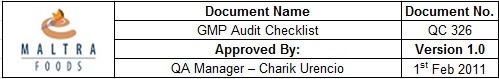

QC 326 GMP Audit Checklist

QC326 GMP Monthly Audit Checlklist

Date

-

Date of the Audit

-

Month

- January

- February

- March

- April

- May

- June

- July

- August

- September

- October

- November

- December

-

Year

Batching

-

1. GMP Practices

-

2. Raw Materials Storage Conditions

-

3. Colour Coded Utensils Condition

-

4. Equipment Cleanliness

-

5. Scales Calibrated and in Good Condition

-

6. Walls Condition

-

7. Ceiling Condition

-

8. Door Condition

-

9. Floor Condition

-

10. Pallet Condition

-

11. Is the area clean and clear of any unessential items?

-

12. Are lights covered and in good condition?

-

13. No objectionable or odd odours percieved

-

14. Pest Control traps condition

-

15. Tape not present or used as temporary repair

-

16. Rework containers condition and properly identified

-

17. No open containers (bags, cartons, pails, etc)

-

18. Vacuum cleaner Condition

-

19. No evidence of broken glass and/or hard plastic on equipment

-

20. Control Forms Completed and Signed Off

Batching Corrective Actions

-

Batching CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Blending

Blending Room No. 1 - White Products

-

21. GMP Practices

-

22. Coloured Coded Utensils Condition

-

23. Equipment Cleanliness

-

24. Walls Condition

-

25. Ceiling Condition

-

26. Door Condition

-

27. Floor Condition

-

28. Top Mezzanine Condition

-

29. Is the area clear of any unessential items?

-

30. No objectionable or odd odours percieved

-

31. Vacuum cleaner Condition

-

32. Tape not present or used as a temporary repair

-

33. BIN condition

-

34. Desk condition

-

35. No evidence of broken glass and/or hard plastic on equipment

-

36. QC253 Operator Production ID Sheet complete and signed off

-

37. QC313 inspection of Sieve complete with verification sign off

Blending Room No. 2 - Special Products

-

38. GMP Practices

-

39. Coloured Coded Utensils Condition

-

40. Equipment Cleanliness

-

41. Walls Condition

-

42. Ceiling Condition

-

43. Door Condition

-

44. Floor Condition

-

45. Top Mezzanine Condition

-

46. Is the area clear of any unessential items?

-

47. No objectionable or odd odours percieved

-

48. Vacuum cleaner Condition

-

49. Tape not present or used as a temporary repair

-

50. BIN condition

-

51. Desk condition

-

52. No evidence of broken glass and/or hard plastic on equipment

-

53. QC253 Operator Production ID Sheet complete and signed off

-

54. QC313 inspection of Sieve complete with verification sign off

Blending Room No. 3 - Dark Products

-

55. GMP Practices

-

56. Coloured Coded Utensils Condition

-

57. Equipment Cleanliness

-

58. Walls Condition

-

59. Ceiling Condition

-

60. Door Condition

-

61. Floor Condition

-

62. Top Mezzanine Condition

-

63. Is the area clear of any unessential items?

-

64. No objectionable or odd odours perceived

-

65.Vacuum cleaner Condition

-

66. Tape not present or used as a temporary repair

-

67. BIN condition

-

68. Desk condition

-

69. No evidence of broken glass and/or hard plastic on equipment

-

70. QC253 Operator Production ID Sheet complete and signed off

-

71. QC313 inspection of Sieve complete with verification sign off

-

72. QC321 McDonalds Batch Register complete with verification sign off

Blending Corrective Actions

-

Blending CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Packing

Packing Room No. 1 - Fawema

-

73. GMP Practices

-

74. Colour Coded Utensils Condition

-

75. Equipment Cleanliness

-

76. Walls condition

-

77. Ceiling condition

-

78. Floor condition

-

79. Door condition

-

80. Is the area clear of any unessential items?

-

81. Are the lights covered and in good condition?

-

82. No objectionable or odd odours perceived?

-

83. Tools clean and located at designated areas

-

84. Tape not present or used as temporary repair

-

85. BIN condition

-

86. Desk condition

-

87. Control forms complete and signed off

-

88. Vacuum cleaner condition

-

89. No evidence of broken glass and/or hard plastic on equipment

Packing Room No. 2 - Canning

-

90. GMP Practices

-

91. Colour Coded Utensils Condition

-

92. Equipment Cleanliness

-

93. Walls condition

-

94. Ceiling condition

-

95. Floor condition

-

96. Door condition

-

97. Is the area clear of any unessential items?

-

98. Are the lights covered and in good condition?

-

99. No objectionable or odd odours perceived?

-

100. Tools clean and located at designated areas

-

101. Tape not present or used as temporary repair

-

102. BIN condition

-

103. Desk condition

-

104. Control forms complete and signed off

-

105. Vacuum cleaner condition

-

106. No evidence of broken glass and/or hard plastic on equipment

Packing Room No. 3 - FR-2

-

107. GMP Practices

-

108. Colour Coded Utensils Condition

-

109. Equipment Cleanliness

-

110. Walls condition

-

111. Ceiling condition

-

112. Floor condition

-

113. Door condition

-

114. Is the area clear of any unessential items?

-

115. Are the lights covered and in good condition?

-

116. No objectionable or odd odours perceived?

-

117. Tools clean and located at designated areas

-

118. Tape not present or used as temporary repair

-

119. BIN condition

-

120. Desk condition

-

121. Control forms complete and signed off

-

122. Vacuum cleaner condition

-

123. No evidence of broken glass and/or hard plastic on equipment

Packing Room No. 4 - Manual

-

124. GMP Practices

-

125. Colour Coded Utensils Condition

-

126. Equipment Cleanliness

-

127. Walls condition

-

128. Ceiling condition

-

129. Floor condition

-

130. Door condition

-

131. Is the area clear of any unessential items?

-

132. Are the lights covered and in good condition?

-

133. No objectionable or odd odours perceived?

-

134. Tools clean and located at designated areas

-

135. Tape not present or used as temporary repair

-

136. BIN condition

-

137. Desk condition

-

138. Control forms complete and signed off

-

139. Vacuum cleaner condition

-

140. No evidence of broken glass and/or hard plastic on equipment

Packing Room No. 5 - Manual

-

141. GMP Practices

-

142. Colour Coded Utensils Condition

-

143. Equipment Cleanliness

-

144. Walls condition

-

145. Ceiling condition

-

146. Floor condition

-

147. Door condition

-

148. Is the area clear of any unessential items?

-

149. Are the lights covered and in good condition?

-

150. No objectionable or odd odours perceived?

-

151. Tools clean and located at designated areas

-

152. Tape not present or used as temporary repair

-

153. BIN condition

-

154. Desk condition

-

155. Control forms complete and signed off

-

156. Vacuum cleaner condition

-

157. No evidence of broken glass and/or hard plastic on equipment

Packing Room No. 6 - Manual

-

158. GMP Practices

-

159. Colour Coded Utensils Condition

-

160. Equipment Cleanliness

-

161. Walls condition

-

162. Ceiling condition

-

163. Floor condition

-

164. Door condition

-

165. Is the area clear of any unessential items?

-

166. Are the lights covered and in good condition?

-

167. No objectionable or odd odours perceived?

-

168. Tools clean and located at designated areas

-

169. Tape not present or used as temporary repair

-

170. BIN condition

-

171. Desk condition

-

172. Control forms complete and signed off

-

173. Vacuum cleaner condition

-

174. No evidence of broken glass and/or hard plastic on equipment

Packing Corrective Actions

-

Packing CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Packing Area

Packing Area

-

175. GMP Practices

-

176. Colour Coded Utensils Condition

-

177. Goods Storage condition

-

178. Walls condition

-

179. Ceiling condition

-

180. Floor condition

-

181. Door condition

-

182. Pallet Racking condition

-

183. Pallets condition

-

184. Quarantine area condition

-

185. Product in Quarantine is properly identified

-

186. Is the area clear of any unessential items?

-

187. Are the lights covered and in good condition?

-

188. No objectionable or odd odours perceived

-

189. Tape not present or used as temporary repair

-

190. Waste area condition

-

191. Control forms complete and signed off

-

192. No evidence of broken glass and/or hard plastic on equipment

Packing Area Corrective Actions

-

Packing CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Wet & Dry Room

Wet Room

-

193. GMP Practices

-

194. Cleaning tools conditions

-

195. Cleaning tools storage conditions

-

196. Area conditions

-

197. Walls conditions

-

198. Ceiling conditions

-

199. Doors conditions

-

200. Floor conditions

-

201. No objectionable or odd odours perceived

-

202. Is the area clear of any unessential items?

-

203. Are the lights covered and in good condition?

-

204. No evidence of broken glass and/or hard plastic on equipment

Dry Room

-

205. GMP Practices

-

206. Cleaning tools conditions

-

207. Cleaning tools storage conditions

-

208. Equipment conditions

-

209. Walls conditions

-

210. Ceiling conditions

-

211. Doors conditions

-

212. Floor conditions

-

213. No objectionable or odd odours perceived

-

214. Is the area clear of any unessential items?

-

215. Are the lights covered and in good condition?

-

216. No evidence of broken glass and/or hard plastic on equipment

Wet & Dry Rooms Corrective Actions

-

Wet & Dry Room CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Maintenance

Maintenance

-

217. GMP Practices

-

218. Area condition

-

219. Walls condition

-

220. Ceiling condition

-

221. Doors condition

-

222. Tools kept on designated areas

-

223. Food Grade oils properly stored and identified

-

224. Are the lights covered and in good condition?

-

225. No evidence of broken glass and/or hard plastic on equipment

Maintenance Corrective Actions

-

Maintenance CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Compresor Area

Compressor Area

-

226. GMP Practices

-

227. Walls condition

-

228. Ceiling condition

-

229. Floors condition

-

230. Doors condition

-

231. Stairs condition

-

232. Pipework condition

-

233. Compressors condition

-

234. Filters racking condition

-

235. Pest Control traps condition

-

236. Is the area clear of any unessential items?

-

237. Are the lights covered and in good condition?

-

238. No evidence of broken glass and/or hard plastic on equipment

Compressor Corrective Actions

-

Compressor Area CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Warehouse

Warehouse

-

239. GMP Practices

-

240. Goods storage conditions

-

241. Walls conditions

-

242. Ceiling conditions

-

243. Doors conditions

-

244. Floors conditions

-

245. Pallets conditions

-

246. Is the area clear of any unessential items?

-

247. Are the lights covered and in good condition?

-

248. Forklifts conditions

-

249. Pest Control traps

-

250. No open containers (bags, cartons, pails, etc)

-

251. Allergen Control

-

252. Desk condition

-

253. QC101 Goods Delivery Register complete and signed off

-

254. QC103 Finish Product Dispatch Check complete and signed off

-

255. No evidence of broken glass and/or hard plastic on equipment

Warehouse Corrective Action

-

Warehouse CAR assigned to

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Enter any corrective actions that will be undertaken

Exterior & Parking

Exterior and Parking Areas

-

256. GMP Practices

-

257. Building Exterior

-

258. Floors Conditions

-

259. Waste Area Conditions

-

259. Green Areas Conditions

-

260. Is the area clear of any unessential items?

-

261. Pest Control traps

-

262. Security Conditions

-

263. Smoking Area Conditions

-

264. Warehouse Dispatch Area Conditions

-

265. Are the lights covered and in good condition?

External and Parking Area Corrective Action

-

External and Parking Areas CAR assigned to

-

Enter any corrective actions that will be undertaken

Audit Summary

Audit Summary

-

Comments

-

Due Date

-

Completed by

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Verified by

- Charik Urencio

- Louise Norman

- Sylvia Parker-Bull

- Steve Blair

- Susie

- Erianna

- Carlos

- Hulya

- Praveen Kasturi

- Boris Mircovic

- Not Applicable

-

Date Completed