Title Page

-

Document No.

-

Lifting Activity Assessed

-

Add a detailed description of activity via notes or add as media (video or .pdf)

-

Version number

-

Purpose of new issue

- general review (2 years since last review)

- Due to an accident

- Due to change in process

- Risk assessment no longer suitable

-

Add detailed description of review

-

Location

-

Assessment Date

-

Review Date

-

Assessor (name)

-

Assisted by (names)

Overall risk rating of the lifting activity

-

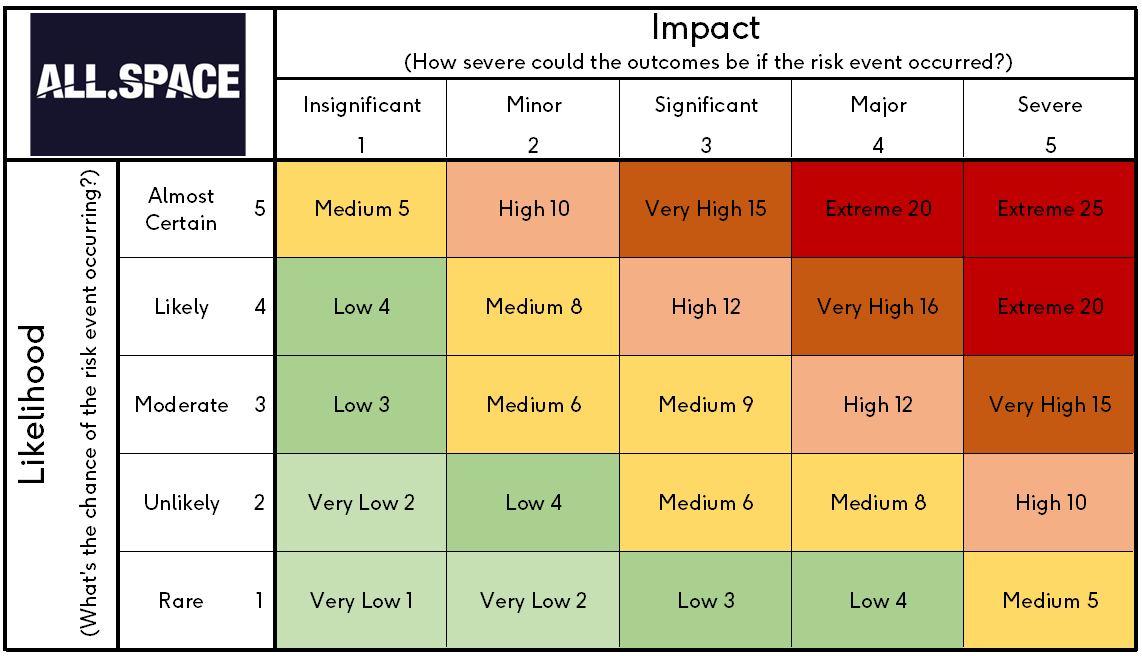

What is the likelihood of an incident occurring? (1= rare, 2 = unlikely, 3 = moderate, 4 = likely, 5 = almost certain)

-

What would be the impact of the incident? (1= insignificant, 2 = minor, 3 = moderate, 4 = significant, 5 = severe)

-

Risk number is:

-

Use the Risk Matrix to determine the risk rating for this hazard

-

What is the overall risk rating for this assessment?

- 20-25 Extreme

- 15-19 Very High

- 10-14 High

- 5-9 Medium

- 3-4 Low

- 1-2 Very Low

-

Actions will be raised within this assessment to reduce the risk rating for this task by implementing an improved control measures

-

Is this an external company undertaking the lift?

-

Name of Company Undertaking the Lift

-

Have they submitted a lift plan?

-

Attach the lifting plan

-

Has the lift plan been reviewed?

-

This task should be stopped until a lifting plan has been completed.

Load Details

-

Description of the Load

-

Total weight being lifted (Kg), including any packaging.

-

Dimensions of the load

-

Are there lifting points on the load?

Lifting Plant, Equipment & Personnel

-

What equipment is being used in this lift?

- Forklift Truck

- Big Red

- Pallet Truck

- Lifting Beam

- Chain

- Hook

- Sling

- D-Shackle

- T-Bolt

- Eyebolt

- Other

-

FLT reference number

-

Does the forklift truck have a current & valid LOLER certificate of thorough examination?

-

The forklift should not be used for this lift

-

Include the LOLER Examination details

-

Is the capacity of the FLT adequate to carry out the task?

-

The forklift should not be used for this lift

-

Provide evidence in the notes as to why it is adequate

-

Equipment reference number

-

Does the lifting beam have a current & valid LOLER certificate of thorough examination?

-

The lifting beam should not be used for this lift

-

Include the LOLER Examination details

-

Is the capacity of the lifting beam adequate to carry out the task?

-

The lefting beam should not be used for this lift

-

Provide evidence in the notes as to why it is adequate

-

Equipment reference number

-

Do the accessories have a current & valid LOLER certificate of thorough examination?

-

The lifting accessory should not be used for this lift

-

Include the LOLER Examination details

-

Is the capacity of the lifting accessory adequate to carry out the task?

-

The lifting accessory should not be used for this lift

-

Provide evidence in the notes as to why it is adequate

-

Lifting equipment required

-

Equipment reference number

-

Does the lifting equipment current & valid LOLER certificate of thorough examination?

-

The lifting equipment should not be used for this task

-

Include the LOLER Examination details

-

Is the capacity of the lifting equipment adequate to carry out the task?

-

The lifting equipment should not be used for this task

-

Provide evidence in the notes as to why it is adequate

-

Does Big Red have a current & valid LOLER certificate of thorough examination?

-

The forklift should not be used for this lift

-

Include the LOLER Examination details

-

Is the capacity of the FLT adequate to carry out the task?

-

The forklift should not be used for this lift

-

Provide evidence in the notes as to why it is adequate

Lift Area & Immediate Surroundings

-

Is there a lifting journey/ map available?

-

draw basic plan including stopping points and any locations of concern.

-

What is the starting point of the lift?

-

What is the end point of the lift?

-

Are there any obstacles of concern? (e.g, narrow access points, changes in level or lighting etc.

-

What are the obstacles of concern?

- Narrow access points e.g. doors

- changes in level e.g. steps

- Sharp turns/ blind spots

- Fixed objects e.g. walls/ barriers

- Overhead fixtures/ fittings e.g cables, lighting, fire alarm beams

- other

-

What is the obstacle of concern?

-

How will this obstacle be mitigated?

-

How will this obstacle be mitigated?

-

Are there stopping points along the lifting journey?

-

Where are the stopping points?

-

Is lift journey/ area suitably & sufficiently barriered off?

-

Is access to lift area suitably controlled by signaling operators?

-

Is the lifting operation performed outside?

-

Additional consideration should be made regarding the weather conditions. If inclement weather, consider slippery surfaces and stability of the lift if windy. If clement weather, consider the operator being exposed to heat and UV.

Personnel Involved

-

Who is the designated lift team coordinator?

-

Who else is involved in the lifting operation and what is their role?

-

For example, John Smith - FLT operator, Sarah Jones - Signaling operator.

-

Are personnel involved trained in using the lifting equipment/ task specific to their role as detailed above?

-

only personnel trained in the operation of the equipment should be involved in this lifting task

Sign Off

-

Lift Team Coordinator Name & Signature

-

Lift Plan Assessor Name & Signature

-

This document must now be communicated with all relevant persons involved with the lifting task