Title Page

-

Fitter Signature

-

Electrician Signature

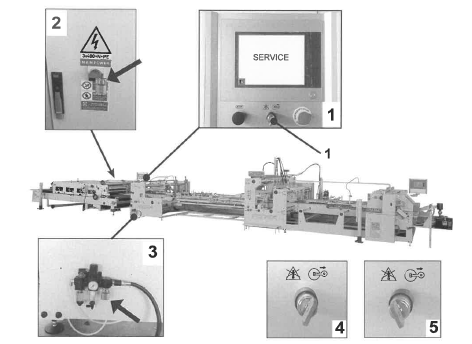

Machine Isolation

-

-

A - Stop The Machine

-

B - Turn the security switch to the left, on the monitor marked 'SERVICE' appears: the machine is on Emergency (see picture 1). Remove the key from the lock.

-

C - Bring a general switch to position O with fitted lock and closed (see photo 2)

Oil Lubrication - Marked with a circle

-

-

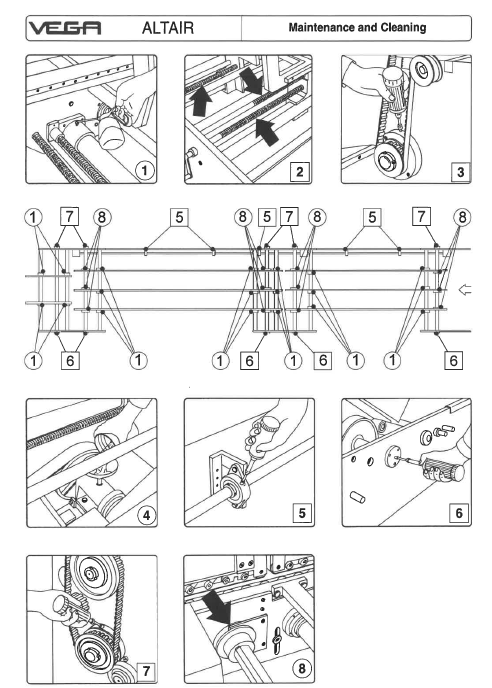

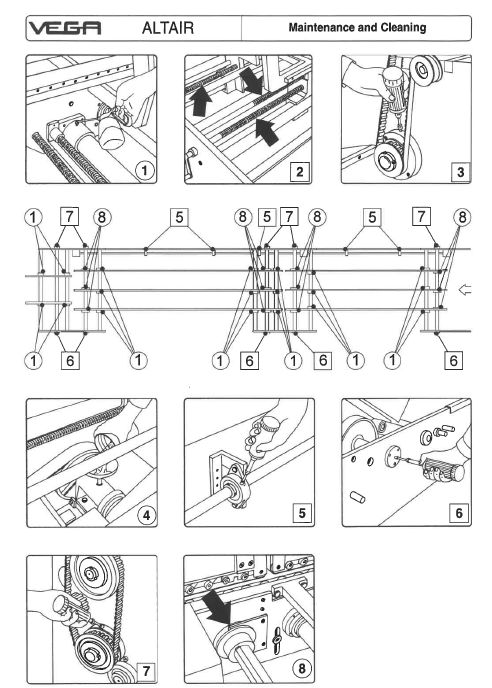

Sliding Flanges - Weekly - Folding Section - Marked 1

-

Sliding Flanges - Closing Section - Marked 1

-

Sliding Flanges - Delivery Section - Marked 1

-

Sliding Guide Blocks - Weekly - Transports - Marked 8

Greasing - Marked with a square - Lubricate, using the special device supplied.

-

-

Bearings - Monthly - Toothed Gear Bearing - Marked 3

-

Belt Shaft - Monthly - Pulley Belt Shaft - Marked 4

-

Bearings - Monthly - Drive Shaft Bearings - Marked 5

-

Belt Shaft - Monthly - Belt Wheel Shafts - Marked 6

-

Bearings - Monthly - Toothed Gear Bearing - Marked 7

-

Shifting Screws - Weekly - Apply by brush grease on the shifting screw - Marked 2

General

-

Compressed air - Check for air leaks and repair if necessary

-

Warning systems - Check operation of main panel warning system pedestals - emergency stop operation & overload activation (manually activate each overload & ensure warning light activates)

-

Safety systems - Check that all installed safety systems including EM switches, light beams, limit switches etc. are working and in good order.

-

Electrical sockets - Check condition of all electrical sockets and replace if necessary

-

Cleanliness of machine - Check general cleanliness of machine

-

Filters - Clean the filter of the vacuum pump

-

Filters - Clean the filter of the motors

-

Weekly - Pneumatic Plant - Check the oil level in the relevant containers periodically, topping up the atomisers oil when necessary - 100 / 105

Hand Back Check List

-

General - Ensure that all tools and equipment have been removed and area is clean and tidy

-

Enter in full detail why this was not done.

-

Safety Guards - Ensure that all guards are refitted and secured correctly

-

Enter in full detail why this was not done.

-

Machine Start up - Removal of lockout/tag out devices and carry out power up procedure

-

Enter in full detail why this was not done.

-

Emergency systems - Test operation of all emergency systems located as per attached drawing

-

Enter in full detail why this was not done.

-

Production Start Up - Monitor operation of machine and confirm with supervisor that equipment is operating satisfactory

-

Enter in full detail why this was not done.

General Feedback

-

Add any general notes here

-

PM Start Time

-

PM End Time

-

Machine Supervisor Signature

-

Shift Manager's Signature

-

Engineer Supervisor Signature