Title Page

-

Conducted on

-

Prepared by

-

Location

-

Fitter Signature

-

Electrician Signature

Multi Loader

-

Operation of multiloader - Check operation of multiloader infeed conveyor, lift & feeder table - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Panel & Motors - Clean all motor grills & panel filter - Ensure panel cooling fan is operating

-

Conveyor - Check condition of conveyor track / bearings

-

Lift shafts, bearings, chains etc. - Check condition of shafts, bearings, lifting chains etc. - report any wear

-

Prefeeder carrier belts - Check condition & clean belts as required including guide rollers

-

Squaring plates - Check condition of squaring system components

-

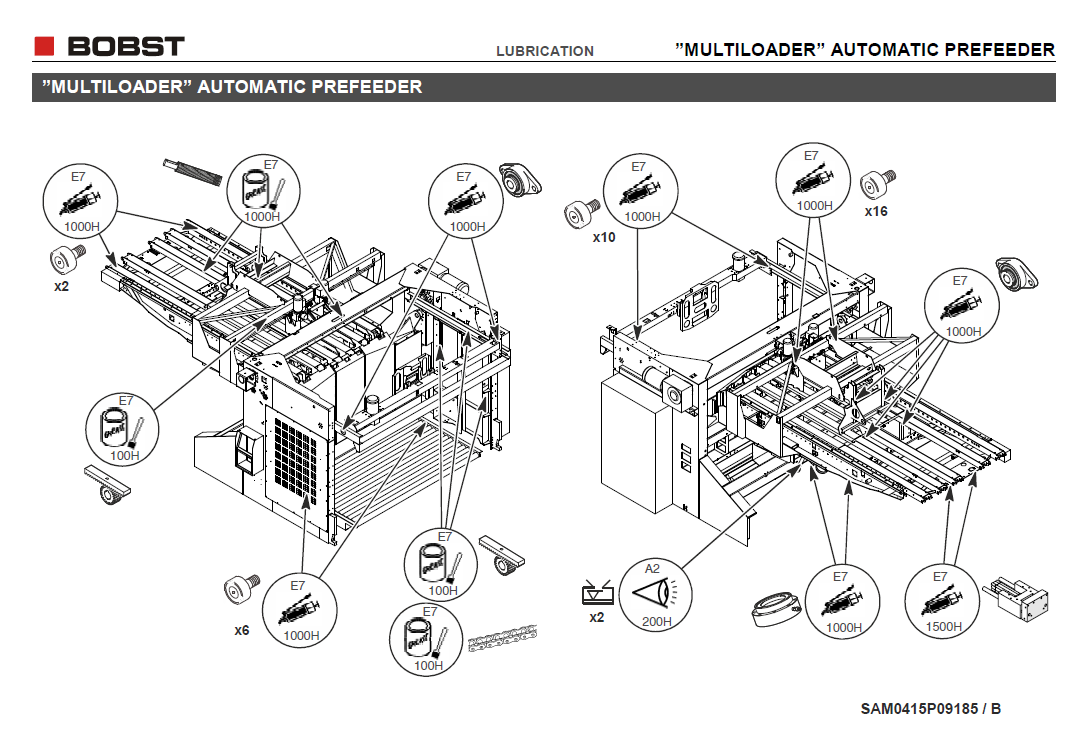

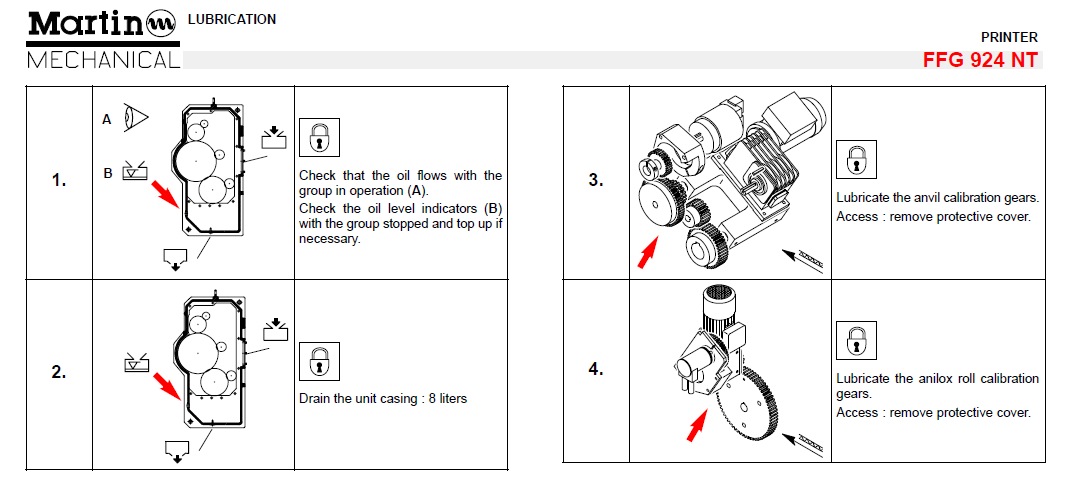

Lubrication - Check & lubricate all points as per below drawing

-

Feeder

-

Operation of feeder - Check operation of feed rolls, belt & vacuum motor - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Feed Gate Position - Check for correct position & parallelism of both feed gates

-

Measure the thickness of the feeder belts

-

Thickness of Operator Side belt near the middle

-

Thickness of Drive Side belt near the middle

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Suction fan - Check condition of suction fan & clean as required

-

Feed rolls & rubber roll - Check condition & parallelism of rolls - report & adjust if required

-

Drive belts / Gears - Check condition & clean belts as required - report any anomalies

-

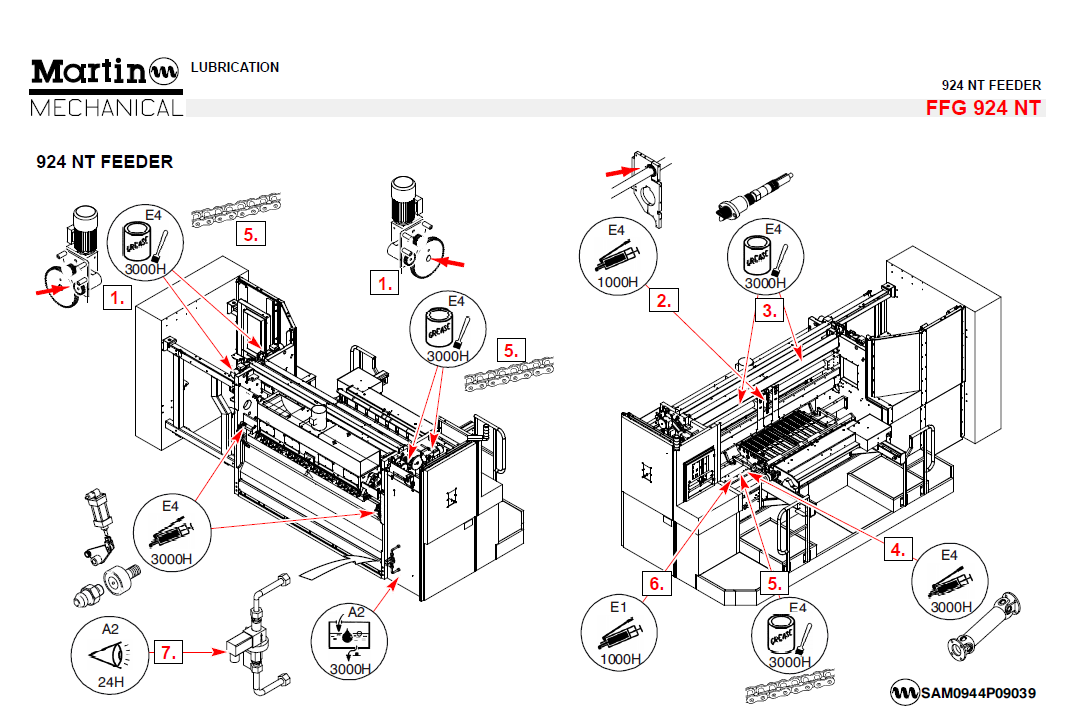

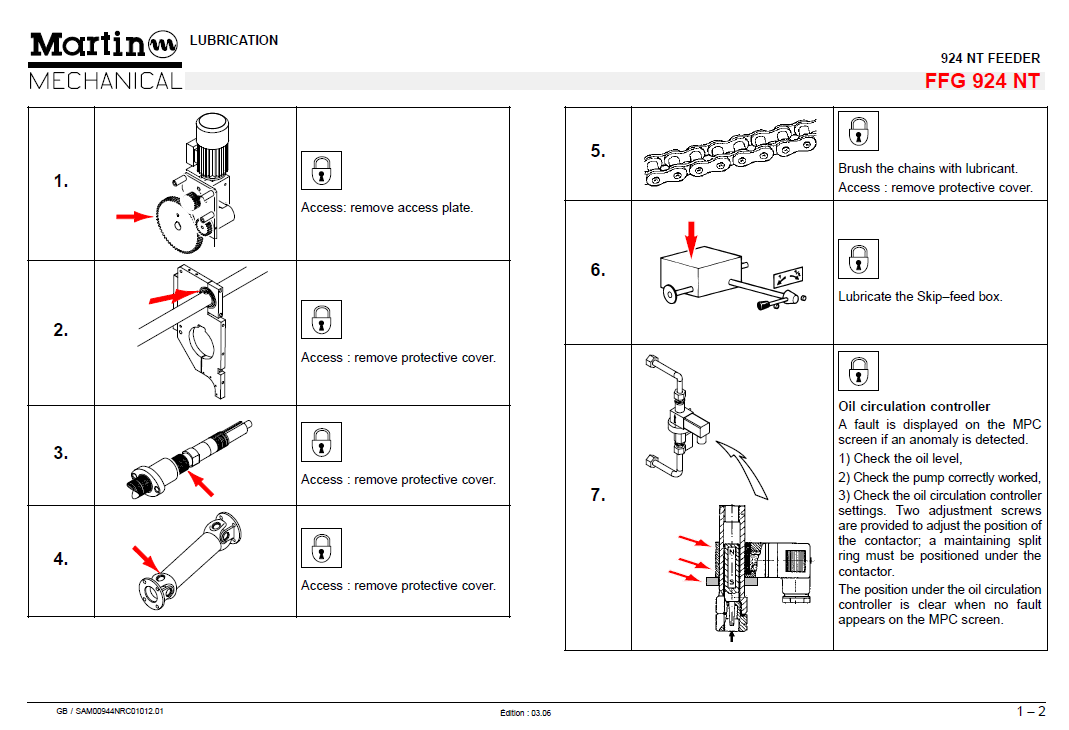

Lubrication - Check & lubricate all points as per below drawing

-

-

Print Units 1-3

-

Which Print Unit is being cleaned? (if none select a print unit and enter Not Done for all tasks)

- Print Unit 1

- Print Unit 2

- Print Unit 3

-

Operation of print units - Check operation of anilox, doctor & stereo rolls, belts & vacuum transfer - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Ink flow sensors - Check condition of flow sensors & clean as required

-

Ink chambers - Check condition of chambers for leaks before operator cleaning - report any issues

-

Ink pump - Check condition of pump & flexible pipe for wear - replace if required

-

Anilox roll - Check condition & parallelism of rolls - report & adjust if required

-

Drive belts / Gears - Check condition & clean belts as required - report any anomalies

-

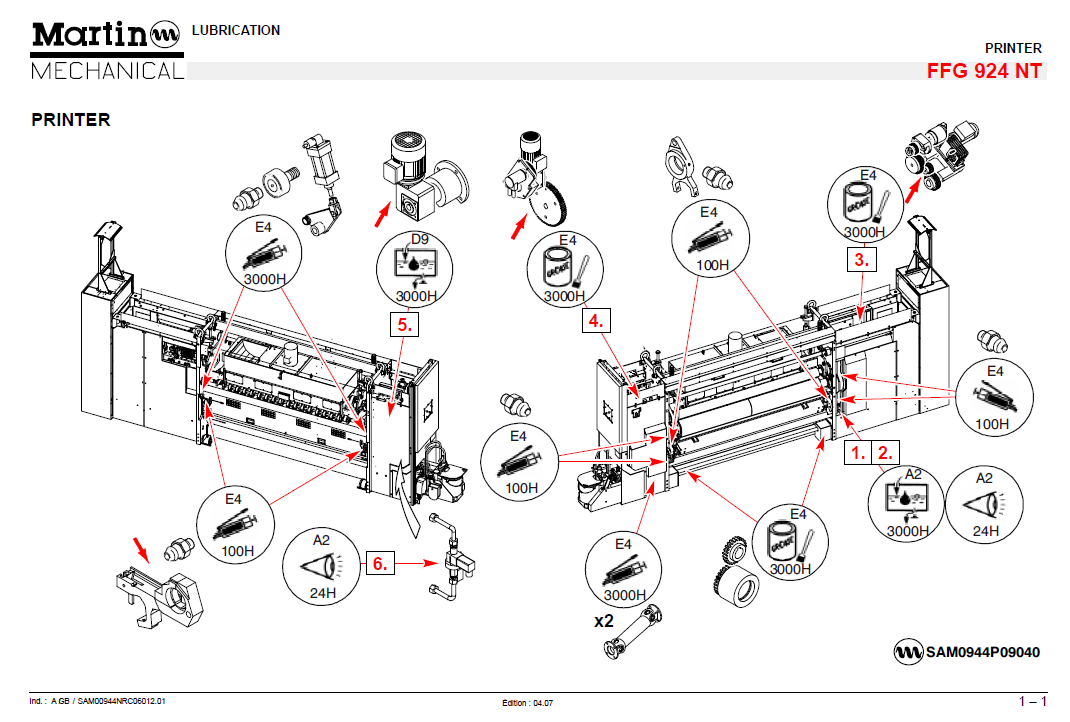

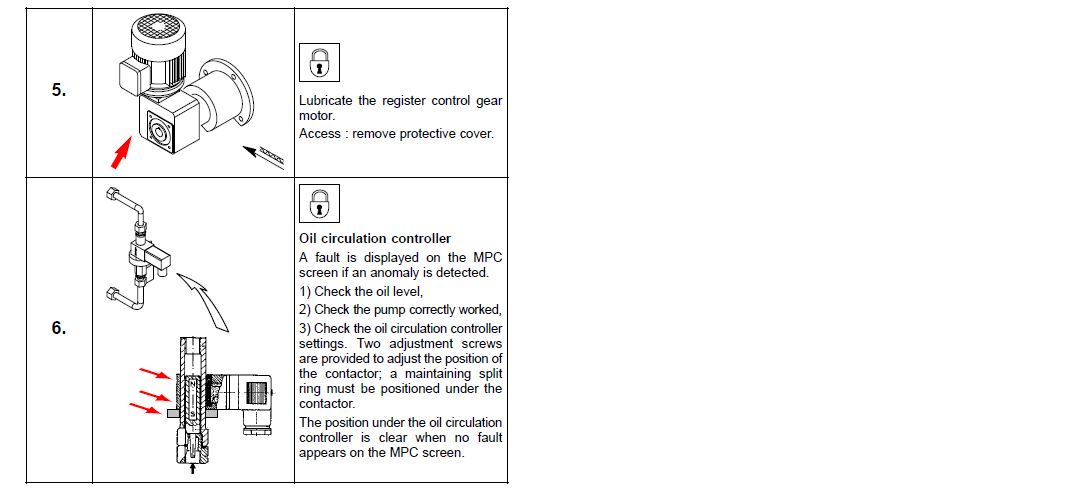

Lubrication - Check & lubricate all points as per below drawing

-

-

-

-

Operation of print units - Check operation of anilox, doctor & stereo rolls, belts & vacuum transfer - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Ink flow sensors - Check condition of flow sensors & clean as required

-

Ink chambers - Check condition of chambers for leaks before operator cleaning - report any issues

-

Ink pump - Check condition of pump & flexible pipe for wear - replace if required

-

Anilox roll - Check condition & parallelism of rolls - report & adjust if required

-

Drive belts / Gears - Check condition & clean belts as required - report any anomalies

-

Lubrication - Check & lubricate all points as per below drawing

-

-

-

-

Operation of print units - Check operation of anilox, doctor & stereo rolls, belts & vacuum transfer - investigate & report any anomalies and/or suspect noises - speak with operators for any reported issues

-

Photocell operation - Clean all photocells / limit switches & check operation

-

Encoders - Check condition of encoder & gear - report any anomalies immediately

-

Panel & Motors - Clean all motor grills/air intakes & panel filters - Ensure panel cooling fan is operating

-

Ink flow sensors - Check condition of flow sensors & clean as required

-

Ink chambers - Check condition of chambers for leaks before operator cleaning - report any issues

-

Ink pump - Check condition of pump & flexible pipe for wear - replace if required

-

Anilox roll - Check condition & parallelism of rolls - report & adjust if required

-

Drive belts / Gears - Check condition & clean belts as required - report any anomalies

-

Lubrication - Check & lubricate all points as per below drawing

-

-

-

Hand Back Check List

-

Print Units - Ink Cup Covers have been removed from all units.

-

Enter full details why this wasn't done.

-

General - Ensure that all tools and equipment have been removed and area is clean and tidy

-

Enter full details why this wasn't done.

-

Safety Guards - Ensure that all guards are refitted and secured correctly

-

Enter full details why this wasn't done.

-

Machine Start Up - Removal of lockout/tagout devices and carry out power up procedure

-

Enter full details why this wasn't done.

-

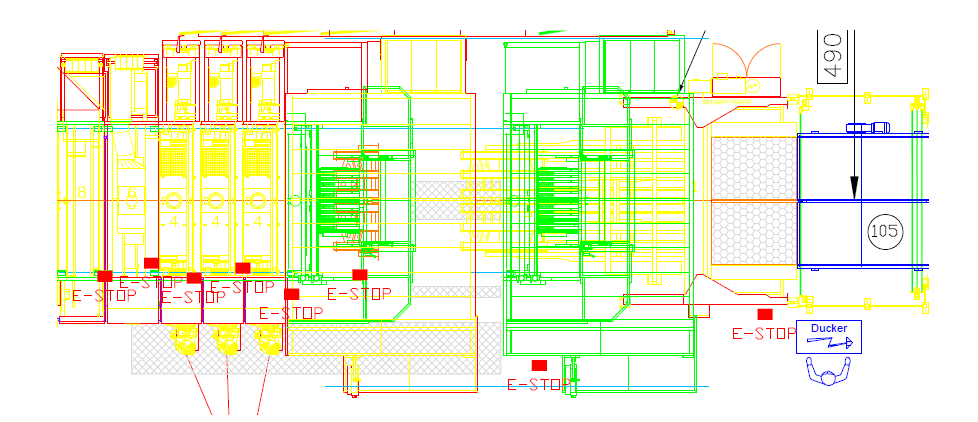

Emergency Systems - Test operation of all emergency systems located as per below drawing

-

Enter full details why this wasn't done.

-

-

Production Start Up - Monitor operation of machine and confirm with supervisor that equipment is operating satisfactory

-

Enter full details why this wasn't done.

General

-

Add any general notes here

-

PM Start Time

-

PM End Time

-

Machine Supervisor Signature

-

Shift Manager Signature

-

Engineer Supervisor Signature