Title Page

-

Store number

-

Store Name

-

Division

-

Region

-

Store Manager

-

Date Audited

-

Shrinkage Compliance Manager

Communication Area

-

Has the communication area been completed in full

Which elements are completed correctly

-

Computer generated map on coms board

-

Stockroom communication area created and to planogram

-

Information displayed on coms board is up to date/current week

-

Actions the store must take

-

Expected completion date

Stockroom map/zone setup

-

Has the stockroom map and zone set up been completed in full

Which elements are completed correctly

-

Computer generated map available in key locations all floors of stockroom and loading bay/delivery area

-

Put away areas clearly highlighted using colour coding on map

-

Actions the store must take

-

Expected completion date

-

From a random sample check were all specific put away zones I.e 1/5/20/21/22/25 set up correctly within AURA to match physical locations within the stockroom

End of aisle signage

-

Have all end of aisle signage been completed in full

Which elements are completed correctly

-

All aisles to have A4 laminated, yellow/black aisle numbers attached

-

A5 area cards on all main routes to highlight zones in aisle to to aide put away

-

Shelf arrow guide to be located on main walkways

-

Weight notices positioned in key areas, stockroom entrance, main walkways etc

-

Actions the store must take

-

Expected completion date

Bay signage

-

Have all bay signage been completed in full

Which elements are completed correctly

-

All zone indicators correctly in place on all uprights

-

Location arrows on all shelves

-

Yellow Floating Z's in place on all bottom shelves

-

Actions the store must take

-

Expected completion date

Fast track collection

-

Has the fast track area been completed in full

Which elements are completed correctly

-

Area 1 shelf edge strips placed on all shelves within the area

-

Zone 1 A5 put away card positioned on aisle end

-

Zone 1 zone indicator on the upright in each bay

-

Stock stored below 2m (J location and below)

-

Minimum of one shelf of Corex boxes created, zoned individually to corporate standard

-

Area located as close to the customer as possible with store layout considerations

-

Actions the store must take

-

Expected completion date

EBay Area

-

Has the EBay area been completed in full

Which elements are completed correctly

-

EBay shelf edge strips placed on all shelves within the area

-

Stock stored below 2m (J location and below)

-

Minimum of one shelf of Corex boxes created, zoned individually to corporate standard

-

Area located next to/within Area 1 of the stockroom

-

EBay locations barcoded

-

Actions the store must take

-

Expected completion date

Small item pick

-

Has the small pick - Area 5 been completed in full

Which elements are completed correctly

-

Area 5 shelf edge strips placed on top and bottom shelf of Correx/ Wax box locations in each bay and all shelves used for loose Barton stock

-

Zone 5 A5 put away card positioned on aisle end

-

Zone 5 zone indicator on the upright of each bay

-

Stock stored below 2m (J location and below)

-

Correx/Wax boxes are zoned individually to corporate standard ( black text on yellow)

-

Actions the store must take

-

Expected completion date

Jewellery & Watches - Area 8

-

Has the Jewellery & Watch - area 8 been completed in full

Which elements are completed correctly

-

Zone 8 zone indicator on the upright in each bay

-

De-boxed Jewellery trays have a location on each tray front

-

Boxed Jewellery zoned to upright J1 locations

-

High value lines stored in a locked location, with key control in place

-

Actions the store must take

-

Expected completion date

-

Is the Jewellery door visible to customers

-

Is the door free from signage

-

Is there signage on the Jewellery door

Security - Area 9

-

Has Security -Area 9 been set up completely

Which elements are completed correctly

-

Zone 9 zone indicator on the upright in each bay

-

Zone 9 A5 put away card positioned on door

-

Correx/Wax boxes are zoned individually to corporate standard (black text on yellow)

-

Think 21 VGS/DVD area created with area 21 shelf edge strips on all relevant shelves

-

Actions the store must take

-

Expected completion date

Gas Storage - Area 20

-

Has the gas storage - Area 20

Which elements are completed correctly

-

Area 20 shelf edge strips placed on all shelves within the area

-

Zone 20 A5 put away card positioned on aisle end

-

Zone 20 zone indicator on the upright in each bay

-

Stock stored below below 2m (J location and below)

-

Location of area meets required H&S standards: end of a dead end aisle or in an area not considered a main fire exit route

-

Actions the store must take

-

Expected completion date

Think 21 - Area 21

-

Has area 21 been completed in full

Which elements are completed correctly

-

Area 21 shelf edge strips placed on all shelves within the area

-

Zone 21 A5 put away card positioned on aisle end

-

Zone 21 zone indicator on the upright in each bay

-

Stock stored below below 2m (J location and below)

-

Actions the store must take

-

Expected completion date

-

Is area 21 on the same floor as collection (to minimise handling of product between area and customer)

-

Is this best suited for store layout

Date rotation - Area 22

-

Has the date rotation - Area 22 been completed in full

Which elements are completed correctly

-

Area 22 shelf edge strips placed on all shelves within the area

-

Orange food rotation labels in place on all shelf edges

-

Zone 22 A5 put away card positioned on door

-

Zone 22 zone indicator on the upright in each bay

-

No food products stored in Z locations

-

Products stored in correct date order on shelf

-

Stock stored below 2m (J location and below)

-

Actions the store must take

-

Expected completion date

Multi choice - Area 25

-

Has the multiple choice -Area 25 been completed in full

Which elements are completed correctly

-

Area 25 shelf edge strips placed on all shelves within the area

-

Zone 25 A5 put away card positioned on aisle end

-

Zone 25 zone indicator on the upright in each bay

-

Stock stored below below 2m (J location and below)

-

Actions the store must take

-

Expected completion date

-

Are Correx boxes in use

-

Correx boxes individually zoned to corporate standard

Faulty returns area

-

Has the faulty returns area been completed in full

Which elements are completed correctly

-

Faulty returns shelf edge strips placed on all shelves within the area

-

Upright strips replaced with yellow

-

Repack kit is stored within the are using labelled Correx boxes

-

Adequate stock of repack kit available for use

-

Faulty products stored safely/neatly on shelving

-

Actions the store must take

-

Expected completion date

Views and returns

-

Have the views and returns area been completed in full

Which elements are completed correctly

-

Views and return shelf edge strips placed on all shelves within the area

-

Insurance claim shelf edge strips placed on all shelves within the area

-

Upright location strips replaced with blue/green strips

-

Minimum of 2 shelves available for insurance claims layout could vary/expand if required in store

-

Actions the store must take

-

Expected completion date

Missing parts area

-

Is space available

-

Has the missing parts area been completed in full

Which elements are completed correctly

-

Views and return shelf edge strips placed on all shelves within the area

-

Insurance claim shelf edge strips placed on all shelves within the area

-

Upright location strips replaced with blue/green strips

-

Minimum of 2 shelves available for insurance claims layout could vary/expand if required in store

-

Actions the store must take

-

Expected completion date

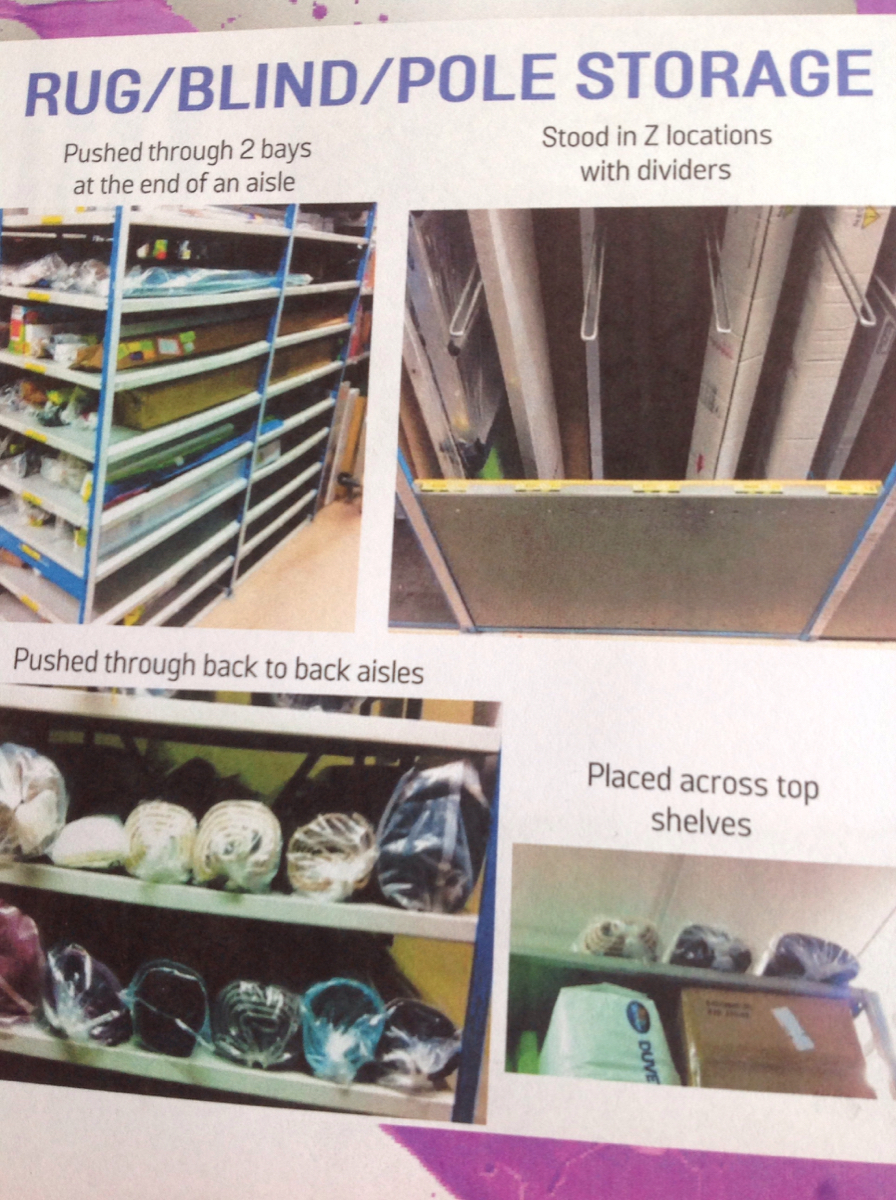

Rug/blind/pole storage

-

Have the store adopted one of the following storage solutions:<br>

Which elements are completed correctly

-

Actions the store must take

-

Expected completion date

-

Examples

Television Storage

-

Is there adequate space to allow for the storage of televisions as per OGW

-

Has the Television storage solution been completed in full

Which elements are completed correctly

-

Double deep binning used to store large screen TV's on their bases

-

Location strip only visible from one side of the location

-

Cross braces left in place to comply with H&S

-

Actions the store must take

-

Expected completion date

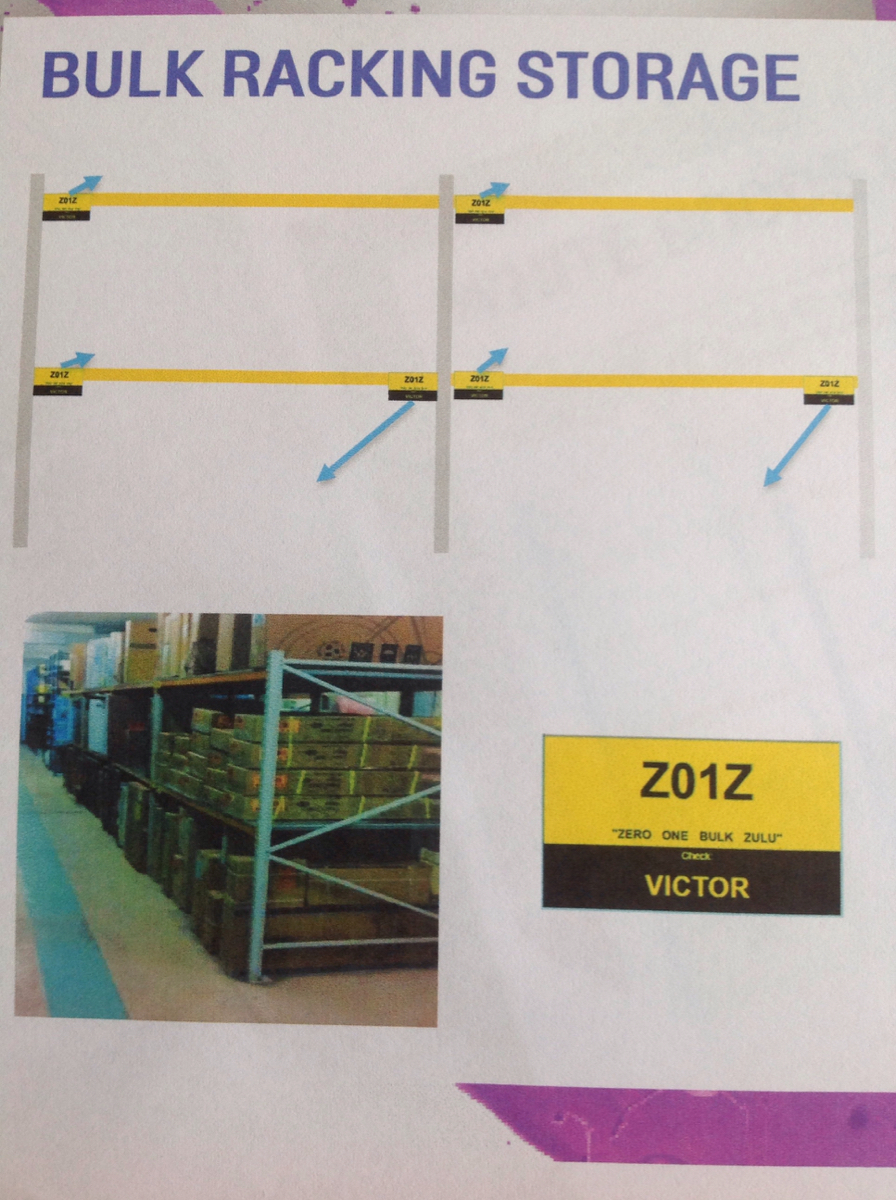

Bulk racking storage

-

Does the store have bulk racking

Which elements are completed correctly

-

Medium (Correx box) size location labels used

-

Actions the store must take

-

Expected completion date

-

White goods storage

-

Do the store have white goods in floor bulk areas

-

Has the area been marked out with hazard tape and clearly labelled

-

Action store must take

-

Expected date of completion

-

Is it possible for white goods to be stored within the racking (consider space restraints)

-

Are white goods stored within the racking

Weights storage

-

Are there space constraints that prevent the store from completing the weight storage as per OGW

-

Has the weights storage area been completed in full

Which elements are completed correctly

-

Weights stored in Z locations or on reinforced shelves

-

Poles laid flat on the shelves above the weights

-

Load notice signage placed at the end of aisles where weight storage is implemented

-

Actions the store must take

-

Expected completion date

Stockroom equipment storage

-

Has the stockroom storage been completed in full

Which elements are completed correctly

-

Ladder storage in a safe position located with hazard tape

-

Minimum of one ladder per aisle

-

Is there a utility board in store

-

Utilities board fully stocked

-

Trollies, sack trucks and pallet trucks stored in a safe location not causing an obstruction

-

Actions the store must take

-

Expected completion date

Delivery area

-

Has the delivery area been completed in full

Which elements are completed correctly

-

Cage retention ares marked out with hazard tape

-

Pallet storage areas marked out with hazard tape

-

Hi-viz jackets and gloves stored safely/neatly and available for use

-

Delivery equipment (I.e. Poles/chains) stored safely/neatly and available for use

-

Actions the store must take

-

Expected completion date

Collection counter layout

-

Has the collection counter been completed in full

Which elements are completed correctly

-

Each collection counter split into locations 0-9, left to right from the customer viewpoint

-

Are the top shelves utilised for space depending on peak/non peak strategy

-

Actions the store must take

-

Expected completion date

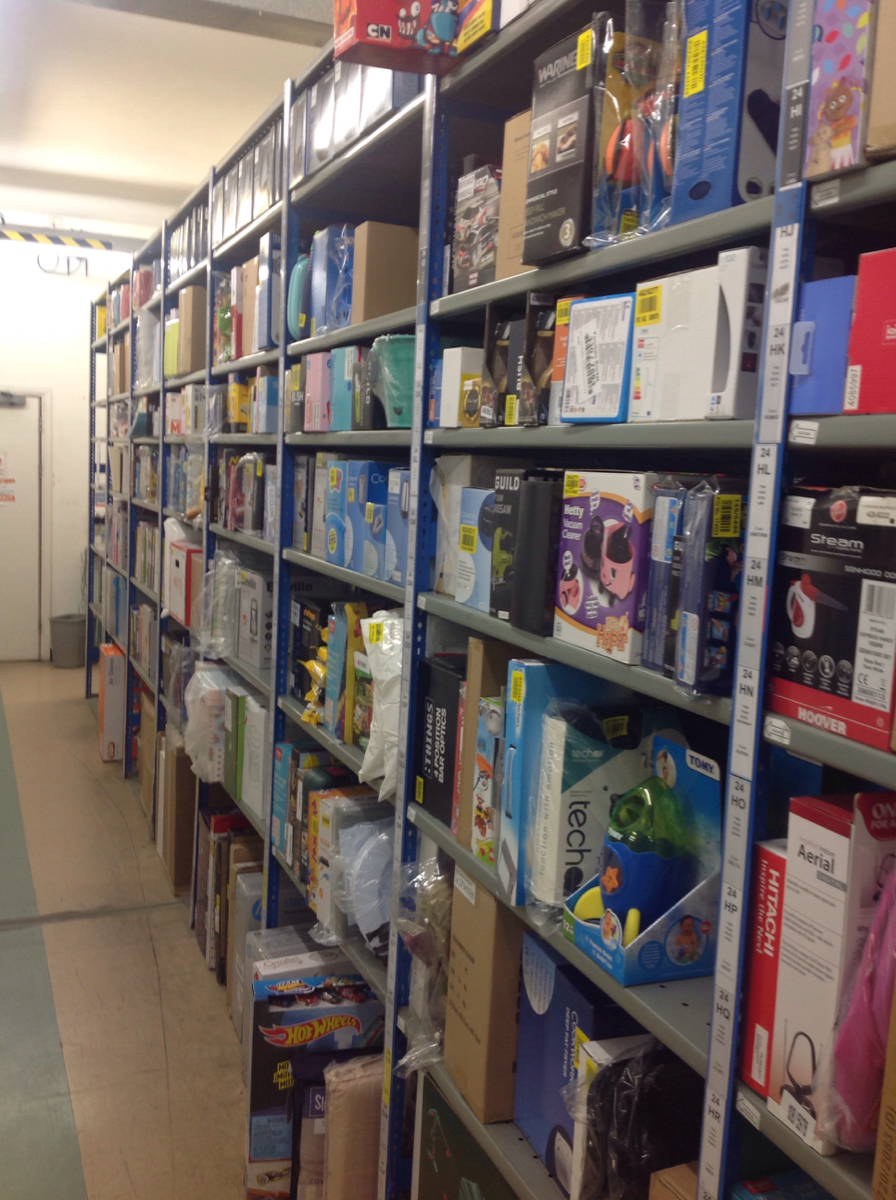

Shelf put away standards

-

Are shelf standards as per OGW

Which elements are completed correctly

-

Stock put away to the front of the shelf on all shelves

-

Stock put away to the left of each shelf with space visible on the right

-

Catalogue numbers facing outwards wherever possible

-

Approximately, no more than two finger spacing above the item and the shelf above

-

Actions the store must take

-

Expected completion date

Hub Stores Only

-

Hub store

-

Has the pick and pack bench been completed in full

Which elements are completed correctly

-

Packing bench set up correctly

-

Time-clock highlighting departure times visible behind/close to the packing bench

-

Area tidy and free from any unnecessary equipment/materials

-

Actions the store must take

-

Expected completion date

-

Has the marshalling area been set up completely

Which elements are completed correctly

-

Area as close to the back door as possible

-

Area split by van (colour coded)

-

Each colour representing a set of postcodes split by sector and highlighted on a visible map

-

Within each coloured sector the shelves should be split by postcode and highlighted with shelf labels

-

Actions the store must take

-

Expected completion date

-

Has the spoke consolidation area been set up completly

Which elements are completed correctly

-

Area as close to the back door as possible

-

Designated space for each spoke highlighted by signage

-

Signage colour coded to match the relevant van that the spoke should be loaded t0

-

Actions the store must take

-

Expected completion date

Before you Leave

-

The following actions need to be completed before you leave the store

-

Ensure all actions and deadlines are noted on relevant sections

-

Ensure the team are clear on how to provide you with photographic evidence of the completion of all actions

-

Take some pictures of the great standards in store

-

Email a copy of the sign-off guide to allow for completion along with a copy to the RM and your line manager