Packages are sorted as per drop-off location and MUs are created with respect to the drop-off location. -

Is there General Operations related observation?

-

Please describe the General Operations observation.

-

Proposed Action/Counter-Measure for the General Operations observation.

Employee Engagement & Observation and Recommendations

Employee Engagement

-

While engaging with the employees, please keep in mind the following point.

- Ask employees if there is any improvement that an be done to in the system?

- Ask if there any challenges that the employees face?

- Are the employees satisfied with the current management style of the facility?

- Ask the employees if they are regularly trained for the job?

- Any additional concerns or issues brought up by employees on the floor?

- Ask employees if there efforts are recognized and appreciated?

- Ask the 5S champion what can be done to improve the implementation of 5S practices and spread awareness among the employees. -

Is there any employee related observation in the Facility?

-

Please describe the employee related observation.

-

Proposed Action/Counter-Measure for the employee related observation.

Additional Observation and Recommendations

-

Specify the observation category.

- Processes and Asset’s efficiency/ optimization

- Facility Maintenance / Asset

- Security and Surveillance

- Other

-

Please describe the observation.

-

Proposed Action/Counter-Measure for the observation.