Title Page

-

Assessment completed by:

-

Date & time of the assessment:

-

Work Area:

-

Specify Work Area:

-

Aggregation Zone:

-

Site Address:

-

Work Type

-

How many operatives are on site?

-

Operative 1 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 8 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 8 Name:

-

Operative 9 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 8 Name:

-

Operative 9 Name:

-

Operative 10 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 8 Name:

-

Operative 9 Name:

-

Operative 10 Name:

-

Operative 11 Name:

-

Operative 1 Name:

-

Operative 2 Name:

-

Operative 3 Name:

-

Operative 4 Name:

-

Operative 5 Name:

-

Operative 6 Name:

-

Operative 7 Name:

-

Operative 8 Name:

-

Operative 9 Name:

-

Operative 10 Name:

-

Operative 11 Name:

-

Operative 12 Name:

-

Have all operatives clocked in?

-

A Point of Work Risk Assessment must be completed for every site and day. It must be signed by all operatives on site.

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All Accidents, Hazards & Near miss incidents to be reported to your Manager, Supervisor & Health & Safety Manger immediately.

All incidents must also be recorded, you can do this by scanning the QR code at the end of this report, or by clicking the following link https://sfty.io/e/xYELwWTpKwb

Point of Work Risk Assessment

-

What Type of work is being assessed?

Site Clear

-

Is there a weather warning for your work area? Visit https://www.metoffice.gov.uk/ for information on your local weather conditions:

-

STOP! Think about the impact the current weather could have on your current task, if the risk of continuing work is to high contact a supervisor/manager immediately for advice before proceeding.

-

Upload a screen shot from Met Office website, showing description of weather warning:

-

Are you able to commence work without obstruction or hindrance?

-

STOP! Contact a supervisor/manager immediately to discuss options before proceeding.

-

Describe the obstruction or hindrance?

-

Upload picture of the obstruction or hindrance:

-

Always ensure the work are is free from risk for the general public, for example:

- Ensure all work equipment, tools, cable and rope are enclosed within the barriered work area and do not create trip hazards.

- Ensure open chambers are adequately enclosed within a barriered work area.

Documentation / Information

-

Have you review the relevant risk assessment/s for the current task?

-

STOP! Close this inspection and open inspection named "The Swiftlinks Site File" to review Risk Assessments.

-

Are all control measures in place as detailed in the generic task risk assessment?

-

STOP! Read the risk assessment for the current task and ensure all controls have been implement as instructed.

-

Have any of the operatives on site been working with the company for less than 17 weeks and do not hold all the task relevant qualifications/accreditations?

-

Stop! Consider the following: is there a competent trained operative on site to supervise the works of the undertrained operative, if No then stop work and contact your manager/supervisor. Do not allow untrained operatives to work unsupervised.

All Operatives must hold all relevant qualifications/accreditations after 17 weeks working with company, all operatives found working passed this point without qualifications/accreditations will be asked to leave site. -

Detail opertive/s full name and date started with company:

-

Is a qualified operative on site that can supervise all works carried out by the untrained operative?

-

Stop! contact your manager and do not allow the untrained operative to work unsupervised.

Street Works

-

Does at least one operative hold the required NRSWA units for the work activity?

-

STOP! Contact your supervisor/manager immediately and request a trained operative be sent to site, await operative arrival before proceeding.

-

Upload Image of NRSWA ID Card:

-

All work areas must be adequately signed & guarded as per the Safety at Street Works and Road Works A Code of Practice.

Safety at Street Works and Road Works A Code of Practice

click the link to be redirected to an online copy of the red book Safety at Street Works and Road Works A Code of Practice.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/321056/safety-at-streetworks.pdf

Working In/Near Open Chambers

-

Does this job involve working in or around and open chamber?

-

Toolbox Talk Open Chambers:

-

No Smoking or naked flames within 10m of open chambers.

-

An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED)

-

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water. -

Is an operative who is qualified to SA002 underground safety on site and will remain on site until completion of works?

-

STOP! Contact a supervisor/manager immediately and request a qualified operative, DO NOT begin work until the trained operative has arrived.

-

Are the locations where work in open chambers is required, safe and hazard free?

-

Can you add further control measures to mitigate any hazards?

-

STOP! Contact your Manager or Supervisor to discuss further arrangements or postpone work until the works can be carried out safely.

-

Explain the hazards & control measures:

Asbestos Containing Material (ACM)

-

Toolbox Talk Asbestos:

-

Has any asbestos containing material (ACM) been identified prior to works?

-

STOP! identify the areas containing ACM's and mark ACM's with paint if possible, if there is a risk of disturbing/breaking ACM's STOP and implement control measures to ensure that ACM's are not broken or disturbed.

-

Have control measures been put in place to proceed?

-

Stop! implement control measures before proceeding, if unable to implement control measures to protect ACM's, contact your manager and supervisor immediately to discuss alternative process to avoid ACM's.

-

Detail control measures:

Personal Protective Equipment (PPE), Tools & Equipment

-

Are the relevant PPE, Tools or Equipment available to be used and in good condition?

-

STOP! If any of the task relevant PPE, tools or equipment is missing or damaged, contact your manager or supervisor for repair / replacement, DO NOT work with defective PPE, tools or equipment.

-

Is specialist PPE required? If yes, give detail in comments!

-

Detail Required specialist PPE being used: (if PPE is not available STOP WORK and contact a supervisor/manager to obtain relevant PPE before continuing with task)

-

Is there enough 4 head GDU's available for the works, are they within calibration date and in good working order?

-

STOP! An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED) contact your manager or supervisor for replacement

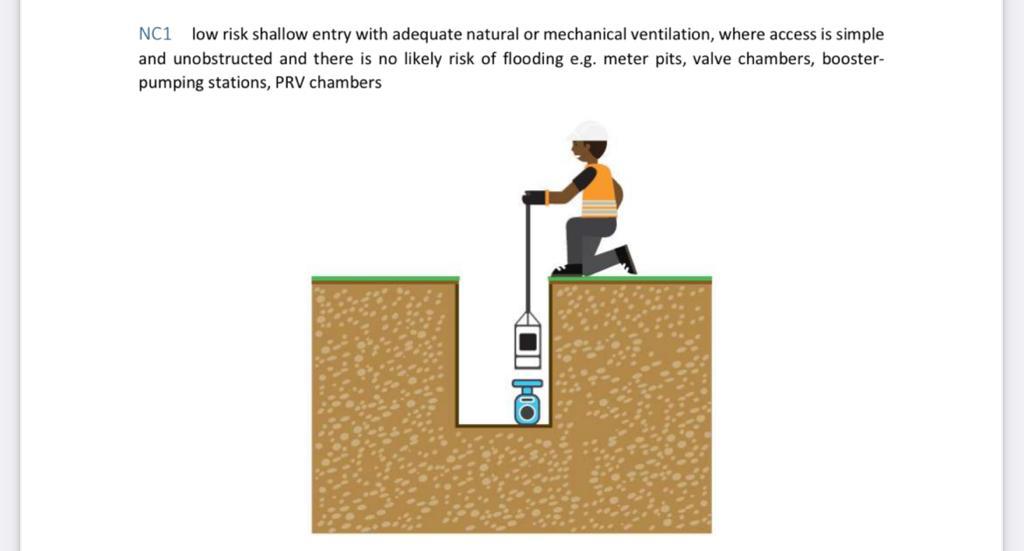

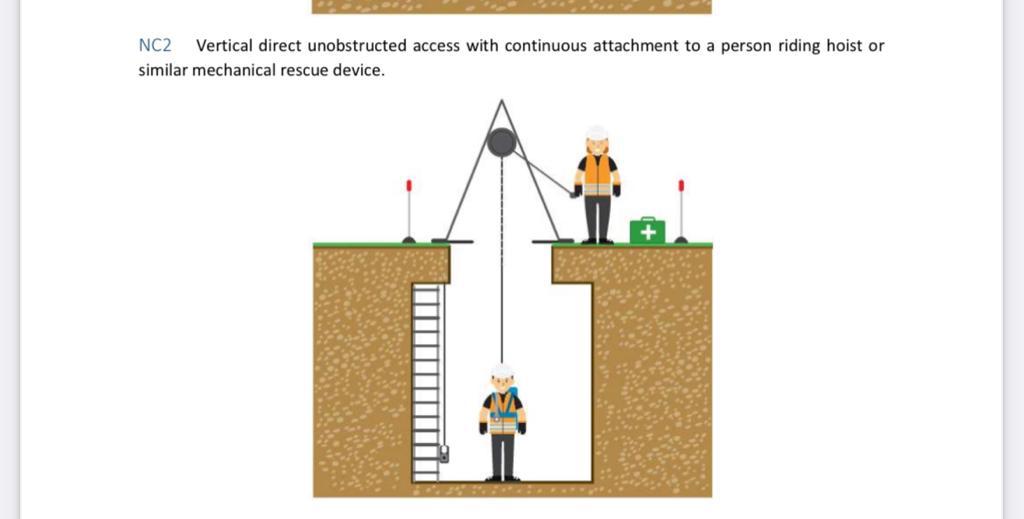

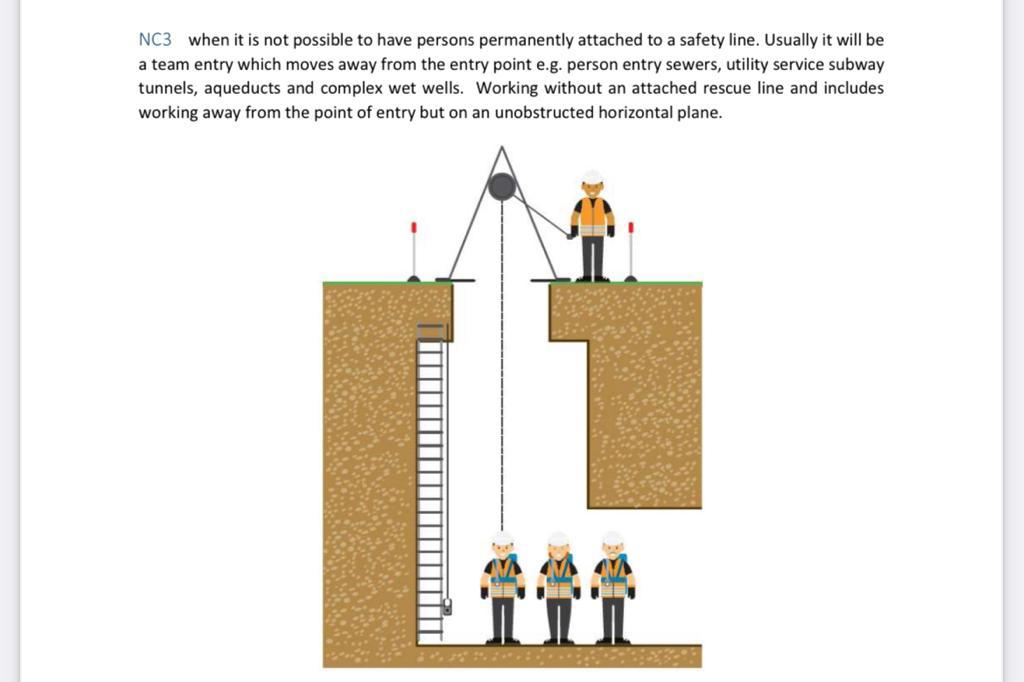

Manhole Entry

-

Do you need to enter a manhole?

-

What type of Confined space entry is required?

-

Ensure operative entering confined space have carried out an atmospheric test prior to entering.

-

Complete the confined space risk assessment and entry permit prior to entering confined space,

Operative must be wearing a Hard Hat, Safety Boots, Safety Goggles, Half Face Respirator, Working GDU, Full Body Harness and Lanyard.

confined team must also set up and use a forced air fan to ensure adequate oxygen levels are maintained within manhole at all times during the work. -

Has the mandatory Manhole Entry Permit been completed?

-

STOP WORK and complete the confined space risk assessment and permit before proceeding.

-

What is the manhole entry permit number:

-

Do not enter confined space and contact your manager immediately.

-

Do not enter confined space and contact your manager immediately.

-

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water.

Environment

-

Are spill kits and an instructed operative available on site?

-

STOP! Do not continue without a fully stocked Spill Kit, contact your manager or supervisor for instruction on where to purchase or collect a spill kit prior to continuing with task.

Works Near a Railway

-

Will you be working within 200 metres of a Network Rail Crossing?

-

Have obtained the relevant approvals?

-

STOP! Contact your manager or supervisor immediately and request they contact the local authorities to obtain approval. DO NOT commence work without the relevant approvals.

-

Upload a photo or file, for proof of approval:

Working near Water

-

Are you within 10 metres (on, over or near) a watercourse or floodwater?

-

Is there a physical barrier to prevent you falling into the water, or have you already agreed a Safe System of Work with a site-specific risk assessment for the task?”

-

STOP! Contact your manager or supervisor to discuss other options to complete task or to assess works further and implement a safe system of work to access work area.

-

Take Picture of Physical Barrier or safe system of work, preventing accidental contact with body of water.

Other Risks

-

Are You Working in Close Vicinity of a School, Hospital, Airport, Motorway or emergency services building?

-

Provide a description of the control measures implemented to decrease the likelihood of accidents arising from the dangers associated with working in proximity to the above mentioned buildings?

-

Is It Safe to Proceed with the task?

-

STOP! Assess the work area and the hazards that arise due to working near School, Hospital, Airport, Motorway or emergency services buildings.

Contact your manager or Supervisor for advice on how to proceed.

Site Clear

-

Is there a weather warning for your work area? Visit https://www.metoffice.gov.uk/ for information on your local weather conditions.

-

STOP! Think about the impact the current weather could have on your current task, if the risk of continuing work is to high contact a supervisor/manager immediately for advice before proceeding.

-

Upload a screen shot from Met Office website, showing description of weather warning:

-

Are you able to commence work without obstruction or hindrance?

-

STOP! Contact a supervisor/manager immediately to discuss options before proceeding.

-

Describe the obstruction or hindrance?

-

Upload picture of the obstruction or hindrance:

-

Always ensure the work are is free from risk for the general public, for example:

- Ensure all work equipment, tools, cable and rope are enclosed within the barriered work area and do not create trip hazards.

- Ensure open chambers are adequately enclosed within a barriered work area.

Documentation / Information

-

Have you review the relevant risk assessment/s for the current task?

-

STOP! Close this inspection and open inspection named "The Swiftlinks Site File" to review Risk Assessments.

-

Are all control measures in place as detailed in the generic task risk assessment?

-

STOP! Read the risk assessment for the current task and ensure all controls have been implement as instructed.

-

Have any of the operatives on site been working with the company for less than 17 weeks and do not hold all the task relevant qualifications/accreditations?

-

Stop! Consider the following: is there a competent trained operative on site to supervise the works of the undertrained operative, if No then stop work and contact your manager/supervisor. Do not allow untrained operatives to work unsupervised.

All Operatives must hold all relevant qualifications/accreditations after 17 weeks working with company, all operatives found working passed this point without qualifications/accreditations will be asked to leave site. -

Detail opertive/s full name and date started with company:

-

Is a qualified operative on site that can supervise all works carried out by the untrained operative?

-

Stop! contact your manager and do not allow the untrained operative to work unsupervised.

Street Works

-

Does at least one operative hold the required NRSWA units for the work activity?

-

STOP! Contact your supervisor/manager immediately and request a trained operative be sent to site, await operative arrival before proceeding.

-

Upload Image of NRSWA ID Card:

-

All work areas must be adequately signed & guarded as per the Safety at Street Works and Road Works A Code of Practice.

Safety at Street Works and Road Works A Code of Practice

click the link to be redirected to an online copy of the red book Safety at Street Works and Road Works A Code of Practice.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/321056/safety-at-streetworks.pdf

Overhead Power

-

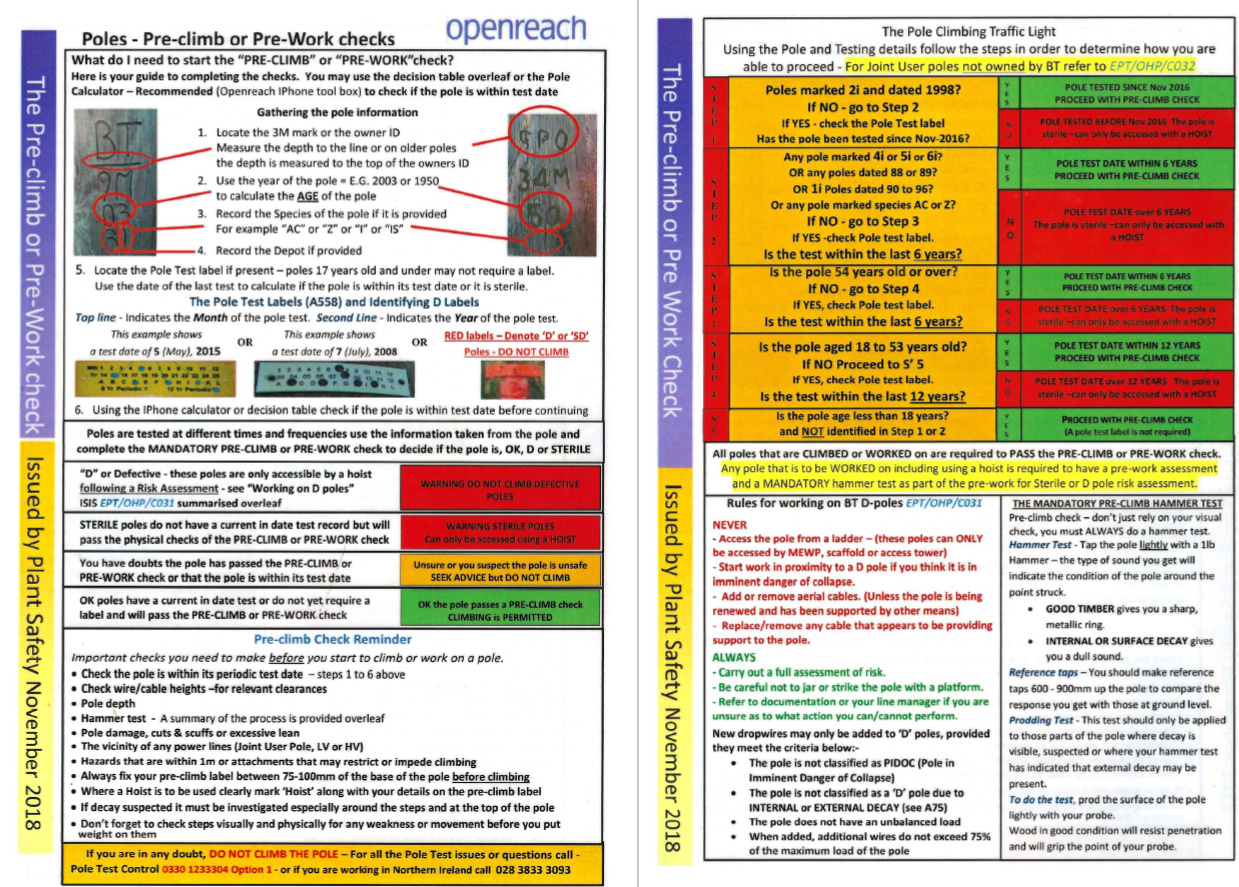

Refer to the overhead power glove box guide when working near electricity.

-

Overhead Power Glovebox Guide:

-

Is all Plant being used for lifting appropriate for use and stabilised as per manufacturer’s instructions?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

-

Is a Competent Ground support Person (GSP) on site?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

-

Is a MEWP or PEU to be used within 25m of overhead HV power or is a joint user pole (JUP) to be accessed?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

Working at Height

-

Does this job involve Working at Height?

-

Ensure to complete the Pre climb check before accessing any pole by either climbing or MEWP access

-

Have you completed a pre climb check? (required for MEWP and climb)

-

Are all members of this gang trained in Working at Height?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

-

Has the equipment that will be used for Working at Height been Inspected for condition before use and is in good condition?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

-

Are the locations where Work at height activity is involved on this job, safe and hazard free?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

Working In/Near Open Chambers

-

Does this job involve working in or around and open chamber?

-

Toolbox Talk Open Chambers:

-

No Smoking or naked flames within 10m of open chambers.

-

An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED)

-

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water. -

Is an operative who is qualified to SA002 underground safety on site and will remain on site until completion of works?

-

STOP! Contact a supervisor/manager immediately and request a qualified operative, DO NOT begin work until the trained operative has arrived.

-

Are the locations where work in open chambers is required, safe and hazard free?

-

Can you add further control measures to mitigate any hazards?

-

STOP! Contact your Manager or Supervisor to discuss further arrangements or postpone work until the works can be carried out safely.

-

Explain the hazards & control measures:

Asbestos Containing Material (ACM)

-

Toolbox Talk Asbestos:

-

Has any asbestos containing material (ACM) been identified prior to works?

-

STOP! identify the areas containing ACM's and mark ACM's with paint if possible, if there is a risk of disturbing/breaking ACM's STOP and implement control measures to ensure that ACM's are not broken or disturbed.

-

Have control measures been put in place to proceed?

-

Stop! implement control measures before proceeding, if unable to implement control measures to protect ACM's, contact your manager and supervisor immediately to discuss alternative process to avoid ACM's.

-

Detail control measures:

Personal Protective Equipment (PPE), Tools & Equipment

-

Are the relevant PPE, Tools or Equipment available to be used and in good condition?

-

STOP! If any of the task relevant PPE, tools or equipment is missing or damaged, contact your manager or supervisor for repair / replacement, DO NOT work with defective PPE, tools or equipment.

-

Is specialist PPE required? If yes, give detail in comments!

-

Detail Required specialist PPE being used: (if PPE is not available STOP WORK and contact a supervisor/manager to obtain relevant PPE before continuing with task)

-

Is there enough 4 head GDU's available for the works, are they within calibration date and in good working order?

-

STOP! An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED) contact your manager or supervisor for replacement

Manhole Entry

-

Do you need to enter a manhole?

-

What type of Confined space entry is required?

-

Ensure operative entering confined space has carried out an atmospheric test prior to entering.

-

Complete the confined space risk assessment and entry permit prior to entering confined space,

Operative must be wearing a Hard Hat, Safety Boots, Safety Goggles, Half Face Respirator, Working GDU, Full Body Harness and Lanyard.

confined team must also set up and use a forced air fan to ensure adequate oxygen levels are maintained within manhole at all times during the work. -

Has the mandatory Manhole Entry Permit been completed?

-

STOP WORK and complete the confined space risk assessment and permit before proceeding.

-

What is the manhole entry permit number:

-

Do not enter confined space and contact your manager immediately.

-

Do not enter confined space and contact your manager immediately.

-

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water.

Environment

-

Are spill kits and an instructed operative available on site?

-

STOP! Do not continue without a fully stocked Spill Kit, contact your manager or supervisor for instruction on where to purchase or collect a spill kit prior to continuing with task.

Works Near a Railway

-

Will you be working within 200 metres of a Network Rail Crossing?

-

Have obtained the relevant approvals?

-

STOP! Contact your manager or supervisor immediately and request they contact the local authorities to obtain approval. DO NOT commence work without the relevant approvals.

-

Upload a photo or file, for proof of approval:

Working near Water

-

Are you within 10 metres (on, over or near) a watercourse or floodwater?

-

Is there a physical barrier to prevent you falling into the water, or have you already agreed a Safe System of Work with a site-specific risk assessment for the task?”

-

STOP! Contact your manager or supervisor to discuss other options to complete task or to assess works further and implement a safe system of work to access work area.

-

Take Picture of Physical Barrier or safe system of work, preventing accidental contact with body of water.

Other Risks

-

Are You Working in Close Vicinity of a School, Hospital, Airport, Motorway or emergency services building?

-

Provide a description of the control measures implemented to decrease the likelihood of accidents arising from the dangers associated with working in proximity to the above mentioned buildings?

-

Is It Safe to Proceed with the task?

-

STOP! Assess the work area and the hazards that arise due to working near School, Hospital, Airport, Motorway or emergency services buildings.

Contact your manager or Supervisor for advice on how to proceed.

Site Clear

-

Always ensure the work are is free from risk for the general public, for example:

- Ensure all work equipment, tools, cable and rope are enclosed within the barriered work area and do not create trip hazards.

- Ensure open chambers are adequately enclosed within a barriered work area. -

Is there a weather warning for your work area? Visit https://www.metoffice.gov.uk/ for information on your local weather conditions.

-

STOP! Think about the impact the current weather could have on your current task, if the risk of continuing work is to high contact a supervisor/manager immediately for advice before proceeding.

-

Upload a screen shot from Met Office website, showing description of weather warning:

-

Are you able to commence work without obstruction or hindrance?

-

STOP! Contact a supervisor/manager immediately to discuss options before proceeding.

-

Describe the obstruction or hindrance:

-

Upload picture of the obstruction or hindrance:

Documentation / Information

-

Have you review the relevant risk assessment/s for the current task?

-

STOP! Close this inspection and open inspection named "The Swiftlinks Site File" to review Risk Assessments.

-

Are all control measures in place as detailed in the generic task risk assessment?

-

STOP! Read the risk assessment for the current task and ensure all controls have been implement as instructed.

-

Have any of the operatives on site been working with the company for less than 17 weeks and do not hold all the task relevant qualifications/accreditations?

-

Stop! Consider the following: is there a competent trained operative on site to supervise the works of the undertrained operative, if No then stop work and contact your manager/supervisor. Do not allow untrained operatives to work unsupervised.

All Operatives must hold all relevant qualifications/accreditations after 17 weeks working with company, all operatives found working passed this point without qualifications/accreditations will be asked to leave site. -

Detail opertive/s full name and date started with company:

-

Is a qualified operative on site that can supervise all works carried out by the untrained operative?

-

Stop! contact your manager and do not allow the untrained operative to work unsupervised.

Street Works

-

All work areas must be adequately signed & guarded as per the Safety at Street Works and Road Works A Code of Practice.

Safety at Street Works and Road Works A Code of Practice

click the link to be redirected to an online copy of the red book Safety at Street Works and Road Works A Code of Practice.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/321056/safety-at-streetworks.pdf -

Does at least one operative hold the required NRSWA units for the work activity?

-

STOP! Contact your supervisor/manager immediately and request a trained operative be sent to site, await operative arrival before proceeding.

-

Upload Image of NRSWA ID Card:

Working In/Near Open Chambers

-

Does this job involve working in or around and open chamber?

-

Toolbox Talk Open Chambers:

-

No Smoking or naked flames within 10m of open chambers.

-

An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED)

-

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water. -

Is an operative who is qualified to SA002 underground safety on site and will remain on site until completion of works?

-

STOP! Contact a supervisor/manager immediately and request a qualified operative, DO NOT begin work until the trained operative has arrived.

-

Are the locations where work in open chambers is required, safe and hazard free?

-

Can you add further control measures to mitigate any hazards?

-

STOP! Contact your Manager or Supervisor to discuss further arrangements or postpone work until the works can be carried out safely.

-

Explain the hazards & control measures:

Personal Protective Equipment (PPE), Tools & Equipment

-

Are the relevant PPE, Tools or Equipment available to be used and in good condition?

-

STOP! If any of the task relevant PPE, tools or equipment is missing or damaged, contact your manager or supervisor for repair / replacement, DO NOT work with defective PPE, tools or equipment.

-

Is specialist PPE required? If yes, give detail in comments!

-

Detail Required specialist PPE being used: (if PPE is not available STOP WORK and contact a supervisor/manager to obtain relevant PPE before continuing with task)

-

Is there enough 4 head GDU's available for the works, are they within calibration date and in good working order?

-

STOP! An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED) contact your manager or supervisor for replacement

Environment

-

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water.

Works Near a Railway

-

Will you be working within 200 metres of a Network Rail Crossing?

-

Have obtained the relevant approvals?

-

STOP! Contact your manager or supervisor immediately and request they contact the local authorities to obtain approval. DO NOT commence work without the relevant approvals.

-

Upload a photo or file, for proof of approval:

Working near Water

-

Are you within 10 metres (on, over or near) a watercourse or floodwater?

-

Is there a physical barrier to prevent you falling into the water, or have you already agreed a Safe System of Work with a site-specific risk assessment for the task?”

-

STOP! Contact your manager or supervisor to discuss other options to complete task or to assess works further and implement a safe system of work to access work area.

-

Take Picture of Physical Barrier or safe system of work, preventing accidental contact with body of water.

Other Risks

-

Are You Working in Close Vicinity of a School, Hospital, Airport, Motorway or emergency services building?

-

Provide a description of the control measures implemented to decrease the likelihood of accidents arising from the dangers associated with working in proximity to the above mentioned buildings?

-

Is It Safe to Proceed with the task?

-

STOP! Assess the work area and the hazards that arise due to working near School, Hospital, Airport, Motorway or emergency services buildings.

Contact your manager or Supervisor for advice on how to proceed.

Site Clear

-

Is there a weather warning for your work area? Visit https://www.metoffice.gov.uk/ for information on your local weather conditions.

-

STOP! Think about the impact the current weather could have on your current task, if the risk of continuing work is to high contact a supervisor/manager immediately for advice before proceeding.

-

Upload a screen shot from Met Office website, showing description of weather warning:

-

Are you able to commence work without obstruction or hindrance?

-

STOP! Contact a supervisor/manager immediately to discuss options before proceeding.

-

Describe the obstruction or hindrance?

-

Upload picture of the obstruction or hindrance:

-

Always ensure the work are is free from risk for the general public, for example:

- Ensure all work equipment, tools, cable and rope are enclosed within the barriered work area and do not create trip hazards.

- Ensure open chambers are adequately enclosed within a barriered work area.

Documentation / Information

-

Have you review the relevant risk assessment/s for the current task?

-

STOP! Close this inspection and open inspection named "The Swiftlinks Site File" to review Risk Assessments.

-

Are all control measures in place as detailed in the generic task risk assessment?

-

STOP! Read the risk assessment for the current task and ensure all controls have been implement as instructed.

-

Have any of the operatives on site been working with the company for less than 17 weeks and do not hold all the task relevant qualifications/accreditations?

-

Stop! Consider the following: is there a competent trained operative on site to supervise the works of the undertrained operative, if No then stop work and contact your manager/supervisor. Do not allow untrained operatives to work unsupervised.

All Operatives must hold all relevant qualifications/accreditations after 17 weeks working with company, all operatives found working passed this point without qualifications/accreditations will be asked to leave site. -

Detail opertive/s full name and date started with company:

-

Is a qualified operative on site that can supervise all works carried out by the untrained operative?

-

Stop! contact your manager and do not allow the untrained operative to work unsupervised.

Street Works

-

Does at least one operative hold the required NRSWA units for the work activity?

-

STOP! Contact your supervisor/manager immediately and request a trained operative be sent to site, await operative arrival before proceeding.

-

Upload Image of NRSWA ID Card:

-

All work areas must be adequately signed & guarded as per the Safety at Street Works and Road Works A Code of Practice.

Safety at Street Works and Road Works A Code of Practice

click the link to be redirected to an online copy of the red book Safety at Street Works and Road Works A Code of Practice.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/321056/safety-at-streetworks.pdf

Working In/Near Open Chambers

-

Does this job involve working in or around and open chamber?

-

Toolbox Talk Open Chambers:

-

No Smoking or naked flames within 10m of open chambers.

-

An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED)

-

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water. -

Is an operative who is qualified to SA002 underground safety on site and will remain on site until completion of works?

-

STOP! Contact a supervisor/manager immediately and request a qualified operative, DO NOT begin work until the trained operative has arrived.

-

Are the locations where work in open chambers is required, safe and hazard free?

-

Can you add further control measures to mitigate any hazards?

-

STOP! Contact your Manager or Supervisor to discuss further arrangements or postpone work until the works can be carried out safely.

-

Explain the hazards & control measures:

Asbestos Containing Material (ACM)

-

Toolbox Talk Asbestos:

-

Has any asbestos containing material (ACM) been identified prior to works?

-

STOP! identify the areas containing ACM's and mark ACM's with paint if possible, if there is a risk of disturbing/breaking ACM's STOP and implement control measures to ensure that ACM's are not broken or disturbed.

-

Have control measures been put in place to proceed?

-

Stop! implement control measures before proceeding, if unable to implement control measures to protect ACM's, contact your manager and supervisor immediately to discuss alternative process to avoid ACM's.

-

Detail control measures:

Personal Protective Equipment (PPE), Tools & Equipment

-

Are the relevant PPE, Tools or Equipment available to be used and in good condition?

-

STOP! If any of the task relevant PPE, tools or equipment is missing or damaged, contact your manager or supervisor for repair / replacement, DO NOT work with defective PPE, tools or equipment.

-

Is specialist PPE required? If yes, give detail in comments!

-

Detail Required specialist PPE being used: (if PPE is not available STOP WORK and contact a supervisor/manager to obtain relevant PPE before continuing with task)

-

Is there enough 4 head GDU's available for the works, are they within calibration date and in good working order?

-

STOP! An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED) contact your manager or supervisor for replacement

Manhole Entry

-

Do you need to enter a manhole?

-

What type of Confined space entry is required?

-

Ensure operative entering confined space has carried out an atmospheric test prior to entering.

-

Complete the confined space risk assessment and entry permit prior to entering confined space,

Operative must be wearing a Hard Hat, Safety Boots, Safety Goggles, Half Face Respirator, Working GDU, Full Body Harness and Lanyard.

confined team must also set up and use a forced air fan to ensure adequate oxygen levels are maintained within manhole at all times during the work. -

Has the mandatory Manhole Entry Permit been completed?

-

STOP WORK and complete the confined space risk assessment and permit before proceeding.

-

What is the manhole entry permit number:

-

Do not enter confined space and contact your manager immediately.

-

Do not enter confined space and contact your manager immediately.

-

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water.

Environment

-

Are spill kits and an instructed operative available on site?

-

STOP! Do not continue without a fully stocked Spill Kit, contact your manager or supervisor for instruction on where to purchase or collect a spill kit prior to continuing with task.

Works Near a Railway

-

Will you be working within 200 metres of a Network Rail Crossing?

-

Have obtained the relevant approvals?

-

STOP! Contact your manager or supervisor immediately and request they contact the local authorities to obtain approval. DO NOT commence work without the relevant approvals.

-

Upload a photo or file, for proof of approval:

Working near Water

-

Are you within 10 metres (on, over or near) a watercourse or floodwater?

-

Is there a physical barrier to prevent you falling into the water, or have you already agreed a Safe System of Work with a site-specific risk assessment for the task?”

-

STOP! Contact your manager or supervisor to discuss other options to complete task or to assess works further and implement a safe system of work to access work area.

-

Take Picture of Physical Barrier or safe system of work, preventing accidental contact with body of water.

Other Risks

-

Are You Working in Close Vicinity of a School, Hospital, Airport, Motorway or emergency services building?

-

Provide a description of the control measures implemented to decrease the likelihood of accidents arising from the dangers associated with working in proximity to the above mentioned buildings?

-

Is It Safe to Proceed with the task?

-

STOP! Assess the work area and the hazards that arise due to working near School, Hospital, Airport, Motorway or emergency services buildings.

Contact your manager or Supervisor for advice on how to proceed.

Site Clear

-

Is there a weather warning for your work area? Visit https://www.metoffice.gov.uk/ for information on your local weather conditions.

-

STOP! Think about the impact the current weather could have on your current task, if the risk of continuing work is to high contact a supervisor/manager immediately for advice before proceeding.

-

Upload a screen shot from Met Office website, showing description of weather warning:

-

Are you able to commence work without obstruction or hindrance?

-

STOP! Contact a supervisor/manager immediately to discuss options before proceeding.

-

Describe the obstruction or hindrance?

-

Upload picture of the obstruction or hindrance:

-

Always ensure the work are is free from risk for the general public, for example:

- Ensure all work equipment, tools, cable and rope are enclosed within the barriered work area and do not create trip hazards.

- Ensure open chambers are adequately enclosed within a barriered work area.

Documentation / Information

-

Have you review the relevant risk assessment/s for the current task?

-

STOP! Close this inspection and open inspection named "The Swiftlinks Site File" to review Risk Assessments.

-

Are all control measures in place as detailed in the generic task risk assessment?

-

STOP! Read the risk assessment for the current task and ensure all controls have been implement as instructed.

-

Have any of the operatives on site been working with the company for less than 17 weeks and do not hold all the task relevant qualifications/accreditations?

-

Stop! Consider the following: is there a competent trained operative on site to supervise the works of the undertrained operative, if No then stop work and contact your manager/supervisor. Do not allow untrained operatives to work unsupervised.

All Operatives must hold all relevant qualifications/accreditations after 17 weeks working with company, all operatives found working passed this point without qualifications/accreditations will be asked to leave site. -

Detail opertive/s full name and date started with company:

-

Is a qualified operative on site that can supervise all works carried out by the untrained operative?

-

Stop! contact your manager and do not allow the untrained operative to work unsupervised.

Street Works

-

Does at least one operative hold the required NRSWA units for the work activity?

-

STOP! Contact your supervisor/manager immediately and request a trained operative be sent to site, await operative arrival before proceeding.

-

Upload Image of NRSWA ID Card:

-

All work areas must be adequately signed & guarded as per the Safety at Street Works and Road Works A Code of Practice.

Safety at Street Works and Road Works A Code of Practice

click the link to be redirected to an online copy of the red book Safety at Street Works and Road Works A Code of Practice.

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/321056/safety-at-streetworks.pdf

Overhead Power

-

Refer to the overhead power glove box guide when working near electricity.

-

Overhead Power Glovebox Guide:

-

Is all Plant being used for lifting appropriate for use and stabilised as per manufacturer’s instructions?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

-

Is a Competent Ground support Person (GSP) on site?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

-

Is a MEWP or PEU to be used within 25m of overhead HV power or is a joint user pole (JUP) to be accessed?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding

Working at Height

-

Does this job involve Working at Height?

-

Ensure to complete the Pre climb check before accessing any pole by either climbing or MEWP access.

-

Have you completed a pre climb check? (required for MEWP and climb)

-

Are all members of this gang trained in Working at Height?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

-

Has the equipment that will be used for Working at Height been Inspected for condition before use and is in good condition?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

-

Are the locations where Work at height activity is involved on this job, safe and hazard free?

-

STOP WORK and contact a supervisor/manager immediately for advice before proceeding!

Working In/Near Open Chambers

-

Does this job involve working in or around and open chamber?

-

Toolbox Talk Open Chambers:

-

No Smoking or naked flames within 10m of open chambers.

-

An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED)

-

National Gas Emergency – 0800 111 999.

You must call the National Gas Emergency line if:

- If you smell gas when opening a chamber and the smell does not clear

- If you have a damaged gas pipe (even if there is no leak).

Never attempt to repair a damaged service. -

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water. -

Is an operative who is qualified to SA002 underground safety on site and will remain on site until completion of works?

-

STOP! Contact a supervisor/manager immediately and request a qualified operative, DO NOT begin work until the trained operative has arrived.

-

Are the locations where work in open chambers is required, safe and hazard free?

-

Can you add further control measures to mitigate any hazards?

-

STOP! Contact your Manager or Supervisor to discuss further arrangements or postpone work until the works can be carried out safely.

-

Explain the hazards & control measures:

Asbestos Containing Material (ACM)

-

Toolbox Talk Asbestos:

-

Has any asbestos containing material (ACM) been identified prior to works?

-

STOP! identify the areas containing ACM's and mark ACM's with paint if possible, if there is a risk of disturbing/breaking ACM's STOP and implement control measures to ensure that ACM's are not broken or disturbed.

-

Have control measures been put in place to proceed?

-

Stop! implement control measures before proceeding, if unable to implement control measures to protect ACM's, contact your manager and supervisor immediately to discuss alternative process to avoid ACM's.

-

Detail control measures:

Personal Protective Equipment (PPE), Tools & Equipment

-

Are the relevant PPE, Tools or Equipment available to be used and in good condition?

-

STOP! If any of the task relevant PPE, tools or equipment is missing or damaged, contact your manager or supervisor for repair / replacement, DO NOT work with defective PPE, tools or equipment.

-

Is specialist PPE required? If yes, give detail in comments!

-

Detail Required specialist PPE being used: (if PPE is not available STOP WORK and contact a supervisor/manager to obtain relevant PPE before continuing with task)

-

Is there enough 4 head GDU's available for the works, are they within calibration date and in good working order?

-

STOP! An operative must be present at each open chamber, with a working and calibrated GDU. (DO NOT LEAVE OPEN CHAMBERS UNATTENDED) contact your manager or supervisor for replacement

Manhole Entry

-

Do you need to enter a manhole?

-

What type of Confined space entry is required?

-

Ensure operative entering confined space has carried out an atmospheric test prior to entering.

-

Complete the confined space risk assessment and entry permit prior to entering confined space,

Operative must be wearing a Hard Hat, Safety Boots, Safety Goggles, Half Face Respirator, Working GDU, Full Body Harness and Lanyard.

confined team must also set up and use a forced air fan to ensure adequate oxygen levels are maintained within manhole at all times during the work. -

Has the mandatory Manhole Entry Permit been completed?

-

STOP WORK and complete the confined space risk assessment and permit before proceeding.

-

What is the manhole entry permit number:

-

Do not enter confined space and contact your manager immediately.

-

Do not enter confined space and contact your manager immediately.

-

All water found in chambers must be tested for contamination using the water test kit provided, refer to attched document for reference, if water is found to be contaminated it must be pumped out by a licenced contractor,

Contact your manager / supervisor immediately to arrange the removal of any contaminated water.

Environment

-

Are spill kits and an instructed operative available on site?

-

STOP! Do not continue without a fully stocked Spill Kit, contact your manager or supervisor for instruction on where to purchase or collect a spill kit prior to continuing with task.

Works Near a Railway

-

Will you be working within 200 metres of a Network Rail Crossing?

-

Have obtained the relevant approvals?

-

STOP! Contact your manager or supervisor immediately and request they contact the local authorities to obtain approval. DO NOT commence work without the relevant approvals.

-

Upload a photo or file, for proof of approval:

Working near Water

-

Are you within 10 metres (on, over or near) a watercourse or floodwater?

-

Is there a physical barrier to prevent you falling into the water, or have you already agreed a Safe System of Work with a site-specific risk assessment for the task?”

-

STOP! Contact your manager or supervisor to discuss other options to complete task or to assess works further and implement a safe system of work to access work area.

-

Take Picture of Physical Barrier or safe system of work, preventing accidental contact with body of water.

Other Risks

-

Are You Working in Close Vicinity of a School, Hospital, Airport, Motorway or emergency services building?

-

Provide a description of the control measures implemented to decrease the likelihood of accidents arising from the dangers associated with working in proximity to the above mentioned buildings?

-

Is It Safe to Proceed with the task?

-

STOP! Assess the work area and the hazards that arise due to working near School, Hospital, Airport, Motorway or emergency services buildings.

Contact your manager or Supervisor for advice on how to proceed.

Reporting

-

All Accidents, Hazards & Near miss incidents to be reported to your Manager, Supervisor & Health & Safety Manger immediately.

All incidents must also be recorded, you can do this by scanning the QR code, or by clicking the following link https://sfty.io/e/xYELwWTpKwb

Confirmation

-

This (POWRA) Point of work risk assessment forms part of the wider health and safety file and should be used in conjunction with other issued documents within the onsite health and safety file.

By signing this document you agree that that you are happy with the information and controls set out within the POWRA and on site Health & Safety file.

This Risk assessment must be signed by all operatives working on site, if any personnel arrive after this form is completed, it must be completed and signed by all operatives again. -

Full name and signature of team leader completing this risk assessment

-

Full name and signature of operative 1

-

Full name and signature of operative 2

-

Full name and signature of operative 3

-

Full name and signature of operative 4

-

Full name and signature of operative 5

-

Full name and signature of operative 6

-

Full name and signature of operative 7

-

Full name and signature of operative 8

-

Full name and signature of operative 9

-

Full name and signature of operative 10

-

Full name and signature of operative 11