Title Page

-

Conducted on

-

Prepared by

-

Location

-

Fitter Signature

-

Electrician Signature

Slotter

-

Operation of slotter - Check operation of slotter & lap cutter - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Interlocking - Check interlocking between components

-

Chains - Check the tension of the chains & adjust if necessary

-

Anvils - Check the surface state of the scoring, blade & lap anvils

-

Please take 4 measurements between the creasing head and anvil when fully open.

-

Creasing head 1 (mm)

-

Creasing head 2 (mm)

-

Creasing head 3 (mm)

-

Creasing head 4 (mm)

-

Blades - Check condition of slotter & lap cutter blades

-

Guides - Check he gap between the guides & the units, replace wear pads if necessary

-

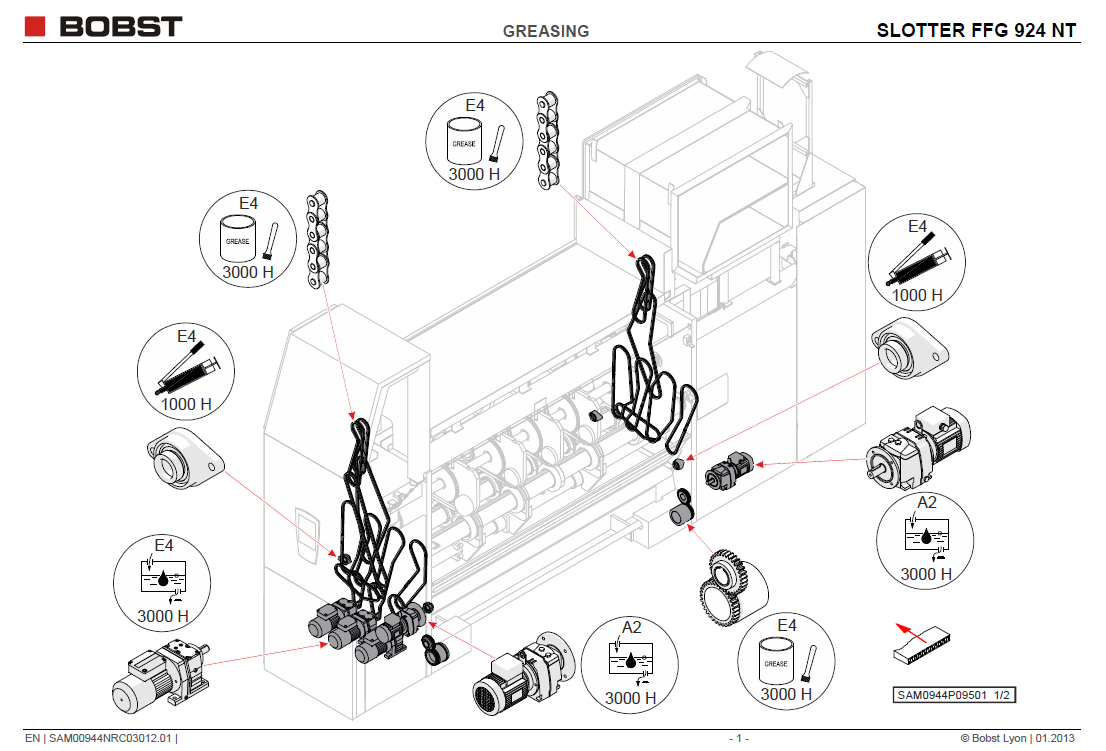

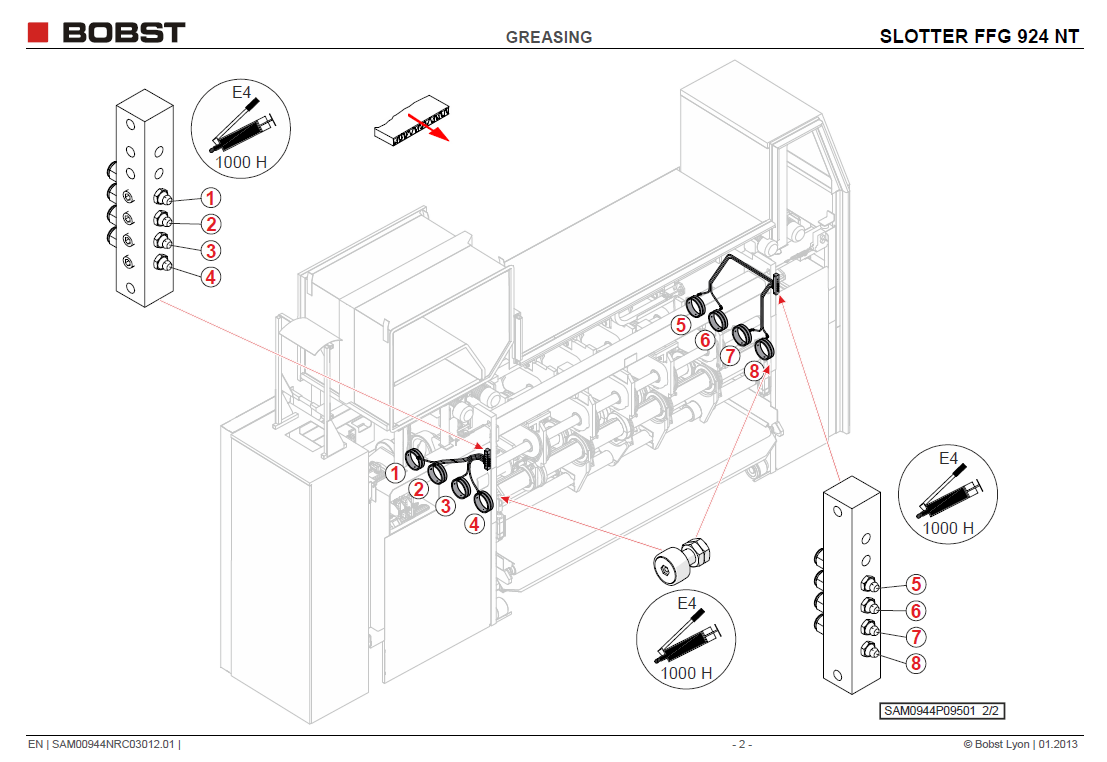

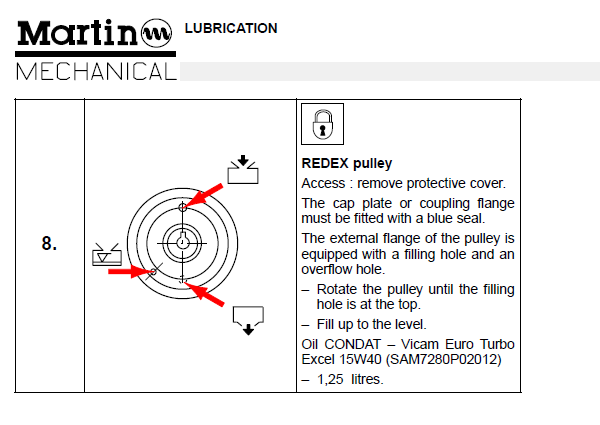

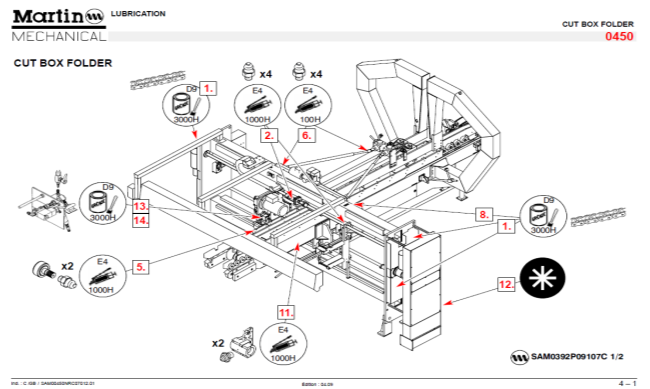

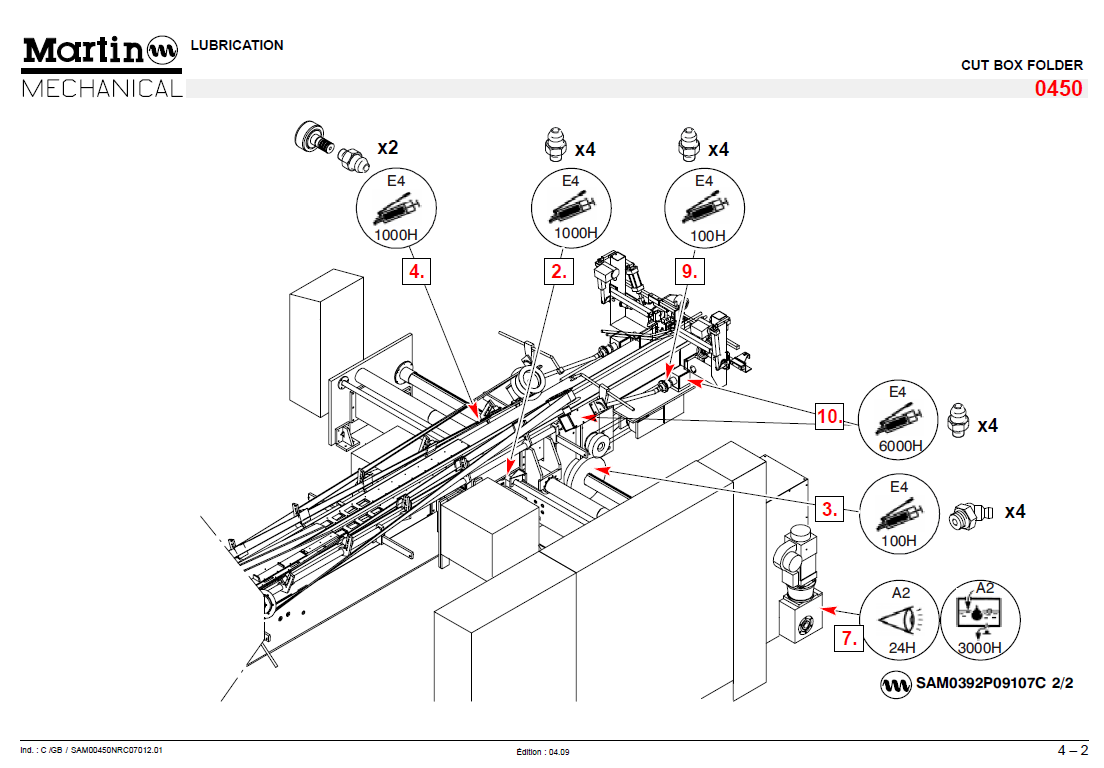

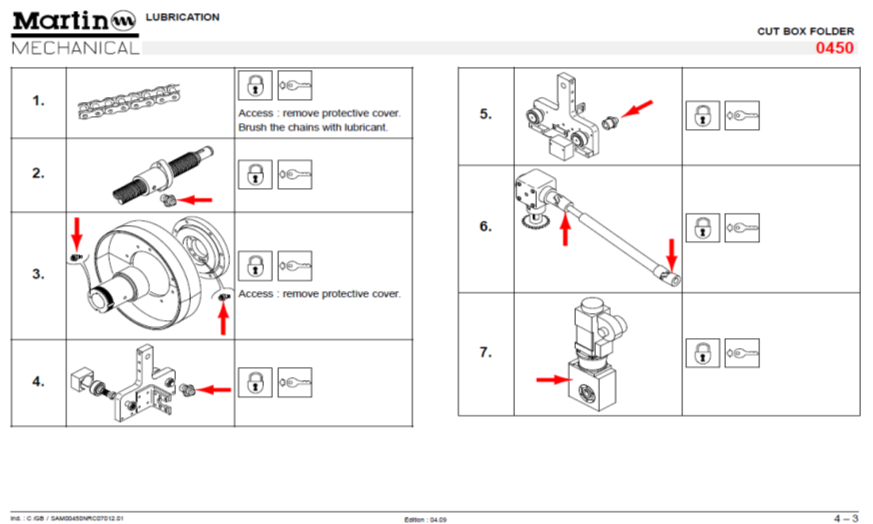

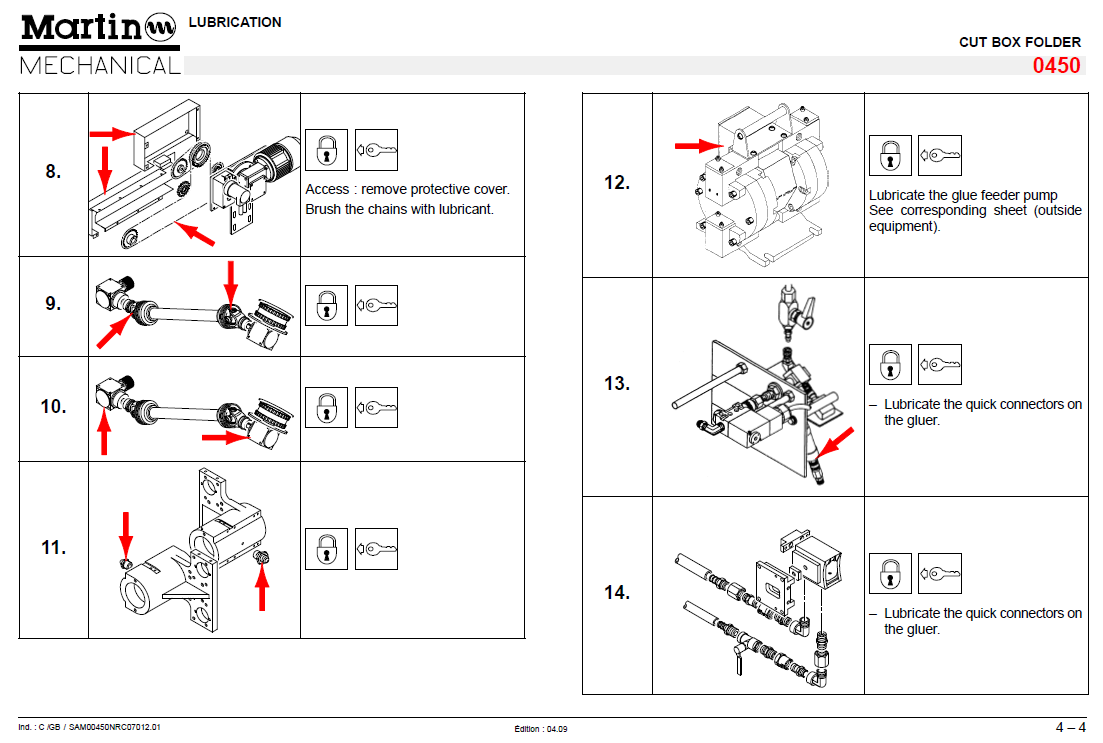

Monthly Greasing - Complete greasing as scheduled as per drawing below.

-

Lubrication Legend

A2 - Omala S2 G 150

E1 - Gadus S2 V220 0

E4 - Gadus S2 V220 2

E7 - Gadus S2 V220 00 -

Die Cutter

-

Operation of die cutter - Check operation of die cutter - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell & Limit switch operation - Clean all photocells / limit switches & check operation

-

Pneumatic Circuits - Check operation of electro valves

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Interlocking - Check interlocking between components

-

Chains - Check the tension of chains & set the chain adjuster

-

Vibration Checks - Check the parts subject to vibration are firmly attached

-

Intake Turbine - Electrically isolate & check for dirt / obstructions

-

Cutting Devices - Check the condition of cutting devices, replace if required

-

Belts - Check the condition & tension of synchronous belts, cariable speed anvil belts & vacuum transfer section belts

-

Folding Arm Covers - Remove both folding arm covers & clear waste / debris

-

Guarding's - Remove extra guards to expose drive belts for cleaning drive belts & rollers

-

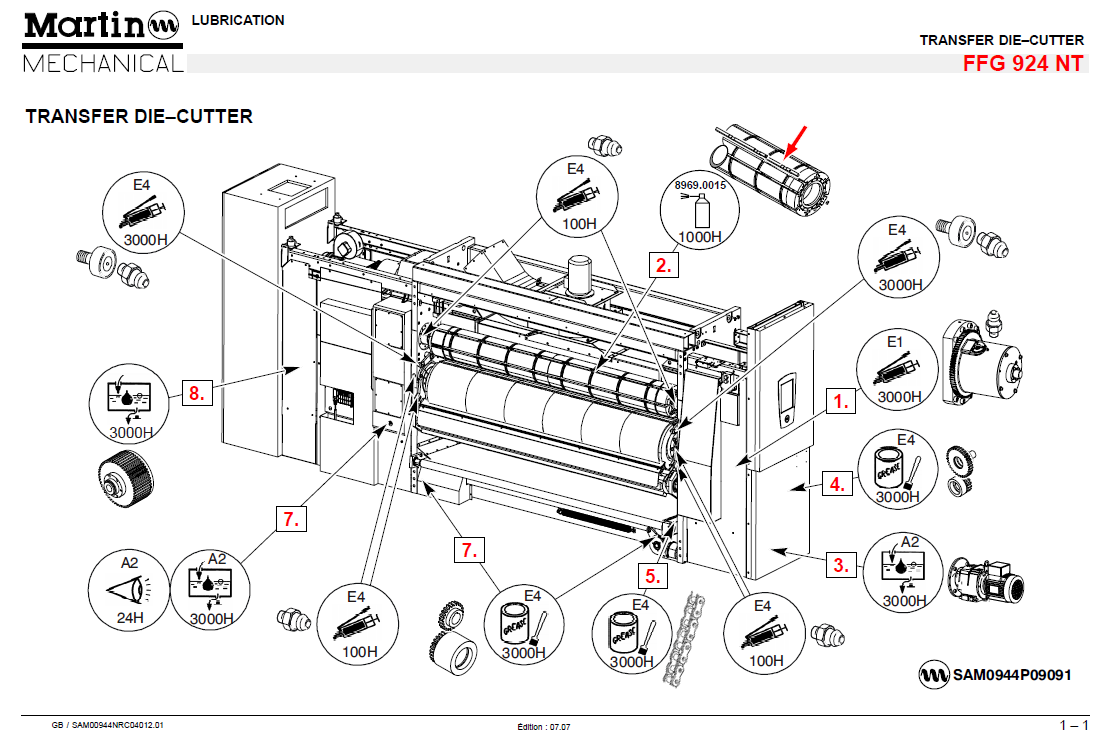

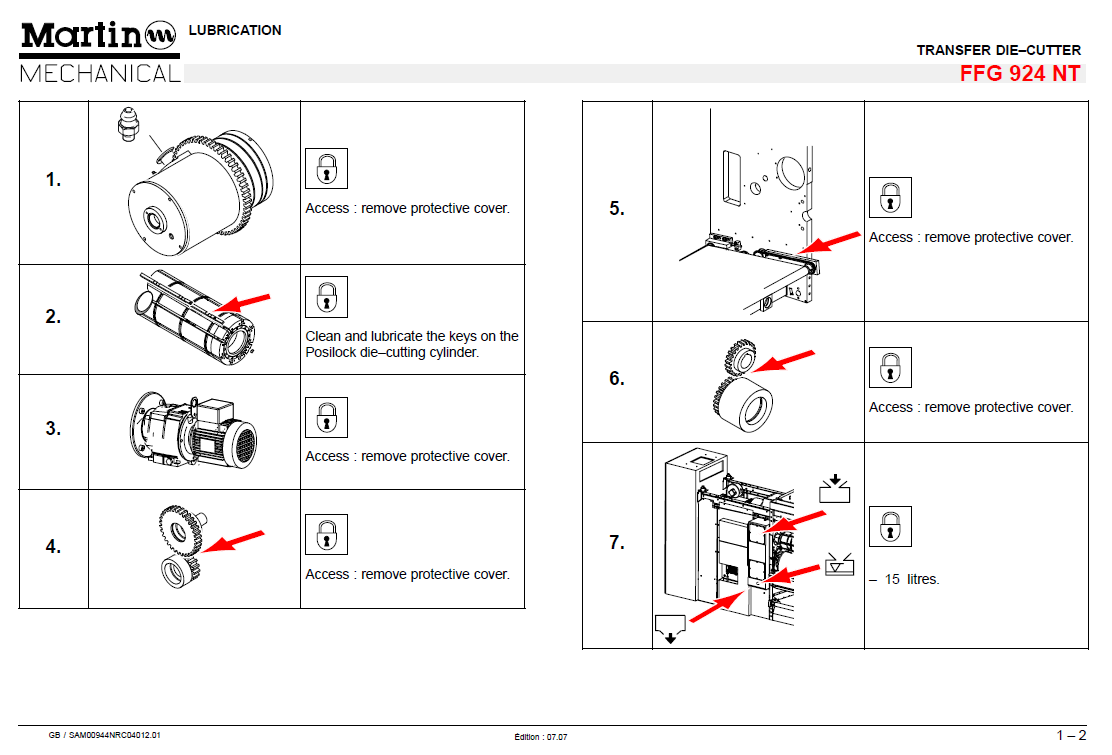

Lubrication - Check & lubricate all points as per drawing below

-

Lubrication Legend

A2 - Omala S2 G 150

E1 - Gadus S2 V220 0

E4 - Gadus S2 V220 2

E7 - Gadus S2 V220 00 -

-

Folder

-

Operation of folder - Check operation of folding section - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel, Suction Fans & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Pneumatic Circuits - Check operation of electro valves

-

Conveyor Belts - Test the conveyor belts, remove guarding & remove dirt / debris

-

Glue Nozzles - Clean & lubricate parts under the gluer to prevent glue splashes sticking

-

Glue Circuit - Check the gluing circuit, check tightness, refasten the sleeves & joints if necessary

-

Vibration Checks - Check the parts subject to vibration are firmly attached

-

Transport Nuts - Check the play of transport nuts

-

Chains - Check the tension of chains & set the chain adjuster

-

Screws - Clean the movement screws & shafts - spray with wax polish

-

Check and Enter the thickness of the Folding Belts

-

Operator Side Thickness

-

Drive Side Thickness

-

Drive belts / Gears - Check condition & clean belts as required - report any anomalies

-

Lubrication - Check & lubricate all points as per drawing below

-

Lubrication Legend

A2 - Omala S2 G 150

E1 - Gadus S2 V220 0

E4 - Gadus S2 V220 2

E7 - Gadus S2 V220 00 -

-

-

Hand Back Check List

-

General - Ensure that all tools and equipment have been removed and area is clean and tidy

-

Enter full details why this wasn't done.

-

Safety Guards - Ensure that all guards are refitted and secured correctly

-

Enter full details why this wasn't done.

-

Machine Start up - Removal of lockout/tagout devices and carry out power up procedure

-

Enter full details why this wasn't done.

-

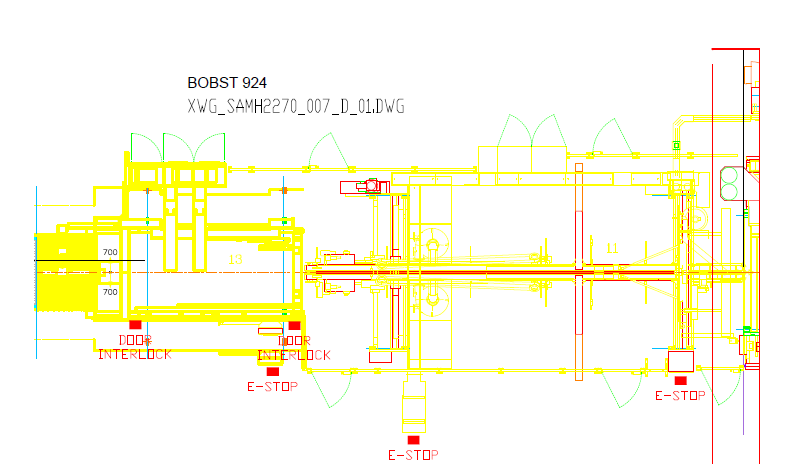

Emergency systems - Test operation of all emergency systems located as per drawing below

-

Enter full details why this wasn't done.

-

-

Production Start Up - Monitor operation of machine and confirm with supervisor that equipment is operating satisfactory

-

Enter full details why this wasn't done.

General

-

Add any general notes here

-

PM Start Time

-

PM End Time

-

Machine Supervisor Signature

-

Shift Manager Signature

-

Engineer Supervisor Signature